Concrete pouring pipe device for preventing concrete segregation and method

A technology of concrete and pouring pipes, applied in dams, buildings, wall dams, etc., can solve the problems of difficult construction of cut-off walls, high cost of demolition, and overhead phenomena, and achieve the effect of avoiding concrete segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

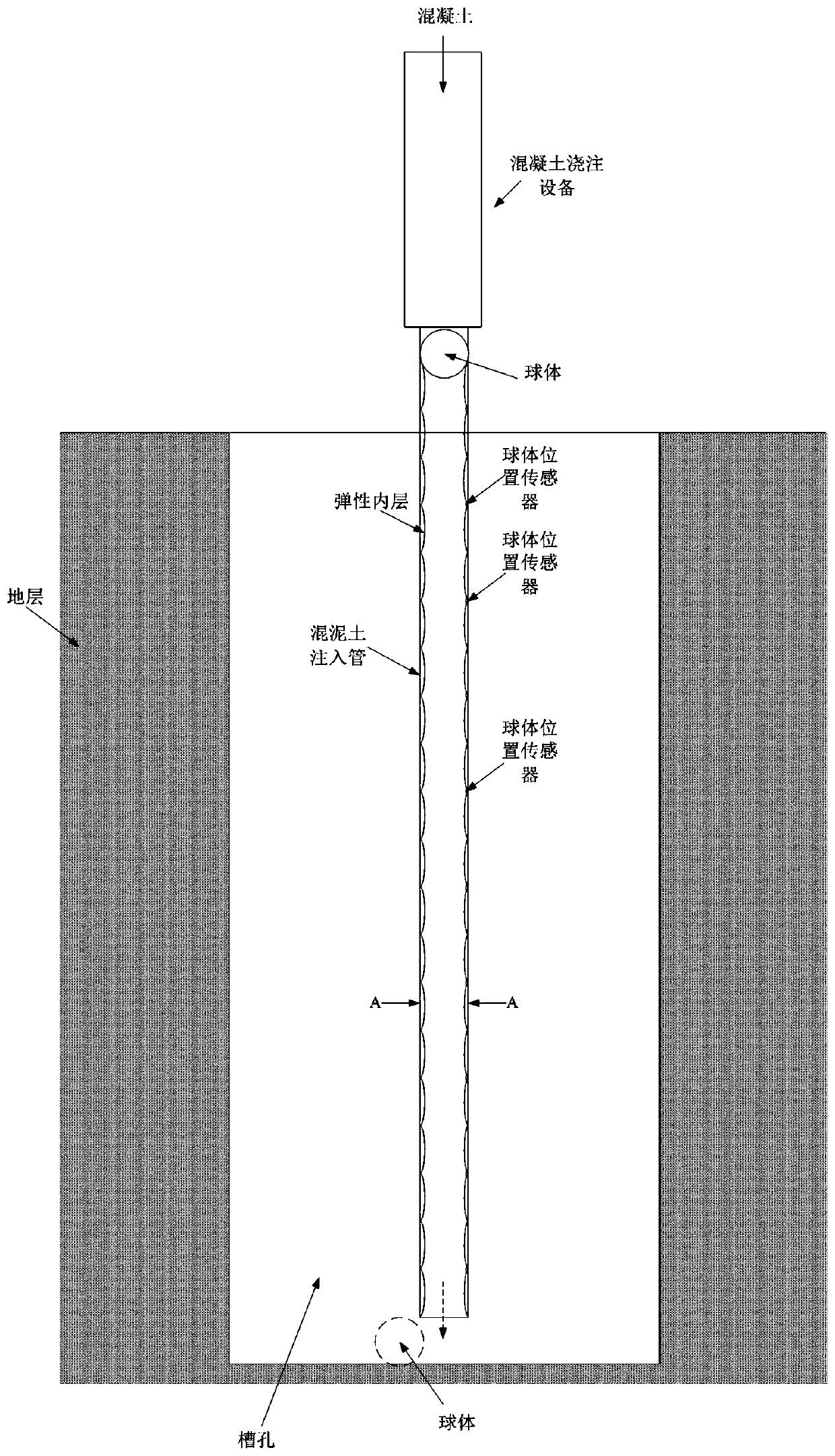

[0044] figure 1 The first embodiment of the concrete pouring pipe device for preventing concrete segregation of the present invention is shown. The concrete pouring pipe device for preventing concrete segregation in the first embodiment includes: concrete pouring equipment; a concrete pouring pipe docked with the concrete pouring equipment.

