Tea seed saponin as well as preparation method and application thereof

A technology of tea seed saponin and tea seed, which is applied in the field of tea seed saponin and its preparation, can solve the problems of tea saponin such as poor color, complex process, and low purity, and achieve low solvent consumption, high yield purity, and selectivity high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A preparation method of tea seed saponin, comprising the steps of:

[0050] (1) Tea seed cake is pulverized to obtain tea seed powder;

[0051] (2) Mix the tea seed powder prepared in step (1) with an alkaline ethanol solution with a pH of 9.07 and an ethanol volume fraction of 73.35% according to a solid-to-liquid ratio of 1:9. Under microwave-assisted extraction for 8 minutes, the extract was concentrated to obtain crude tea seed saponin;

[0052] (3) Weigh 10.0g of the crude tea seed saponin prepared in step (2), dissolve it in 200mL of hot water at 60°C, add active dry yeast to ferment for 6h, centrifuge, and take the supernatant; add Calcium oxide (16% of the mass of the supernatant), reacted in a constant temperature water bath at 30°C for 2 hours, centrifuged, discarded the supernatant, and obtained a precipitate;

[0053] (4) Mix the precipitate obtained in step (3), ammonium bicarbonate (2.5 times the mass of calcium oxide) and water, release in a constant te...

Embodiment 2

[0058] A preparation method of tea seed saponin, comprising the steps of:

[0059] (1) Tea seed cake is pulverized to obtain tea seed powder;

[0060] (2) The tea seed powder prepared in step (1) is mixed with an alkaline ethanol solution having a pH of 8 and an ethanol volume fraction of 60% according to a solid-to-liquid ratio of 1:10, and the temperature is 50°C and the microwave power is 650W. Under microwave-assisted extraction for 7 minutes, the extract was concentrated to obtain crude tea seed saponin;

[0061] (3) Weigh 10.0g of the crude tea seed saponin prepared in step (2), dissolve it in 200mL of hot water at 60°C, add active dry yeast to ferment for 6h, centrifuge, and take the supernatant; add Calcium oxide (16% of the mass of the supernatant) was reacted in a constant temperature water bath at 30° C. for 2 hours. Centrifuge, discard the supernatant, and obtain the precipitate;

[0062] (4) Mix the precipitate obtained in step (3), ammonium bicarbonate (2.5 ti...

Embodiment 3

[0066] A preparation method of tea seed saponin, comprising the steps of:

[0067] (1) Tea seed cake is pulverized to obtain tea seed powder;

[0068] (2) The tea seed powder prepared in step (1) is mixed with an alkaline ethanol solution having a pH of 9.5 and an ethanol volume fraction of 75% according to a solid-to-liquid ratio of 1:12, and the temperature is 70°C and the microwave power is 600W. Under microwave-assisted extraction for 10 minutes, the extract was concentrated to obtain crude tea seed saponin;

[0069] (3) Weigh 10.0g of the crude tea seed saponin prepared in step (2), dissolve it in 200mL of hot water at 60°C, add active dry yeast to ferment for 6h, centrifuge, and take the supernatant; add Calcium oxide (16% of the mass of the supernatant), reacted in a constant temperature water bath at 30°C for 2 hours, centrifuged, discarded the supernatant, and obtained a precipitate;

[0070] (4) Mix the precipitate obtained in step (3), ammonium bicarbonate (2.5 ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

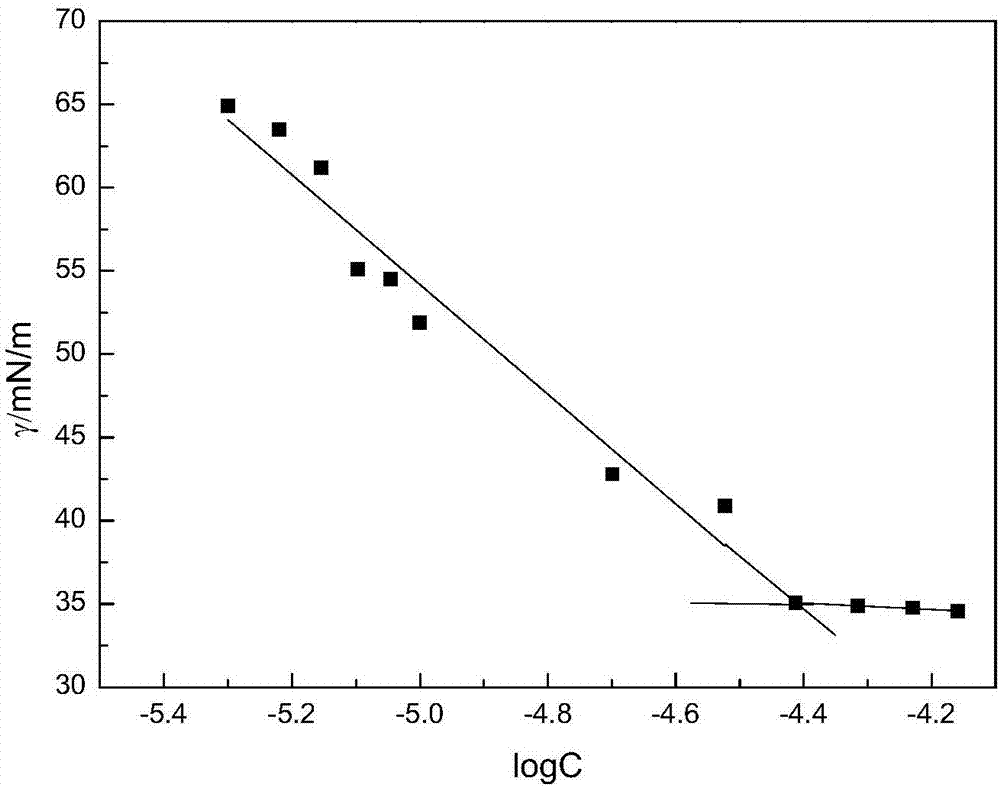

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com