Positive electrode material and preparation method thereof, and secondary battery

A positive electrode material and positive electrode technology, applied in the overcharge-proof positive electrode material and its preparation, and in the field of secondary batteries, can solve the problems of limited improvement in battery overcharge safety, deterioration of battery electrochemical performance, and additive content limitations, etc., to achieve Reduce overcharge safety hazards, improve the first discharge capacity and capacity retention rate, and the effect of uniform delithiation degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

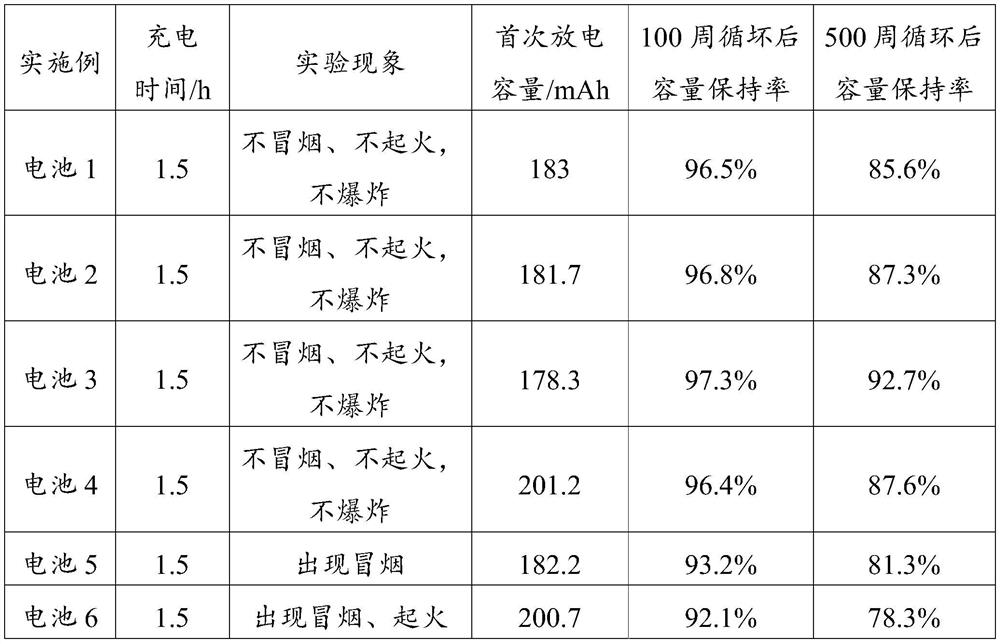

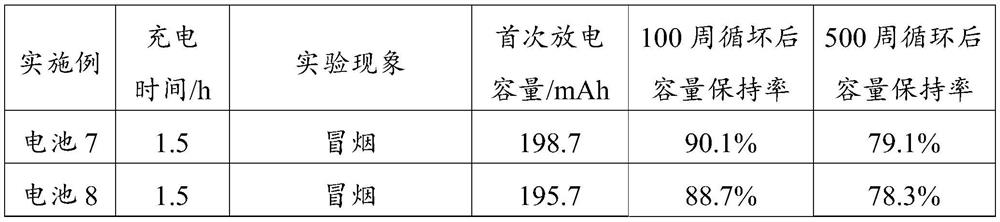

Examples

preparation example Construction

[0026] The present invention also provides a preparation method of positive electrode material, comprising:

[0027] (1) Preparation of lithium nickel manganese oxide

[0028] A lithium nickel manganese oxide powder material with a spinel structure with a D50 of 30-100 nm was prepared by a liquid phase sol-gel method;

[0029] (2) Coating of lithium nickel manganese oxide

[0030] A dry coating method is used to coat the lithium nickel manganese oxide on the core material with a layered structure.

[0031] Wherein, the preparation of lithium nickel manganese oxide includes: according to the chemical formula LiNi 0.5 mn (1.5-x) m x o 4, where M is Al or Ti, 0≤x≤0.08, weigh the Li source, Ni source, Mn source and M source in the formula, mix them uniformly and dissolve them in water to obtain a mixed solution, heat and stir the mixed solution and slowly add the precipitate Control the pH value to be neutral, then slowly add ammonia water and continue to stir, heat up and k...

Embodiment 1

[0035] A cathode material including LiCoO 2 Core material and LiNi with spinel structure cladding the core material 0.5 mn 1.5 o 4 , LiNi 0.5 mn 1.5 o 4 The D50 is 58nm, and the specific surface area BET is 24m 2 / g, the discharge voltage platform is 4.95V, and occupies LiCoO 2 8% of the mass of the core material.

[0036] Its preparation method is:

[0037] (1) Preparation of lithium nickel manganese oxide

[0038] Li(CH 3 COO).2H 2 O, Ni(CH 3 COO) 2 .4H 2 O and Mn(CH 3 COO) 2 .4H 2 O, weigh and mix according to the formula amount and dissolve in a certain quality of water to prepare a 1mol / L solution. After mixing, stir at 50°C and gradually drop in citric acid, control the pH value to be neutral and drop slowly Add ammonia water and keep stirring continuously for 4 hours, then increase the solution temperature to 85°C, and keep stirring until a gel state with high viscosity is formed, then dry at 85°C for 24 hours, and use a sand mill to grind the dried pre...

Embodiment 2

[0042] A cathode material including LiCoO 2 Core material and LiNi with spinel structure cladding the core material 0.5 mn 1.49 Ti 0.01 o 4 , LiNi 0.5 mn 1.49 Ti 0.01 o 4 The D50 is 55nm, the specific surface area BET is 30m 2 / g, the voltage platform is 5V, and occupies LiCoO 2 10% of the mass of the core material.

[0043] Its preparation method is:

[0044] (1) Preparation of lithium nickel manganese oxide

[0045] Li(CH 3 COO).2H 2 O, Ni(CH 3 COO) 2 .4H 2 O, Mn(CH 3 COO) 2 .4H 2 O and Ti(CH 3 COO) 2 .4H 2 O is weighed and mixed according to the formula amount and dissolved in a certain quality of water to prepare a 1mol / L solution. After mixing, stir at 50°C and gradually drop in citric acid, control the pH value to be neutral and slowly drop in At the same time, keep stirring the ammonia water continuously for 4 hours, then increase the temperature of the solution to 90°C, and keep stirring until a gel state with high viscosity is formed, and then dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com