Double-sided superimposed shear wall cavity concrete pouring tool

A technology of superimposed shear walls and concrete, which is applied in the direction of construction, building structure, and building material processing, can solve the problems of waste, inconvenient and inconvenient concrete pouring methods for cavities, and achieve waste reduction, low cost, and Create handy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The double-sided laminated shear wall cavity concrete pouring tool of the present invention has a double-sided laminated shear wall thickness of 200mm, wherein the double-sided 50mm is prefabricated concrete, and the middle 100mm is the cavity cast-in-place concrete, and the middle is connected by truss reinforcement. Concrete pouring tools include hoisting buckets and conduits.

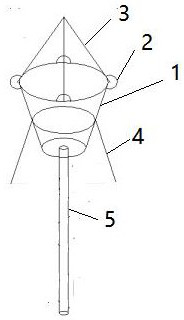

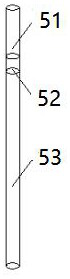

[0026] see now figure 1 , figure 1 It is a structural schematic diagram of a pouring tool according to an embodiment of the present invention. As shown in the figure, the hoisting barrel is a round table-shaped barrel body 1 with a large upper opening and a small lower opening. The upper opening of the barrel body is open and four lifting lugs 2 are arranged on the circumference edge, and steel wire ropes are arranged inside the lifting lugs. 3. It is convenient for tower hoisting and hoisting of the bucket; the middle circumference edge of the round table type bucket is equally divided into...

Embodiment 2

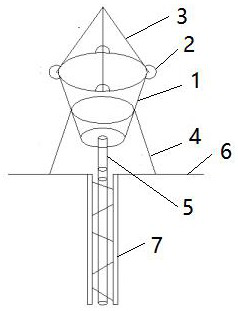

[0030] figure 2 It is a schematic diagram of the use state of the pouring tool according to the embodiment of the present invention. The use method of the double-sided laminated shear wall cavity concrete pouring tool of the present invention:

[0031] 1. Place the pouring tools stably on the floor 6 and stand in the middle of the double-sided laminated wall 7.

[0032] 2. When pouring concrete, pour the concrete into the pouring tool through the pump pipe, and pour the concrete into the cavity of the double-sided laminated shear wall through the pouring tool.

[0033] 3. The concrete is made of fine stone concrete, and the mobile type is coordinated with a tower crane.

[0034] 4. Use a vibrating rod with a diameter of 30mm to vibrate.

[0035] Points for attention in the use of the double-sided laminated shear wall cavity concrete pouring tool of the present invention:

[0036] 1. Manufacture in strict accordance with the drawings to ensure the welding quality, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com