Concrete disintegration resisting steel mesh hollow chamber floor system

The technology of cavity floor and steel mesh is applied in the direction of floor slab, building material processing, building components, etc. It can solve problems such as affecting the normal use of construction equipment, changing the strength of concrete structures, and blocking the pipeline of cast-in-place concrete delivery pumps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

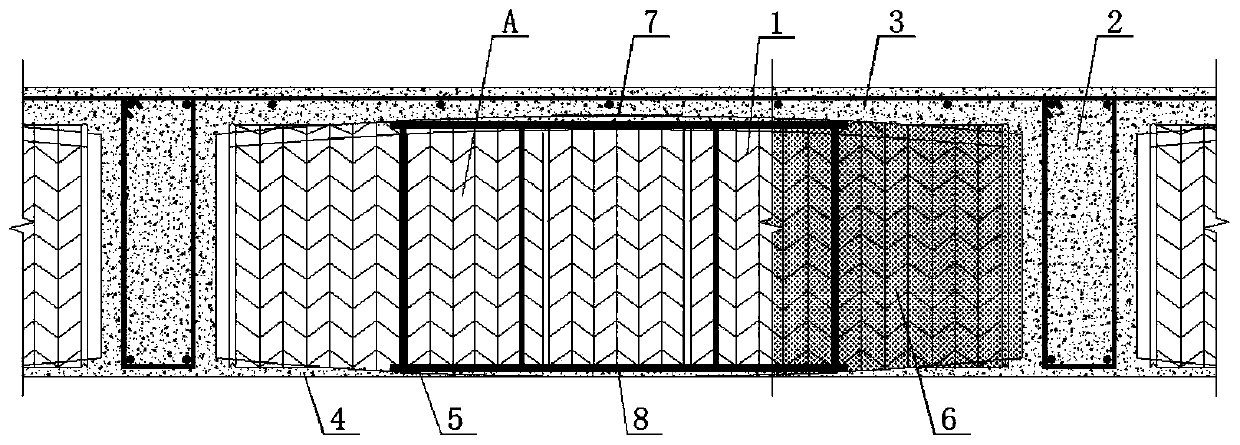

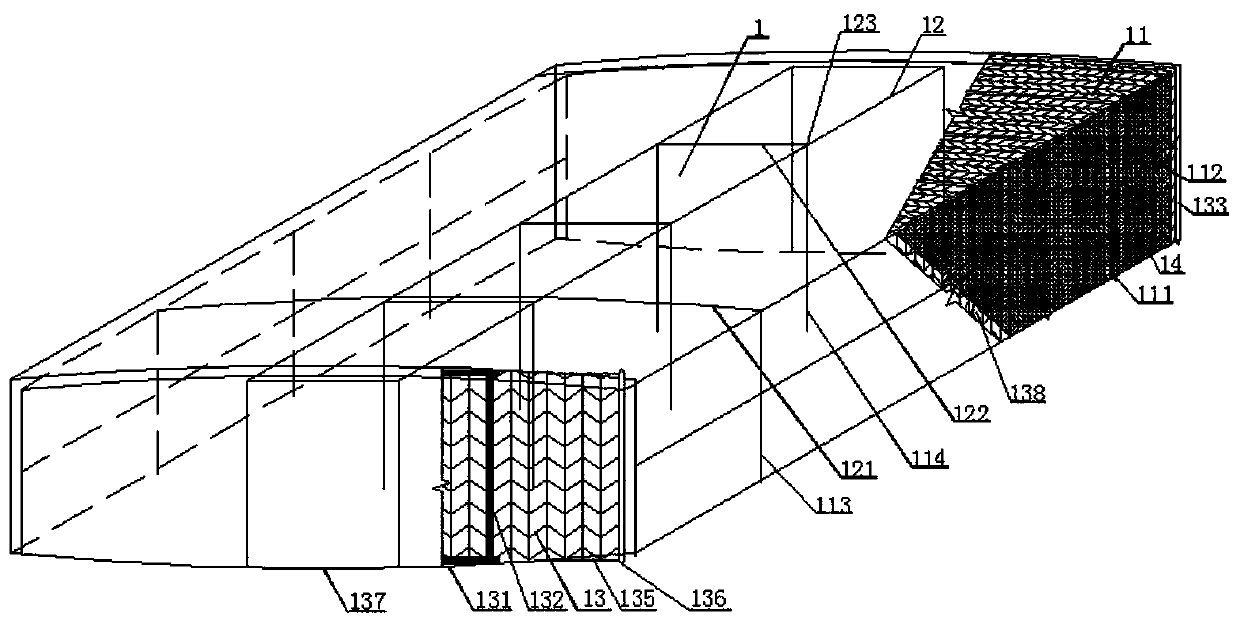

[0017] figure 1 It is a cross-sectional view of the side of the arc-shaped steel mesh plugging head of the concrete segregation-resistant cavity floor embodiment of the present invention. When the present invention is implemented, the designed cavity floor A is a T-shaped section plate with two-way stress, and the longitudinal rib The length of the beam 2 is greater than or equal to that of the transverse rib beam, and the arc-shaped steel mesh is used as the hole-forming member, and the arc-shaped steel mesh member 1 is used to form the upper flange plate 7 with arc-shaped arching to improve the stress state of the cavity floor; The extremely thin non-woven fabric 6 is wound into the arc-shaped stencil member 1 to effectively solve the problem of segregation and leakage of concrete mortar into the arc-shaped stencil when the slump of the concrete is too large; without...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com