Ultrahigh-pressure long-distance pumping concrete and preparation method thereof

A long-distance pumping concrete technology, applied in the field of concrete, can solve the problems affecting the quality and progress of the project, the shortening of the initial setting time of concrete, the blockage of the delivery pipe, etc., and achieve the effect of reducing the temperature difference between inside and outside, ensuring the strength and improving the retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

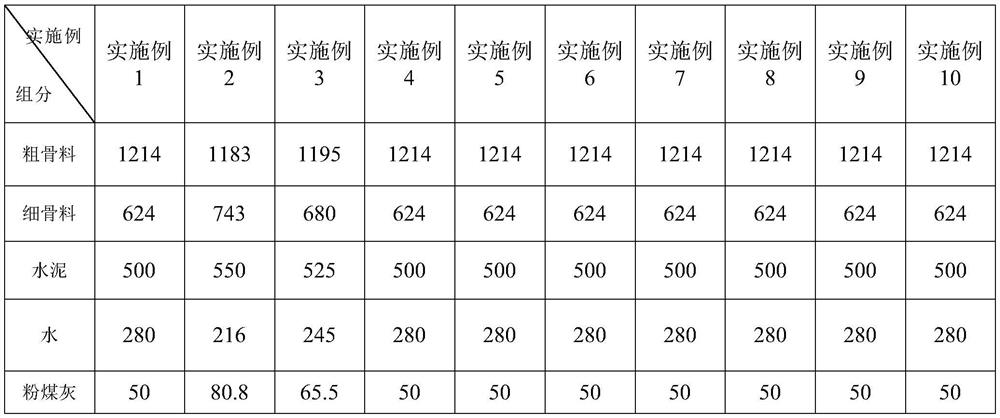

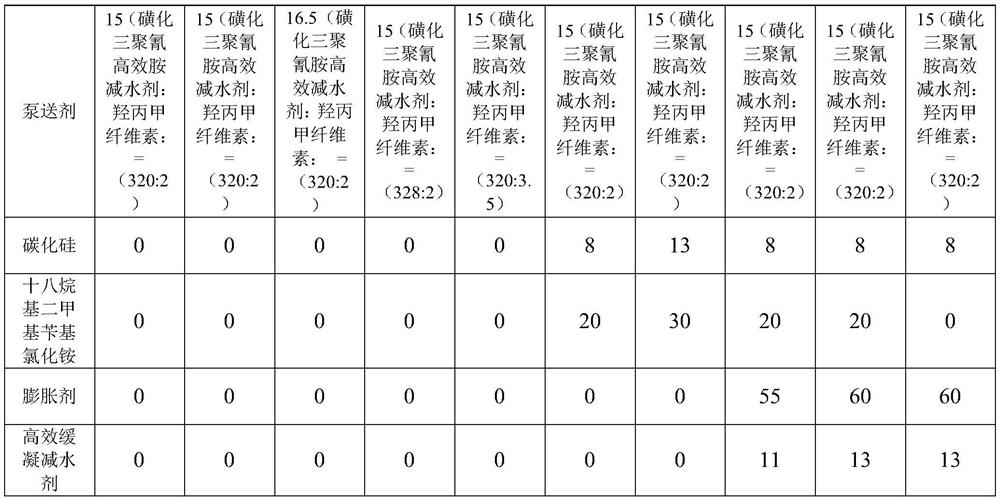

[0055] Table 2 shows the components and proportions of the ultra-high pressure long-distance pumping concrete in each embodiment.

[0056] Components and ratios of ultra-high pressure long-distance pumping concrete in each embodiment of Table 2

[0057]

[0058]

[0059] The preparation method and steps of embodiment 1-5 are as follows:

[0060] s1: Under continuous stirring at 25-30°C, according to the ratio in Table 2, take one-half of the water, completely dissolve the sulfonated melamine superplasticizer in the water, and then add a small amount of hypromellose several times slowly Add sulfonated melamine high-efficiency water reducer solution to dissolve, stir evenly to obtain pumping agent;

[0061] s2: According to the ratio in Table 2, mix the coarse aggregate and fine aggregate evenly to obtain the aggregate mixture;

[0062] s3: Mix cement and fly ash according to the ratio in Table 2, add the remaining water, and stir evenly to obtain a gel mixture;

[0063...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com