a li 3 v(moo 4 ) 3 Lithium-ion battery negative electrode material and preparation method thereof

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of uneven distribution of material components, long preparation time, high production costs, etc., achieve excellent electrochemical performance, and simple synthesis conditions , The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

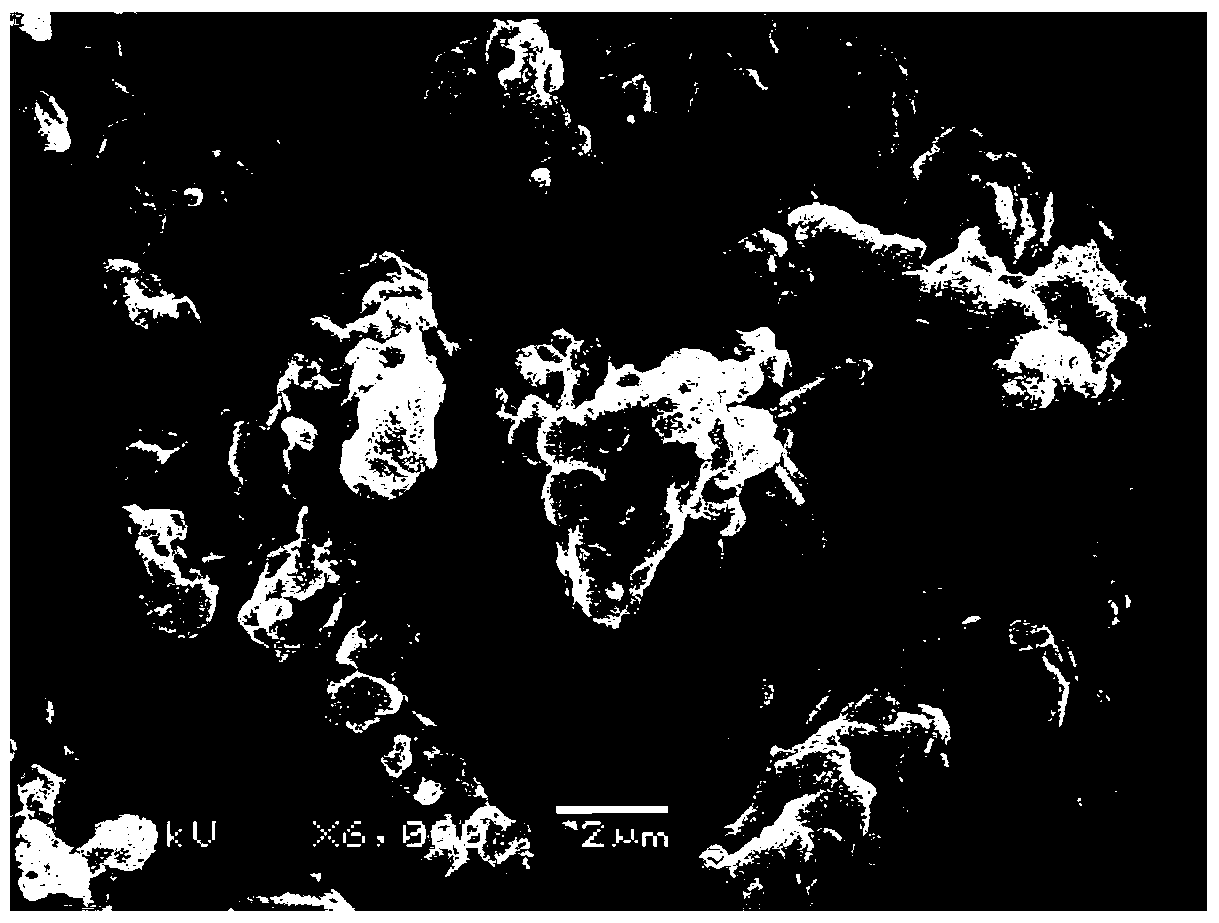

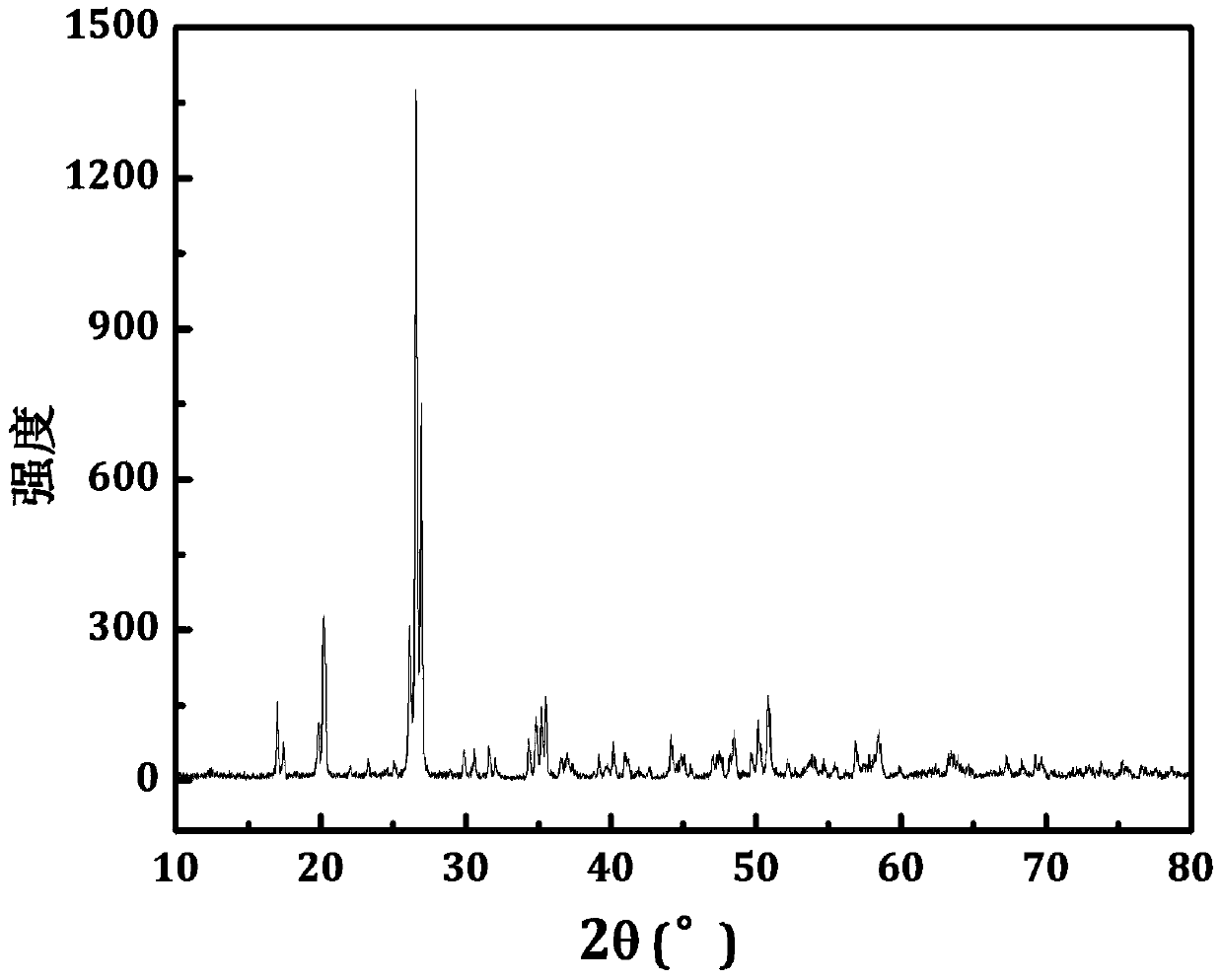

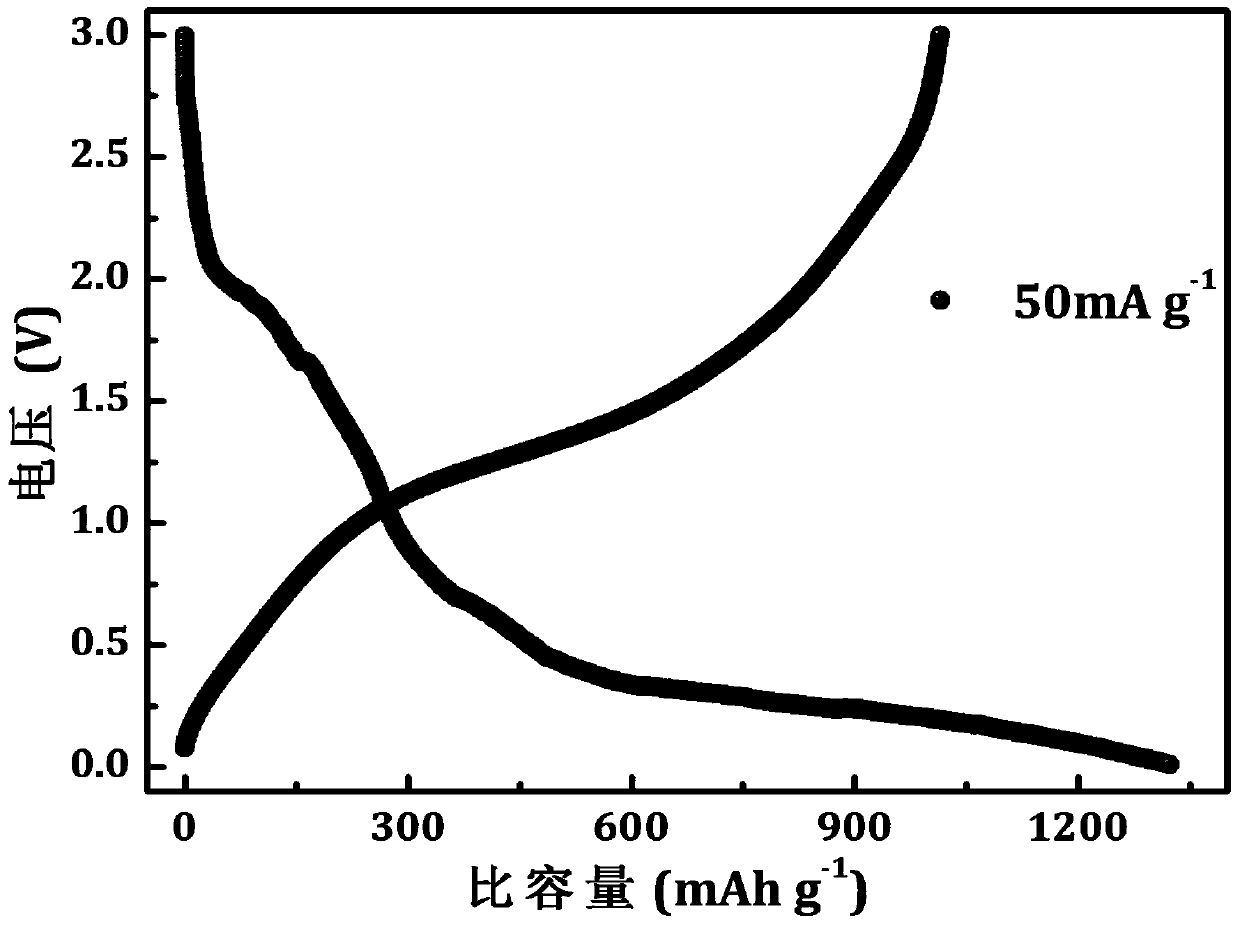

[0032] A kind of Li 3 V(MoO 4 ) 3 The preparation method of lithium ion battery negative electrode material, comprises the following steps:

[0033] 1) Lithium oxalate, vanadium pentoxide and ammonium molybdate are taken by weighing lithium oxalate, vanadium pentoxide and ammonium molybdate in the ratio of 3:1:3 by lithium: vanadium: the molar ratio of molybdenum is dissolved in alcoholic solution, then add 1.2 times of oxalic acid of theoretical amount (theoretical amount is Reducing the vanadium in the vanadium pentoxide to the +3 valence state required amount of oxalic acid) and performing ball milling at room temperature for 5 hours to prepare a submicron precursor.

