Patents

Literature

52 results about "Segregation in concrete" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Segregation in concrete is a case of particle segregation in concrete applications, in which particulate solids tend to segregate by virtue of differences in the size, density, shape and other properties of particles of which they are composed.

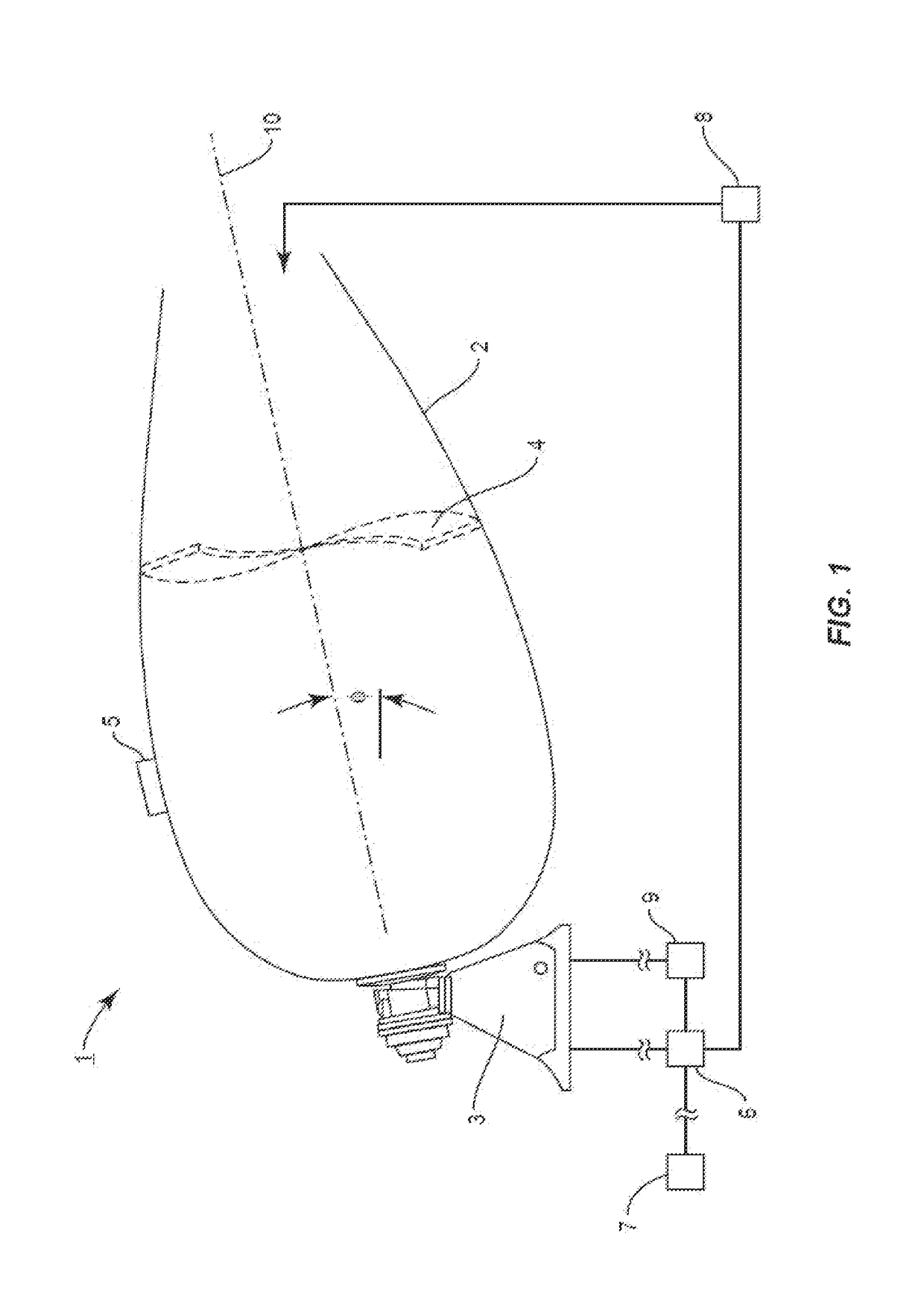

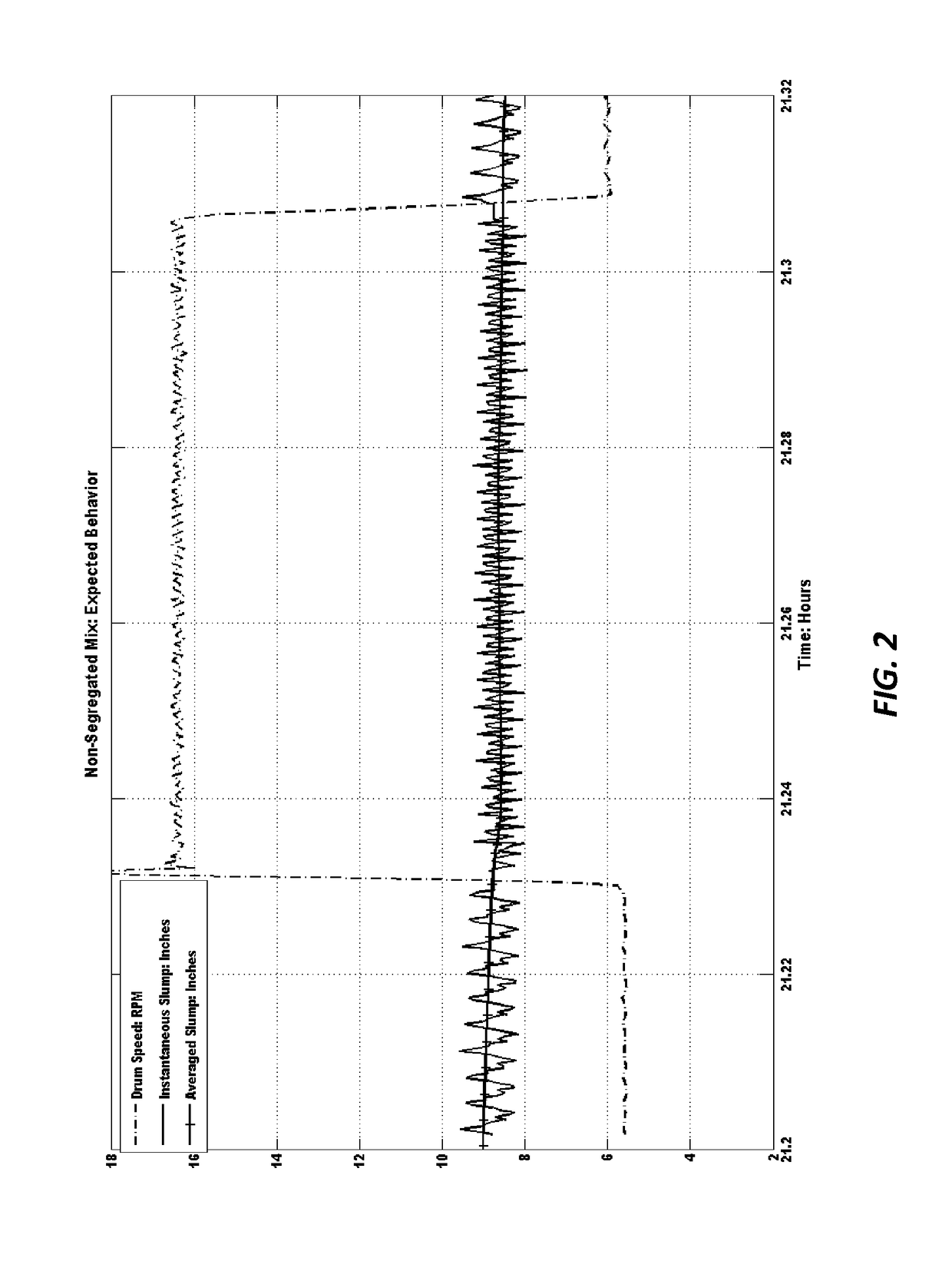

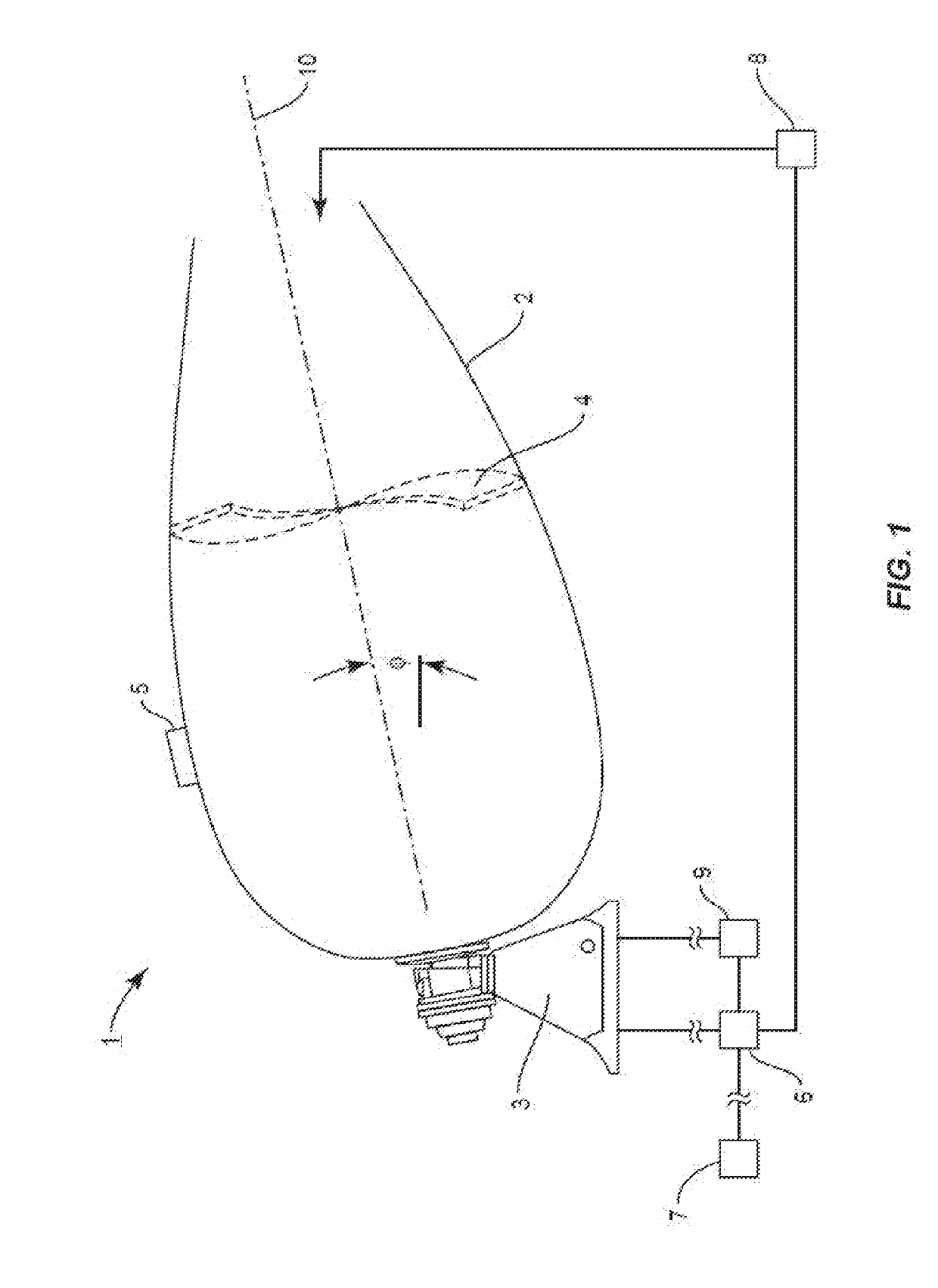

Dynamic segregation monitoring of concrete

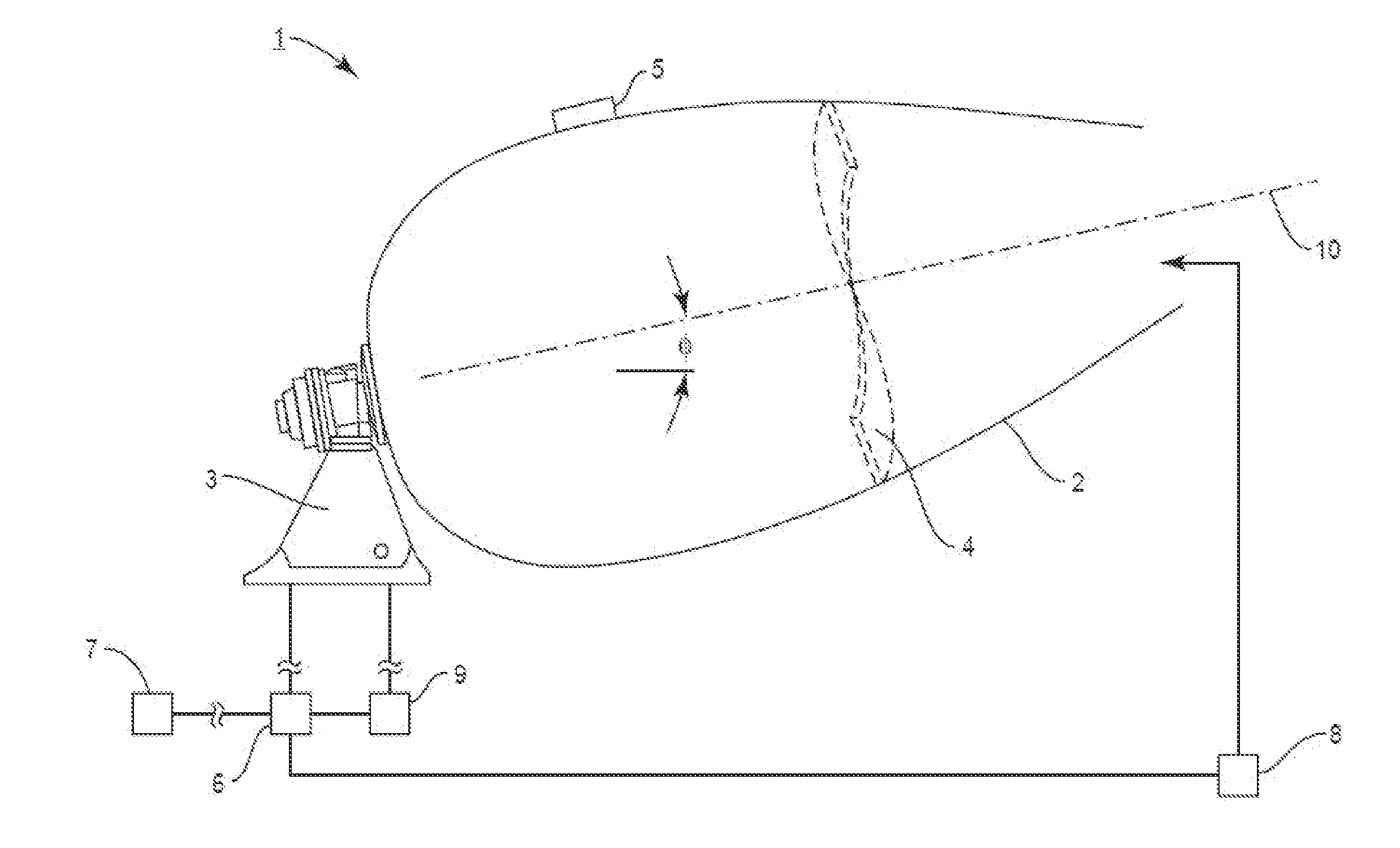

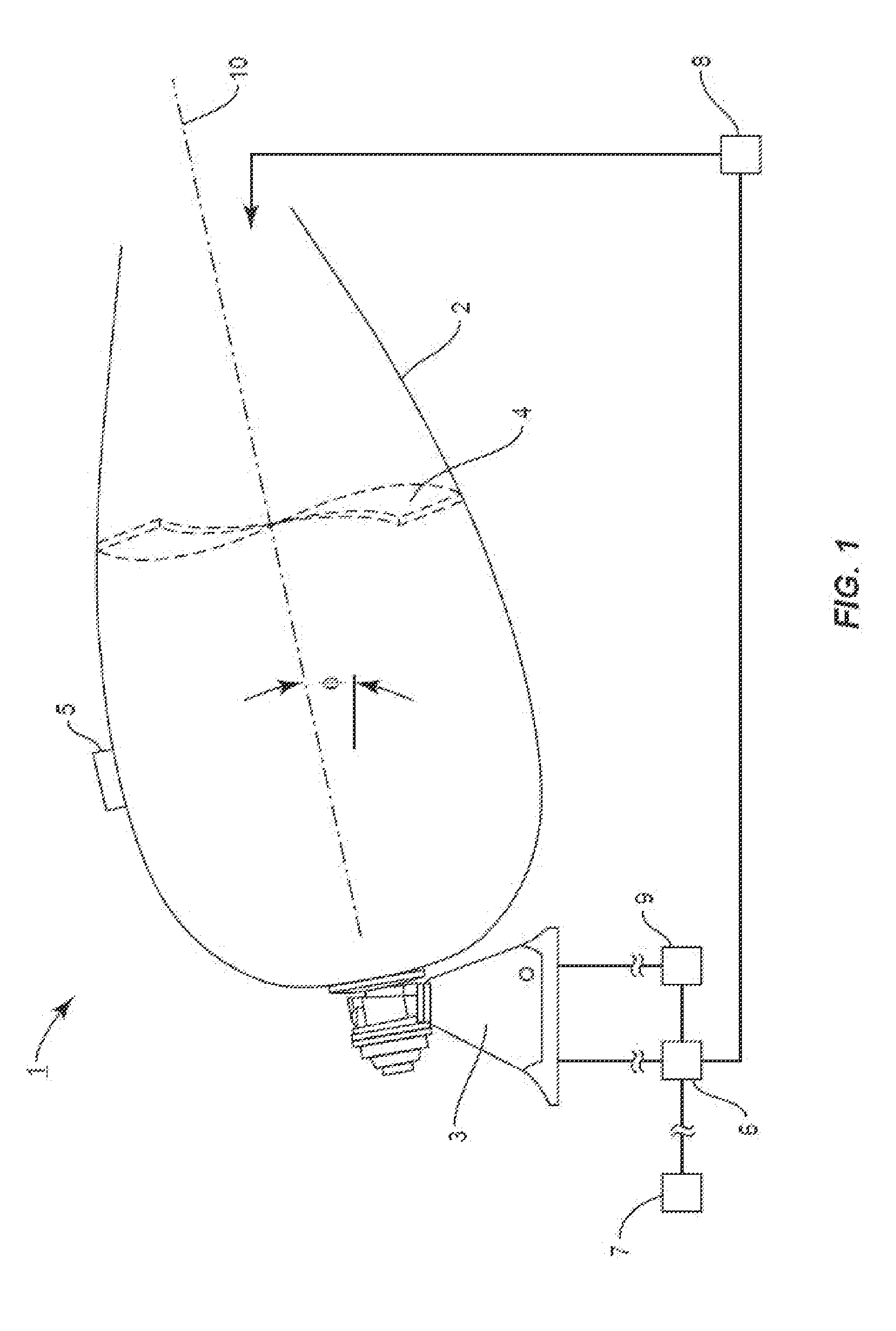

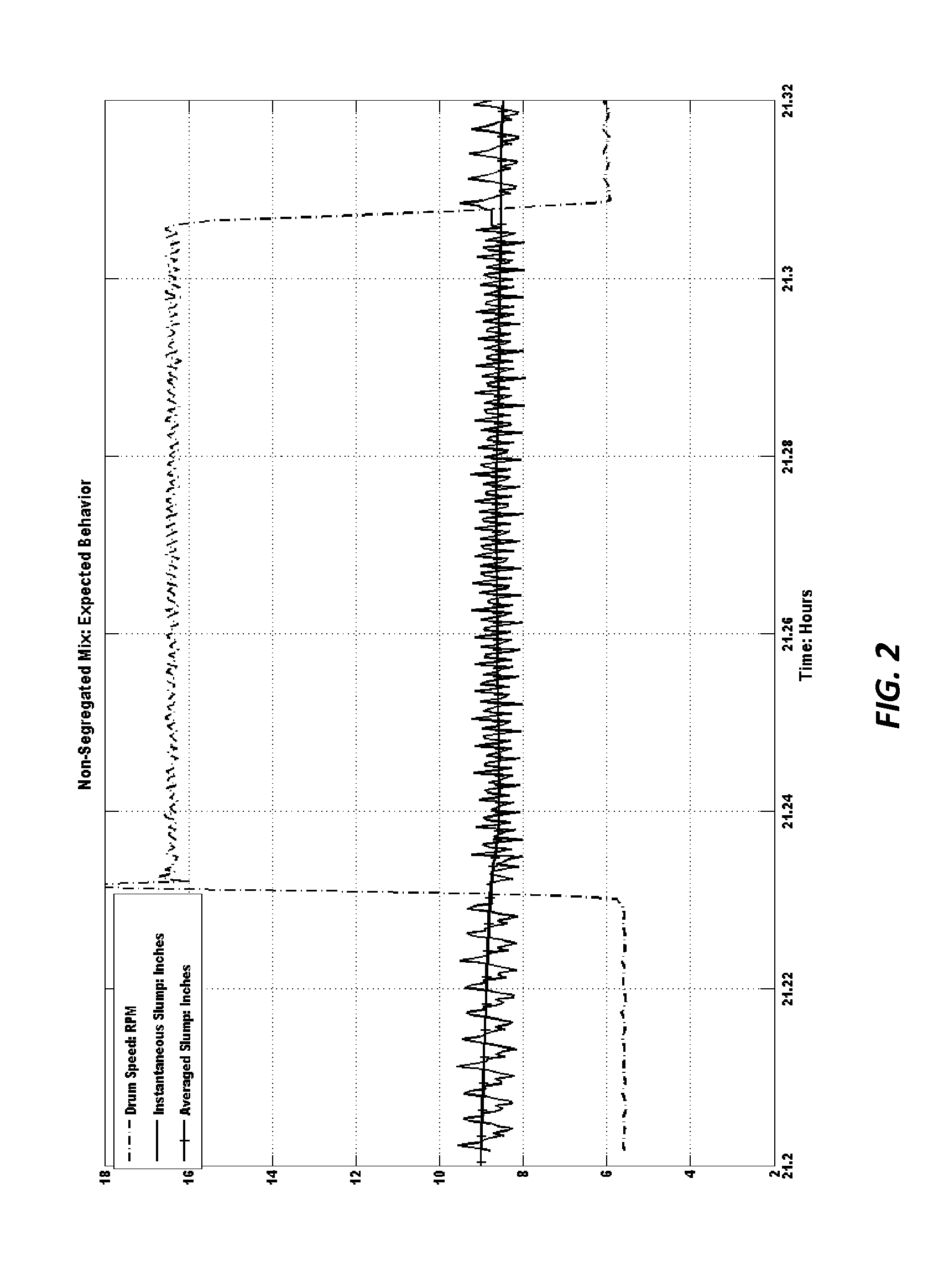

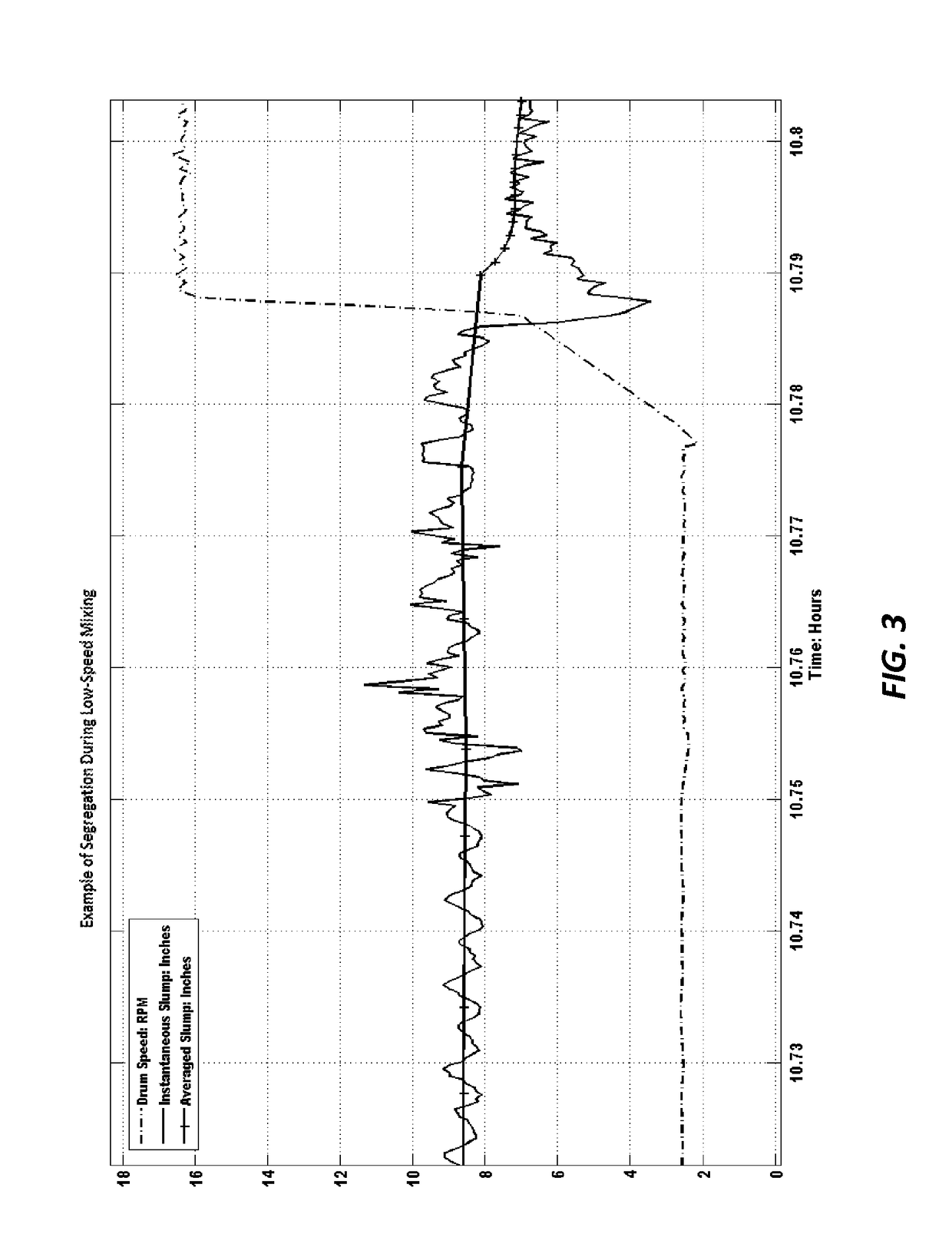

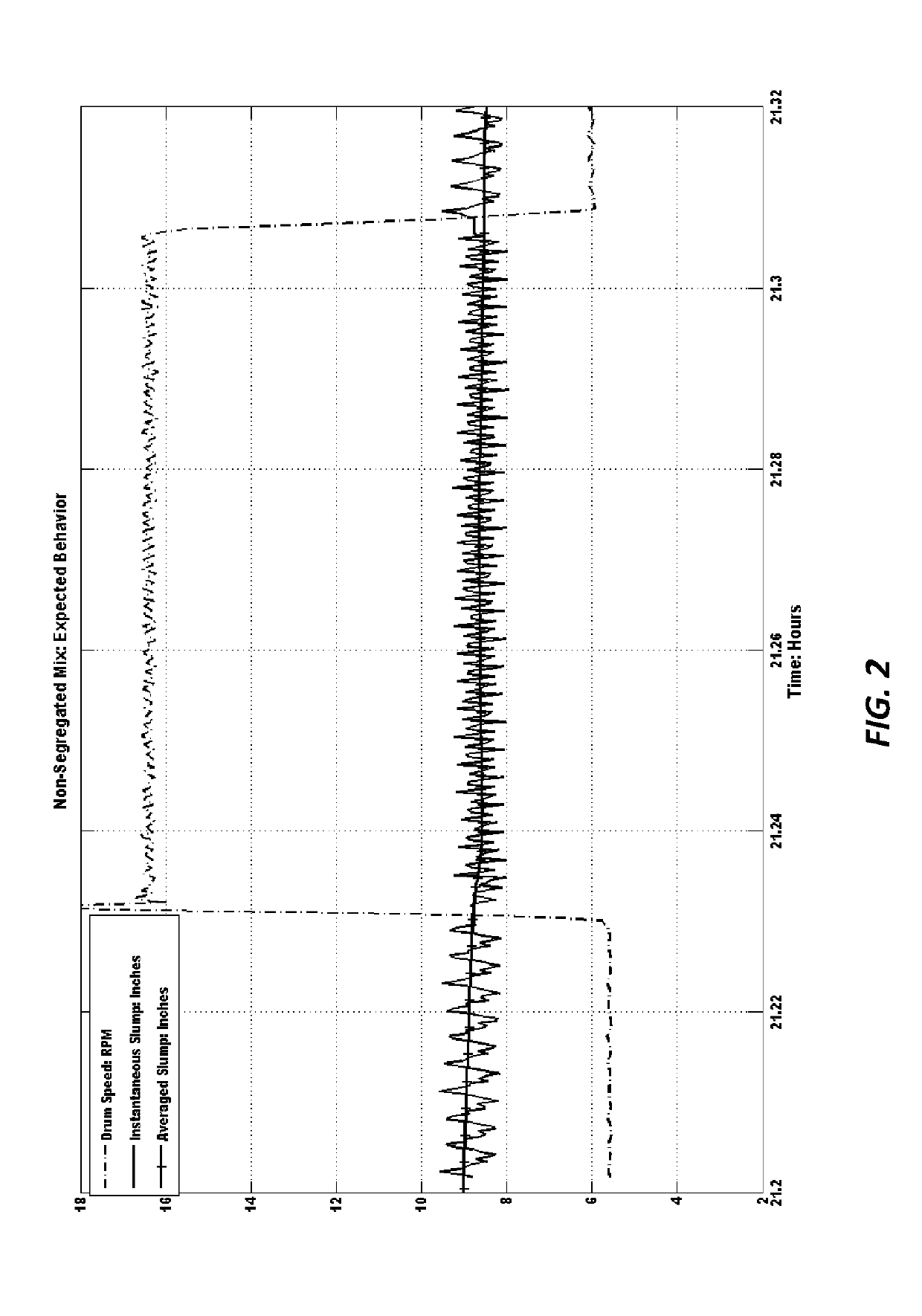

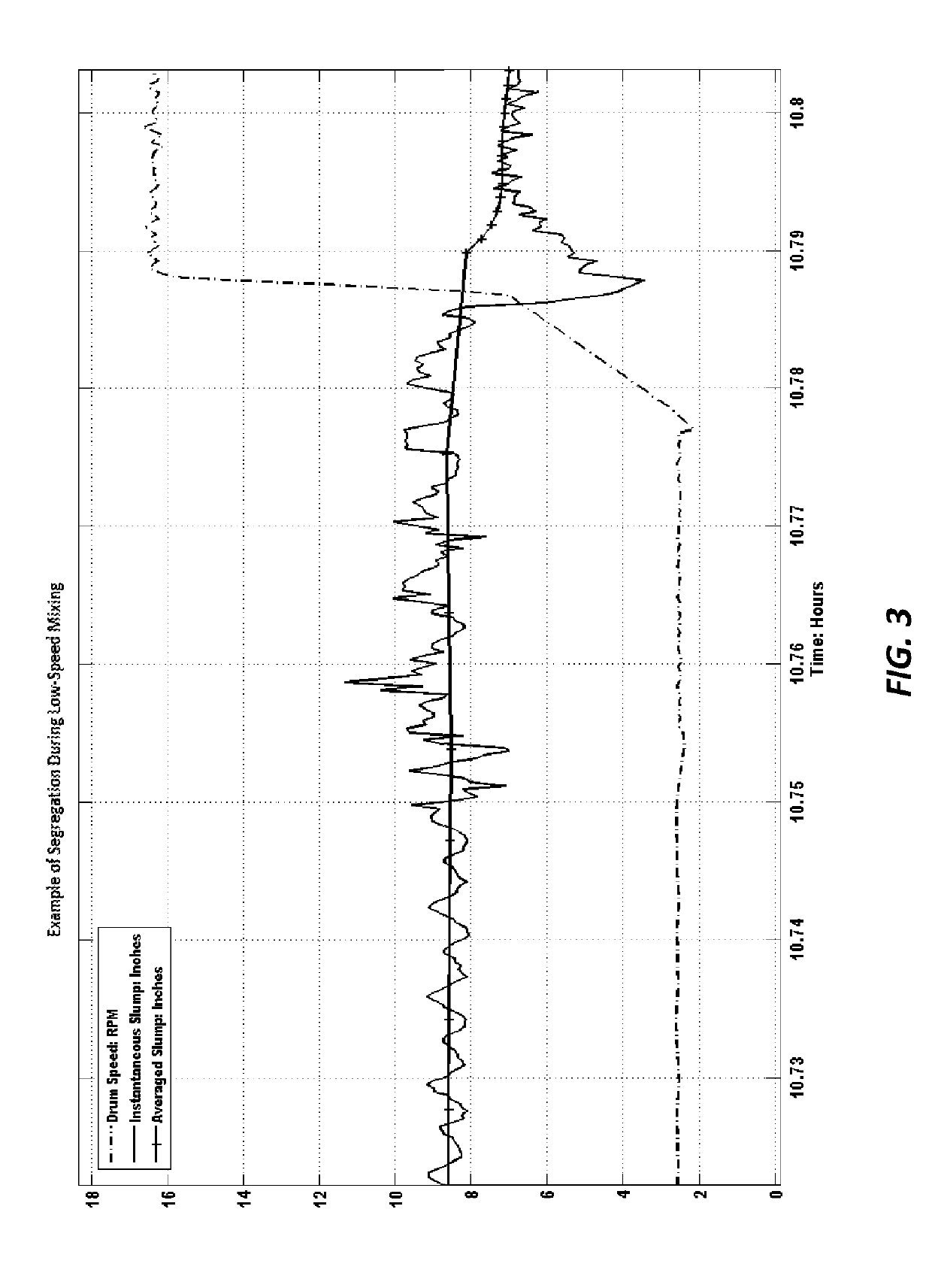

A system and process for detecting dynamic segregation in concrete rotated within a mixer drum, such as mounted on a delivery truck. A system processor is programmed to monitor an instantaneous and averaged rheology parameter (e.g., instantaneous and averaged slump values) and to deploy one or more protocols for detecting the occurrence of segregation. A first protocol comprises monitoring the averaged slump or other rheology value of concrete during and immediately after a jump in drum speed of at least plus or minus four rotations per minute and detecting when a change in the averaged slump value meets or exceeds a threshold limit pre-selected by the user or the system processor; and an optional second protocol comprises monitoring the instantaneous slump or other rheology value of the concrete when the mixer drum is rotating at a constant speed for at least three successive rotations.

Owner:VERIFI

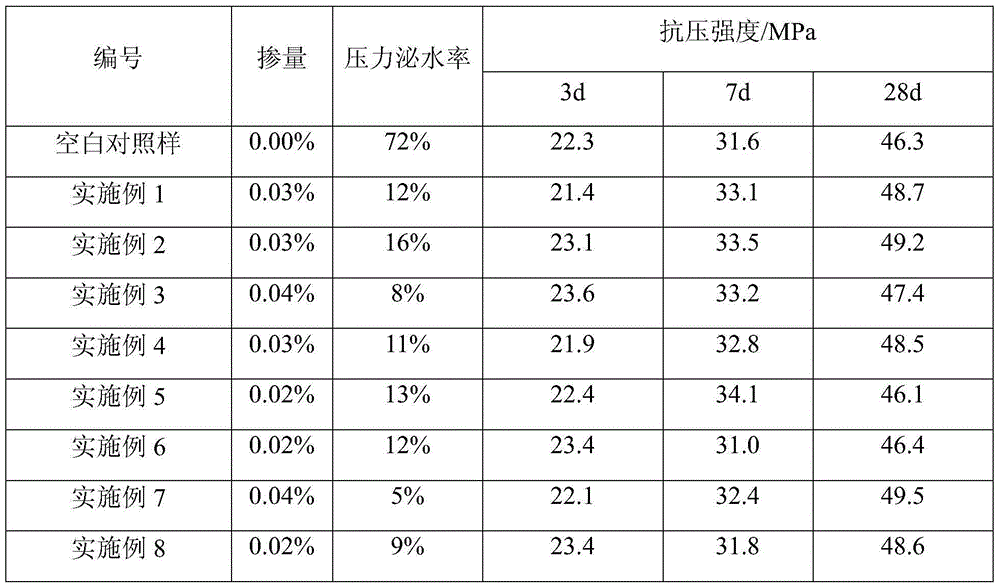

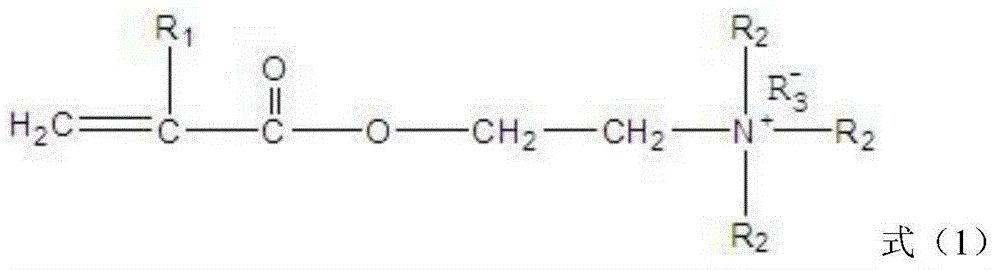

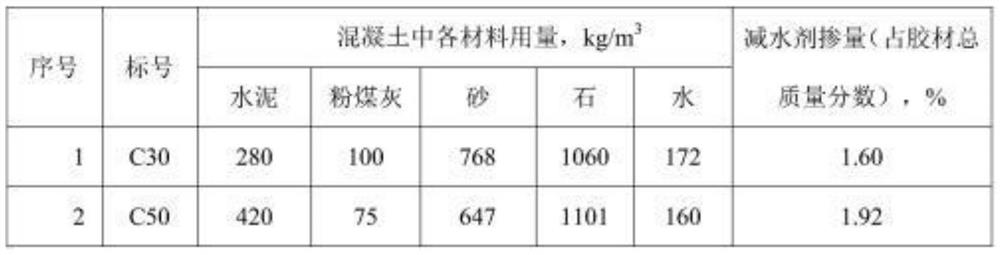

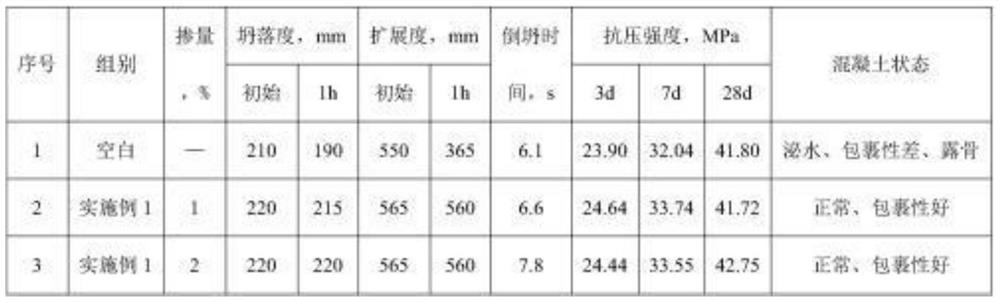

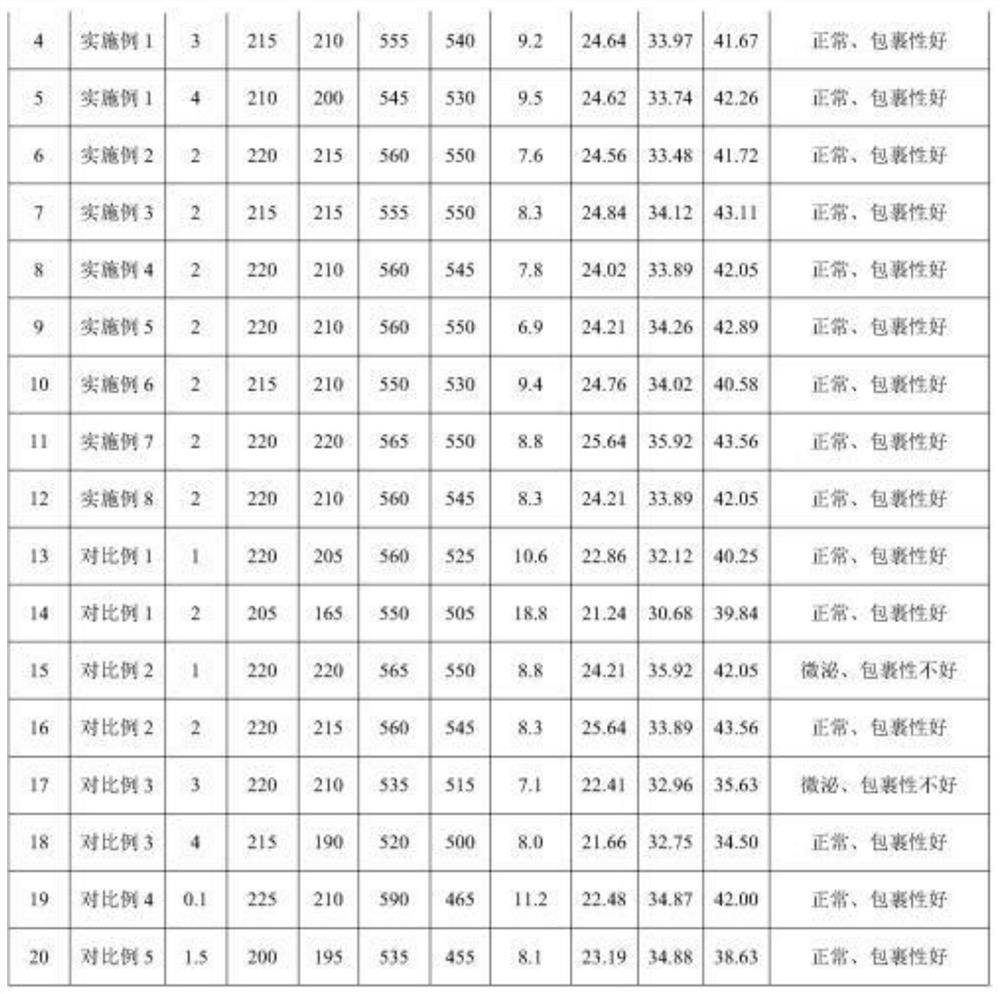

Concrete viscosity adjusting agent and preparation method thereof

ActiveCN104479066AApparent anti-polyelectric propertiesGood viscosity increasing effectUltimate tensile strengthCompatibilization

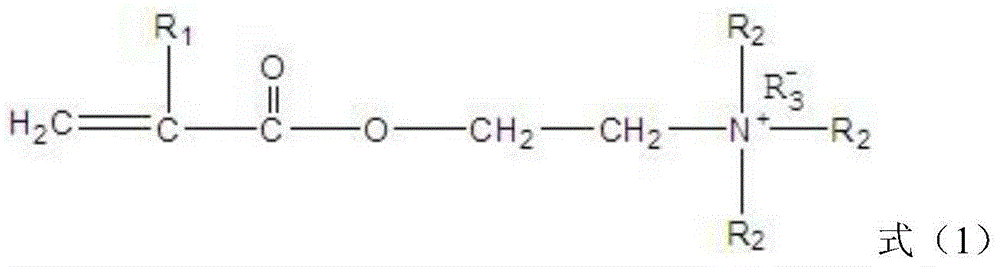

