A construction method of pouring concrete piles with telescopic conduits

A pouring concrete, telescopic technology, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as adverse effects of concrete pouring quality, time-consuming and laborious removal of material pipes, increased difficulty of operation control, etc., to improve project quality And the effect of construction efficiency, overcoming the pouring of concrete material by its own weight, and preventing concrete sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

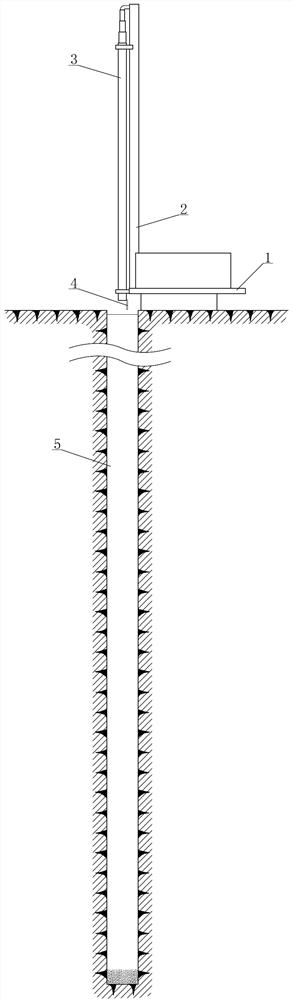

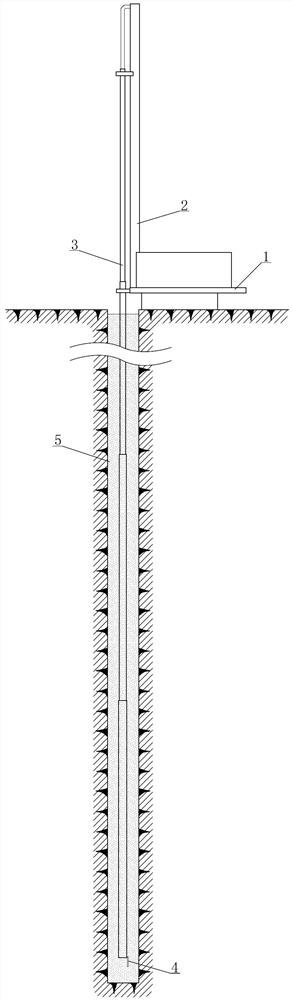

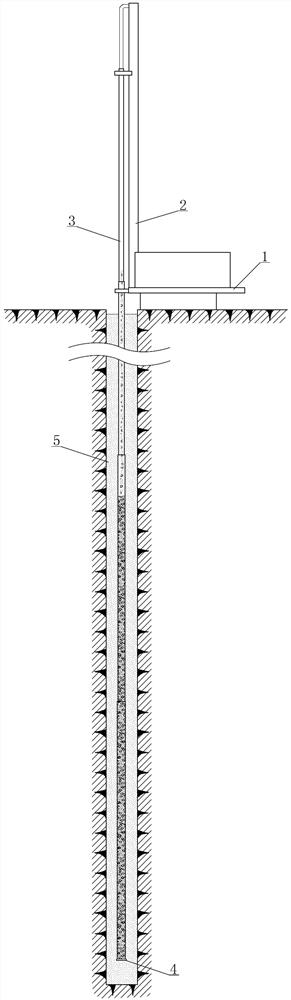

[0048] From Figure 1 to Figure 4 As can be seen, the present invention utilizes the construction method of telescoping conduit pouring concrete pile to comprise the following steps:

[0049] 1) Construction preparation:

[0050] A construction platform 1 is set on the top of the pile hole 5 to be poured, and a support mast 2 for placing a conduit is erected on the construction platform. The support mast is equipped with a lifter, and the lifter is driven by a hydraulic motor or an electric motor to lift along the mast; the conduit 3 Hoisted on the supporting mast by a lifter;

[0051] The catheter adopts a telescopic tube body structure. Each section of the catheter is assembled in a suit, and after being stretched, the diameter increases gradually from top to bottom; Bottom door for sealing; a sealing mechanism is provided at the junction of each section of the conduit, and the sealing mechanism adopts an annular capsule, and the installation method is: an annular card gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com