Mixed insulating oil and preparation method thereof

An insulating oil, hybrid technology, applied in the petroleum industry, lubricating compositions, base materials, etc., can solve the problems of high freezing point, high viscosity and poor oxidation resistance of natural esters, and achieve inhibition of insulation aging and high breakdown. The effect of voltage and good environmental performance

Inactive Publication Date: 2010-01-06

CHONGQING UNIV

View PDF0 Cites 21 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Although natural esters (vegetable oils) have high water saturation, natural esters are difficult to popularize due to problems such as high freezing point, poor oxidation resistance, and high viscosity, and are usually only used as impregnants for capacitors

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0027] Vegetable oil 15%; mineral insulating oil 85%.

Embodiment 2

[0029] Vegetable oil: 15%; Mineral insulating oil: 84%; 2,6-di-tert-butyl-p-cresol: 0.5%; Alkylated phenyl-α-naphthylamine: 0.5%.

Embodiment 3

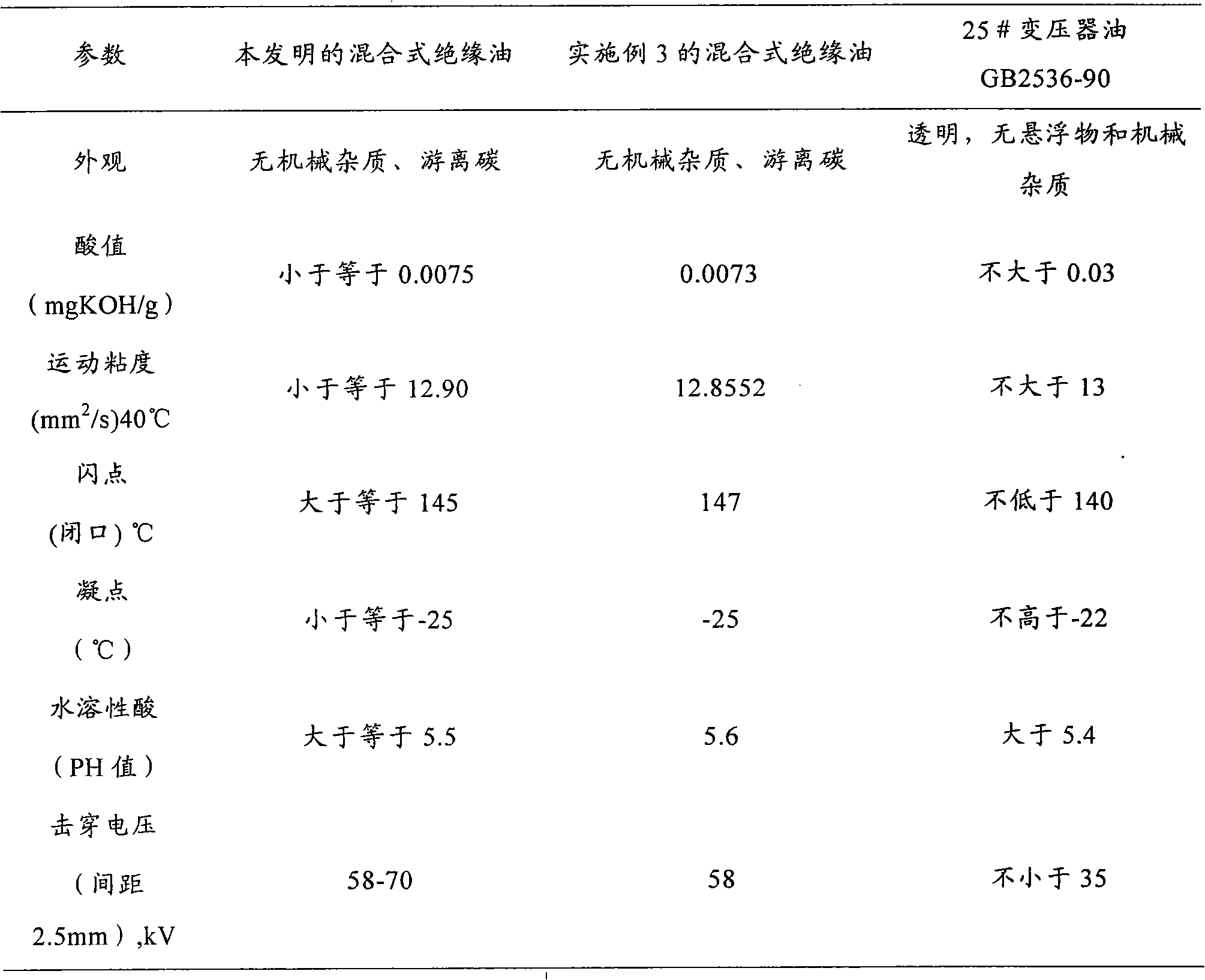

[0031] Vegetable oil: 20%; Mineral insulating oil: 79.5%; 2,6-di-tert-butyl-p-cresol: 0.2%; Alkylated phenyl-α-naphthylamine: 0.3%.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Solidifying point | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

Login to View More

Abstract

The invention provides mixed insulating oil which has high degree of water saturation and can effectively restrain the aging of insulating paper. The mixed insulating oil contains the following raw materials in percentage by weight: 15-25 percent of plant oil and 75-85 percent of mineral insulating oil. Compared with the prior transformer oil, the mixed insulating oil has better oxidation stability and environmental-friendly performance as well as higher breakdown voltage and can effectively restrain the aging of the insulating paper so as to prolong the service life of a transformer, reduce the equipment fault and improve the safety and the reliability of the operation of the transformer. In addition, the invention also provides a preparation method of the mixed insulating oil.

Description

technical field [0001] The invention relates to transformer insulating oil and a preparation method thereof. Background technique [0002] Existing transformer insulating oil mainly adopts mineral insulating oil, and the mineral insulating oil is obtained by refining and refining petroleum. The aging rate of insulating paper in transformers will increase with the increase of moisture content, and the water saturation of mineral insulating oil is very low, which is not conducive to inhibiting the influence of moisture on the aging of oil-paper insulation. Although natural esters (vegetable oils) have high water saturation, they are difficult to popularize due to problems such as high freezing point, poor oxidation resistance, and high viscosity. They are usually only used as impregnants for capacitors. Contents of the invention [0003] In view of this, in order to solve the above problems, the present invention provides a hybrid insulating oil with high water saturation, ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C10M101/00C10M169/04C10N40/16C10N30/10

Inventor 杨丽君廖瑞金梁帅伟周湶李剑孙才新郝建唐超尹建国

Owner CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com