The invention discloses a concrete viscosity adjusting agent and a preparation method thereof. The concrete viscosity adjusting agent is prepared by copolymerizing a cationic monomer, an anion carboxyl monomer and an inner cross-linking agent together with a free radical, wherein the mole ratio of the cationic monomer to the anion carboxyl monomer and the inner cross-linking agent is 1:(0.5-5):(0.01-0.1). As the cationic monomer and the anion carboxyl monomer are adopted to copolymerize to obtain an amphoteric polymer, the concrete viscosity adjusting agent has remarkable antipolyelectrolyte property and is relatively good in viscosity improvement property; due to adoption of the inner cross-linking agent, three-dimensional net-shaped structures are formed among the viscosity adjusting agent and binding material grains, the concrete disintegration bleeding problem is greatly solved, and the peaceability of concrete is improved. The prepared concrete viscosity adjusting agent is good in compatibility with other additives, the strength development of concrete is not affected, and particularly the concrete disintegration bleeding problem can be effectively solved under the condition of low binding materials.

Owner:CHINA STATE CONSTR READY MIXED CONCRETE CO LTD

Dynamic segregation monitoring of concrete

A system and process for detecting dynamic segregation in concrete rotated within a mixer drum, such as mounted on a delivery truck. A system processor is programmed to monitor an instantaneous and averaged rheology parameter and to deploy protocols for detecting segregation. A first protocol comprises monitoring the averaged slump during and immediately after a jump in drum speed of at least plus or minus four rotations per minute and detecting when a change in the averaged slump value meets or exceeds a threshold; and a second protocol comprises monitoring the instantaneous slump when the mixer drum is rotating at a constant speed for at least three successive rotations and detecting when the instantaneous slump value meets or exceeds a threshold limit. Once segregation is detected, one or more operations can be initiated, such as initiating an alarm or adjusting the mix.

