Aluminum-doped nickel-manganese binary precursor and preparation method thereof

A precursor, nickel-manganese technology, applied in the direction of chemical instruments and methods, electrical components, nickel compounds, etc., can solve the problems of poor performance, poor cycle performance, nickel-manganese binary precursor performance can not meet the requirements, etc., to achieve Good cycle performance, good safety performance, and the effect of avoiding large particle size fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

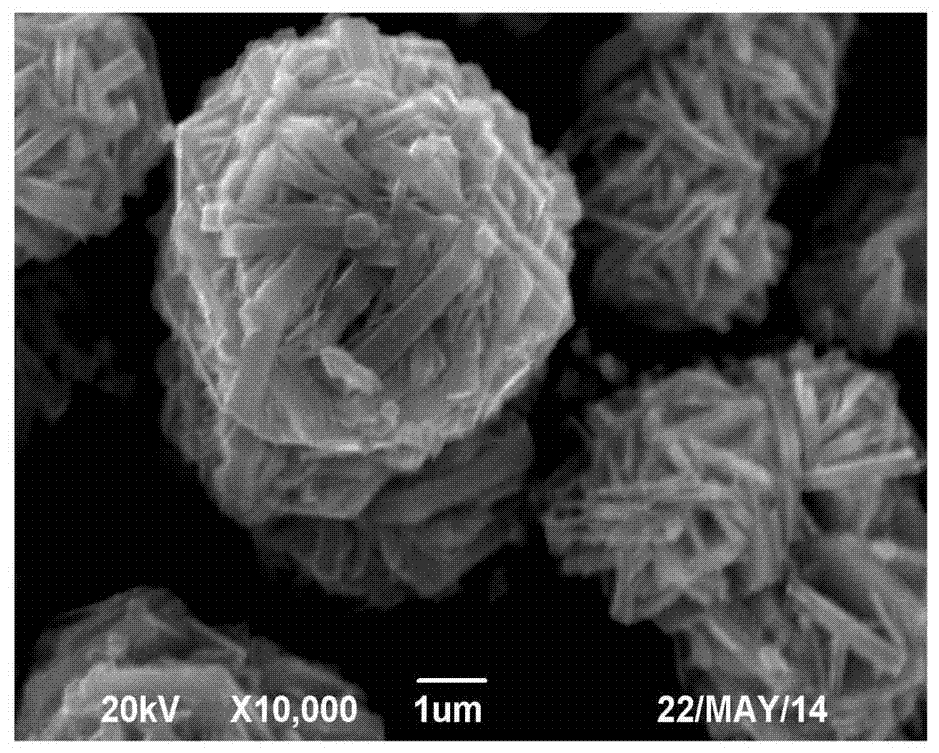

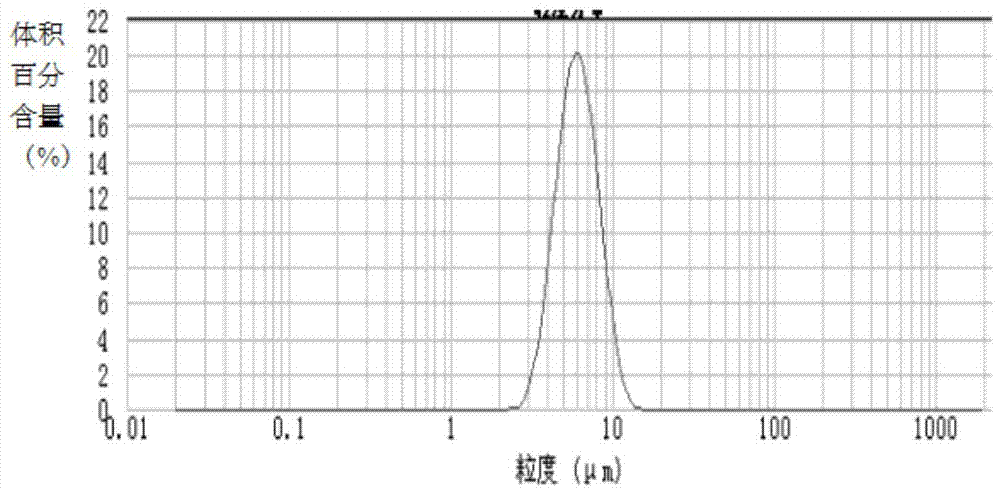

[0029] An aluminum-doped nickel-manganese binary precursor of the present invention, the aluminum-doped nickel-manganese binary precursor is in the form of spherical particles (such as figure 1 ), its chemical formula is: NiMn 3 Al 0.2 (OH) 8.6 , its preparation method comprises the following steps:

[0030] (1) Dissolve nickel sulfate and manganese sulfate in pure water at about 45°C to obtain a nickel manganese sulfate solution with a Ni:Mn molar ratio of 1:3 and a concentration of 2mol / L;

[0031] (2) Dissolve aluminum nitrate in an excess sodium hydroxide solution with a mass fraction of 15%, and stir for 2 hours to obtain a sodium metaaluminate solution with a concentration of 0.375 mol / L;

[0032] (3) After cleaning the reaction kettle with pure water, add pure water to reach the overflow port, turn on the stirring motor of the reaction kettle, adjust the frequency so that the rotation speed is about 600r / min, and then add ammonia water with a mass fraction of 15%. M...

Embodiment 2

[0050] An aluminum-doped nickel-manganese binary precursor of the present invention, the aluminum-doped nickel-manganese binary precursor is in the shape of spherical particles, and its chemical formula is: NiMn 3 Al 0.125 (OH) 8.375 , its preparation method comprises the following steps:

[0051] (1) Dissolve nickel sulfate and manganese sulfate in water at about 45°C to obtain a nickel manganese sulfate solution with a molar ratio of Ni:Mn of 1:3 and a concentration of 2mol / L;

[0052] (2) Dissolve aluminum nitrate in an excess sodium hydroxide solution with a mass fraction of 15%, and stir for 2 hours to obtain a sodium metaaluminate solution with a concentration of 0.375 mol / L;

[0053] (3) After cleaning the reaction kettle with pure water, add pure water to reach the overflow port, turn on the stirring motor of the reaction kettle, adjust the frequency so that the rotation speed is about 600r / min, and then add ammonia water with a mass fraction of 15%. Make the concen...

Embodiment 3

[0057] An aluminum-doped nickel-manganese binary precursor of the present invention, the aluminum-doped nickel-manganese binary precursor is in the shape of spherical particles, and its chemical formula is: NiMn 3 Al 0.25 (OH) 8.75 , its preparation method comprises the following steps:

[0058] (1) Dissolve nickel sulfate and manganese sulfate in water at about 45°C to obtain a nickel manganese sulfate solution with a molar ratio of Ni:Mn of 1:3 and a concentration of 2mol / L;

[0059] (2) Dissolve aluminum nitrate in an excess sodium hydroxide solution with a mass fraction of 15%, and stir for 2 hours to obtain a sodium metaaluminate solution with a concentration of 0.375 mol / L;

[0060] (3) After cleaning the reaction kettle with pure water, add pure water to reach the overflow port, turn on the stirring motor of the reaction kettle, adjust the frequency so that the rotation speed is about 600r / min, and then add ammonia water with a mass fraction of 15%. Make the concentr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com