Supervision and inspection method for field workability of high-performance concrete

A high-performance concrete and inspection method technology, which is applied in the preparation of material inspection products, test samples, instruments, etc., can solve the problems of low efficiency and low accuracy, and achieve the effect of high speed, reducing errors and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

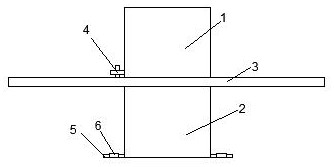

[0021] figure 1 It shows a supervision and inspection method of on-site workability of high-performance concrete, which includes the following steps: a. Obtain the numerical basis of the division standard through tests for five types of special products and conventional products in high-performance concrete, and collect them through engineering practice The testing standard is obtained after continuous optimization of the information data; b. Place the layered separation cylinder on a flat ground during the inspection, and then pour the mixed concrete to be tested into the storage bin of the layered separation drum. The storage bin includes The upper storage bin and the lower storage bin; c. Lift the layered separation cylinder and shake it 3-5 times in the vertical direction to eliminate the large pores in the concrete; d. Then put the layered separation cylinder on the vibration table and open Vibrating table, measure the height of the concrete in the upper storage bin and t...

specific Embodiment 2

[0024] This embodiment further illustrates the structure of the layered separation cylinder on the basis of the specific embodiment 1. The layered separation cylinder includes an upper cylinder 1 and a lower cylinder 2, and an upper cylinder 1 and a lower cylinder 2 are also provided. There is a partition plate 3, and a through hole is provided at the center of the middle part of the partition plate 3. The inner diameter of the through hole is the same as that of the upper cylinder 1 and the lower cylinder 2. One side of the upper cylinder 1 is provided with a rotating mechanism 4, which rotates The fixed shaft of the mechanism 4 is connected to the top of the partition plate 3, and one side of the middle part of the partition plate 3 is also provided with an upper cylinder leakage hole.

[0025] When measuring the concrete height in the upper storage bin of the upper cylinder, it is enough to directly observe the scale on the side of the upper cylinder, but to measure the qual...

specific Embodiment 3

[0027] In this embodiment, a fixing mechanism is added on the basis of the specific embodiment 1, and a fixing mechanism for easy fixing is also provided between the layered separation cylinder and the vibrating table.

[0028] It is convenient to fix the layered separation cylinder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com