[0034] 2) Divide the precursor prepared in step 1) into 5 parts, respectively, under the protection of argon inert gas at 5 ° C min -1 The heating rate was raised to 400 °C, 450 °C, 500 °C, 550 °C and 600 °C, and sintered at a constant temperature for 6 hours, and finally cooled to room temperature natural...

Embodiment 2

[0042] A kind of Li 3 V(MoO 4 ) 3 The preparation method of lithium ion battery negative electrode material, comprises the following steps:

[0043] 1) Lithium oxalate, vanadium pentoxide and ammonium molybdate are taken by weighing lithium oxalate, vanadium pentoxide and ammonium molybdate in the ratio of 3:1:3 by the molar ratio of molybdenum: The vanadium in the vanadium pentoxide is reduced to the required amount of oxalic acid in the +3 valence state) and ball milled at room temperature for 10 hours to prepare a submicron precursor.

[0044] 2) Divide the precursor prepared in step 1) into 4 parts, and under the protection of argon inert gas, -1 The heating rate was raised to 480°C, and sintered at constant temperature for 1h, 6h, 15h, and 20h, respectively, and finally cooled to room temperature naturally to obtain Li 3 V(MoO 4 ) 3 Lithium-ion battery anode material.

[0045] The Li prepared in this embodiment at different sintering temperatures 3 V(MoO 4 ) 3 L...

Embodiment 3

[0049] A kind of Li 3 V(MoO 4 ) 3 The preparation method of lithium ion battery negative electrode material, comprises the following steps:

[0050] 1) Lithium oxalate, vanadium pentoxide and ammonium molybdate are taken by weighing lithium oxalate, vanadium pentoxide and ammonium molybdate in the ratio of 3:1:3 by the molar ratio of molybdenum: Reducing the vanadium in vanadium pentoxide to the +3 valence state requires oxalic acid), and divided into 4 parts, and carried out normal temperature liquid phase ball milling for 2h, 5h, 10h and 15h respectively to prepare submicron precursors.

[0051] 2) The four precursors prepared in step 1) were all heated at 10°C·min under the protection of argon inert gas -1 The heating rate was increased to 480 °C, and sintered at a constant temperature for 6 hours, and finally cooled to room temperature naturally, the Li 3 V(MoO 4 ) 3 Lithium-ion battery anode material.

[0052] The Li that this embodiment is made in different millin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com