Threaded obliquely-arranged ribbed steel tube concrete column and design method thereof

A technology for concrete-filled steel pipe columns and concrete columns, which is applied in the direction of columns, pier columns, pillars, etc., can solve problems such as poor performance of steel-filled steel pipe columns, affecting concrete compactness, and reduced concrete strength, so as to ensure the quality of concrete, simple structure, The effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

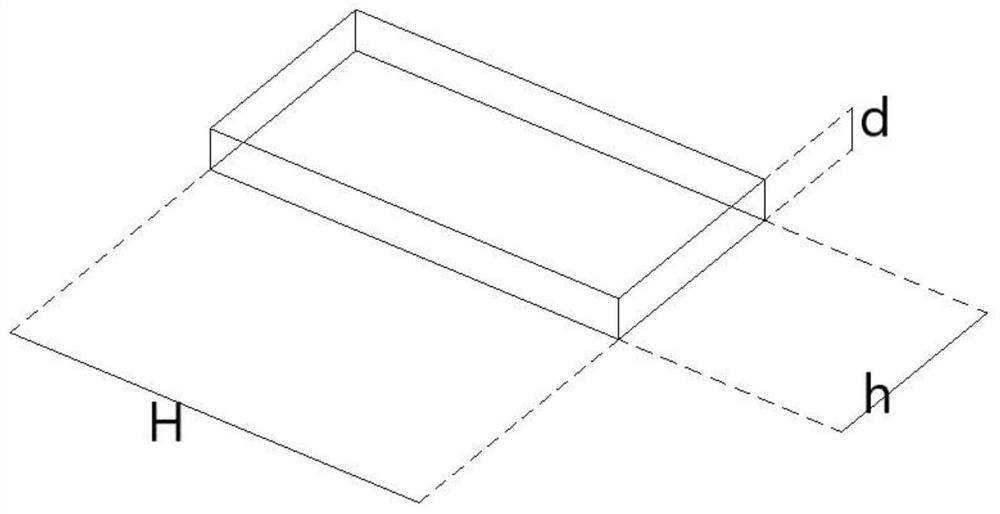

[0046] In this embodiment, the concrete-filled steel tube column of Guangzhou Jiangnan Center is taken as an example. The concrete-filled steel tube column is a circular steel tube with a diameter of 1200mm and a thickness of 18mm, and the concrete grade is C60. The size of the rib in this embodiment is designed in the following way:

[0047] The length of the rib is: H=1200*20%=240mm;

[0048] The width of the rib is: h=240*50%=120mm;

[0049] The thickness of the rib is: d=120*5%=6mm;

