Method and device for joint reinforcement of underground diaphragm wall

An underground diaphragm wall and fixing frame technology, which is applied to sheet pile walls, underwater structures, buildings, etc., can solve the problems of high cost, failure, water leakage of the enclosure structure, quicksand, etc., and achieve low cost and prevention of enclosure structure The effect of water leakage problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

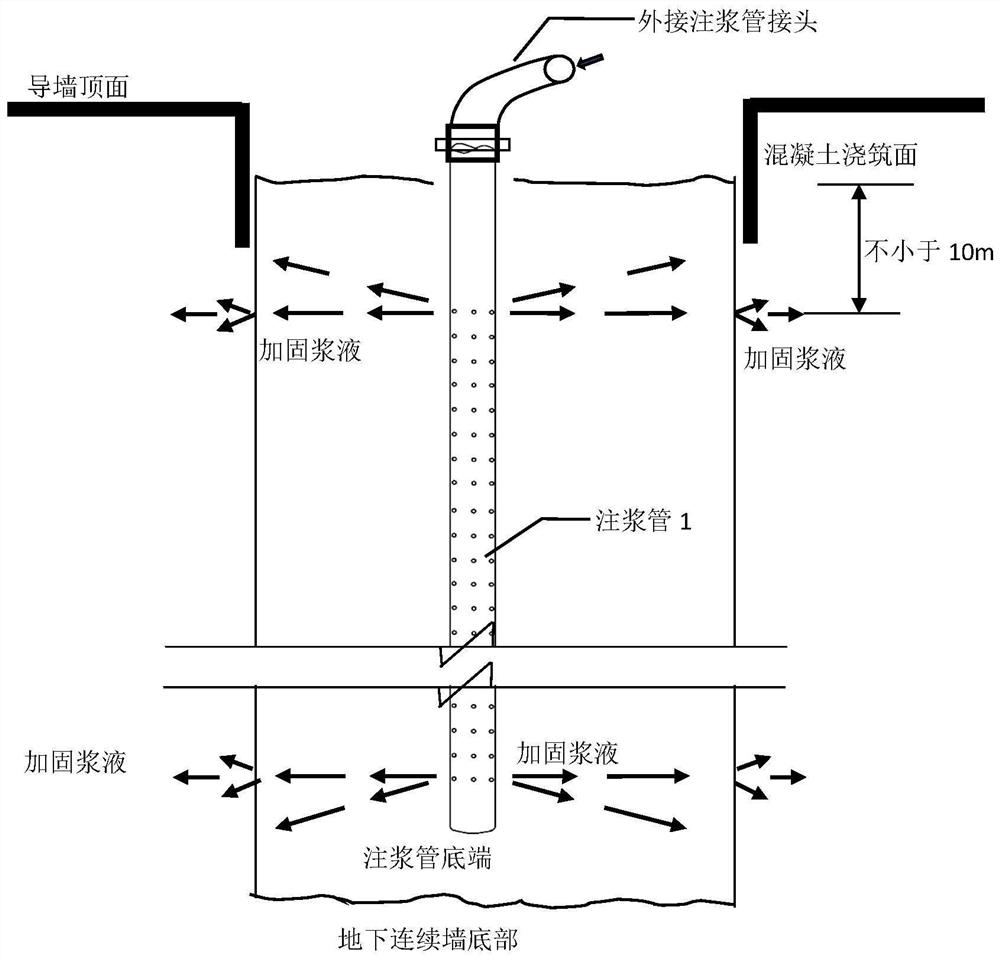

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments

[0031] A joint reinforcement method of an underground continuous wall of the present invention (as attached figure 1 , 2 shown), including steps:

[0032] A. At the end of the trough formation of the underground diaphragm wall of the rear width, the verticality of the trough is detected by ultrasonic wave, the joints are brushed, and the steel cage of the underground diaphragm wall of the running width is completed after the hoisting is completed.

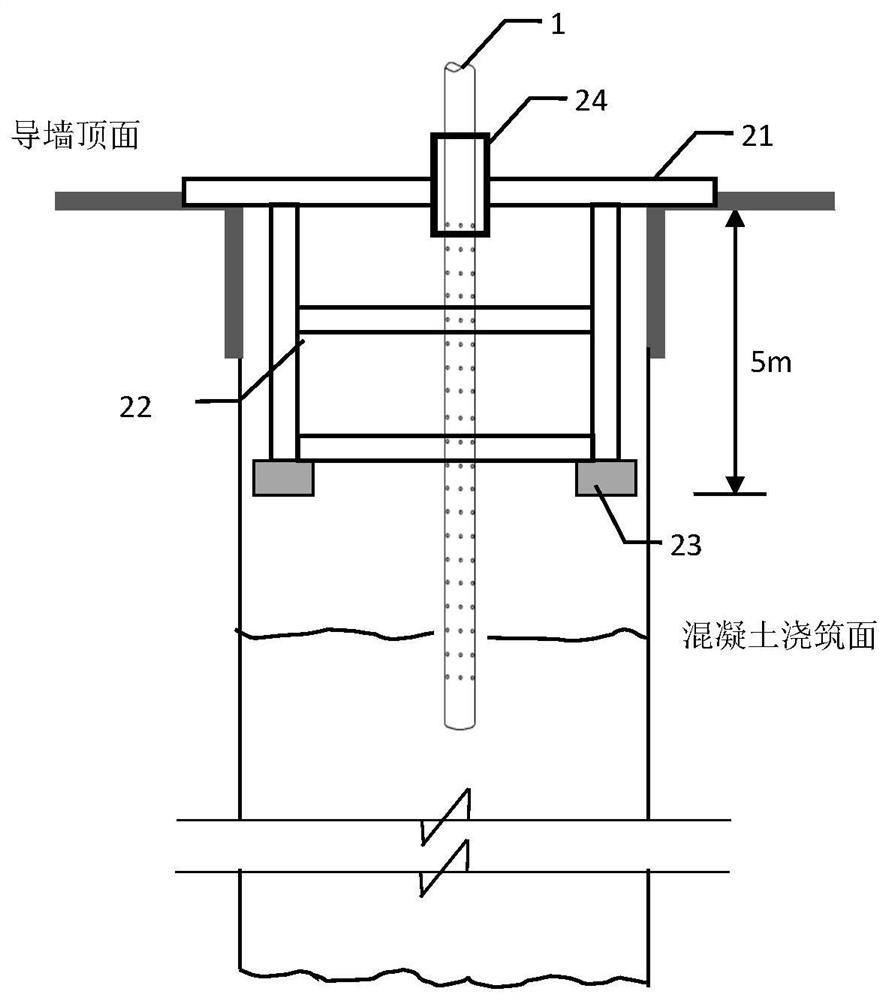

[0033] B. Place the joint grouting pipe fixing frame.

[0034] C. Lay down the grouting pipe, keep the grouting pipe close to the joint wall of the leading underground diaphragm wall by adjusting the regulator on the grouting pipe fixing frame, and adjust the verticality of the grouting pipe inside and outside the foundation pit; the bottom of the grouting pipe should be 1m to 3m above the bottom of the un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com