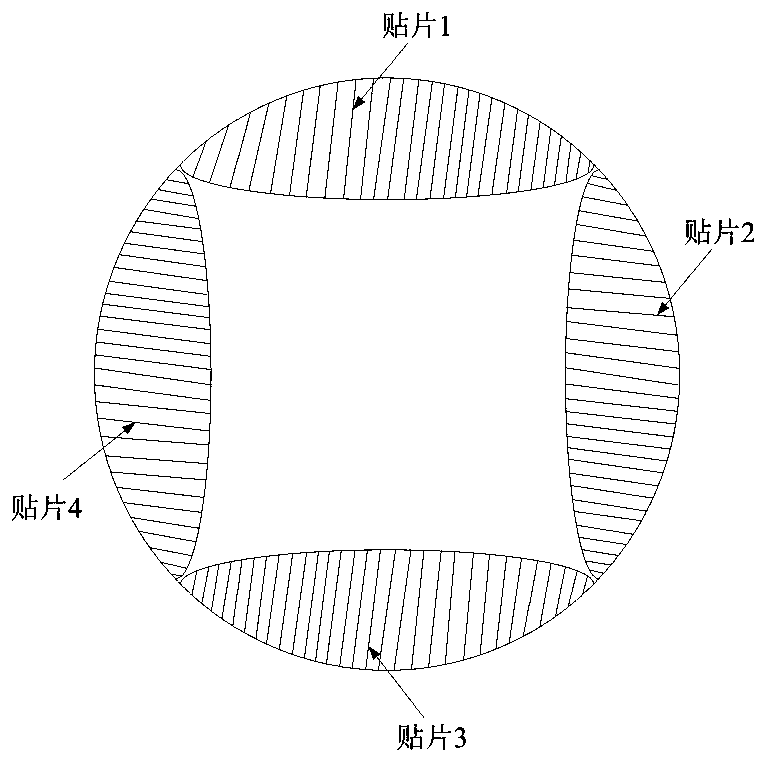

[0045] The concrete pouring pipe comprises: a plurality of pipe body sections; an elastic inner layer arranged in each pipe body section; a ball in frictional contact with the elastic inner layer; a plurality of ball position sensors arranged in the concrete pouring pipe.

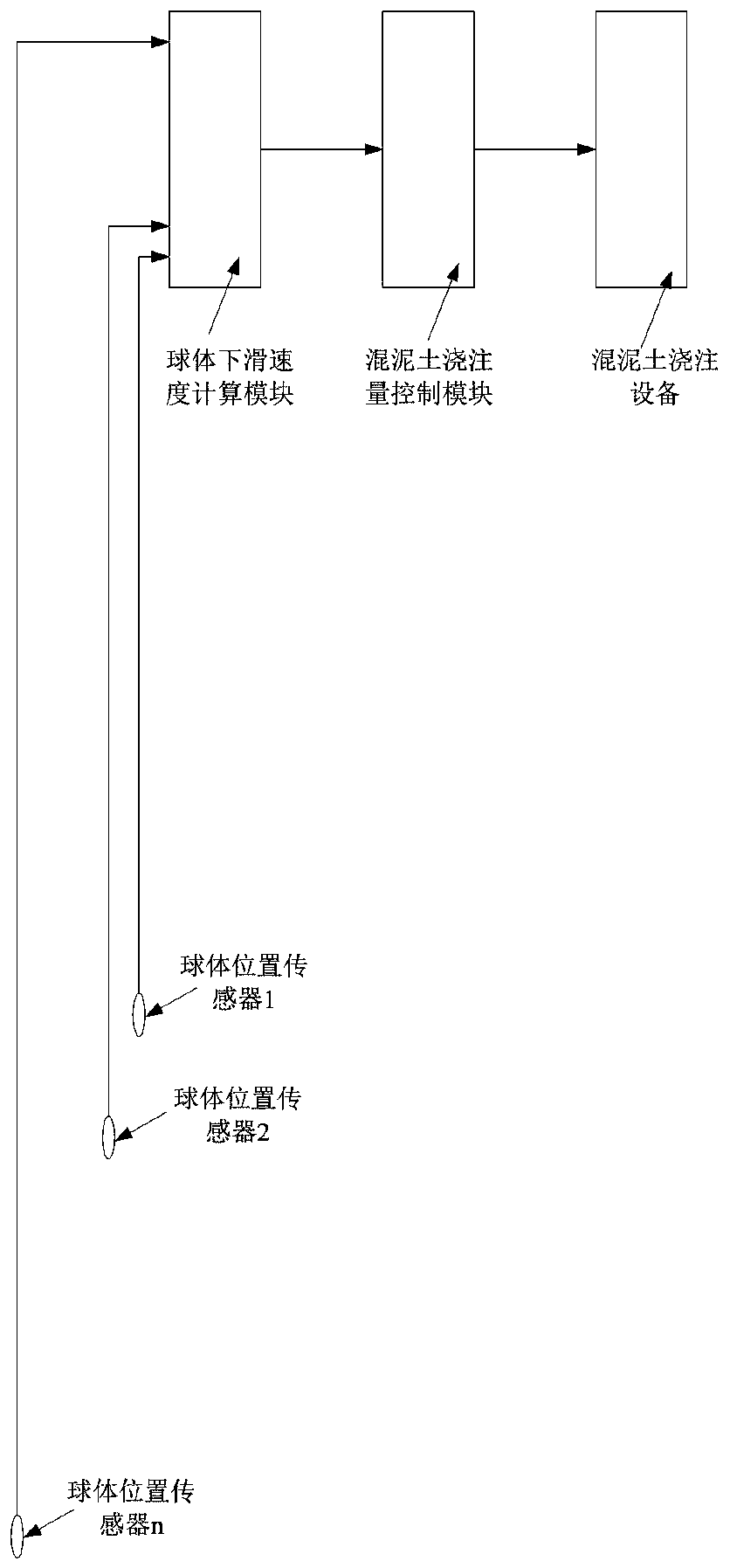

[0046] see figure 2 , the concrete pouring pipe device of the present invention also includes: a controller connected to the plurality of sphere position sensors, and the controller controls the concrete pouring of the concrete pouring equipment according to the preset corresponding relationship between the sphere sliding speed and the concrete pouring amount. Pourin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com