A kind of composite negative electrode material li 3 v(moo 4 ) 3 /livomoo 4 preparation method

A negative electrode material, proportion mixing technology, applied in battery electrodes, electrical components, circuits, etc., can solve problems such as poor cycle performance and rate performance, harsh preparation method control conditions, uneven distribution of material components, etc., to achieve improved electrochemical performance , Improve the stability of the interface, the effect of good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

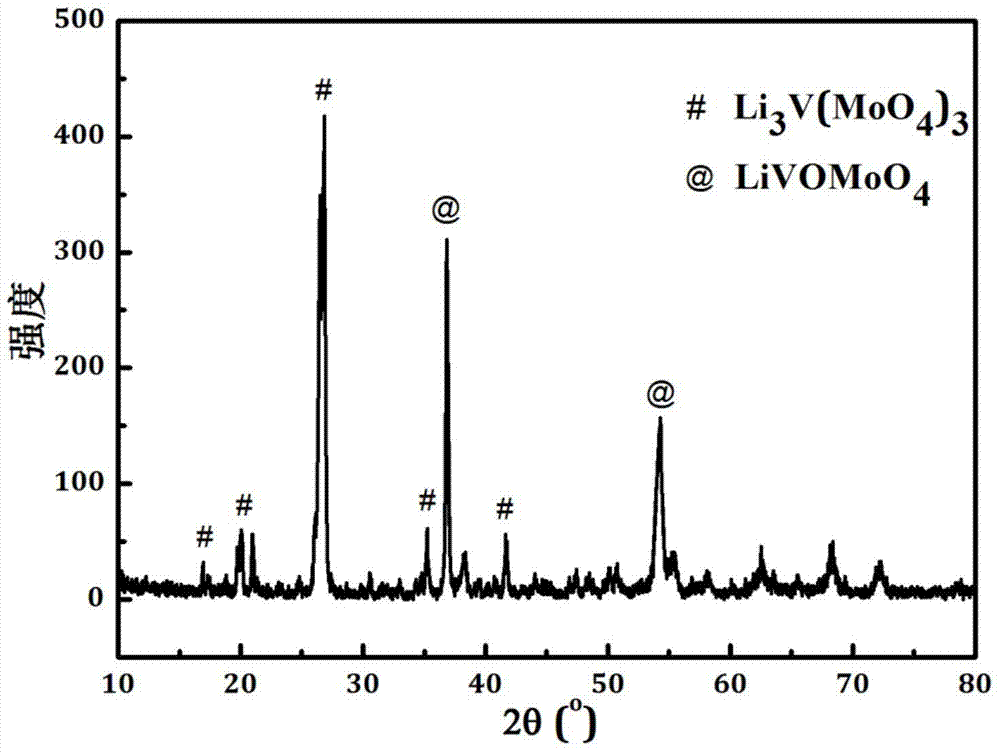

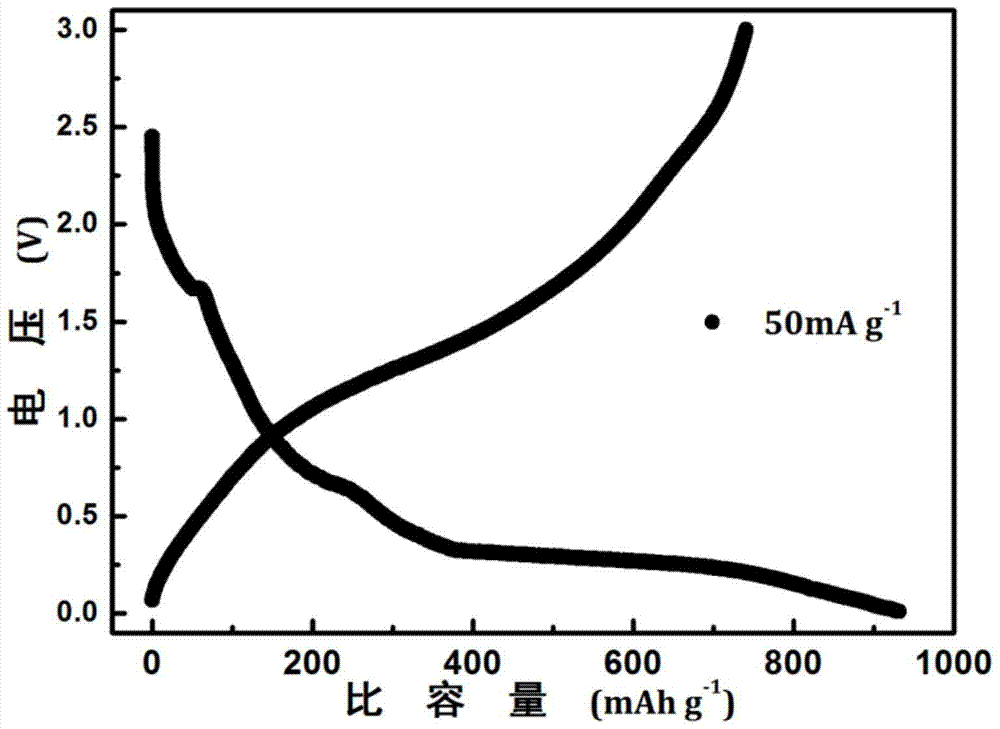

[0036] A kind of composite anode material Li of the present invention 3 V(MoO 4 ) 3 / LiVOMoO 4 The preparation method comprises the following steps:

