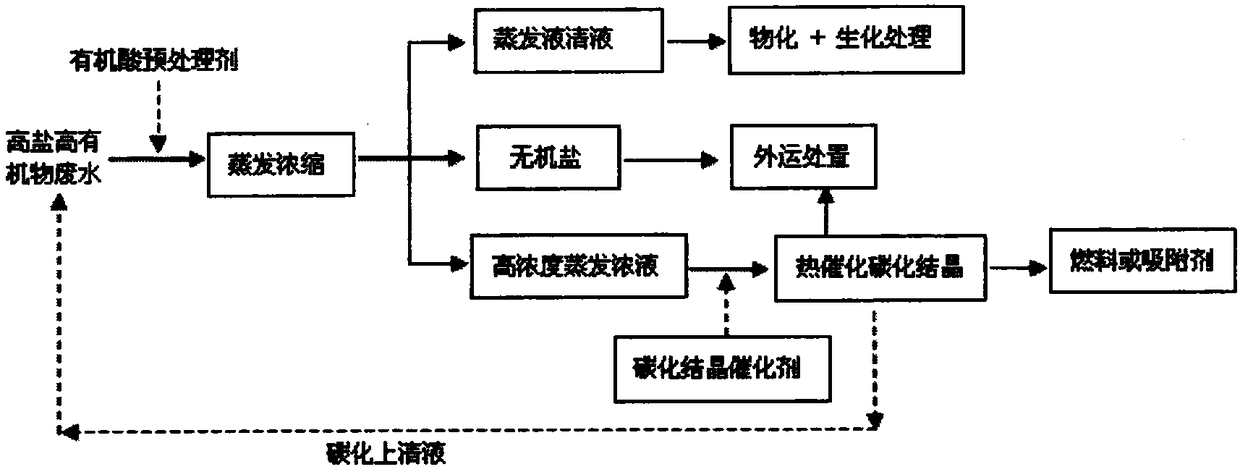

Treatment method for high-salt high-organic-matter waste water by evaporation concentration coupling thermocatalytic carbon crystallization

A thermal catalytic carbon, evaporative concentration technology, used in water/sewage treatment, natural water treatment, chemical instruments and methods, etc., can solve the problems of high COD in wastewater, high salt content and high COD treatment in wastewater, high investment and treatment costs , to achieve the effect of increasing the carbonization crystallization rate, reducing the reaction temperature and reducing the processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] A treatment method for high-salt and high-organic-matter wastewater coupled with thermocatalytic carbon crystallization by evaporation and concentration:

[0026] (1) Take 2.5L of waste water from a certain chemical plant (mass fraction of total salt=6.1%, COD is 52706mg / L, B / C is 0.14, pH=9.5), add 5mg propionic acid, 7.5mg succinic acid, 20mg of glutaric acid, 17.5mg of oxalic acid and 25mg of citric acid, and stir (200rpm) to mix evenly.

[0027] (2) Pour it into an evaporator, and carry out evaporation and desalination under the conditions of 80° C. and a pressure of -0.2 MPa at a temperature, and separate 0.116 kg of inorganic salt and clear liquid of the evaporation liquid (mass fraction of total salt=0.46%, 2.20 L , COD concentration 370mg / L, pH=8.6) and 240mL high-concentration evaporation dope (mass fraction=10.99% of total salt, COD is 522400mg / L, B / C is 0.10, pH=10.3). The evaporated liquid and clear liquid are reused or discharged after physical and chemica...

Embodiment 2

[0031] A treatment method for high-salt and high-organic-matter wastewater coupled with thermocatalytic carbon crystallization by evaporation and concentration:

[0032] (1) Take 2.5L of certain pharmaceutical wastewater (mass fraction of total salt=5.2%, COD is 45706mg / L, B / C is 0.16, pH=9.7), add 2.5mg propionic acid, 5mg succinic acid, 20mg Glutaric acid, oxalic acid 17.5mg and citric acid 25mg, and stir (200rpm) mix well.

[0033] (2) Pour it into an evaporator, and carry out evaporation and desalination at a temperature of 85° C. and a pressure of -0.2 MPa to separate 0.097 kg of inorganic salt and clear liquid of the evaporated liquid (mass fraction of total salt=0.45%, 2.23 L , COD concentration 350mg / L, pH=8.8) and 220mL high-concentration evaporation dope (mass fraction=10.45% of total salt, COD is 451300mg / L, B / C is 0.11, pH=10.5). The evaporated liquid and clear liquid are reused or discharged after physical and chemical and biochemical treatment.

[0034] (3) Add...

Embodiment 3

[0037] A treatment method for high-salt and high-organic-matter wastewater coupled with thermocatalytic carbon crystallization by evaporation and concentration:

[0038] (1) Take 2.5L of certain pesticide wastewater (mass fraction of total salt=5.7%, COD is 68542mg / L, B / C is 0.12, pH=10.2), add 5mg propionic acid, 9mg succinic acid, 20mg valeric acid to it Diacid, oxalic acid 17.5mg and citric acid 25mg, and stir (200rpm) to mix well.

[0039] (2) Pour it into an evaporator, and carry out evaporation and desalination at a temperature of 85° C. and a pressure of -0.2 MPa to separate 0.112 kg of inorganic salt and clear liquid of the evaporation liquid (mass fraction of total salt=0.43%, 2.18 L , COD concentration 420mg / L, pH=9.7) and 230mL high-concentration evaporation dope (mass fraction=9.19% of total salt, COD is 677200mg / L, B / C is 0.10, pH=11.1). The evaporated liquid and clear liquid are reused or discharged after physical and chemical and biochemical treatment.

[0040] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com