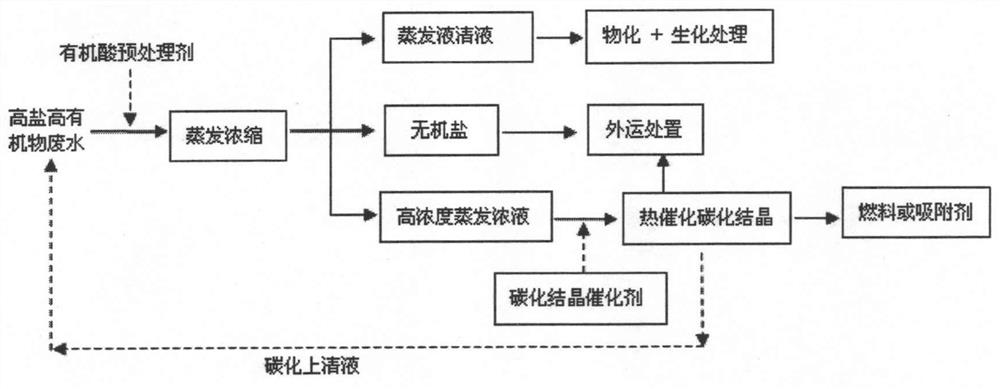

Treatment method of high-salt and high-organic waste water evaporation concentration coupled with thermocatalytic carbon crystallization

A thermal catalytic carbon, evaporative concentration technology, used in natural water treatment, water/sewage treatment, chemical instruments and methods, etc. problems, to achieve the effect of increasing the carbonization crystallization rate, reducing the processing cost, and reducing the reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] A treatment method for high-salt and high-organic-matter wastewater coupled with thermocatalytic carbon crystallization by evaporation and concentration:

[0026] (1) Take 2.5L of waste water from a certain chemical plant (mass fraction of total salt=6.1%, COD is 52706mg / L, B / C is 0.14, pH=9.5), add 5mg propionic acid, 7.5mg succinic acid, 20mg of glutaric acid, 17.5mg of oxalic acid and 25mg of citric acid, and stir (200rpm) to mix evenly.

[0027] (2) Pour it into an evaporator, and carry out evaporation and desalination under the conditions of 80° C. and a pressure of -0.2 MPa at a temperature, and separate 0.116 kg of inorganic salt and clear liquid of the evaporation liquid (mass fraction of total salt=0.46%, 2.20 L , COD concentration 370mg / L, pH=8.6) and 240mL high-concentration evaporation dope (mass fraction=10.99% of total salt, COD is 522400mg / L, B / C is 0.10, pH=10.3). The evaporated liquid and clear liquid are reused or discharged after physical and chemica...

Embodiment 2

[0031] A treatment method for high-salt and high-organic-matter wastewater coupled with thermocatalytic carbon crystallization by evaporation and concentration:

[0032] (1) Take 2.5L of certain pharmaceutical wastewater (mass fraction of total salt=5.2%, COD is 45706mg / L, B / C is 0.16, pH=9.7), add 2.5mg propionic acid, 5mg succinic acid, 20mg Glutaric acid, oxalic acid 17.5mg and citric acid 25mg, and stir (200rpm) mix well.

[0033] (2) Pour it into an evaporator, and carry out evaporation and desalination at a temperature of 85° C. and a pressure of -0.2 MPa to separate 0.097 kg of inorganic salt and clear liquid of the evaporated liquid (mass fraction of total salt=0.45%, 2.23 L , COD concentration 350mg / L, pH=8.8) and 220mL high-concentration evaporation dope (mass fraction=10.45% of total salt, COD is 451300mg / L, B / C is 0.11, pH=10.5). The evaporated liquid and clear liquid are reused or discharged after physical and chemical and biochemical treatment.

[0034] (3) Add...

Embodiment 3

[0037] A treatment method for high-salt and high-organic-matter wastewater coupled with thermocatalytic carbon crystallization by evaporation and concentration:

[0038] (1) Take 2.5L of certain pesticide wastewater (mass fraction of total salt=5.7%, COD is 68542mg / L, B / C is 0.12, pH=10.2), add 5mg propionic acid, 9mg succinic acid, 20mg valeric acid to it Diacid, oxalic acid 17.5mg and citric acid 25mg, and stir (200rpm) to mix well.

[0039] (2) Pour it into an evaporator, and carry out evaporation and desalination at a temperature of 85° C. and a pressure of -0.2 MPa to separate 0.112 kg of inorganic salt and clear liquid of the evaporation liquid (mass fraction of total salt=0.43%, 2.18 L , COD concentration 420mg / L, pH=9.7) and 230mL high-concentration evaporation dope (mass fraction=9.19% of total salt, COD is 677200mg / L, B / C is 0.10, pH=11.1). The evaporated liquid and clear liquid are reused or discharged after physical and chemical and biochemical treatment.

[0040] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com