Owner:VERIFI INC

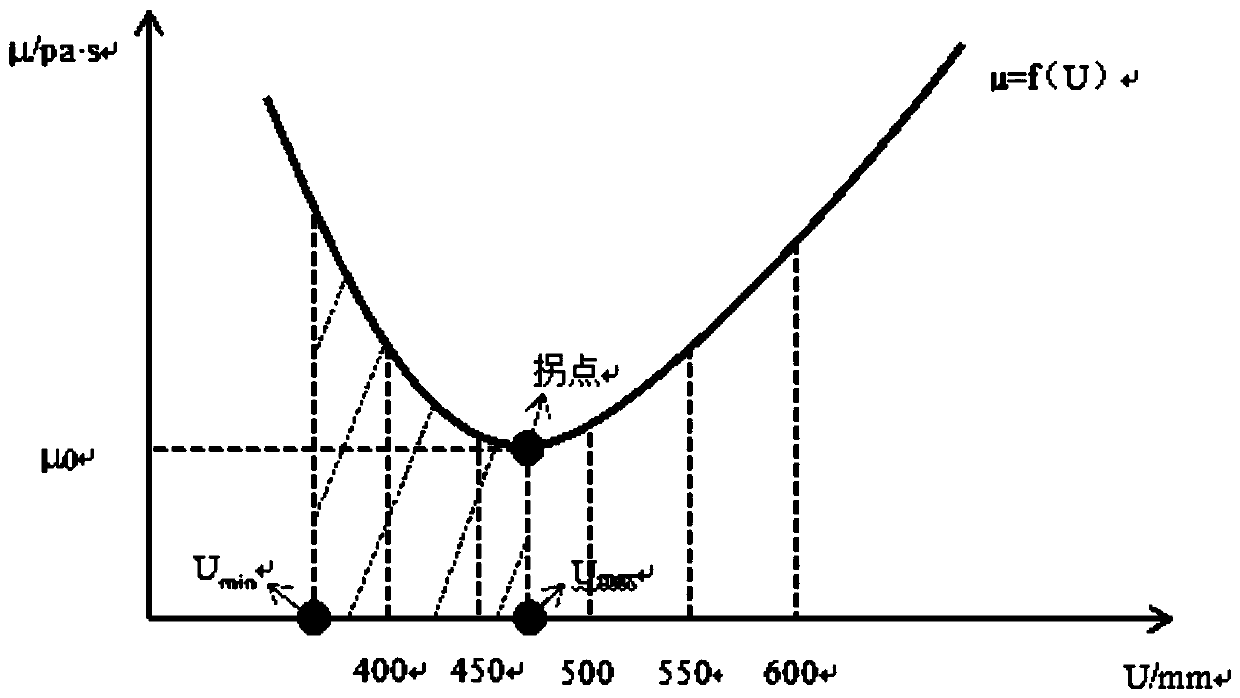

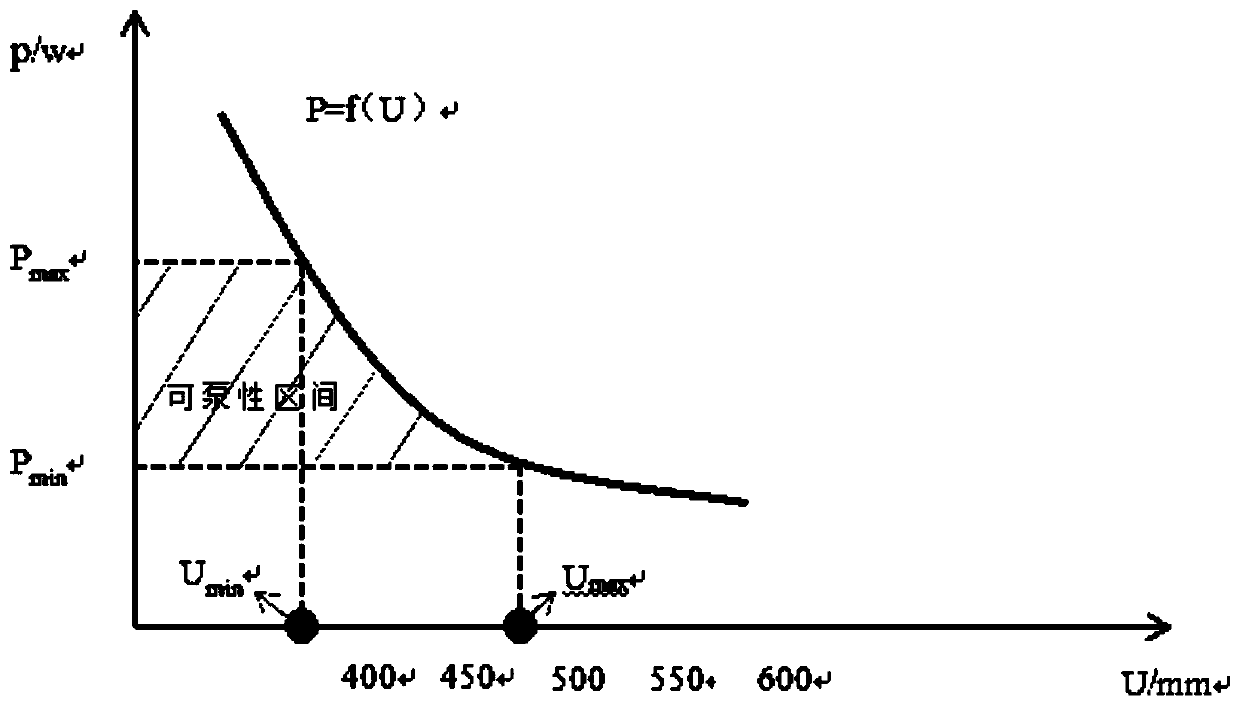

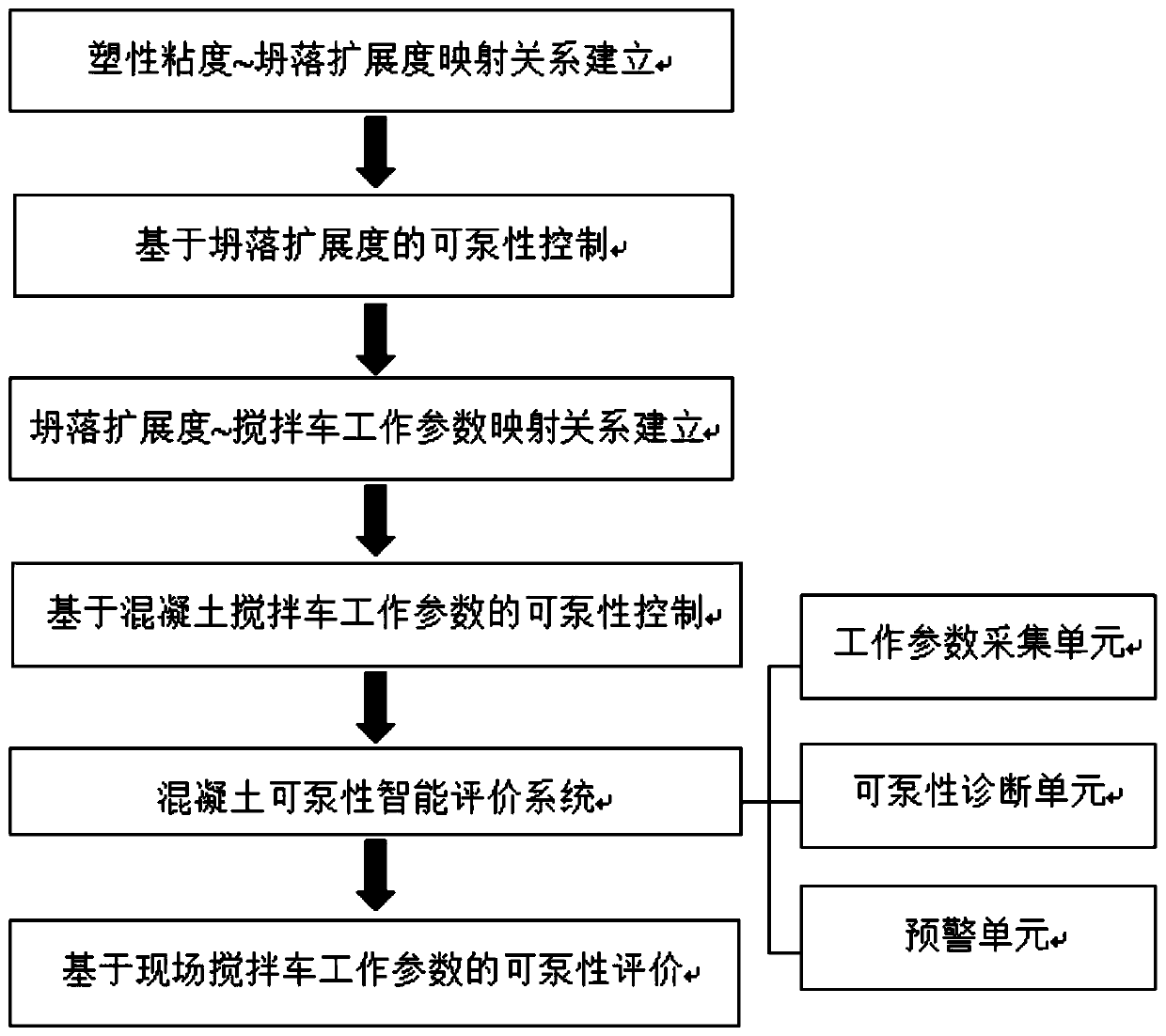

Concrete pumpability on-site rapid evaluation method based on informatization technology

ActiveCN110750919ARapid pumpabilityPumpability scienceDesign optimisation/simulationTotal factory controlInformatizationArchitectural engineering

The invention discloses a concrete pumpability on-site rapid evaluation method based on an informatization technology, and belongs to the technical field of pumping concrete application. The problem that an existing concrete pumpability evaluation method is insufficient in accuracy is solved. According to the method, the working parameters of the concrete mixer are monitored by adopting an informatization means; the concrete pumpability on-site rapid evaluation method based on the informatization technology is provided by determining the mapping relation between the working parameters of the mixer truck and the concrete slump expansion degree and the mapping relation between the concrete slump expansion degree and the rheological parameters, and scientific, reliable and rapid evaluation ofthe concrete pumping performance on the construction site is achieved. According to the method, the on-site actual measurement step sequence of the concrete slump expansion index is effectively replaced, the traditional evaluation limitation that the larger the concrete expansion is, the more beneficial the pumping construction is is broken through, concrete segregation is effectively prevented,pipe blocking, pipe explosion and other accidents are reduced, technical support is provided for the pumping construction of concrete, and smooth proceeding of engineering is ensured.

Owner:SHANGHAI CONSTRUCTION GROUP

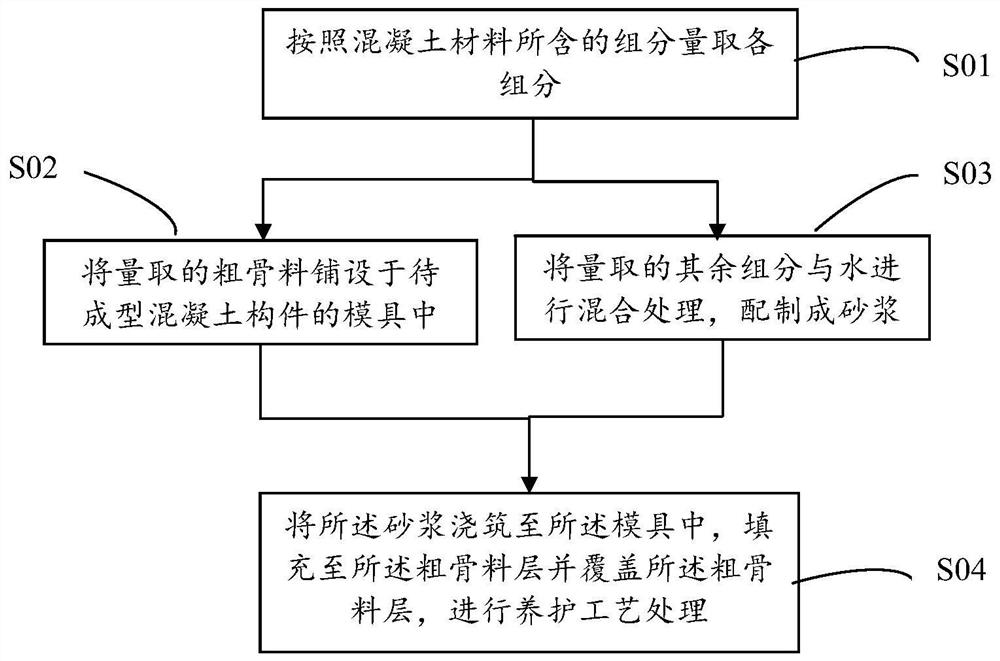

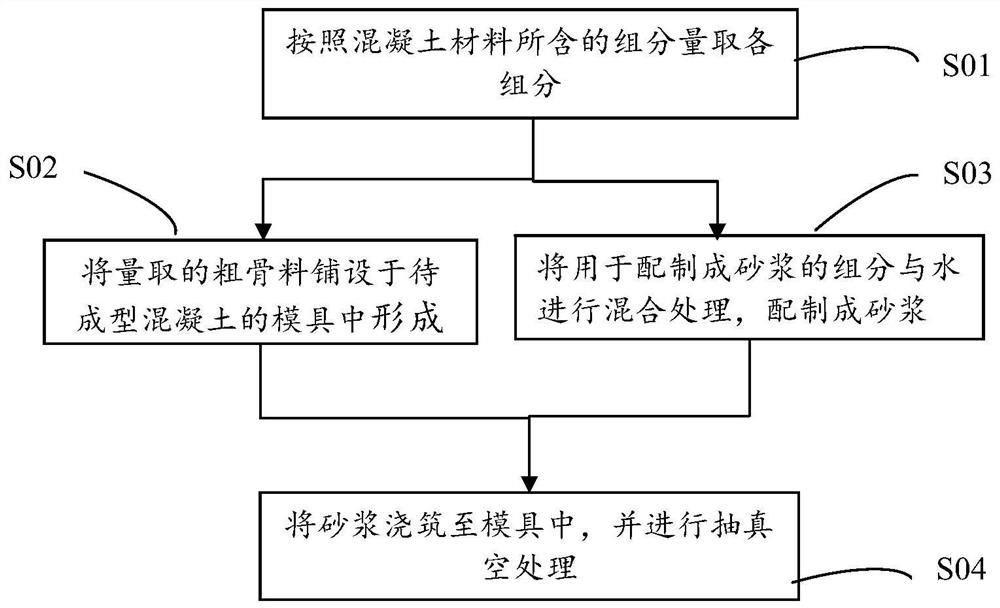

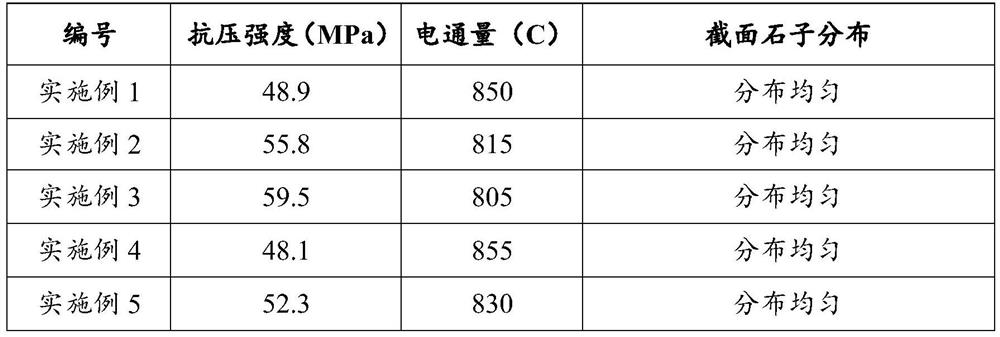

Concrete stacking forming method

PendingCN111890537AImprove mechanical propertiesIncreased durabilityFeeding arrangmentsCement mixing apparatusStructural engineeringSegregation in concrete

The invention discloses a concrete stacking forming method. The concrete stacking forming method comprises the following steps that each component is measured according to the component amount contained in a concrete material; the measured coarse aggregate is laid in a mold of to-be-formed concrete, and a coarse aggregate layer is formed; the rest of the measured components are mixed with water toprepare mortar; and the mortar is poured into the mold, the coarse aggregate layer is filled with the mortar, the coarse aggregate layer is covered with the mortar, and curing process treatment is carried out. According to the concrete stacking forming method, the distribution uniformity of aggregate components can be effectively improved, the problems of segregation, bleeding, coarse aggregate sinking and the like of fluid concrete are reduced, the mechanical property, durability and compactness of the concrete are improved, and the use amount of cementing materials can be reduced.

Owner:GUANGDONG GAITEQI NEW MATERIAL TECH CO LTD

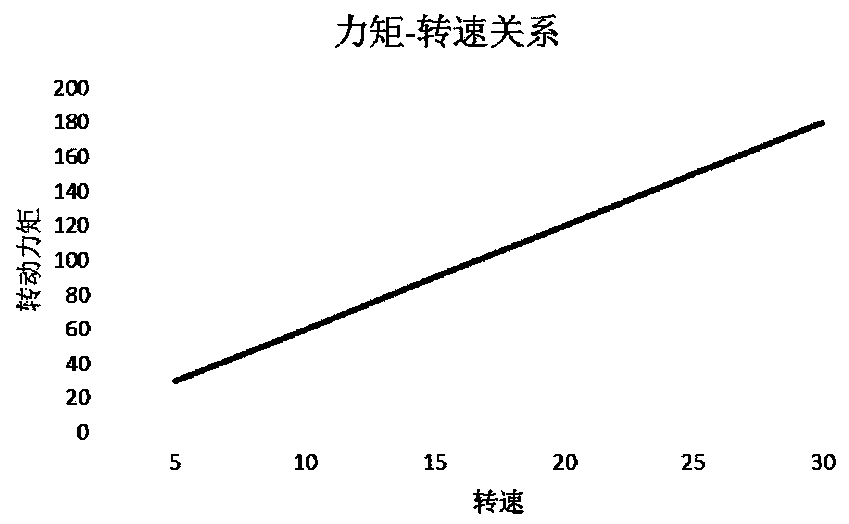

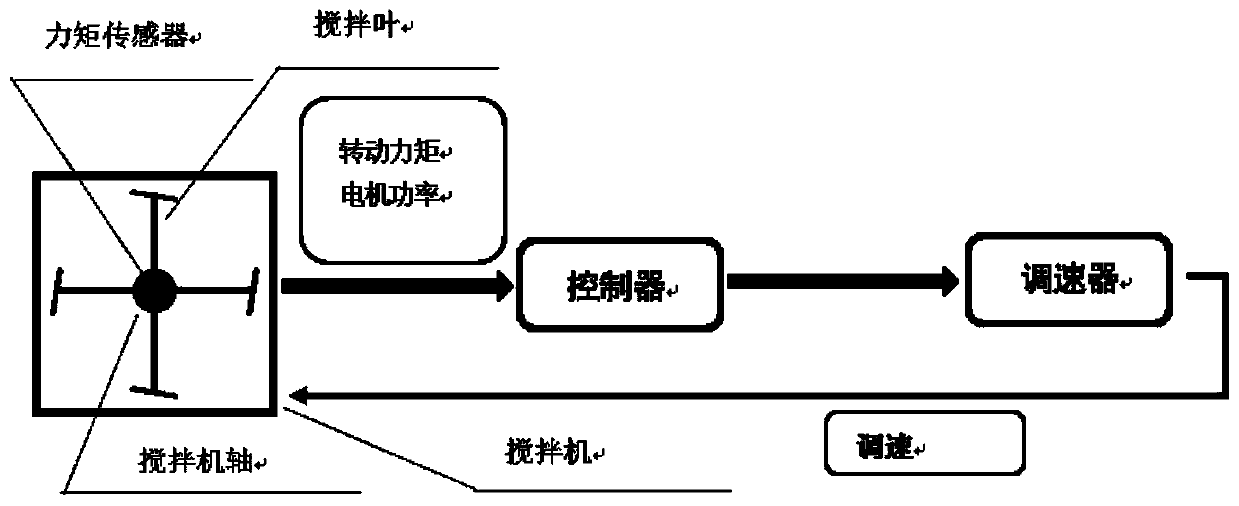

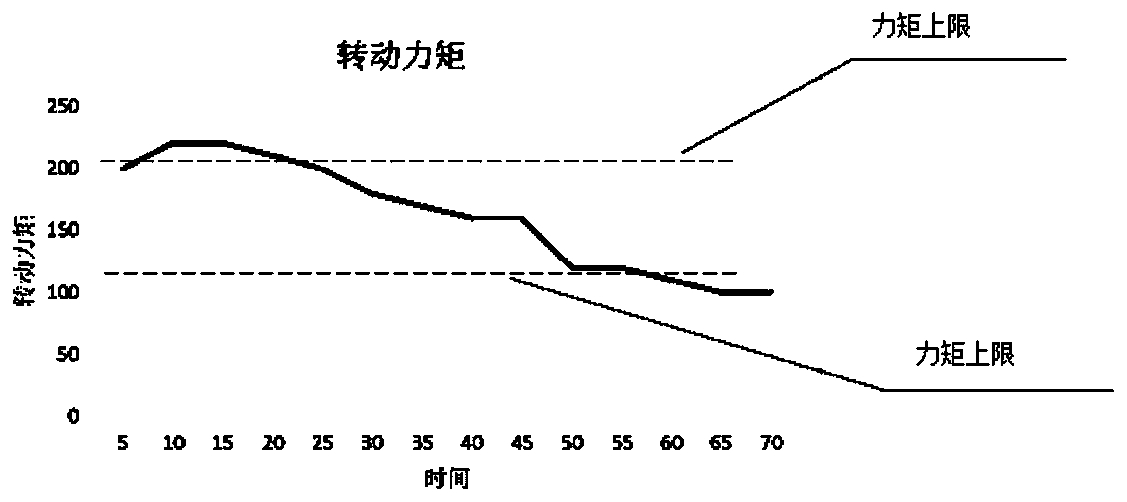

Fresh mixed high-property concrete rheological property control method and device

InactiveCN111015956AMeet the needs of engineering constructionAdjust stirring speed in real timeControl apparatusElectric machineControl engineering

The invention belongs to the technical field of concrete, particularly relates to a fresh mixed high-property concrete rheological property control method and device and aims at providing a novel stirring method and device suitable for high-property concrete. According to the device, a torque sensor and a speed adjuster are arranged on a stirrer, a power meter is arranged on a circuit of the stirrer, the power meter can transmit real-time motor power to a controller during stirring, the stirring speed of the stirrer can be controlled in three stages, the torque sensor is used for automaticallydetecting high-property concrete torque change in the stirring process, when the torque change is higher than the upper limit, and is maintained for a quite long time, the rotating speed is automatically lowered, a motor overload alarm is given out, when the torque change is lower than the lower limit, the rotating speed is automatically lowered, a producer is promoted to observe the concrete state, and quality problems of concrete disintegration, bleeding and the like can be solved.

Owner:SHANGHAI CONSTRUCTION GROUP

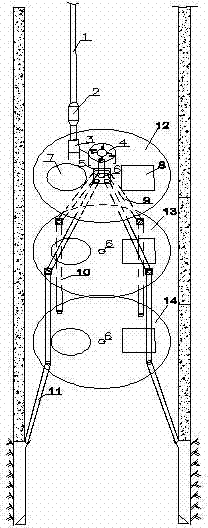

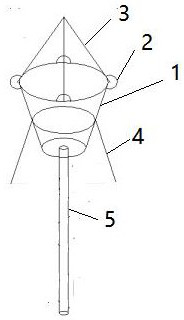

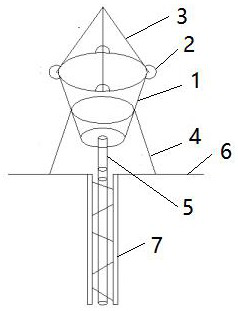

Vertical shaft cement discharging system with secondary stirring device

ActiveCN103939103AInhibition of segregationQuality assuranceShaft liningMechanical engineeringSegregation in concrete

The invention discloses a vertical shaft cement discharging system with a secondary stirring device. The vertical shaft cement discharging system is mainly formed by a main cement sliding pipe, a buffer, a cement hopper, the secondary stirring device, a cement dividing device, center line openings, main lifting horn mouths, auxiliary lifting horn mouths, slide type sliding grooves, a short cement sliding pipe, a rubber soft pipe, a first hanging disc, a second hanging disc and a third hanging disc. The first hanging disc, the second hanging disc and the third hanging disc are respectively provided with the main lifting horn mouths and auxiliary lifting horn mouths in a left-and-right mode, the center line openings are formed in the middles, the cement dividing device is arranged on the upper portion of the first hanging disc, a center line pipe in the middle of the cement dividing device and the center line opening in the first hanging disc are located in the same center line, four cement outlets are formed in the lower portion of the cement dividing device, penetrate through the first hanging disc, and are connected with the four slide type sliding grooves respectively, and the four slide type sliding grooves respectively penetrate through the second hanging disc to be connected with the short cement sliding pipe. By means of the vertical shaft cement discharging system, continuous concrete discharging of a deep vertical shaft is achieved, and meanwhile concrete disintegration is avoided; the concrete quality is accordingly guaranteed, and the working efficiency is improved.