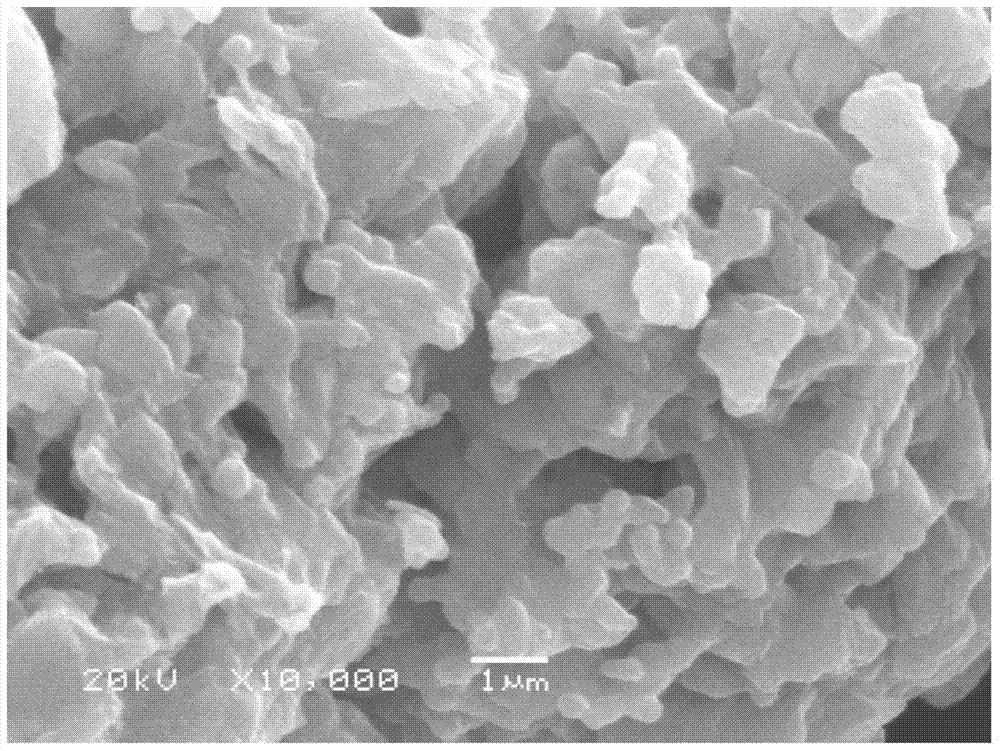

[0037] (1) by lithium, vanadium, molybdenum element molar ratio is 3:1:3, takes by weighing lithium oxalate, vanadium pentoxide and ammonium molybdate and mixes, then adds excessive 20% citric acid as reducing agent (citric acid The addition amount of +5 valent alum is reduced to + 1.2 times of the required theoretical amount of valence alum), with alcohol solution as dispersant, fully mix again, the mixed solution that obtains is joined in the ball mill tank (in the mixed solution The ratio of the mass of the mixture to the volume of ethanol is 0.68g mL -1 ) performing liquid phase ball milling for 8 hours to obtain a submicron reactant precursor;

[0038] (2) Divide the reactant precursor obtained by mechanical activation in step (1) into 4 parts. -1 The heating rate is raised to 300°C for 2 hours, then heated to 500°C, ...

Embodiment 2

[0046] A kind of composite anode material Li of the present invention 3 V(MoO 4 ) 3 / LiVOMoO 4 The preparation method comprises the following steps:

[0047] (1) be 3:1:3 by lithium, vanadium, molybdenum element mol ratio, take by weighing lithium acetate, ammonium metavanadate and sodium molybdate and mix, then add excessive 20% oxalic acid as reducing agent (addition of oxalic acid The amount is 1.2 times that the +5-valent alum is reduced to the required theoretical amount of +3-valent alum), with the alcohol solution as a dispersant, fully mixed again, and the mixed solution obtained is added to the ball mill tank (the mixture in the mixed solution The relative ratio of mass to volume of ethanol is 0.68g mL -1 ), carry out liquid phase ball milling 8h, obtain submicron reactant precursor;

[0048] (2) Divide the reactant precursor obtained by mechanical activation in step (1) into 4 parts. -1 The heating rate was increased to 300 ° C for 2 h, then heated to 600 ° C, ...

Embodiment 3

[0053] A kind of composite anode material Li of the present invention 3 V(MoO 4 ) 3 / LiVOMoO 4 The preparation method comprises the following steps:

[0054] (1) According to lithium, vanadium, molybdenum element molar ratio is 3:1:3, take by weighing 4 parts of lithium carbonate, vanadium peroxyoxalate and molybdenum trioxide with equal mass, and superconducting carbon black of excess 20% as reducing agent (the addition of superconducting carbon black is 1.2 times of the theoretical amount needed to reduce the +5-valent alum to +3-valent alum), with the alcohol solution as the dispersant, fully mixed, the mixed solution obtained is added to the ball mill tank (in the mixed solution, the volume ratio of the mixture mass to ethanol is 0.68g mL -1 ), respectively carrying out liquid phase ball milling for 4h, 6h, 8h and 10h to obtain the submicron reactant precursor;

[0055] (2) The reactant precursor obtained by mechanical activation in step (1) was first heated at 10°C f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com