Dry powder mortar and method for preparing the same

A dry powder mortar and yellow sand technology, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of high labor intensity, large waste of materials, inconvenient transportation, etc., to ensure construction quality and reduce disease transmission. , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

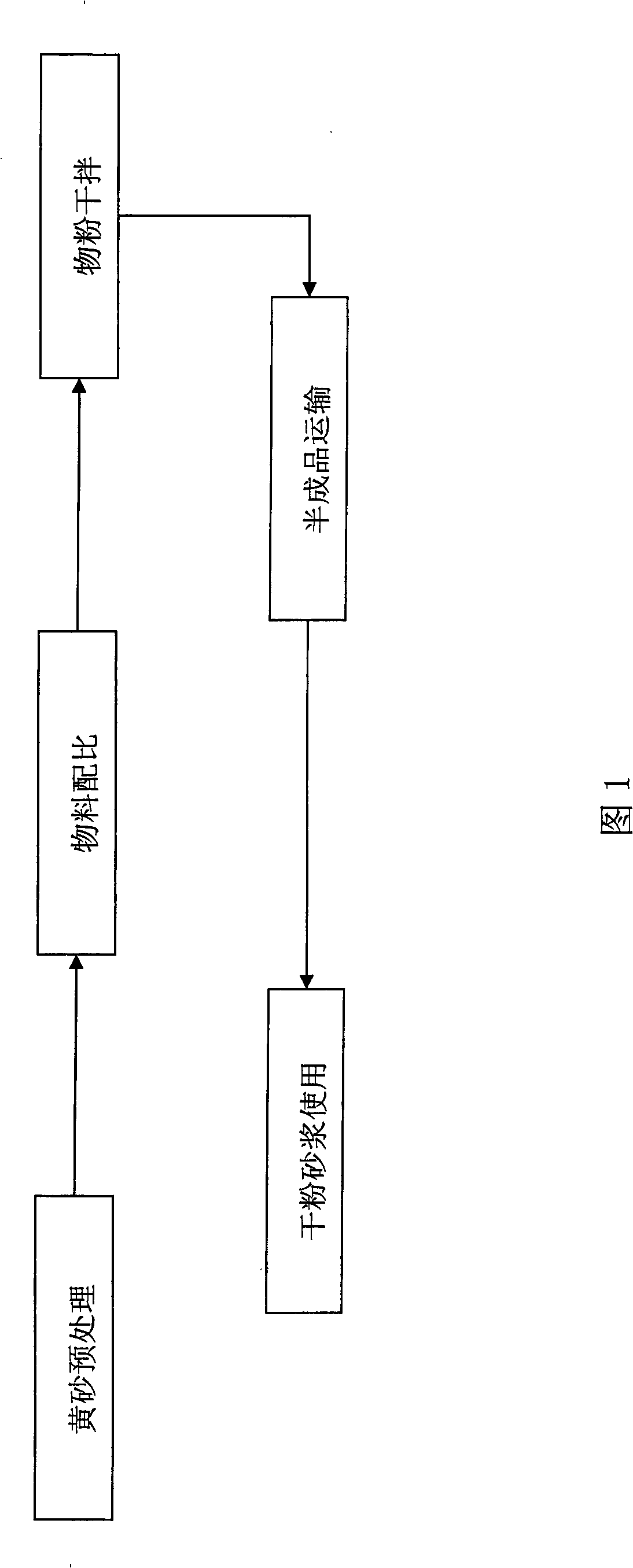

[0025] Yellow sand pretreatment: after the yellow sand is paved and dried, the yellow sand is passed through a coarse sieve to remove large particles of impurities, and the coarse sieved yellow sand is dried in a three-pass sand drying device, and then the dried yellow sand is finely sieved , the fineness modulus of yellow sand is 2.3-2.6 and the maximum particle size of yellow sand is less than or equal to 2.5mm.

[0026] Material ratio: Weigh 76 parts of yellow sand, 15 parts of cement, 6 parts of fly ash, 3 parts of thickened powder and 0.0015 parts of bentonite through a scale.

[0027] Material mixing: put the material into a gravity-free mixer, stir for 180 seconds, and mix evenly to form dry sand powder.

[0028] Dry-mixed sand powder pulping: Dry-mixed sand powder and water are mixed at a ratio of 100:13 to form a slurry before use.

example 2

[0030] Yellow sand pretreatment: after the yellow sand is paved and dried, the yellow sand is passed through a coarse sieve to remove large particles of impurities, and the coarse sieved yellow sand is dried in a three-pass sand drying device, and then the dried yellow sand is finely sieved , the fineness modulus of yellow sand is 2.3-2.6 and the maximum particle size of yellow sand is less than or equal to 2.5mm.

[0031] Material ratio: Weigh 76 parts of yellow sand, 15 parts of cement, 6 parts of fly ash, 3 parts of thickened powder and 0.0015 parts of bentonite by weighing scale, add 0.5% of cellulose ether and 0.2% of water reducer to the total mass of materials .

[0032] Material mixing: Put the materials into a gravity-free mixer, stir for 2.5 hours, and mix them evenly to form dry sand powder.

[0033] Dry-mixed sand powder pulping: Dry-mixed sand powder and water are mixed at a ratio of 100:15 to form a slurry before use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com