Owner:CHINA COAL FIRST CONSTR

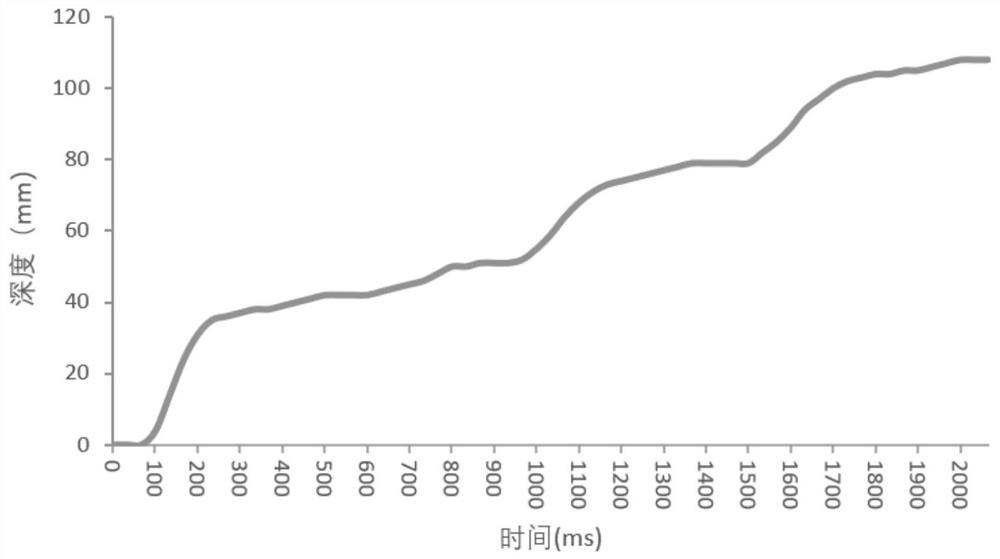

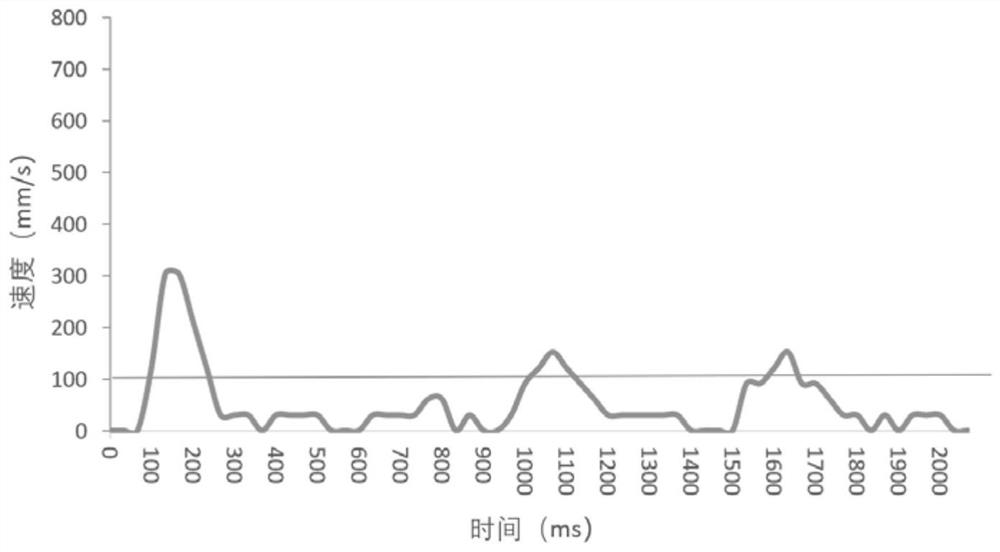

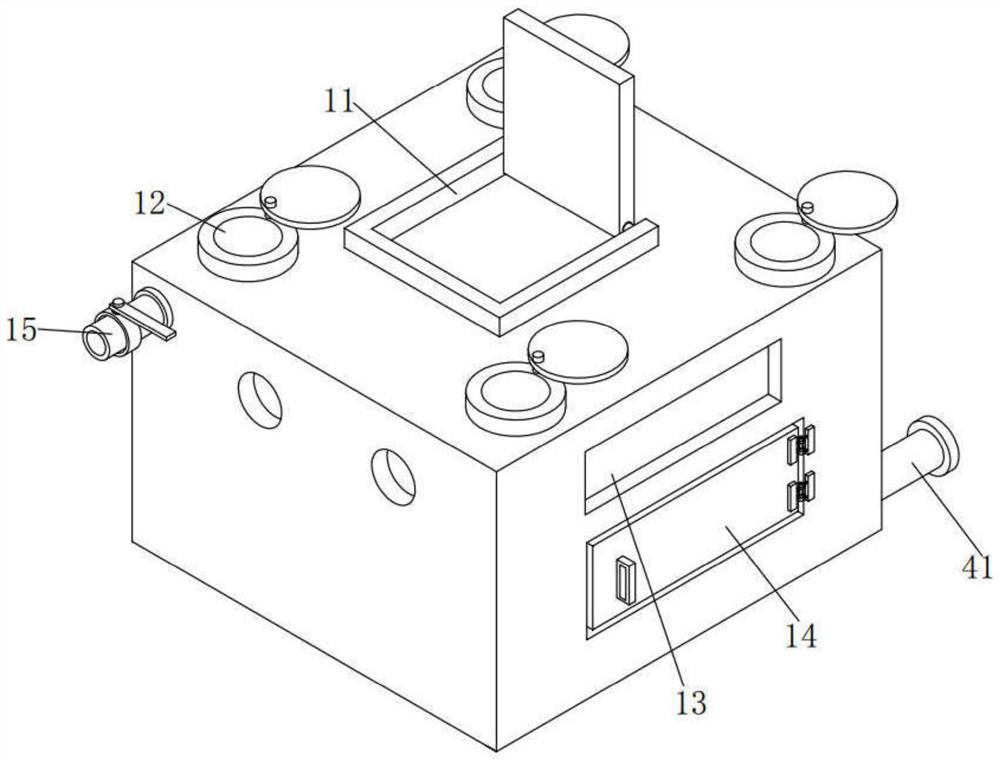

Quantitative evaluation method for analyzing concrete workability based on bottom resistance, and device

PendingCN111811934AAccurate quantification of sinking conditionsThe experimental process is simple and fastMaterial strength using tensile/compressive forcesUsing mechanical meansStructural engineeringSegregation in concrete

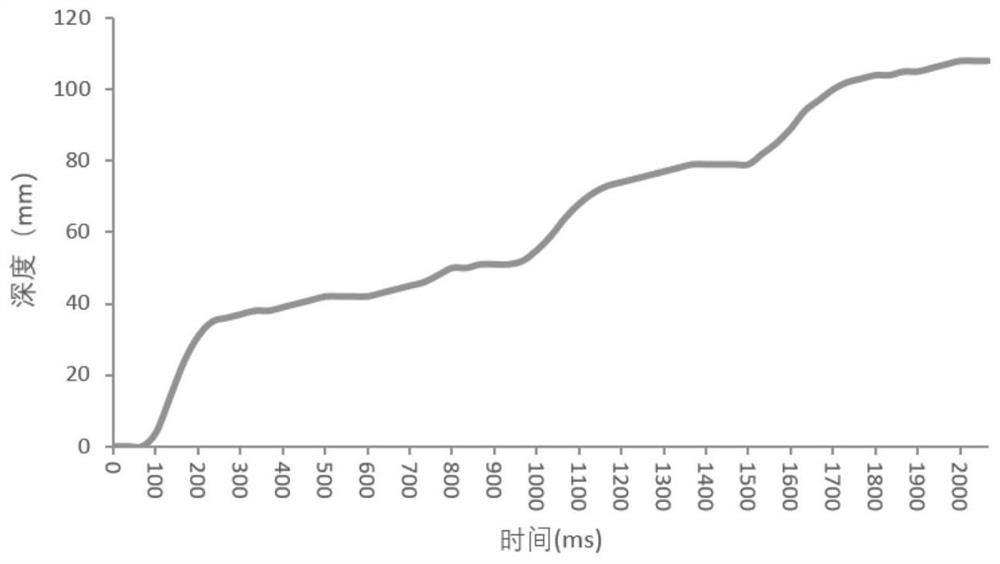

The invention relates to a quantitative evaluation method for analyzing concrete workability based on bottom resistance, and a device. The quantitative evaluation method comprises the following stepsof: (1) carrying out a fresh concrete bottom resistance test; (2) drawing a curve that the displacement and speed of a resistance test piece change along with time; and (3) quantitatively evaluating the concrete workability based on the bottom resistance condition. The device comprises a transparent plastic box, a resistance test piece, a sliding guide rail and a laser displacement sensor. By adopting the quantitative evaluation method and the device, the time and the displacement of the resistance test piece inserted into the concrete bottom can be accurately measured; then, the insertion speed is calculated, the curve that the displacement and the speed change along with time is drawn, and the sinking condition of the fresh concrete aggregate is quantitatively characterized through utilizing a concrete workability comprehensive coefficient, so that the quantitative evaluation of the concrete workability is realized, and the defect that the concrete segregation degree is difficult toquantitatively characterize by adopting a traditional method is overcome.

Owner:湖北省四极新材料有限公司

Concrete segregation repairing agent and preparation method thereof

The embodiment of the invention relates to the technical field of building materials, in particular to a concrete segregation repairing agent and a preparation method thereof. The concrete segregationrepairing agent is prepared from the following components in parts by weight: 10-20 parts of 2-acrylamide-2-methyl propanesulfonic acid, 3-5 parts of acrylic acid, 1-3 parts of fumaric acid, 10-20 parts of acrylamide crystals, 100-120 parts of deionized water and 0.01-0.05 part of potassium persulfate. The beneficial effects are that the concrete segregation repairing agent is formed by polymerization of a high-molecular biopolymer, and the production and use processes are green and pollution-free; acid and alkali resistance is high, compatibility is high, and compatibility is good; the repairing agent does not contain an air entraining component and a thickening component; an aqueous solution of the repairing agent has good viscosity and consistency; when applied to the concrete, the repairing agent can make the concrete have good viscoelasticity, plasticity and toughness, and the phenomena of cracking, hollowing, bubbling, peeling and the like of the concrete can be effectively improved; and bleeding and segregation of the concrete are effectively repaired, so that the concrete structure is more uniform, the pumping performance is not influenced, and the strength of the concreteis not influenced.

Owner:卫辉市东科新型材料有限公司

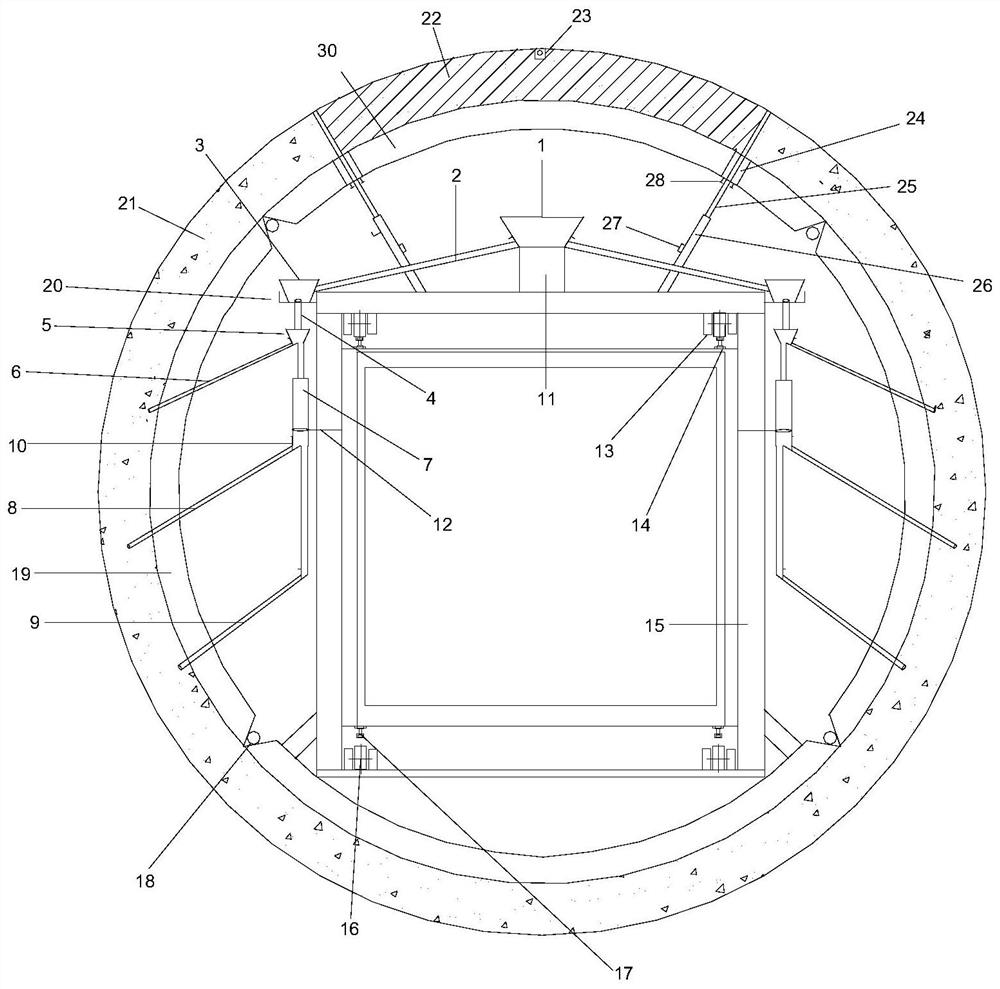

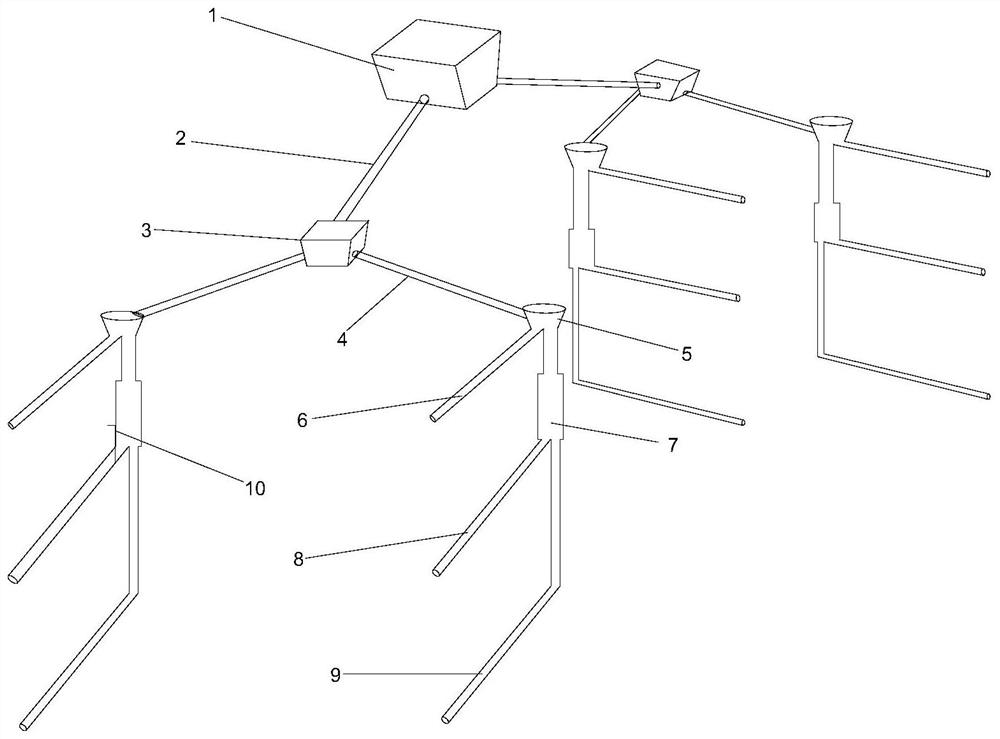

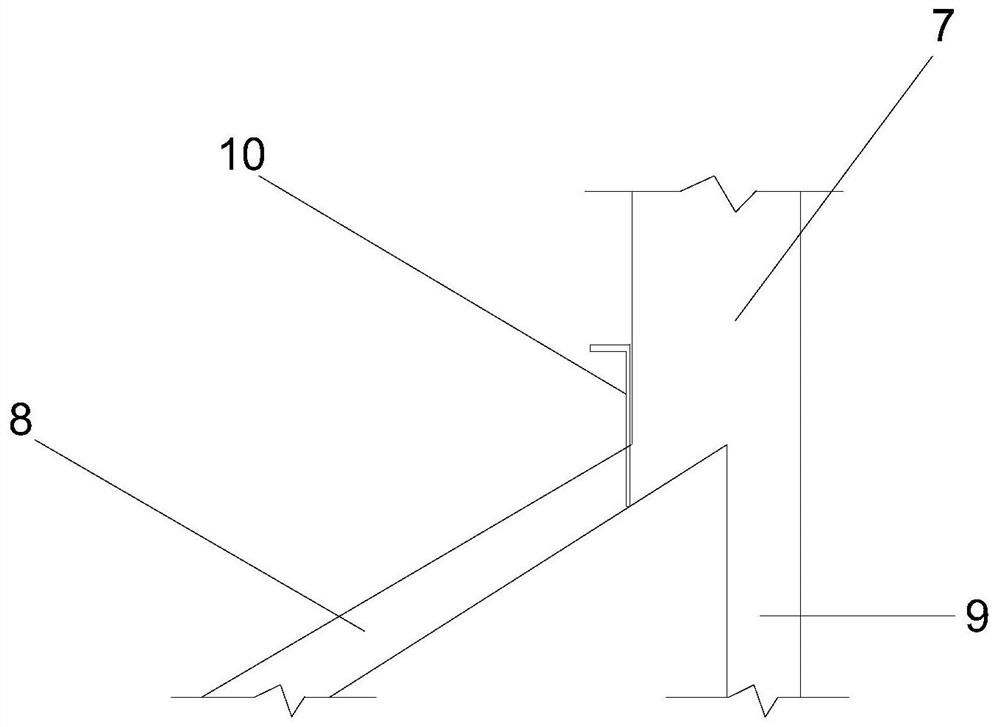

Circular water delivery tunnel wall window-by-window layered pouring system and construction method

ActiveCN111749714AImprove efficiencyReduce labor intensityUnderground chambersTunnel liningArchitectural engineeringTunnel wall

The invention relates to a circular water delivery tunnel wall window-by-window layered pouring system and a construction method. The circular water delivery tunnel wall window-by-window layered pouring system and the construction method are mainly suitable for circular water delivery tunnel wall pouring construction. The layered pouring system is composed of a main hopper, a main flow dividing pipe, a second-level hopper, a secondary flow dividing pipe, a third-level hopper, an upper grouting pipe, a flow dividing string barrel, a middle grouting pipe and a lower grouting pipe. The construction method mainly comprises the construction steps of construction preparation, needle beam formwork system installation, trolley walking, layered pouring system installation, flange plate and groutingassembly installation, camera installation, tunnel side wall concrete pouring, tunnel vault concrete pouring, grouting system dismounting, demolding and lining maintenance. According to the circularwater delivery tunnel wall window-by-window layered pouring system and the construction method, lining side wall concrete enters a mold layer by layer and window by window, the defects of concrete segregation, aggregate accumulation, herringbone slope cold joints and the like are effectively avoided, the entity quality and the appearance quality of lining side wall concrete pouring are improved, the side wall pouring pipe replacing procedure is reduced, the labor intensity is lowered, and the pouring time is saved.

