Vertical shaft cement discharging system with secondary stirring device

A secondary mixing and wellbore technology, which is applied in shaft lining, shaft equipment, mining equipment, etc., can solve the problems of prolonging the time for ash removal, failure to ensure continuous pouring of concrete, waste of manpower, etc., to prevent concrete segregation, ensure concrete quality, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

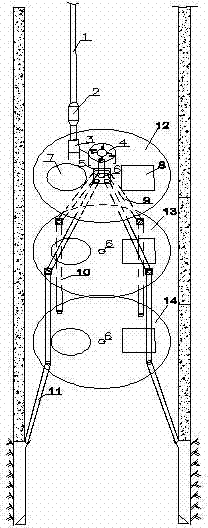

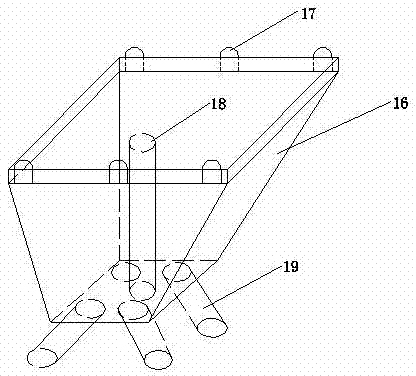

[0013] figure 1 Among them, the ash lowering system of the vertical shaft shaft equipped with the secondary stirring device is mainly composed of the main ash chute pipe 1, the buffer 2, the ash hopper 3, the secondary stirring device 4, the ash separator 5, the center line mouth 6, and the main hoisting horn 7. Auxiliary lifting bell mouth 8, slide chute 9, short ash chute 10, rubber hose 11, hanging pan I12, hanging pan II13 and hanging pan III14, and its hanging pan I12, hanging pan II13 and hanging pan III14 The main hoist bell mouth 7 and the auxiliary hoist bell mouth 8 are arranged on the left and right respectively, and the center line mouth 6 is arranged in the middle. The ash separator 5 is arranged on the upper part of the hanging pan I12, and the middle line pipe 18 in the middle of the ash separator 5 is connected with the center line on the hanging pan I12. The outlet 6 is on a central line, and the four ash outlets 19 provided at the lower part of the ash separ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com