Integrated device for treating aquaculture wastewater and application of integrated device

A technology of breeding wastewater and integrated devices, applied in the field of agricultural resources and the environment, can solve the problems of not achieving complete sterilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] Embodiment 1, integrated device for aquaculture wastewater treatment

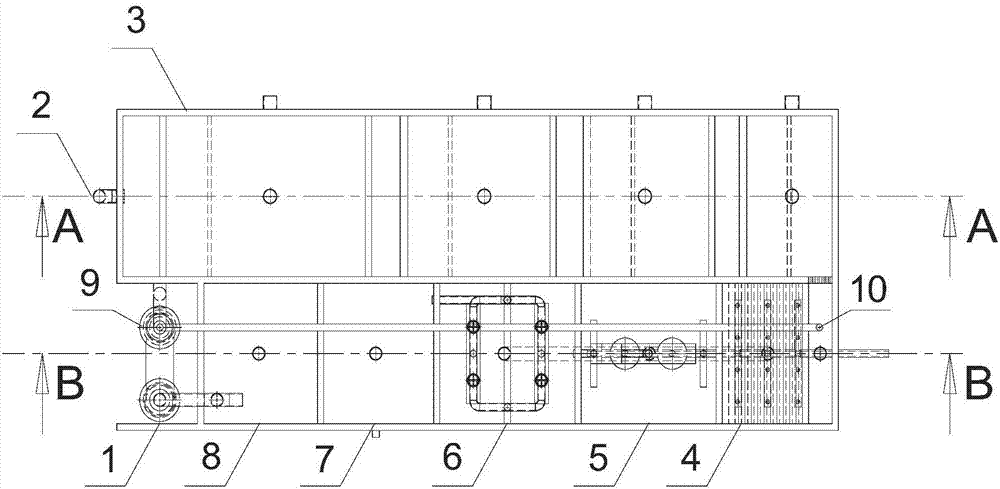

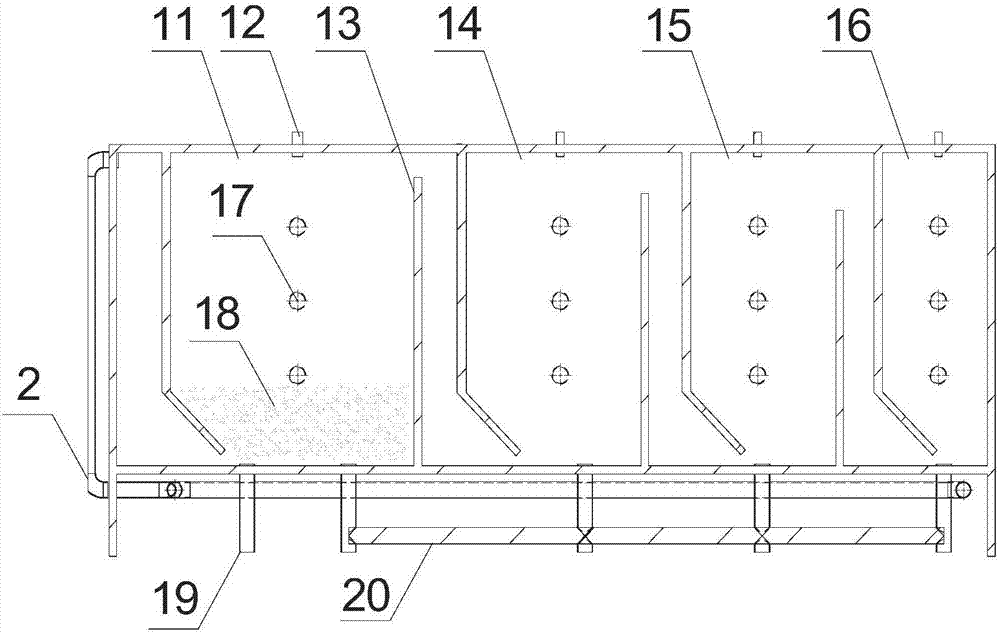

[0083] Such as figure 1 As shown, the integrated device for aquaculture wastewater treatment of the present invention includes: U-shaped tubular hydrothermal reactor 1, high temperature resistant pipe 2, folded plate anaerobic biological flocculation push flow tank 3, inclined plate aeration crystallization tank 4, dynamic ultrafiltration Membrane reaction tank 5, aeration-nanofiltration dual-function membrane reaction tank 6, water collection and sedimentation tank 7 and aquaculture wastewater storage tank 8.