Owner:四川港航建设工程有限公司

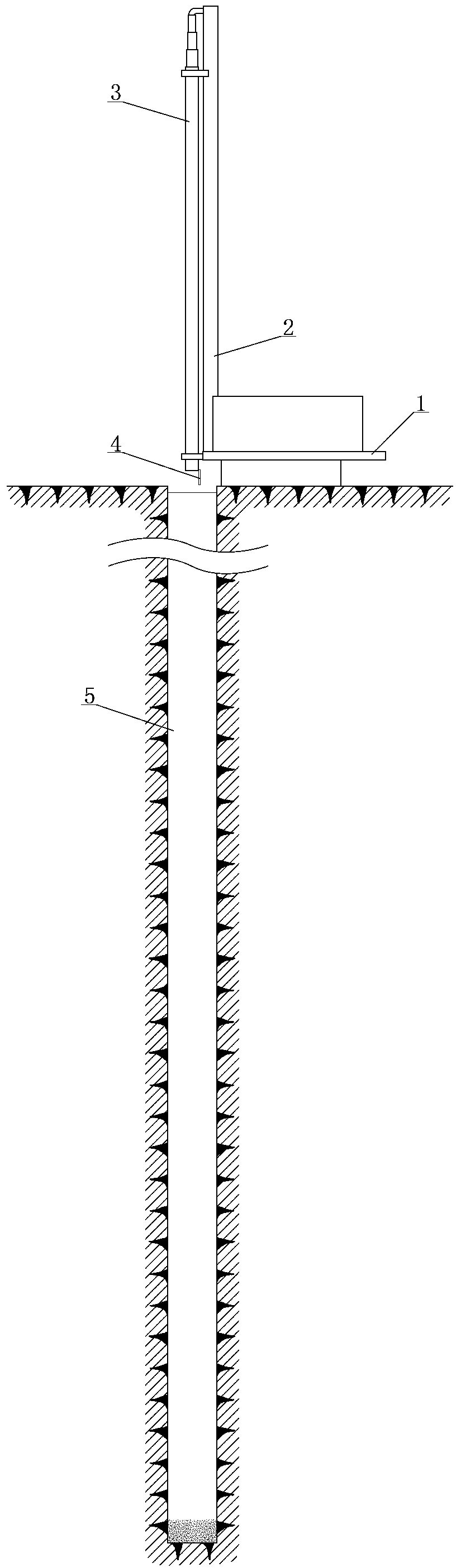

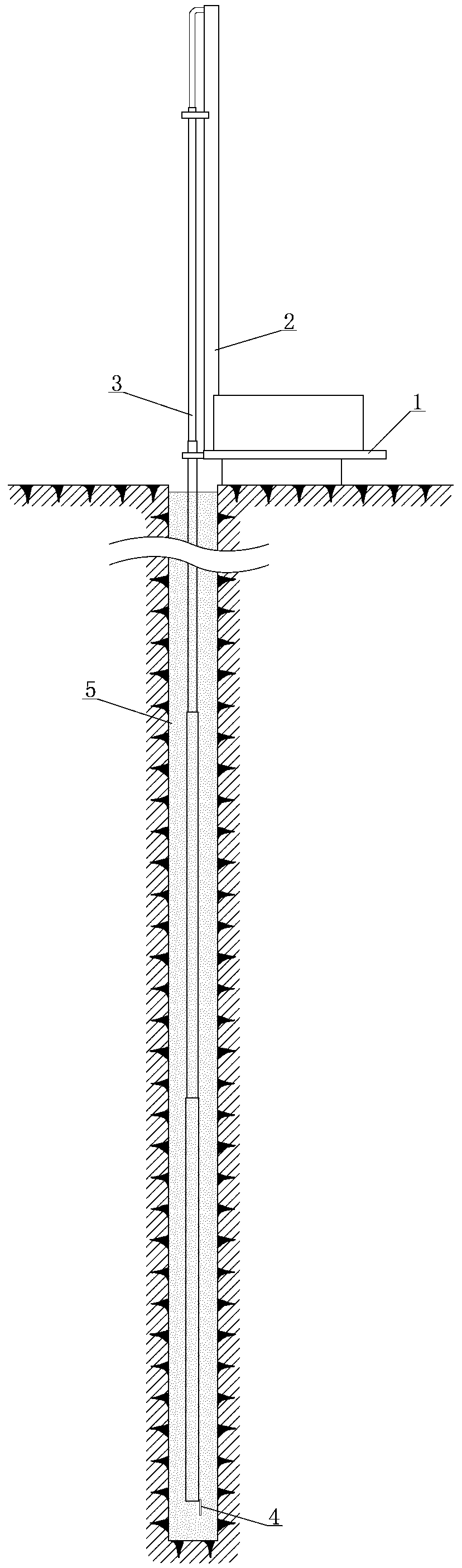

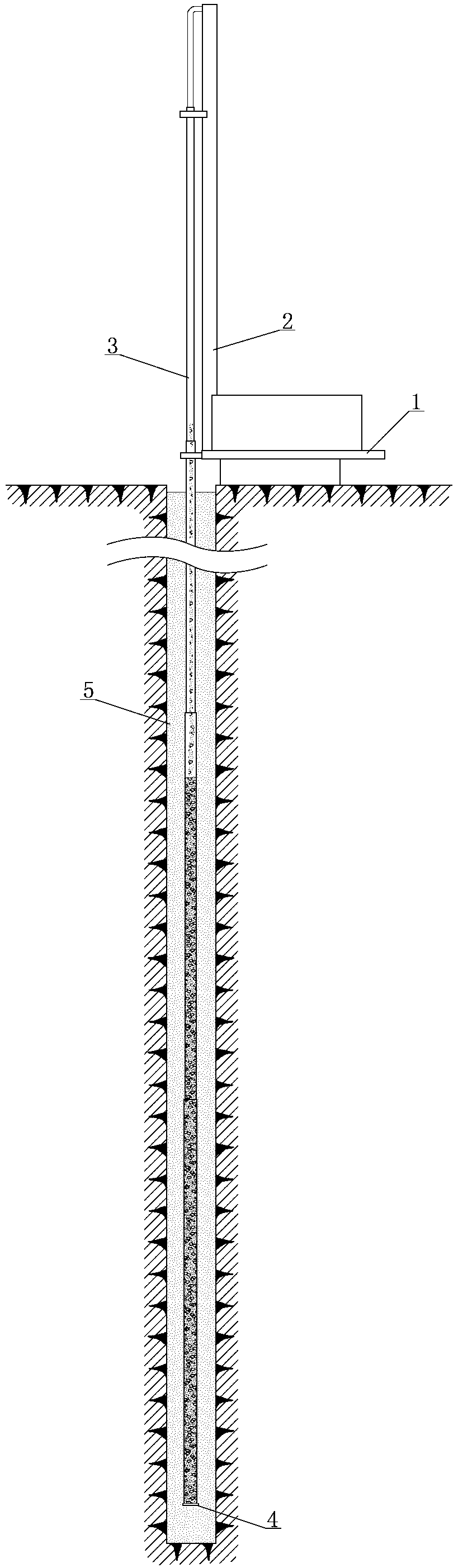

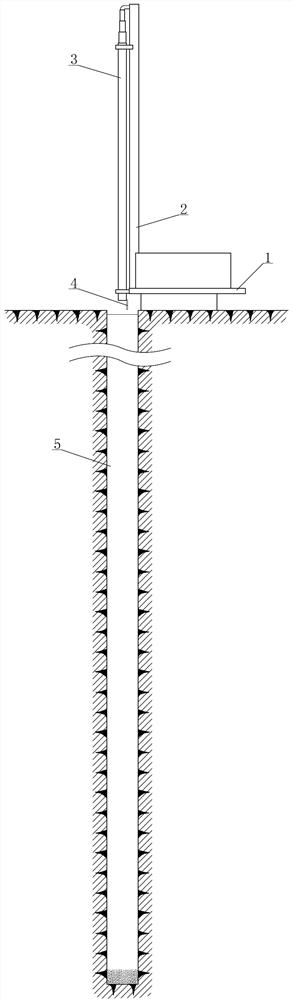

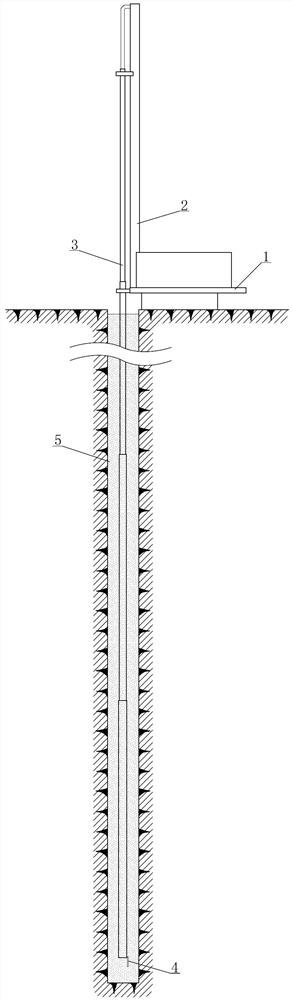

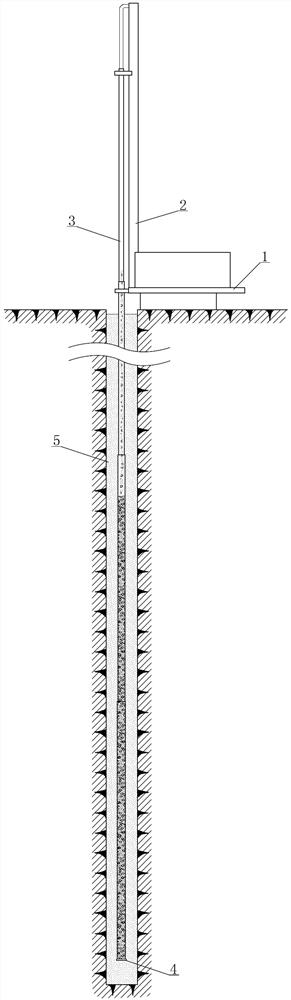

Construction method for pouring concrete pile by using telescopic guide pipe

ActiveCN111305193ANo stuckEliminate pipe blockageBulkheads/pilesArchitectural engineeringStructural engineering

The invention relates to an underwater concrete pouring construction method, in particular to a construction method for pouring a concrete pile by using a telescopic guide pipe. At present, most of the underwater concrete pouring utilizes a concrete material gravity pouring mode, and defects such as intermittent pouring operation and pipe blocking exist in the construction. According to the technical scheme, the telescopic guide pipe provided with a bottom door and a sealable pipe body is adopted, a first batch of poured concrete is conveyed to the bottom of a pile hole, the bottom door is opened to release the concrete so as to seal the bottom, a conveying pump is used for continuously pumping and pouring, and meanwhile, the guide pipe is synchronously contracted along with the rise of the concrete surface until the pouring operation is completed. According to the construction method, the pressure in the pipe is controllable in the concrete pouring process, and the telescopic action of the pipe body is uniform and consistent when the guide pipe is lifted, so that the problems that in the prior art, due to the fact that a material pipe is split, the pouring operation is interruptedmany times, the interruption time is long, the construction efficiency is low, the process is difficult to control, and the engineering quality is affected are solved, and the quality problem of a pile foundation caused by concrete segregation, slag inclusion and the like is avoided.

Owner:张家口众益岩土工程有限公司

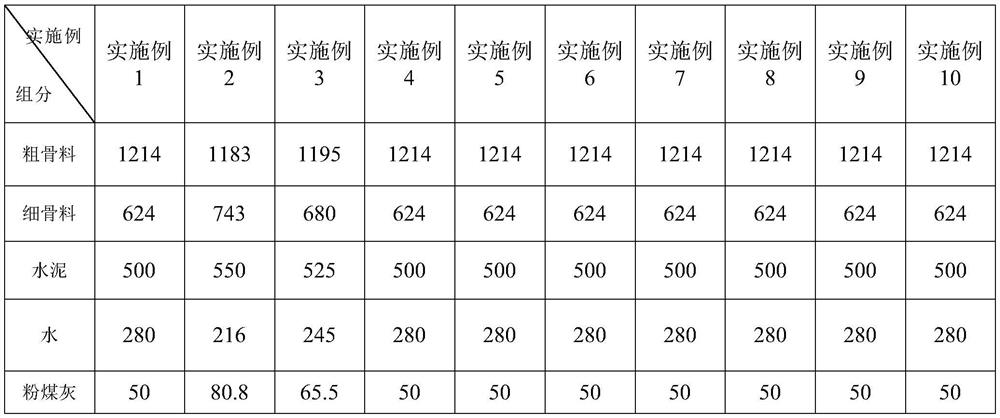

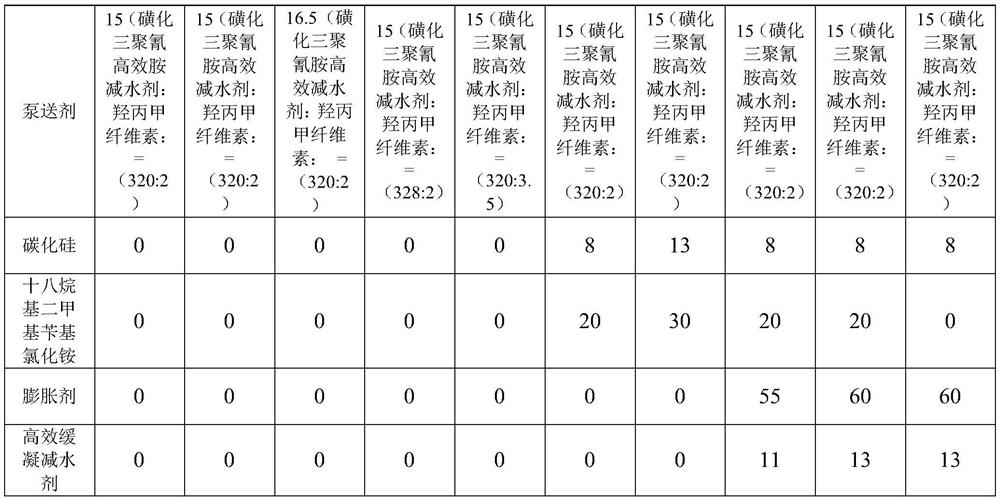

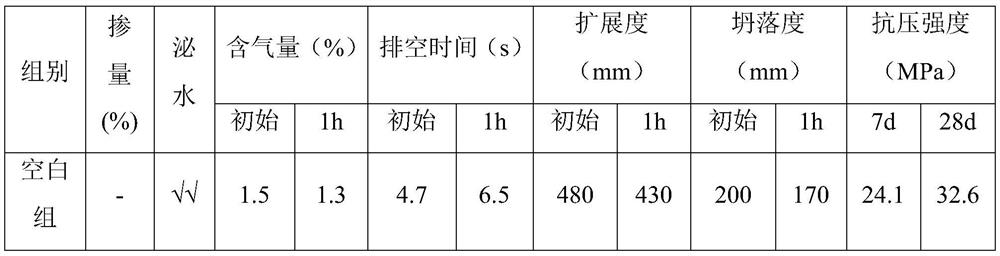

Ultrahigh-pressure long-distance pumping concrete and preparation method thereof

The invention discloses ultrahigh-pressure long-distance pumping concrete and a preparation method thereof, and belongs to the technical field of concrete, wherein the ultrahigh-pressure long-distancepumping concrete comnprises the following composition in parts by weight: 1183-1214 parts of a coarse aggregate, 624-743 parts of a fine aggregate, 500-550 parts of cement, 216-280 parts of water, 50-80.8 parts of fly ash, 15-16.5 parts of a pumping agent, 20-30 parts of silicon carbide powder, 55-60 parts of an expanding agent and 11-13 parts of an efficient retarding and water reducing agent, wherein the pumping agent comprises 320-328 parts of a sulfonated melamine efficient water reducing agent and 2-3.5 parts of hydroxypropyl methylcellulose. According to the ultrahigh-pressure long-distance pumping concrete and the preparation method thereof provided by the invention, the problems that a conveying pipe is easily blocked and the concrete is easy to separate and seep and the engineering quality and progress are influenced due to the fact that concrete is subjected to large resistance of a pumping pipe are solved, and the ultrahigh-pressure long-distance pumping concrete has the advantages of reducing the resistance to the concrete during pumping and being beneficial to ultra-long-distance pumping.

Owner:重庆天地人建设集团有限公司

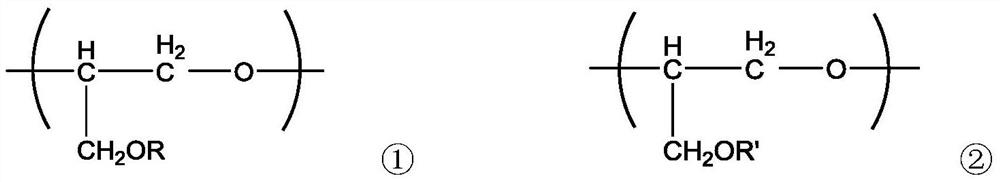

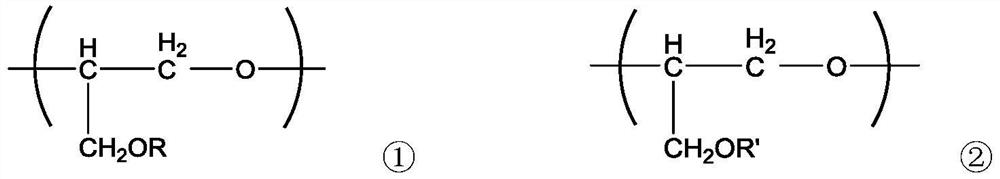

Hyperbranched concrete tackifier as well as preparation method and application thereof

The invention discloses a hyperbranched concrete tackifier as well as a preparation method and application thereof, and belongs to the technical field of building material concrete admixtures. The hyperbranched concrete tackifier is prepared from a hyperbranched polymer A, an unsaturated succinimide monoester monomer, an unsaturated maleic acid diester monomer and an unsaturated sulfonic acid monomer through a free radical polymerization reaction. The hyperbranched polymer A is prepared from an unsaturated ternary oxygen-containing heterocyclic ring monomer through a ring-opening polymerization reaction, and the unsaturated ternary oxygen-containing heterocyclic ring monomer is allyl glycidyl ether or methyl allyl glycidyl ether. The tackifier provided by the invention can effectively improve the workability of fresh concrete, solves the problems of concrete segregation, bleeding and sedimentation, has obvious water retention and tackifying effects and good slurry wrapping effect, and does not have a serious delayed coagulation or air entraining phenomenon.

Owner:WUHAN YUANJIN BUILDING MATERIALS TECH CO LTD

Quantitative evaluation method for analyzing concrete workability based on bottom resistance

ActiveCN111912746AThe method is simple and fastOvercome the defect that it is impossible to quantitatively evaluate concrete segregation and bleedingFlow propertiesPreparing sample for investigationStructural engineeringSegregation in concrete

The invention relates to a quantitative evaluation method for analyzing concrete workability based on bottom resistance. The quantitative evaluation method comprises the following steps: (1) carryingout a fresh concrete bottom resistance test; (2) drawing a time-varying curve of the displacement and speed of the steel sheet; (3) quantitatively evaluating the workability of the concrete based on the bottom resistance condition; according to the method, a newly-mixed concrete bottom resistance test can be effectively carried out, the concrete bottom insertion speed is calculated, a curve that the displacement and the speed change along with time is drawn, and the sinking condition of the newly-mixed concrete aggregate is quantitatively characterized through a concrete workability comprehensive coefficient, so that quantitative evaluation on the concrete workability is achieved; the defect that a traditional method is difficult to quantitatively characterize the concrete segregation degree is overcome.

Owner:GUANGXI UNIV

Dynamic segregation monitoring of concrete

A system and process for detecting dynamic segregation in concrete rotated within a mixer drum, such as mounted on a delivery truck. A system processor is programmed to monitor an instantaneous and averaged rheology parameter (e.g., instantaneous and averaged slump values) and to deploy one or more protocols for detecting the occurrence of segregation. A first protocol comprises monitoring the averaged slump or other rheology value of concrete during and immediately after a jump in drum speed of at least plus or minus four rotations per minute and detecting when a change in the averaged slump value meets or exceeds a threshold limit pre-selected by the user or the system processor; and an optional second protocol comprises monitoring the instantaneous slump or other rheology value of the concrete when the mixer drum is rotating at a constant speed for at least three (and more preferably for at least five) successive rotations and detecting when the instantaneous slump value meets or exceeds a threshold limit pre-selected by the user or processor. Preferably, both protocols are used, in any sequence, to confirm segregation within the rotating drum. Once segregation is detected, one or more operations can be initiated, such as sending an alarm or signal to the operator to confirm dynamic segregation is detected, introducing an admixture to mitigate the segregation, sending data to the batch plant for adjusting the mix design for subsequent deliveries, or other operations.

Owner:VERIFI INC

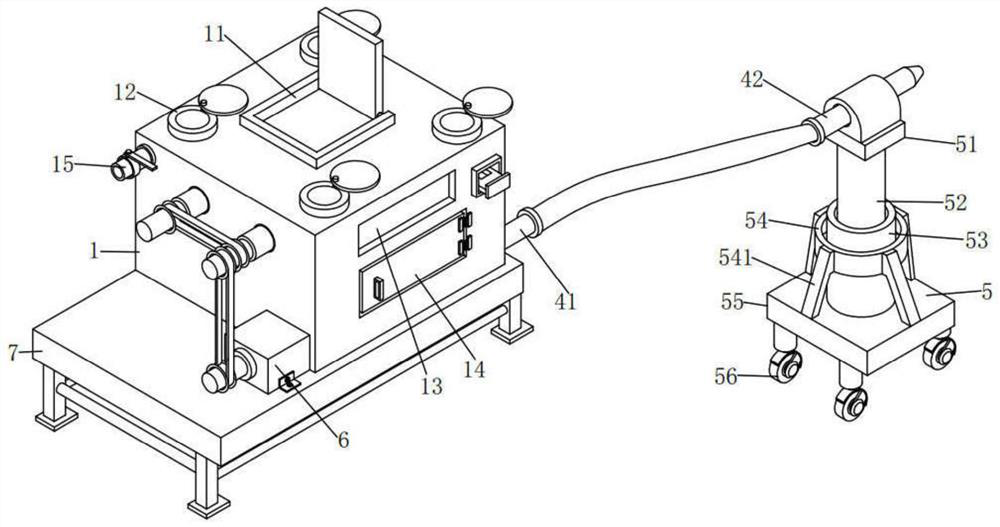

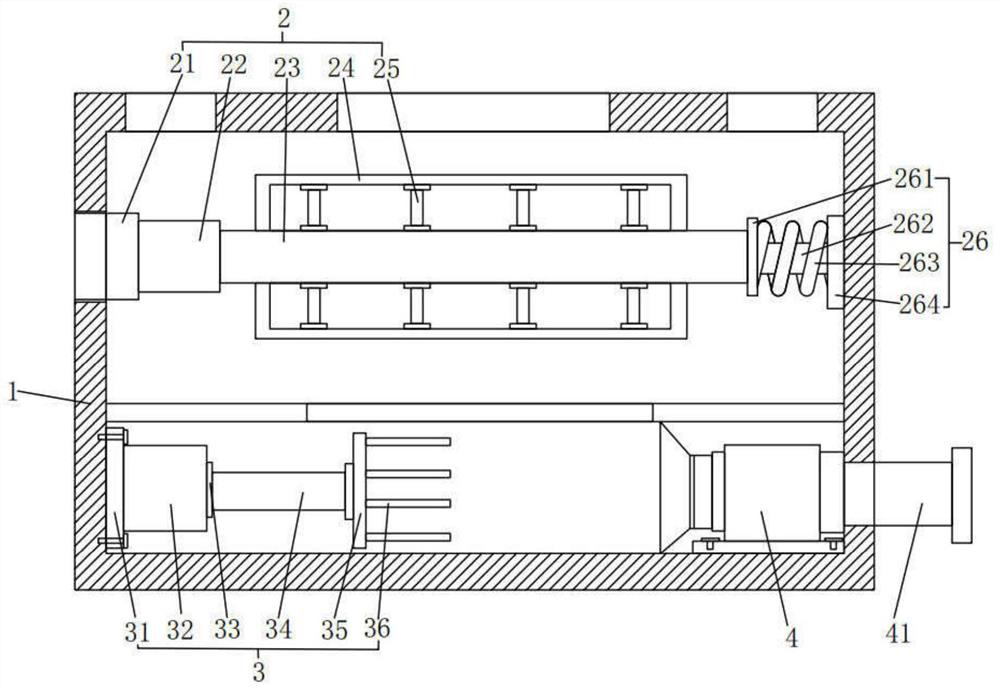

Concrete pouring device for preventing concrete segregation and using method

InactiveCN112776176AAchieving mixing and stirringImprove bearing strengthDischarging apparatusCement mixing apparatusArchitectural engineeringStructural engineering

The invention discloses a concrete pouring device for preventing concrete segregation and a using method. The device comprises a box body, wherein stirring devices are symmetrically arranged on one side of the inner wall of the box body; each stirring device comprises a connecting shaft; each connecting shaft is arranged in a round hole in one side of the inner wall of the box body; an anti-segregation device is arranged below one side of the inner wall of the box body; the anti-segregation device comprises a mounting plate; one side of the mounting plate is connected with the inner wall of the box body; a booster pump is arranged on one side of the lower surface of the inner wall of the box body; a discharging port is formed in a shell of the booster pump and connected with a jet orifice through a pipeline; and a movable lifting device is arranged on the outer wall of the jet orifice. According to the concrete pouring device for preventing concrete segregation, in the concrete processing and pouring construction process, concrete segregation can be prevented, so that the effects of improving the construction quality and the bearing strength of concrete are achieved, and economic losses caused by potential safety hazards can be effectively avoided.

