Method for assisted synthesis of porous composite material by using assistant transfer byproduct

A technology of porous composite materials and by-products, which is applied in the field of preparing porous composite materials assisted by auxiliary transfer reaction by-products, can solve the problem of increasing the difficulty of mother liquor treatment, difficult new synthesis of mother liquor, unreasonable synthesis methods, etc. problems, to achieve the effect of easy conversion, thorough conversion, and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

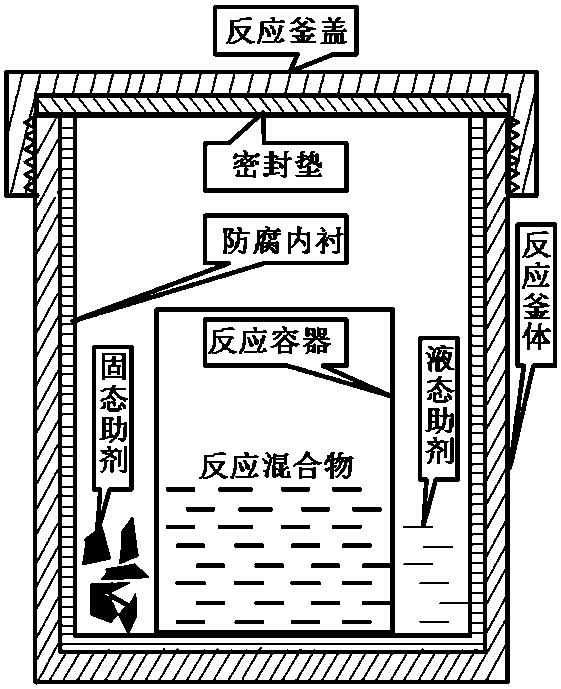

Embodiment 1

[0041] A method for assisting the synthesis of porous composite materials by using auxiliary agents to transfer by-products, specifically: measure 10 milliliters of deionized water and 10 milliliters of industrial alcohol respectively, and mix the two; weigh 3.624 grams of copper nitrate trihydrate and 2.102 Trimellitic acid; Add copper nitrate trihydrate to the aforementioned mixed solvent at 27°C, stir for 0.2 hours, then add trimesic acid, stir for 1.0 hour to form a reaction mixture, add 0.6 grams of sodium hydroxide solid at the bottom of the reaction kettle As an auxiliary agent, the container containing the reaction mixture is sealed in a self-pressurized reactor, and the sodium hydroxide is not in direct contact with the reaction mixture, heated to 110 ° C for 10 hours, cooled, filtered the sample in the container, and dried at room temperature to obtain the product. Collect the by-product sodium nitrate at the bottom of the kettle, which is formed by the reaction of so...

Embodiment 2

[0043] A kind of method that utilizes auxiliary agent to transfer by-product to assist the synthesis of porous composite material, specifically: measure 18 milliliters of deionized water, 5 milliliters of 95 ethanol, 5 milliliters of acetone, 5 milliliters of dimethyl ether and 5 milliliters of ether respectively, and put them Mix; weigh 0.9378 grams of aluminum nitrate nonahydrate, 0.5010 grams of aluminum acetate, 0.6047 grams of ferric nitrate, 0.4055 grams of ferric chloride and 2.102 grams of trimesic acid; add the weighed metal salt to the aforementioned mixed solvent at 30 °C , stirred for 0.5 hour, then added trimesic acid, stirred for 1.5 hours and mixed to form a reaction mixture, placed 1.4 grams of lithium hydroxide as an auxiliary agent at the bottom of the reaction kettle, then sealed the container of the reaction mixture in a self-pressurized reaction kettle, hydrogen Lithium oxide is not in direct contact with the reaction mixture, heated to 108 ° C for 10 hours...

Embodiment 3

[0045] A method for assisting the synthesis of porous composite materials by using auxiliary agents to transfer by-products, specifically: measure 20 milliliters of deionized water and 20 milliliters of ethanol respectively, and mix the two; add 3.624 grams of copper nitrate trihydrate to the aforementioned In the mixed solvent, stir for 0.2 hour, then add 2.102 gram of trimesic acid, stir for 1.0 hour and mix to form a reaction mixture, place 1.2 gram of sodium hydroxide solid at the bottom of the reaction kettle as an auxiliary agent, then the container containing the reaction mixture is sealed in an automatic In the pressure reaction kettle, sodium hydroxide does not directly contact with the reaction mixture, heated to 105 ° C for 10 hours, cooled and filtered to collect the sample in the container, and obtained the product after drying, and collected the by-product sodium nitrate at the bottom of the kettle, which is composed of solid hydrogen It is formed by the reaction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com