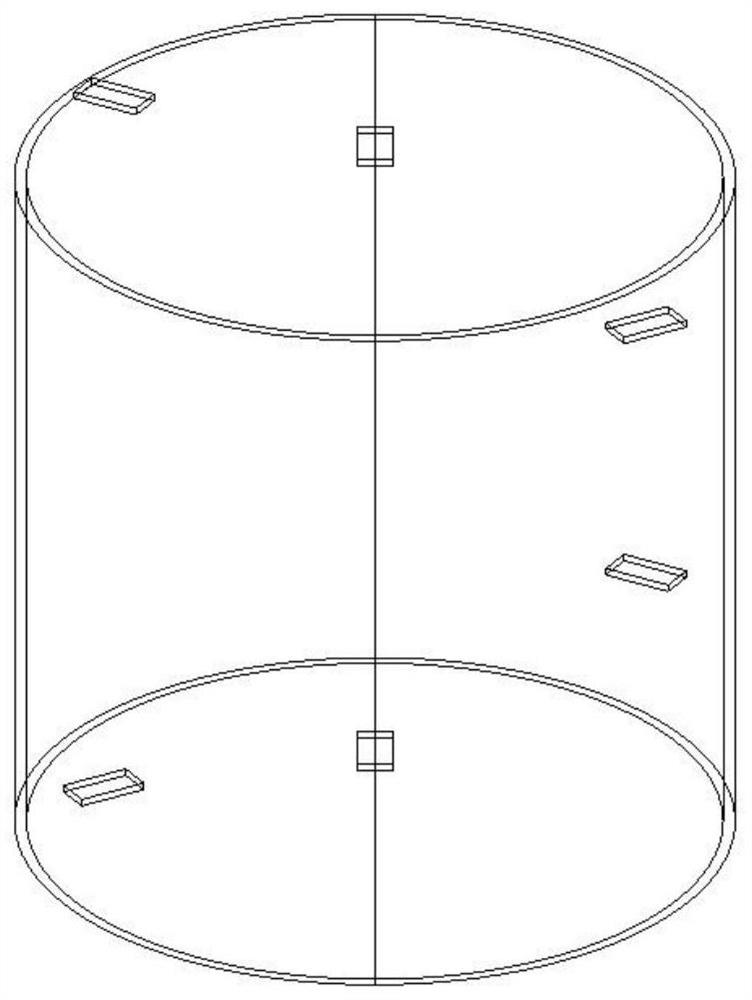

[0050] The distribution position of the ribs is as follows: steel pipe diameter D = 1200mm, 6 ribs are arranged within every 1.2m, and an angle of 60 degrees is formed between adjacent ribs in the steel pipe cross section of a group of ribs, see for details image 3 .

[0051] Weld the ribs and circular steel pipes according to the position in the figure.

Embodiment 2

[0053] In this embodiment, the steel pipe concrete column of the Hong Kong Center Building is taken as an example, wherein the steel pipe concrete column is a square steel pipe, and the long and short side dimensions of the steel pipe are the same as 800mm, and the thickness is 20mm. The size of the rib in this embodiment is designed in the following way:

[0054] The length of the rib is: H=800*20%=160mm;

[0055] The width of the rib is: h=160*50%=80mm;

[0056] The thickness of the rib is: d=80*5%=4mm,

[0057] According to the convenience of welding, the thickness of the rib in this embodiment is 6mm, i.e. d=6mm;

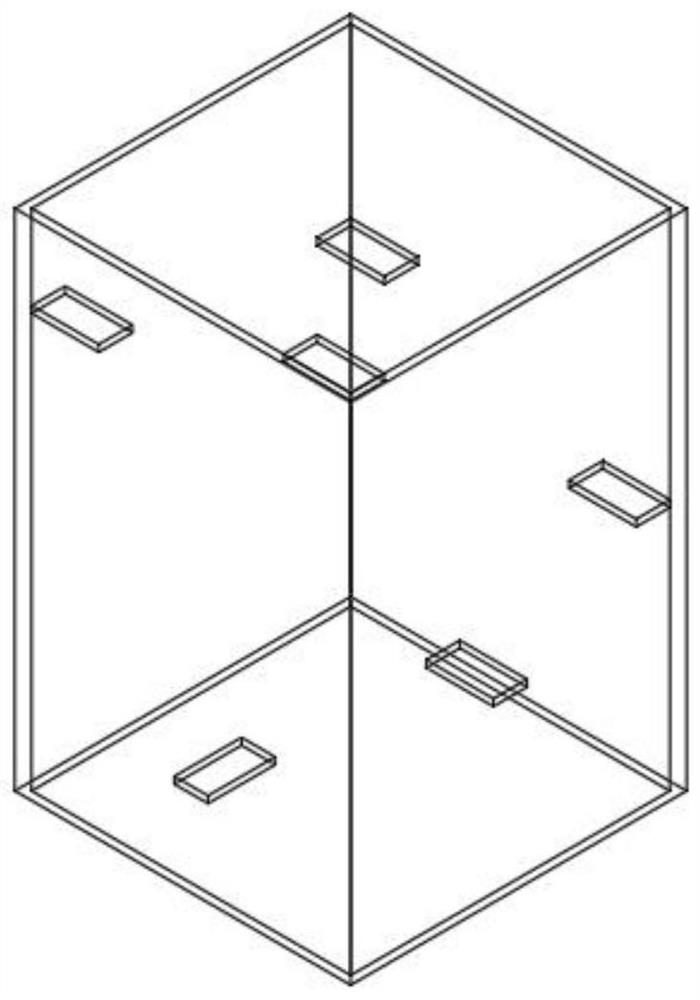

[0058] The distribution position of the ribs is as follows: the cross-sectional size of the square steel pipe is 800mm*800mm, and 6 ribs are arranged in every 1.2m height, and the six ribs generally form a spiral distribution in the height direction. For details, see Figure 4 . In the cross-section of a group of ribs, there are four ribs located at the four...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com