Owner:JIANGXI UNIV OF TECH

A kind of concrete viscosifying type viscosity modifier and preparation method thereof

The invention discloses a concrete viscosity-increasing viscosity regulator and a preparation method thereof, comprising the following steps: dissolving modified polyether monomers, unsaturated amide monomers, unsaturated carboxylic acid monomers and crosslinking agents in deionized water , to obtain a monomer mixed solution; dissolve the unsaturated amide monomer and unsaturated carboxylic acid monomer in deionized water, and record it as liquid A; 2 Under the condition of 40-60°C, slowly add the initiator solution and liquid A into the monomer mixed solution dropwise, continue to stir and react at 60-90°C, adjust the pH value, and dilute with water to obtain the viscosity modifier. The viscosity modifier of the present invention has good compatibility with the polycarboxylate water reducer, can effectively adjust the cohesion of concrete, solve the problems of concrete segregation and bleeding, without affecting the slump retention performance and setting time of concrete, and can resist compression of concrete The strength development is favorable; at the same time, the optimization and regulation of the polymerization process improves the stability of the product, reduces the sensitivity of the product’s dosage, and improves the ease of on-site construction.

Owner:WUHAN YUANJIN BUILDING MATERIALS TECH CO LTD

Concrete stacking forming method

PendingCN111906894AImprove mechanical propertiesImprove compactnessCeramic shaping apparatusStructural engineeringPumping vacuum

The invention discloses a concrete stacking forming method. The concrete stacking forming method comprises the following steps of measuring and taking each ingredient according to ingredients of a concrete material; laying measured coarse aggregates into a mold of concrete to be formed to form a coarse aggregate layer; mixing and treating ingredients for preparing mortar with water to prepare themortar; and pouring the mortar into the mold, and performing vacuumizing treatment. The concrete stacking forming method has the advantages that the aggregate distribution uniformity can be effectively improved; the problems of segregation, bleeding, coarse aggregate sinking and the like of liquid concrete are reduced; bubbles possibly remained in a concrete component are reduced; the concrete compactness is improved; the mechanical property and the durability of the concrete are improved; and the consumption of a cementing material can be reduced.

Owner:佛冈龙清电力器材有限公司

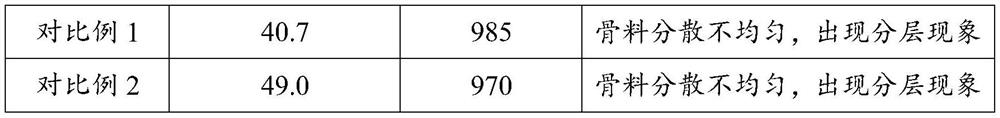

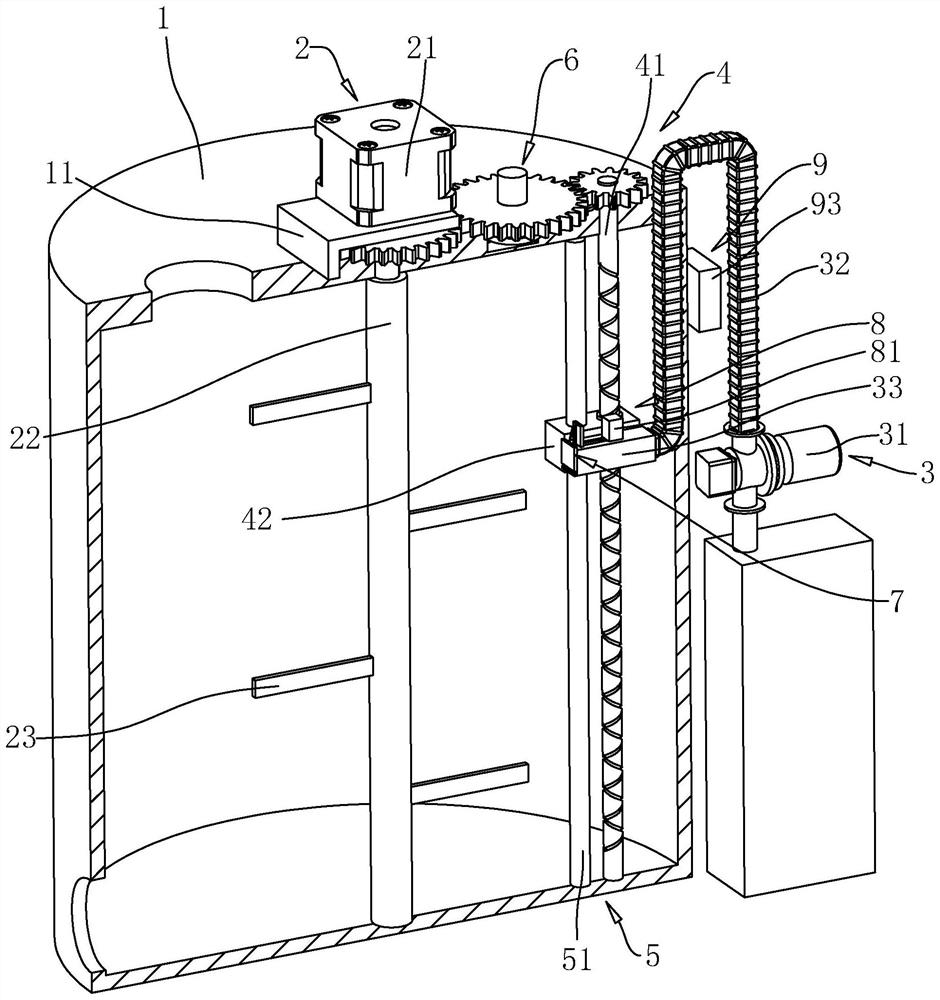

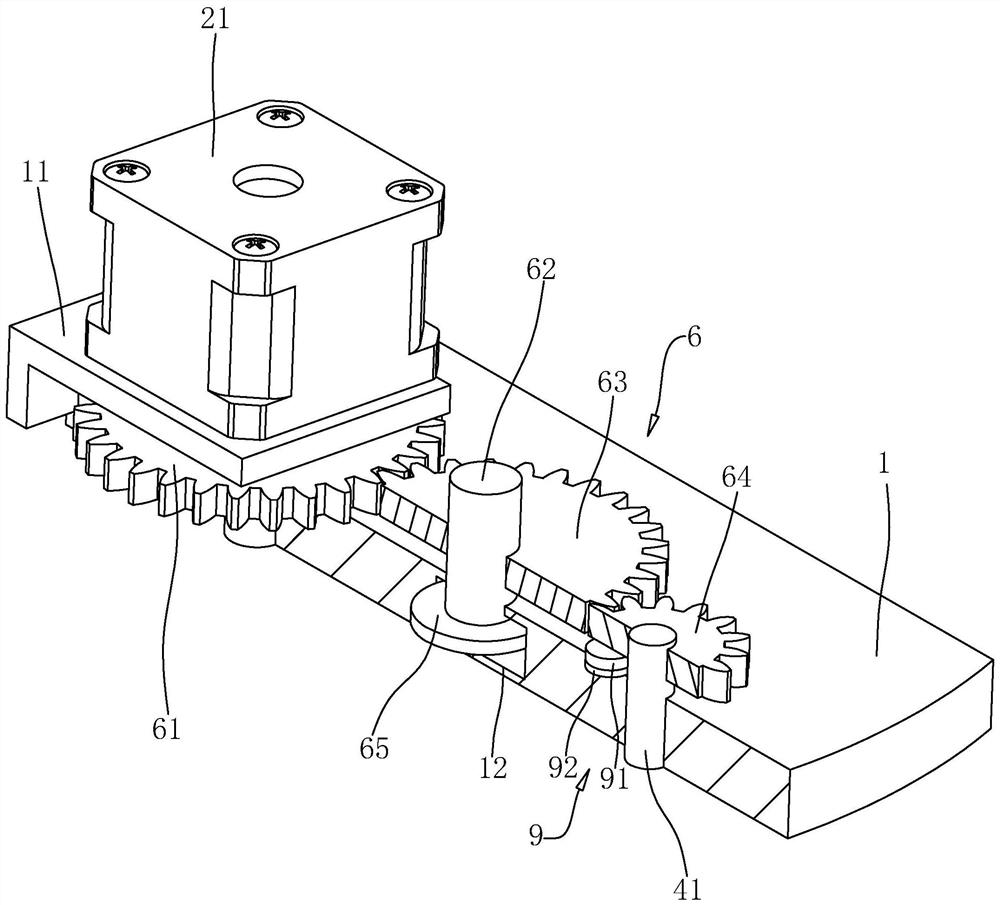

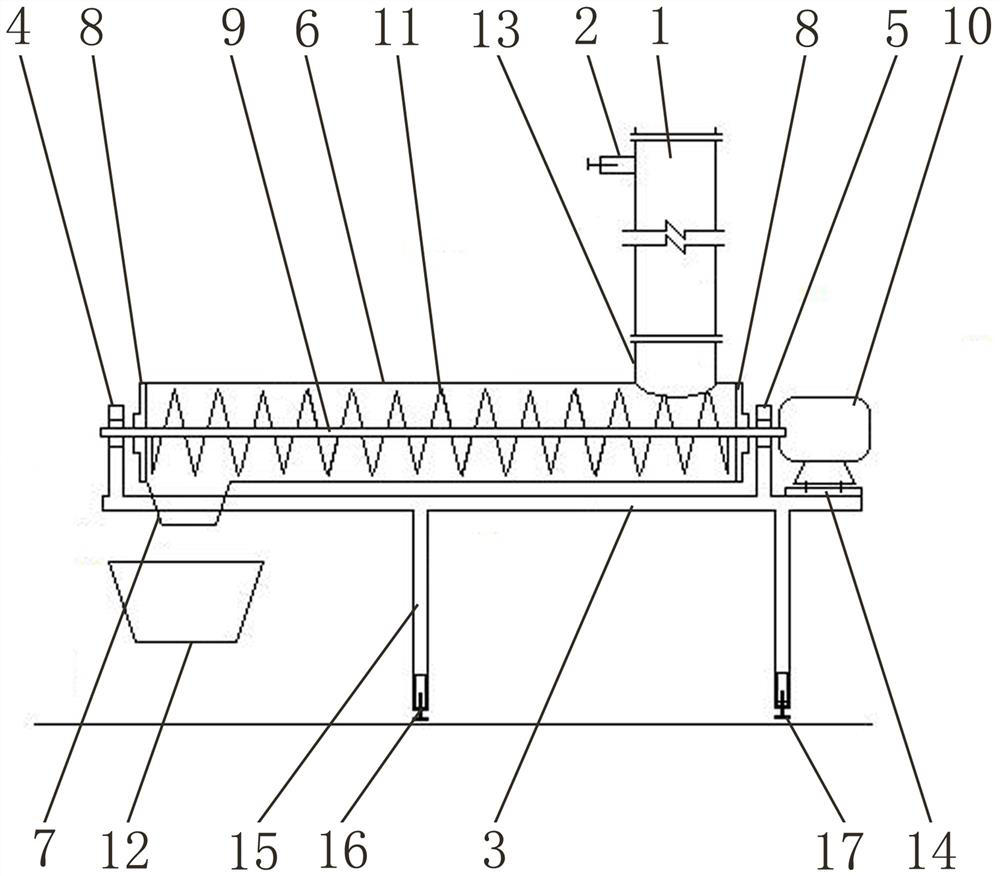

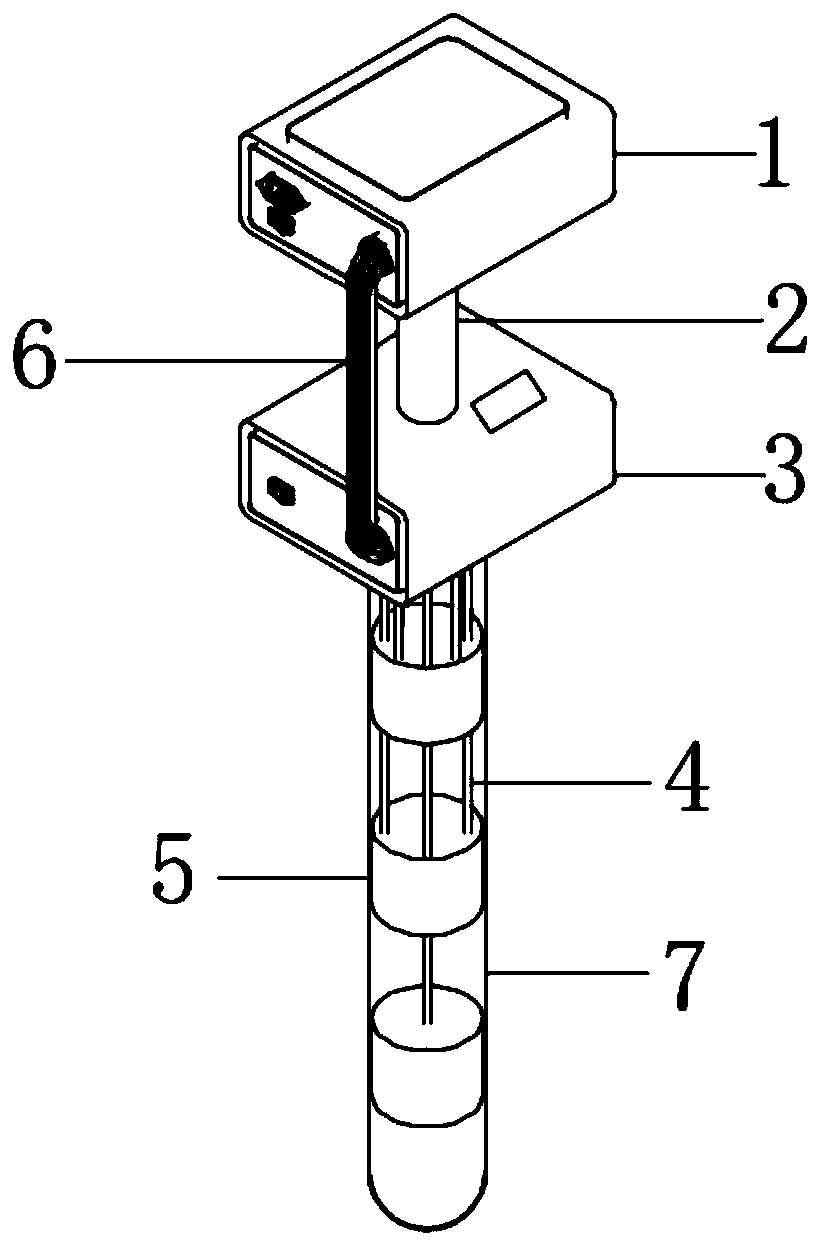

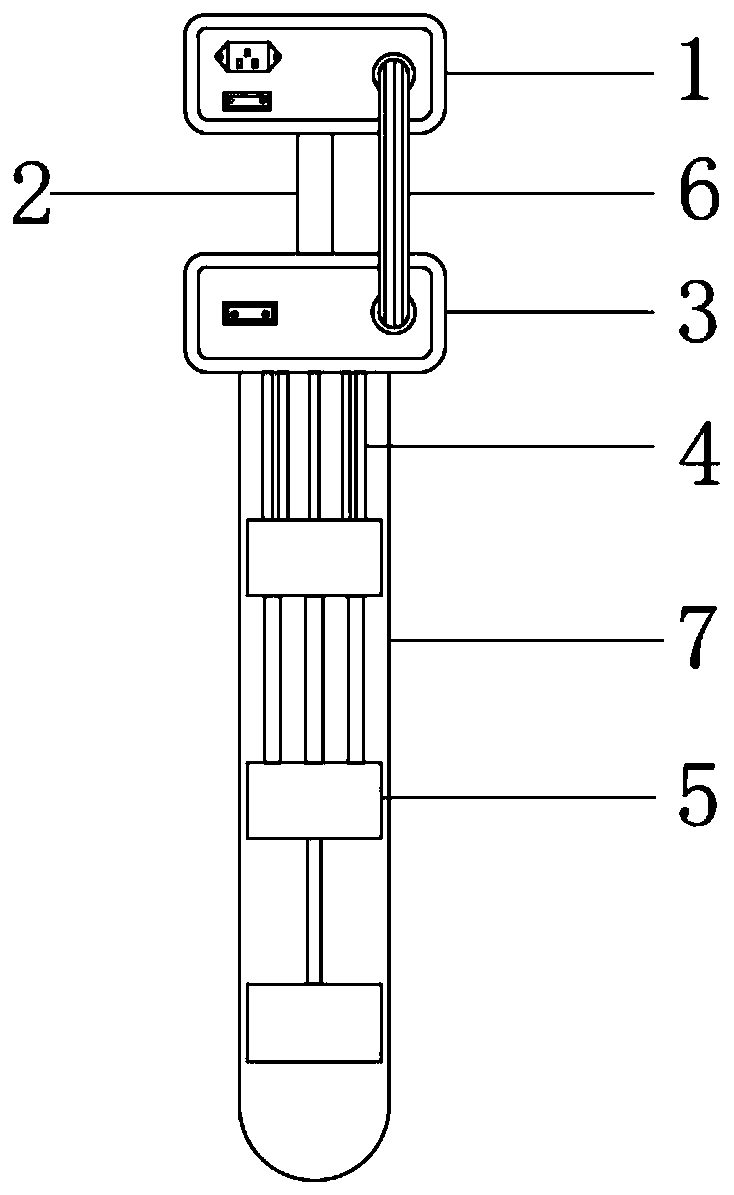

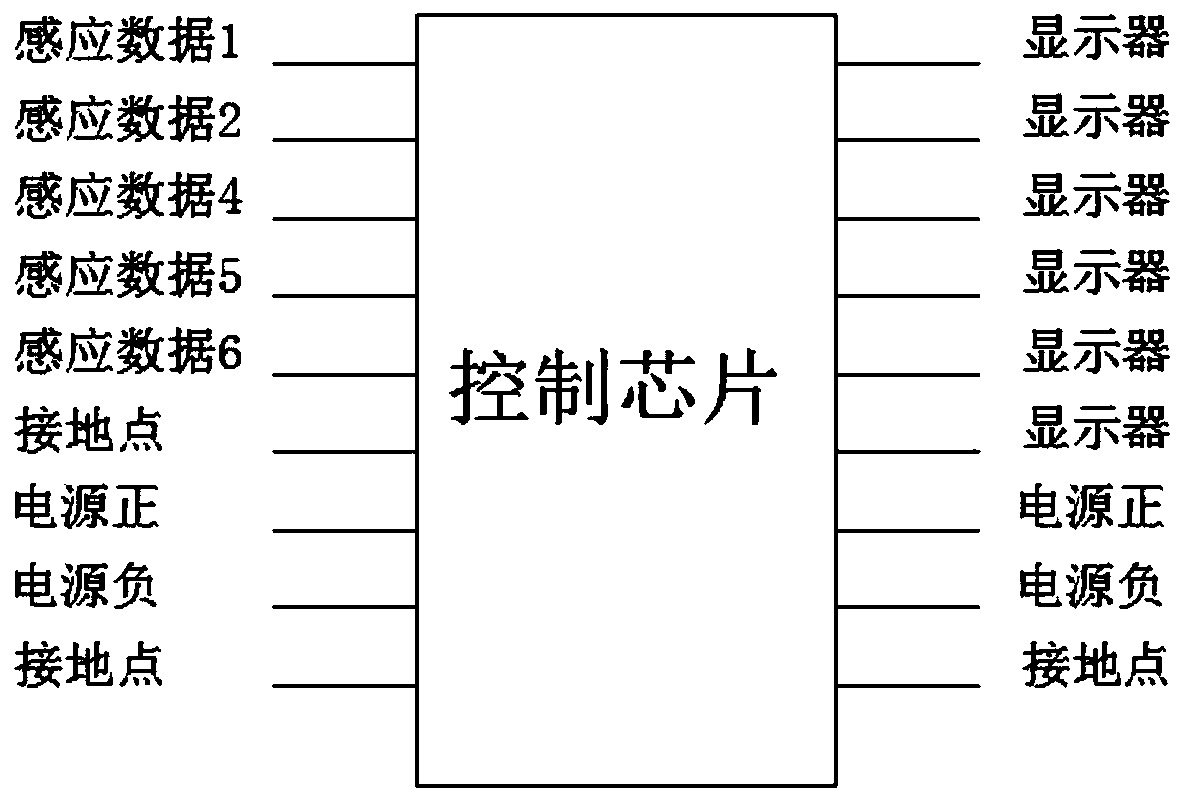

Concrete segregation detection device

PendingCN113834924AImprove the problem of low judgment accuracyImprove stabilityWithdrawing sample devicesMaterial testing goodsPipeScrew thread

The invention relates to the field of detection devices, in particular to a concrete segregation detection device. Theconcrete segregation detection device comprises a stirring barrel and a stirring device installed in the stirring barrel, and a material pumping device used for extracting concrete is installed in the stirring barrel. The material pumping device comprises a material pumping pump fixed on the stirring barrel, a corrugated pipe fixedly connected to the feeding end of the material pumping pump and a material pumping nozzle arranged in the stirring barrel, the end, away from the material pumping pump, of the corrugated pipe is fixedly connected with the material pumping nozzle, and the discharging end of the material pumping pump communicates with the detection assembly through a pipeline; an adjusting part used for adjusting the height of the material pumping nozzle is installed in the stirring barrel and comprises a reciprocating screw rotationally installed in the stirring barrel and an adjusting block arranged on the reciprocating screw in a threaded sleeving mode, the top end of the reciprocating screw penetrates through the outer side of the stirring barrel, and a limiting part used for limiting rotation of the adjusting block is installed in the stirring barrel; and the material pumping nozzle is fixedly connected to the adjusting block. The problem that the judgment accuracy of the concrete segregation degree is low is solved.

Owner:杭州金鼎实业有限公司

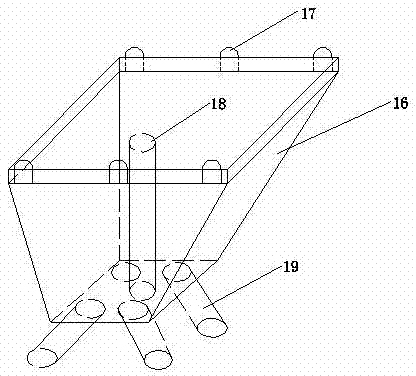

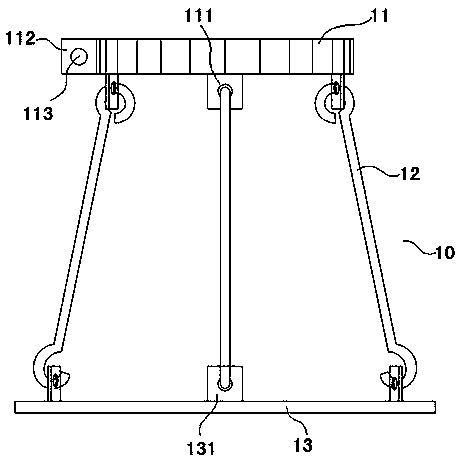

Hanging-type separator used for concrete pouring

PendingCN107762153AEasy to connect and fixRealize connection fixationBuilding material handlingArchitectural engineeringStructural engineering

The invention relates to a hanging-type separator used for concrete pouring. The hanging-type separator comprises a connecting piece and a separator body; the lower portion of the separator body is provided with a first mortar outlet and a second mortar outlet, and the separator body comprises an outer barrel and an inner barrel; a replaceable separation net is mounted on the inner barrel, and a damping rail is fixed to the upper side of the separator body; the upper end and the lower end of the damping rail are provided with connecting plates correspondingly, and connecting holes are formed in the connecting plates; the connecting piece comprises a pump head clamping ring used for being connected with a pumping pipe, and the pump head clamping ring is connected with a sliding ring througha connecting rod; and penetrating nails penetrate through the connecting holes in the upper end and the lower end of the damping rail to fix the sliding ring between the damping rail and the penetrating nails. The hanging-type separator can be fixed to the lower portion of the pumping pipe and can conduct pouring along with moving of the pumping pipe, use is convenient, and operation is easy; andthe separation net on the inner barrel can be selected and replaced according to the workability and the separation proportion of concrete to ensure the workability and strength of the separated concrete and avoid disintegration of the separated concrete; and use is convenient.