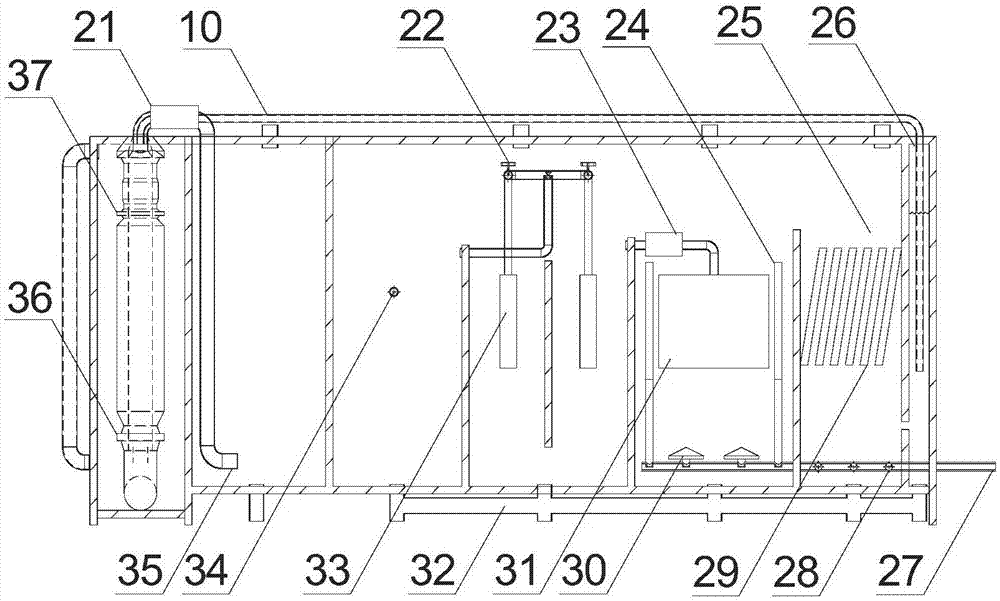

[0084] Such as image 3 As shown, when the reaction starts, the aquaculture wastewater is first introduced into the aquaculture wastewater storage tank 8, and the pressure valve 36 between the heating inner bag and the normal pressure cooling inner bag 9 in the U-shaped tubular hydrothermal reactor 1 is closed, and the wastewater is reused. The lifting pump 21 pumps the aquaculture wastewat...

Embodiment 2

[0091] Embodiment 2. Use of an integrated device for aquaculture wastewater treatment--aquaculture wastewater resources, energy recovery and treatment

[0092] Pour the aquaculture wastewater with a pH of 6.4, a COD value of about 6400mg / L, a TS of about 7700mg / L, an ammonia nitrogen concentration of about 675mg / L, a total phosphorus concentration of about 137mg / L, and a solid content of 9% into the aquaculture wastewater In the liquid storage pool 8, the heating temperature of the U-shaped tubular hydrothermal reactor 1 is controlled by the above-mentioned embodiment to 110°C, and the reaction pressure is 2.0Mpa. After heating for 30 minutes, open the pressure valve between the heating liner and the normal-pressure cooling liner 9 36. The sample is automatically flowed into the normal-pressure cooling inner tank 9 by using the U-shaped tube principle. The ammonia delivery pipe 10 is opened, and the gas containing ammonia is passed into the pre-aeration sedimentation chamber 2...

Embodiment 3

[0093] Example 3, the use of an integrated device for aquaculture wastewater treatment--aquaculture wastewater resources, energy recovery and treatment

[0094]Pour the aquaculture wastewater with a pH of 6.2, a COD value of about 10900mg / L, a TS of about 11850mg / L, an ammonia nitrogen concentration of about 758mg / L, a total phosphorus concentration of about 163mg / L, and a solid content of 9% into the aquaculture wastewater In the liquid storage pool 8, the heating temperature of the U-shaped tube hydrothermal reactor 1 is controlled to 120° C., and the reaction pressure is 2.5 Mpa. After heating for 50 minutes, waste water automatically flows into the normal-pressure cooling inner tank 9 by using the principle of the U-shaped tube. The cooling liner opens the ammonia delivery pipe 10, and the gas containing ammonia is passed into the pre-aeration sedimentation chamber 26 of the inclined plate aeration crystallization tank 4, and the ammonia nitrogen concentration increases by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com