Owner:郑州华亿新型建材有限公司

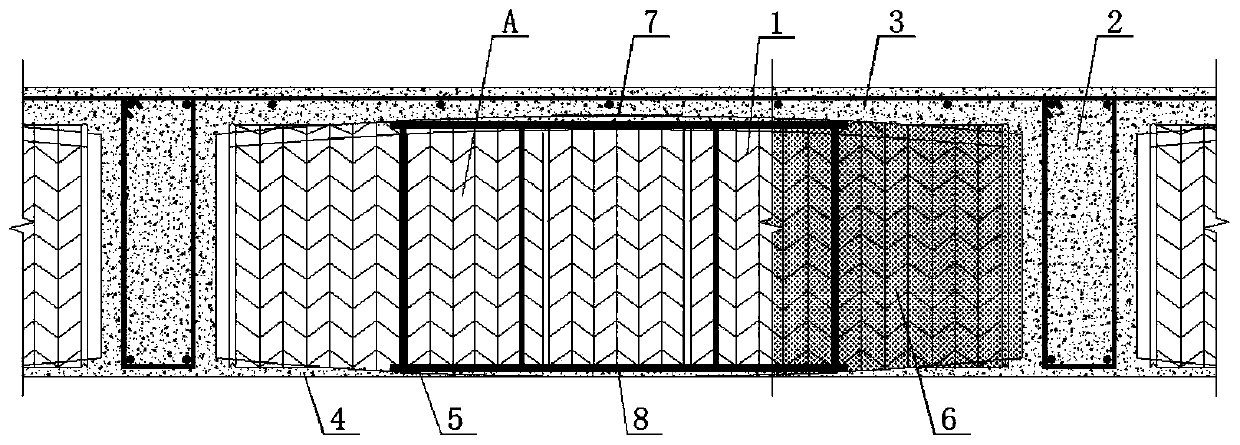

Concrete disintegration resisting steel mesh hollow chamber floor system

PendingCN111270804AImprove the state of stressNo isolationFloorsBuilding material handlingThin slabNonwoven fabric

Owner:HUNAN BDF ENERGY SAVING TECH +2

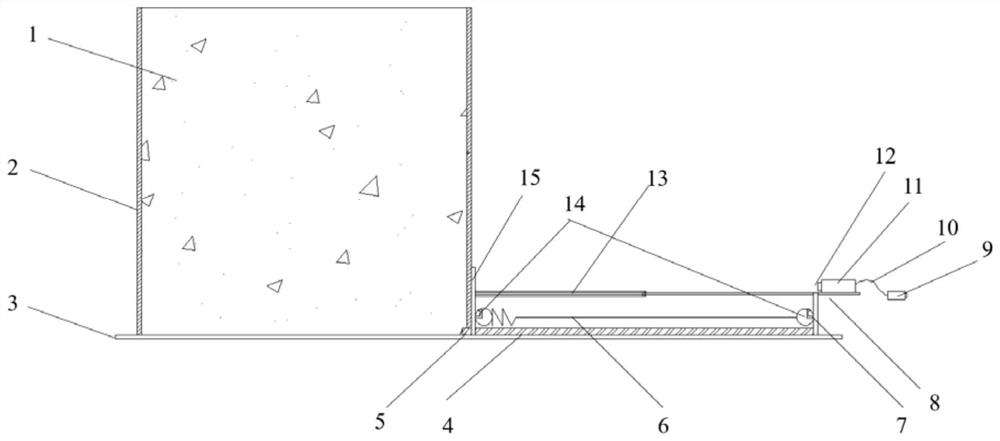

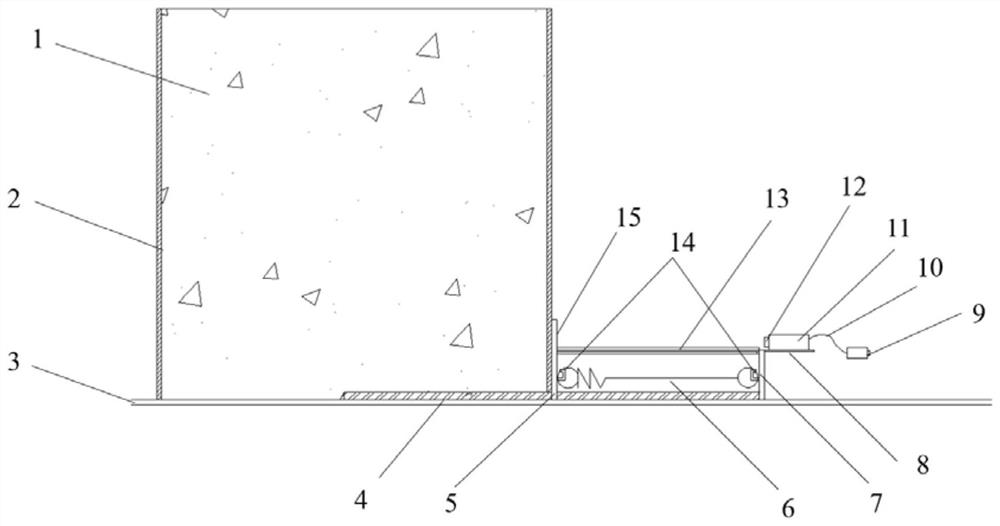

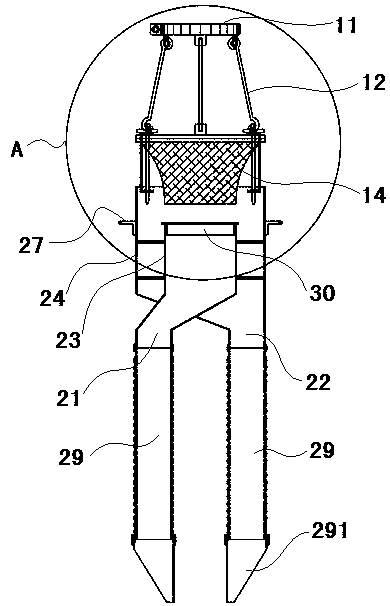

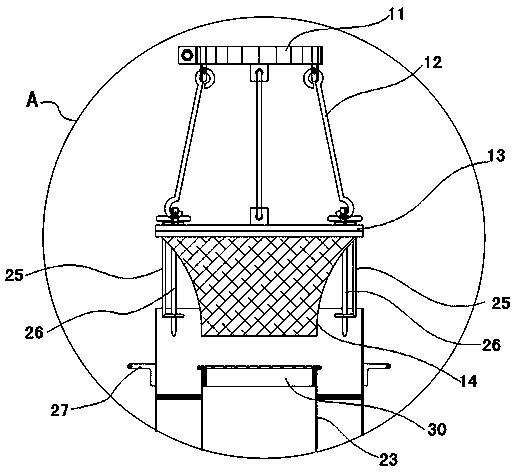

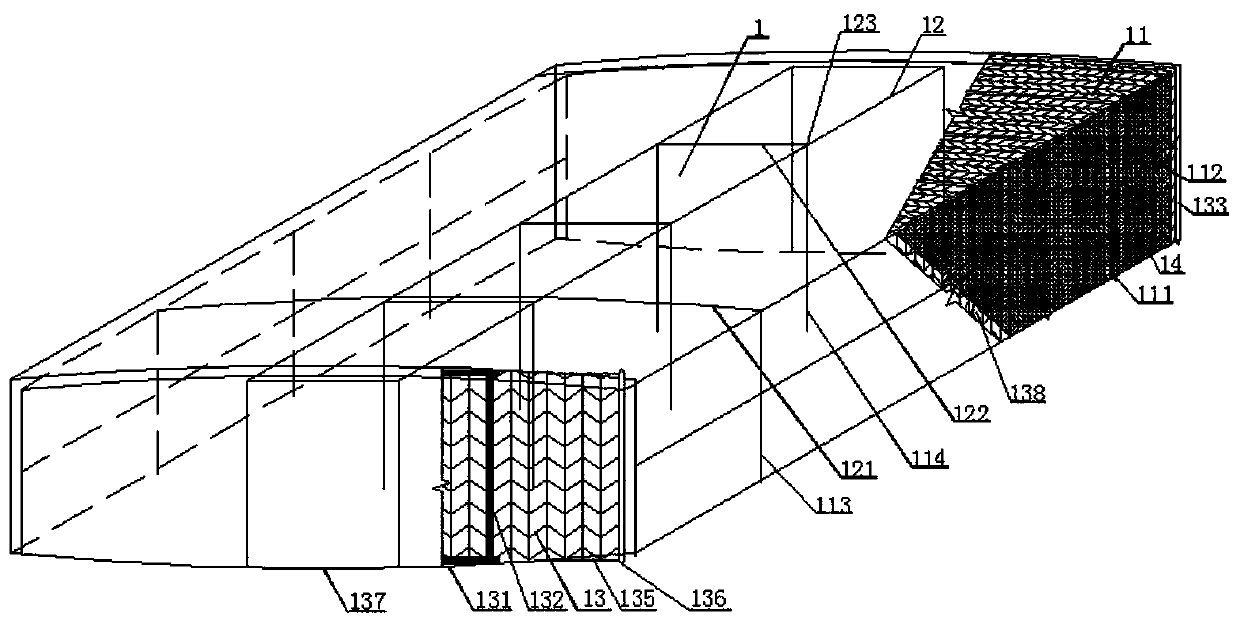

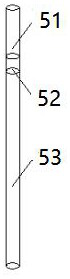

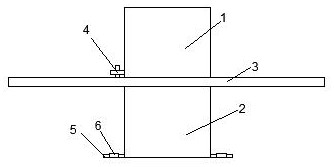

Double-sided superimposed shear wall cavity concrete pouring tool

InactiveCN113503032ASimple structureEasy to manufactureBuilding material handlingArchitectural engineeringPipe

The invention provides a double-sided superimposed shear wall cavity concrete pouring tool. The double-sided superimposed shear wall cavity concrete pouring tool is characterized in that a hoisting barrel is a circular table type barrel body, an upper opening of the barrel body is large, a lower opening of the barrel body is small, four lifting lugs are arranged on the open circumferential edge of the upper opening of the barrel body at equal intervals, steel wire ropes are arranged in the lifting lugs, four supporting legs are arranged on the circumferential edge of the middle of the circular table type barrel body at equal intervals, the bottom of the circular table type barrel body is sealed, and a through hole is formed in the center of a bottom plate of the sealed barrel body; a guide pipe comprises a steel guide pipe body, a hoop and a soft guide pipe body; and one end of the steel guide pipe body is fixedly welded to the through hole of the bottom plate of the barrel body in a matched mode, and the other end of the steel guide pipe body is connected with the soft guide pipe body through the hoop. The double-sided superimposed shear wall cavity concrete pouring tool has the advantages that the pouring tool is simple in structure and convenient to manufacture, the probability of concrete segregation is decreased, the concrete construction quality is guaranteed, concrete is convenient to construct, waste is reduced, the cost is low, the turnover frequency is high, and the labor and material cost is reduced.

Owner:MCC5 GROUP CORP SHANGHAI

Supervision and inspection method for field workability of high-performance concrete

PendingCN111624329AReduce the risk of loss of quality controlFast in qualityPreparing sample for investigationMaterial testing goodsStructural engineeringMechanical engineering

The invention discloses a supervision and inspection method for field workability of high-performance concrete, which comprises the following steps: a, respectively testing five types of special products and conventional products in the high-performance concrete to obtain a numerical basis of a division standard, and continuously optimizing to obtain a detection standard; b, pouring the stirred concrete to be detected into a containing bin of a layered segregation cylinder during inspection; c, lifting the layered segregation cylinder and shaking the cylinder for 3-5 times in the vertical direction; d, placing the layered segregation cylinder on a vibration table, rapidly measuring the height and the mass of the concrete in the upper material containing bin after vibration is completed, and measuring the height and the mass of the concrete in the lower material containing bin at the same time; and e, after measurement, calculating the density rho1 of the concrete in the upper materialcontaining bin and the density rho2 of the concrete in the lower material containing bin respectively to obtain a concrete segregation comparison coefficient I = rho2 / rho1, and comparing the obtainedconcrete segregation comparison coefficient with a detection standard for determination. The problem that an existing inspection method is low in accuracy and efficiency is solved.

Owner:郑州大学建设科技集团有限公司

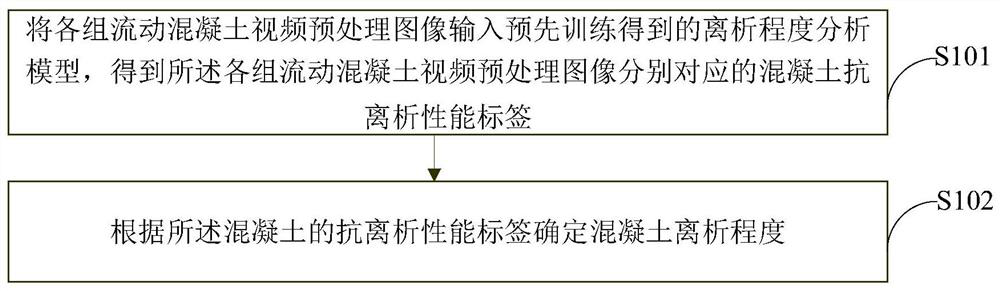

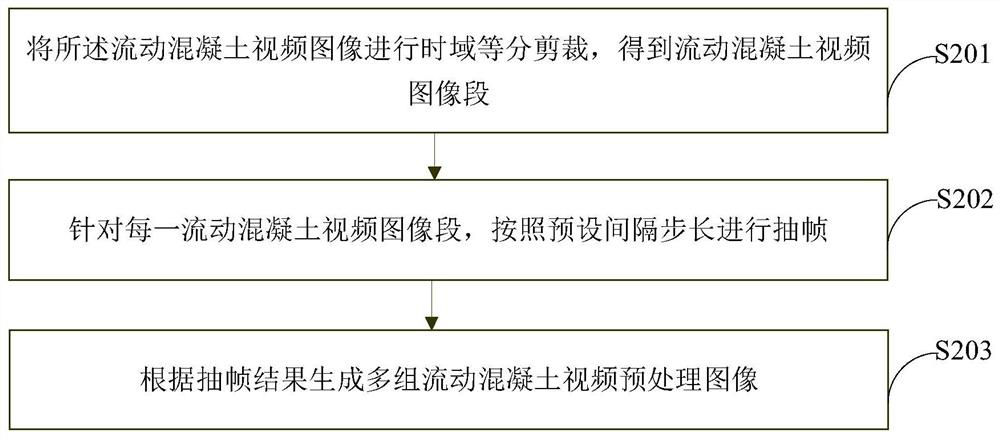

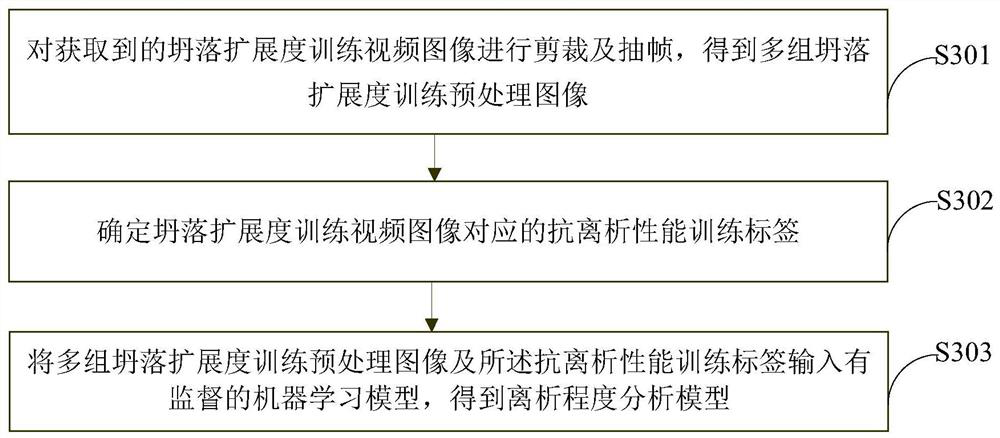

Non-contact concrete segregation degree intelligent real-time analysis method and device

InactiveCN112924653AReduce mistakesImprove accuracyMaterial testing goodsReal time analysisComputer graphics (images)

The invention provides a non-contact concrete segregation degree intelligent real-time analysis method and device. the method comprises the following steps: inputting each group of flowing concrete video preprocessing images into a segregation degree analysis model obtained through pre-training, and obtaining concrete anti-segregation performance labels respectively corresponding to each group of mobile concrete video preprocessing images; and determining the segregation degree of the concrete according to the anti-segregation performance label of the concrete. According to the invention, the segregation degree of the concrete in the flowing concrete video image can be analyzed.

Owner:TSINGHUA UNIV +1

A construction method of pouring concrete piles with telescopic conduits

ActiveCN111305193BSimple working processRealize continuous operationBulkheads/pilesArchitectural engineeringStructural engineering

Owner:张家口众益岩土工程有限公司

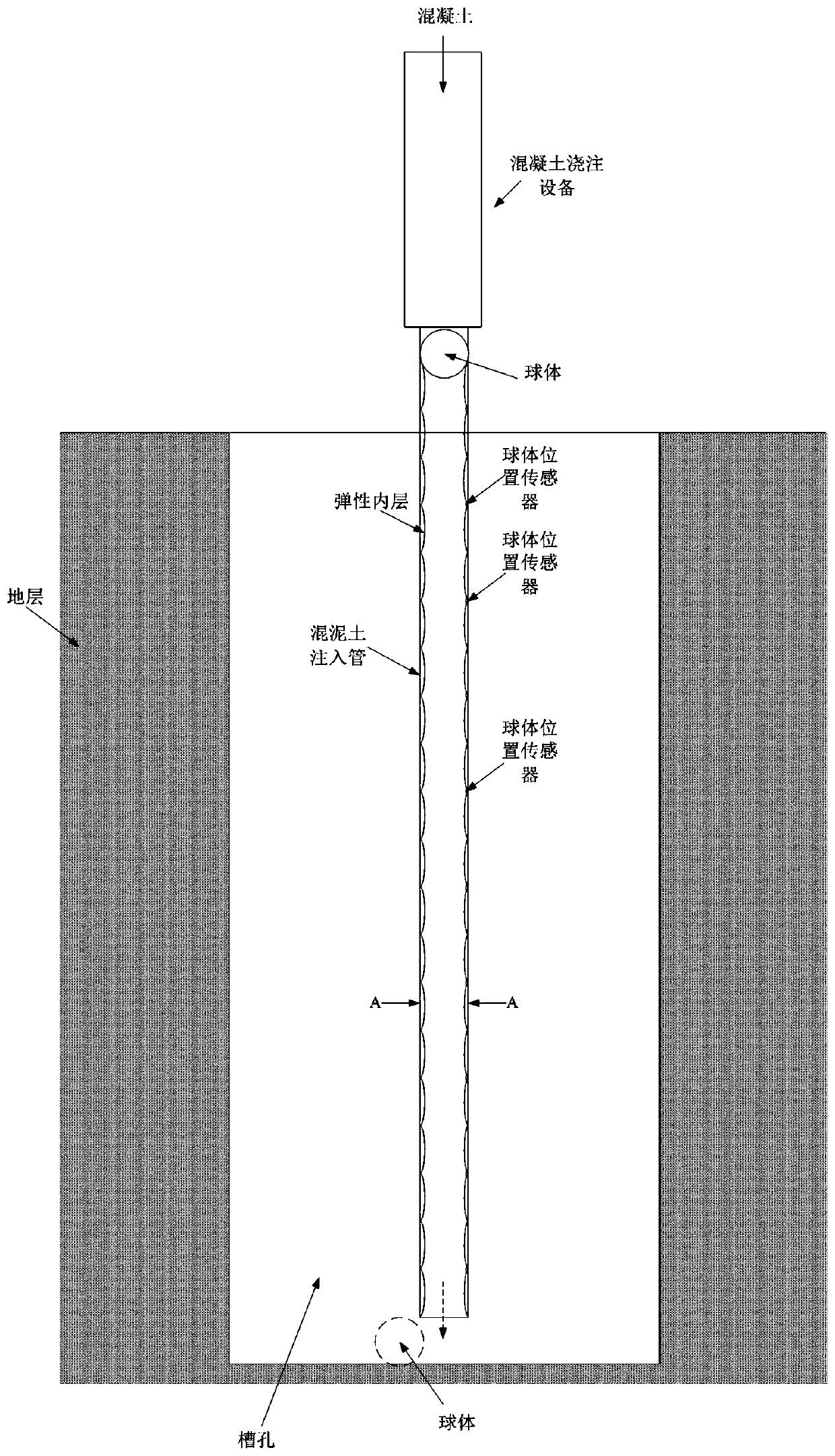

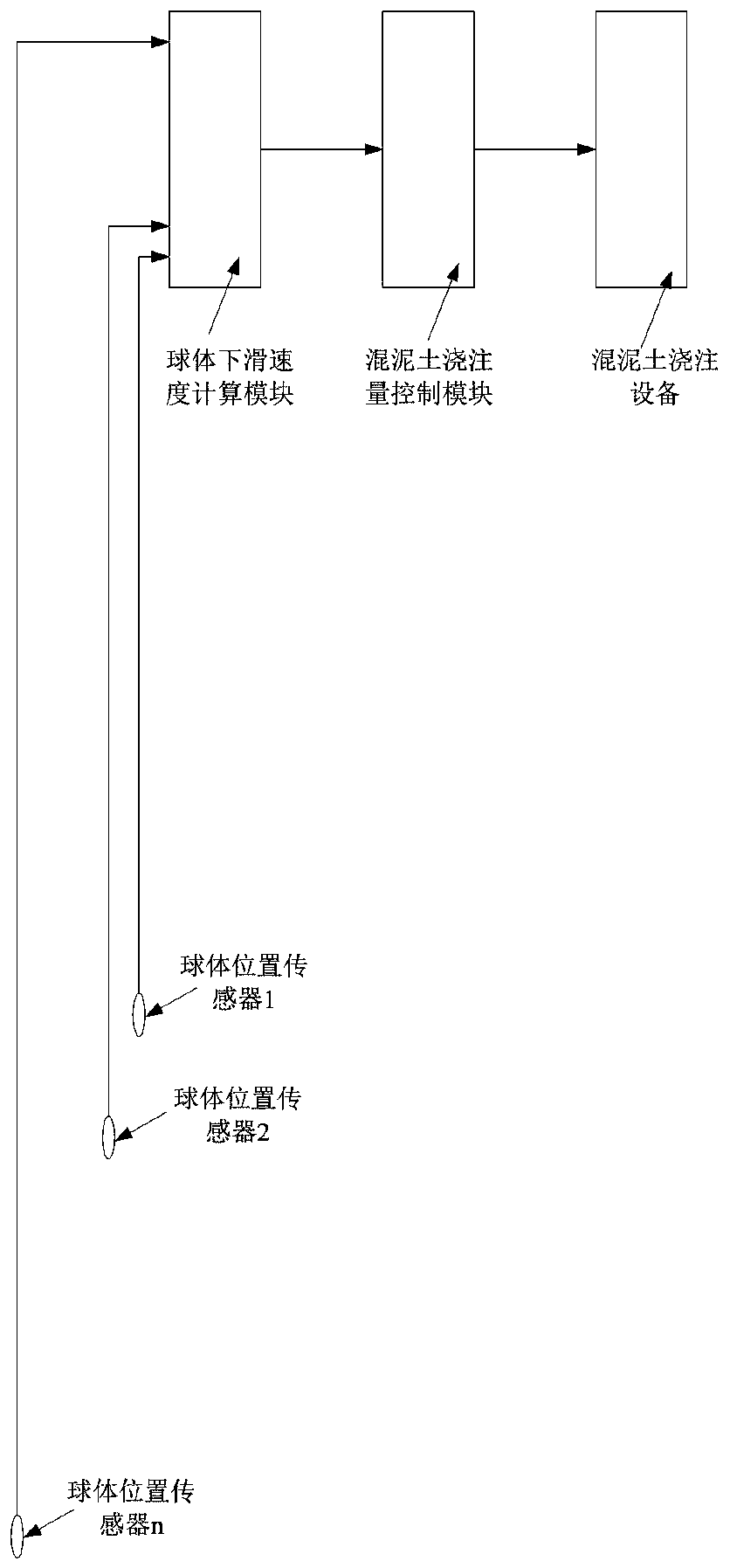

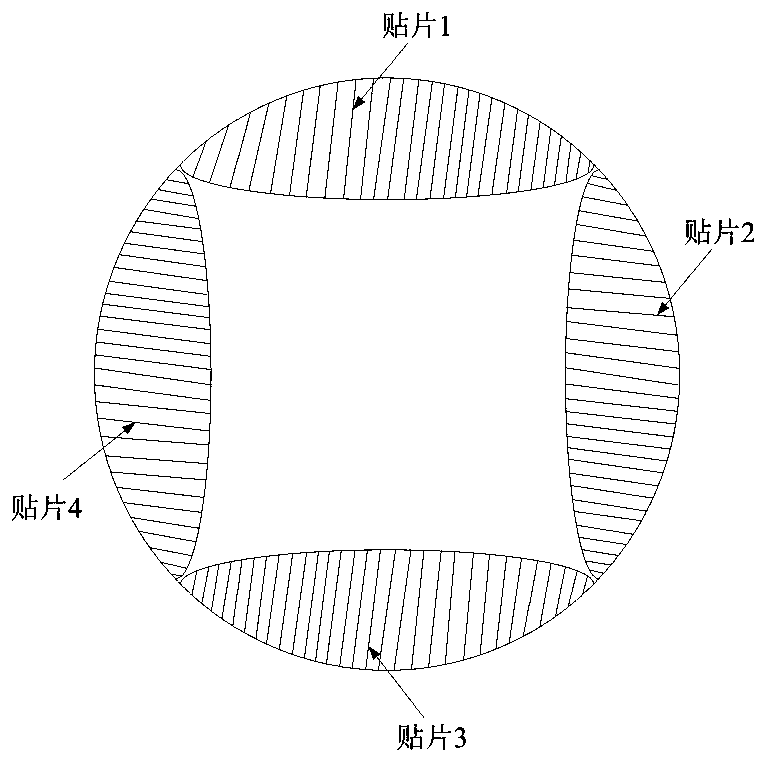

Concrete pouring pipe device for preventing concrete segregation and method

ActiveCN111074897AInhibition of segregationFoundation engineeringWall damsLandslide damSegregation in concrete

The invention discloses a concrete pouring pipe device for preventing concrete segregation and a method. The concrete pouring pipe device for preventing the concrete segregation and the method are used for grooving construction of a diaphragm wall of a landslide dam. The method comprise the steps that pre-explosion treatment is carried out on the axis of the diaphragm wall of the landslide dam, and boulders with large volume are broken into small stones; after the pre-explosion treatment is completed, pre-grouting treatment is carried out on the upstream and the downstream of the axis of the diaphragm wall of the landslide dam, and leakage channels on the upstream and the downstream of the axis of the diaphragm wall of the landslide dam are blocked; after the pre-grouting treatment is completed, the grooving construction of the diaphragm wall of the landslide dam is carried out, specifically, a groove hole is formed through drilling and hole cleaning construction with the axis of the diaphragm wall of the landslide dam as the benchmark, then a concrete pouring pipe is lowered, and concrete pouring equipment is in butt joint with the concrete pouring pipe; and the concrete pouring amount of the concrete pouring equipment is controlled according to the sliding speed of a ball body in the concrete pouring pipe, so that concrete slowly falls to the bottom of the groove hole along with the ball body until the diaphragm wall of the landslide dam is formed through pouring.

Owner:SINOHYDRO FOUND ENG

Control method for preventing concrete segregation during large-height-difference downward concrete conveying

InactiveCN112431204AEasy dockingReduce stepsUnderground chambersNon-rotating vibration suppressionElectric machineStructural engineering

The invention particularly relates to a control method for preventing concrete segregation during large-height-difference downward concrete conveying. The problems that according to an existing large-height-difference downward concrete conveying operation mode, pipe blocking is prone to occurring, and the conveying efficiency is low are solved. The control method for preventing concrete segregation during large-height-difference downward concrete conveying comprises the steps that S1, a control device is assembled, specifically, a vertical guide pipe is mounted firstly, then a left supportingplate and a right supporting plate are fixed to a supporting platform, a horizontal guide pipe is mounted between the left supporting plate and the right supporting plate, then a motor is mounted, anoutput shaft of the motor is connected with a rotary shaft, and finally a low-position receiving hopper is placed under a discharging hopper; S2, pipe wetting is conducted; S3, concrete is discharged;S4, concrete discharging is interrupted; and S5, concrete discharging is recovered. According to the control method, the concrete in the vertical guide pipe can be kept in a full state all the time,the concrete discharging speed of the vertical guide pipe is controllable, and thus segregation and pipe blocking which are prone to occurring during large-height-difference downward concrete conveying are effectively prevented.

Owner:中铁十七局集团第五工程有限公司

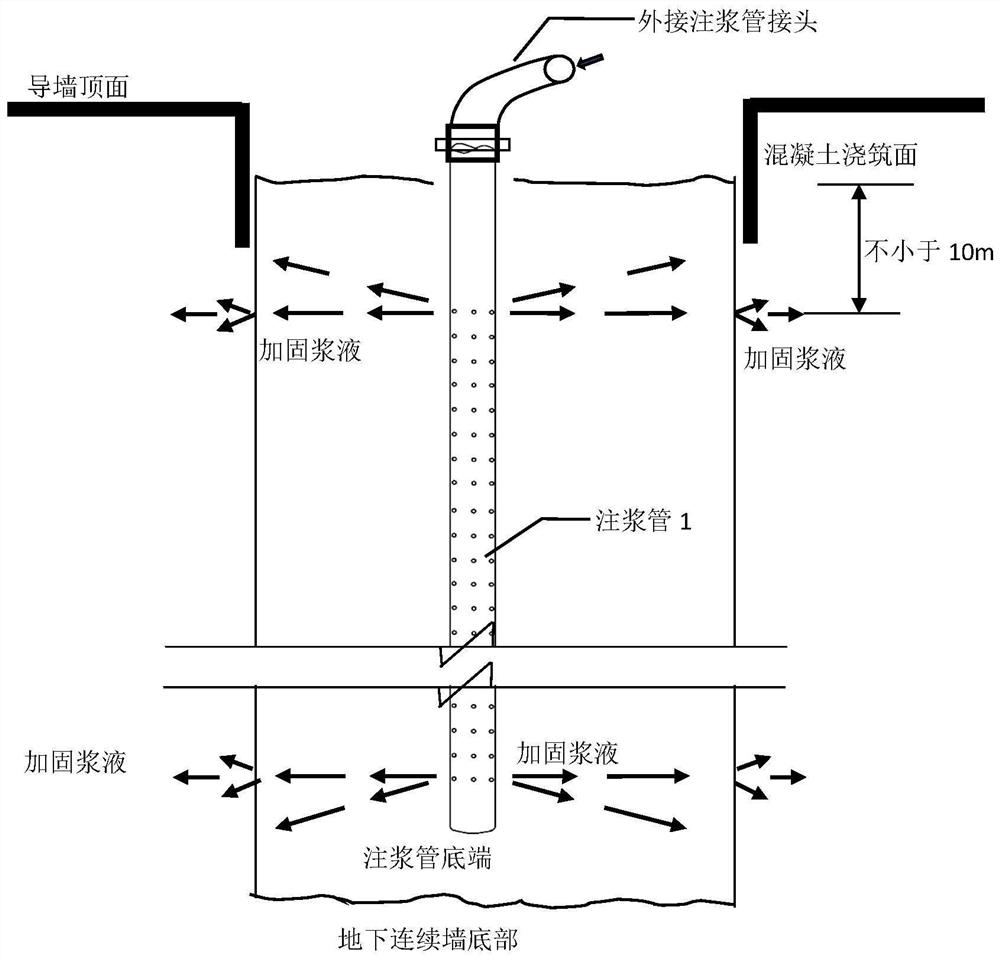

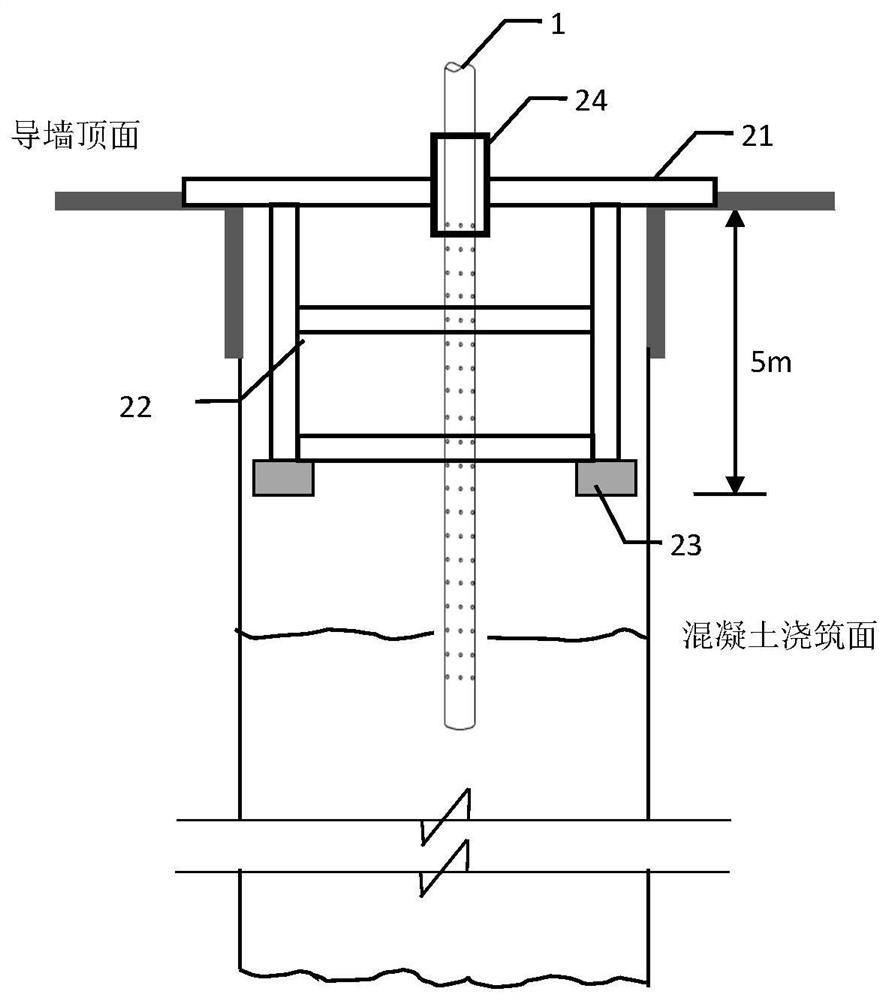

Method and device for joint reinforcement of underground diaphragm wall

ActiveCN110206071BSolve the leakLow costArtificial islandsUnderwater structuresSlurry wallWater leakage

The invention relates to a method and a device for reinforcing a joint of an underground continuous wall, and relates to the technical field of leakage plugging of the underground continuous wall. The steps of the method include: (1) forming a groove in the underground diaphragm wall, performing ultrasonic detection on the verticality of the groove, performing joint brushing, and hoisting to complete the underground diaphragm wall reinforcement cage; (ii) placing the joint grouting pipe fixing frame; Slurry pipe...; IV lowering the concrete pouring conduit...; V The concrete strength of the diaphragm wall reaches 50% of the design strength and above, and the concrete pouring time is not less than 5 days, and the joints of the diaphragm wall are reinforced through the grouting pipe Slurry injection…. The invention solves the problems of mud inclusion, concrete segregation and non-compactness in the joints of the underground continuous wall, effectively prevents the problems of water leakage and quicksand of the underground continuous wall during the excavation of the foundation pit, and proposes a corresponding device. Compared with the underground diaphragm wall plugging method in the process of foundation pit excavation, it has the advantages of safety, low risk, low cost, high efficiency and high quality.

Owner:SHANGHAI JIANKE ENG CONSULTING

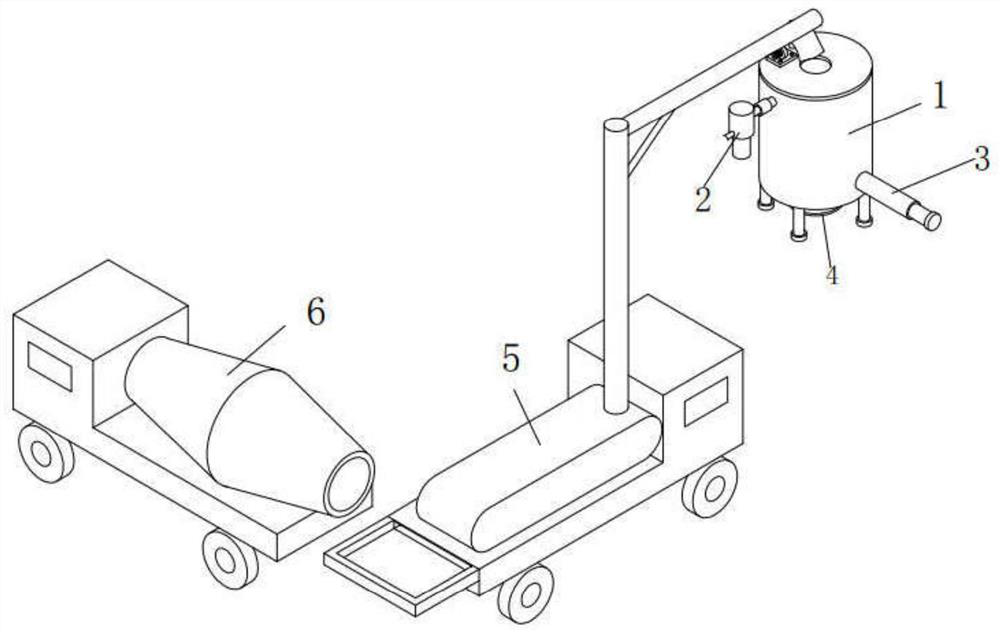

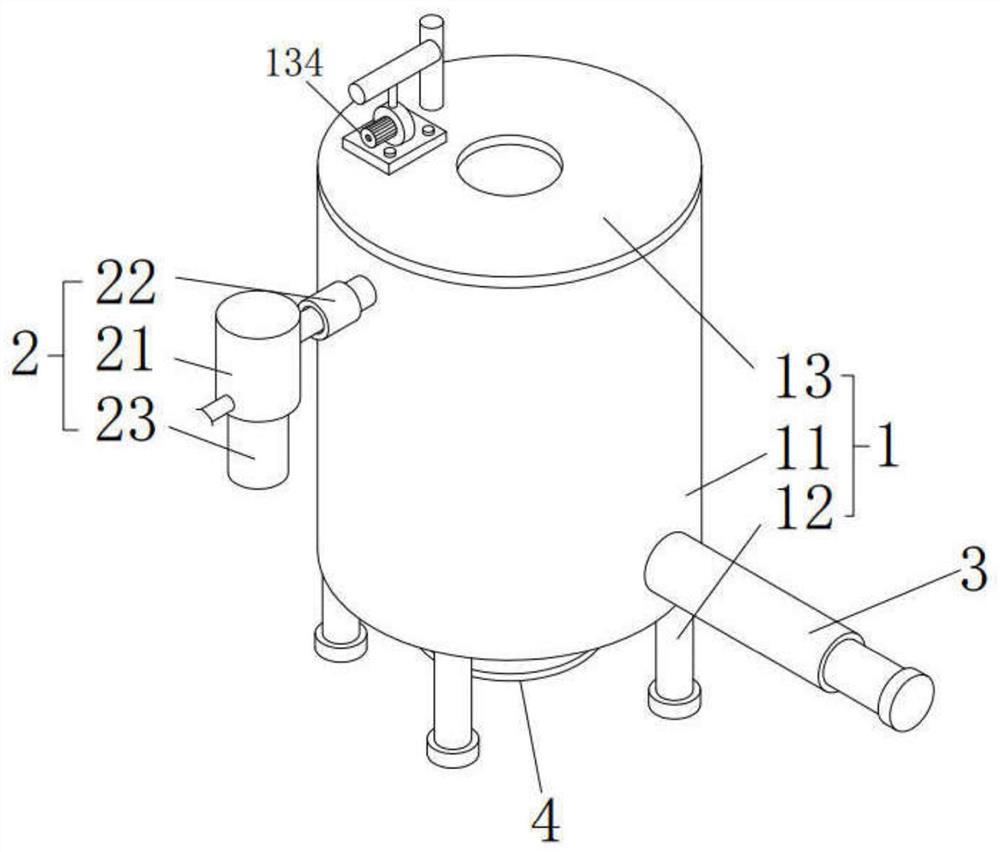

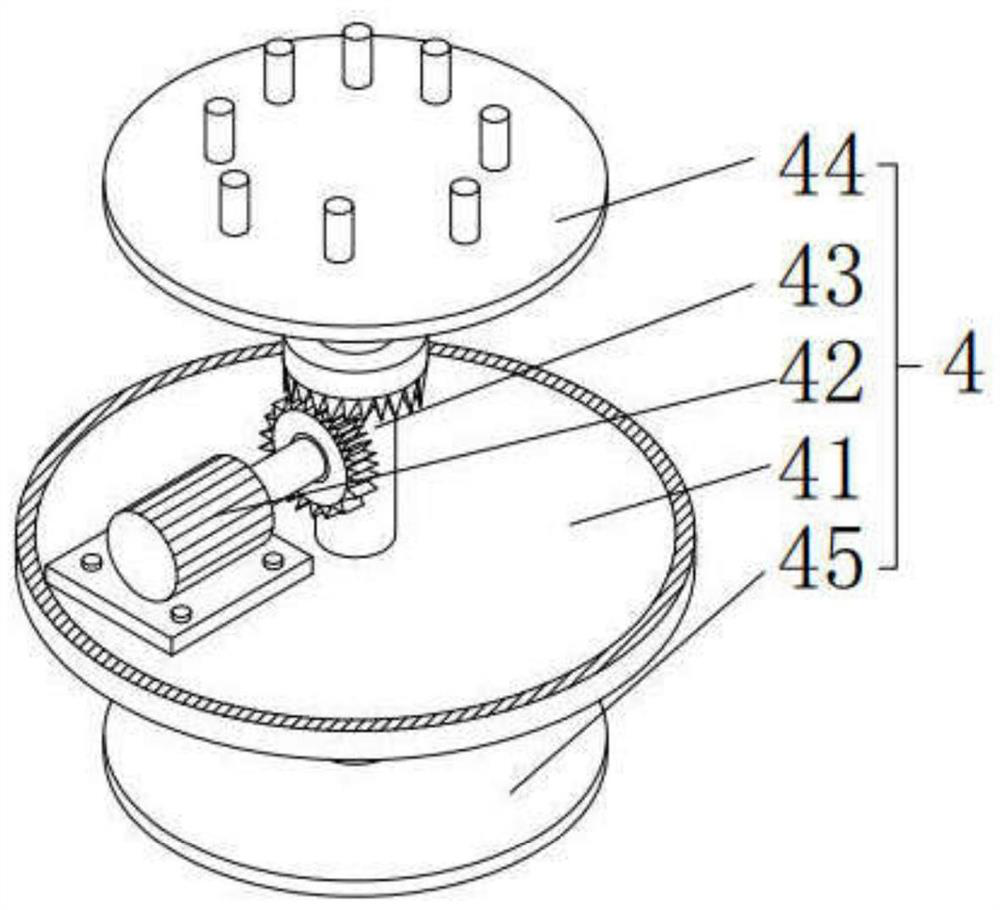

Self-compacting concrete construction system and construction method

ActiveCN112793000AEasy to transportInhibition of segregationBuilding material handlingCement mixing apparatusGear wheelArchitectural engineering

The invention provides a self-compacting concrete construction system and method. The construction system comprises a concrete pouring device, a concrete pump truck and a concrete mixer truck, the concrete pouring device comprises a tank body, the tank body is provided with a supporting base and a cover plate assembly, an adding device is arranged on the sidewall of the tank body and comprises an adding tank, a feeding port is formed in one side of the adding tank, a connecting assembly is arranged between the adding tank and the tank body, a driving assembly is arranged at the bottom of the adding tank, a pouring device is arranged at the bottom of the sidewall of the tank body, a stirring device is arranged at the bottom of the tank body and comprises a box body, a stirring motor is fixed in the box body, a gear at an output end of the stirring motor is engaged with a rotating shaft, a bearing at the upper end of the rotating shaft is connected to the bottom of the tank body and extends to the interior to be connected with a stirring disc, the bottom of the rotating shaft is rotatably connected with the bottom of the inner wall of the box body, and a telescopic assembly is arranged at the bottom of the box body. According to the system and method, concrete disintegration can be prevented, and the self-compacting concrete can be uniformly poured.

Owner:JIANGXI UNIV OF TECH

Concrete forming construction method based on concrete segregation degree testing device

InactiveCN111537566APreliminary situation of accurate formingEffectively obtain the pre-formation situationMaterial resistanceArchitectural engineeringStructural engineering

The invention discloses a concrete forming construction method based on a concrete segregation degree testing device. The method is characterized in that the forming construction method is a method for measuring the resistance value of newly-poured concrete with the relative height in different time periods based on a testing device. The resistance value is detected within 30 minutes in the earlier stage of solidification, so that the resistance resistivity and the segregation value DR are calculated; a handheld testing device is adopted; high portability is realized; therefore, the device canconveniently and quickly test the segregation degree of the concrete; the operation is simple and accurate; the detection efficiency is improved, time is bought for adjustment before a newly-poured concrete component is completely solidified; the concrete forming component which is correspondingly treated is tested and judged through the testing device, good internal homogeneity of the concrete forming component can be achieved, and cracks generated after concrete is formed are avoided; the structural bearing capacity is improved, and the quality of the concrete forming component is effectively improved; and the method is suitable for being widely popularized.

Owner:中天华南建设投资集团有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com