Concrete stacking forming method

A technology of accumulation forming and concrete, applied in the field of building materials, can solve the problems of aggregate subsidence, affecting the overall homogeneity and performance of concrete, and achieve the effect of reducing air bubbles, improving mechanical properties, compactness and durability, and reducing segregation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

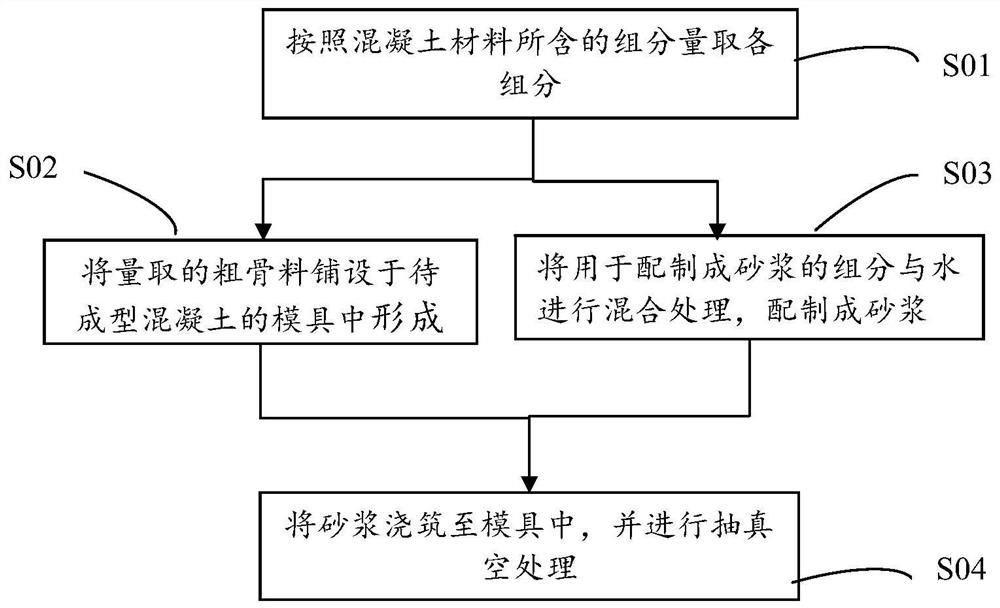

Method used

Image

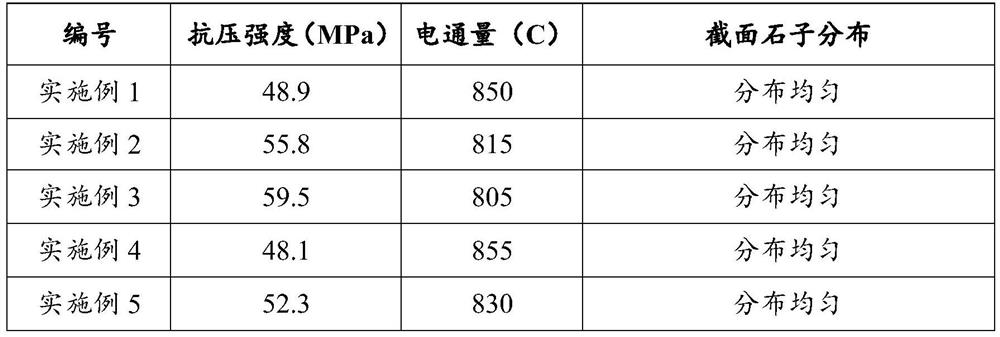

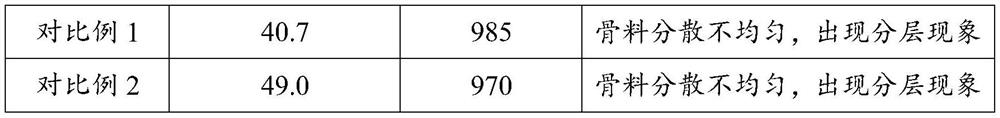

Examples

Embodiment 1

[0048] This embodiment provides a concrete accumulation forming method. Described concrete accumulation molding method comprises the steps:

[0049] S1. Prepare a detachable mold. The assembled mold is a closed cuboid. There is a grouting hole ball valve with a diameter of 50mm on the lower right side of the mold, and a vacuum ball valve with a diameter of 50mm on the upper right side of the mold;

[0050] S2. Put 10 kg of continuous graded basalt coarse aggregate with a particle size of 5-30mm into the mixer, and stir for 60 seconds to obtain evenly mixed coarse aggregate, then spread the coarse aggregate into the mold, spread it flat, and assemble the mold spare;

[0051] S3. Put 3 kg of Portland cement, 1 kg of admixture (mineral powder), and 4 kg of river sand into the mixer and stir for 30 seconds, then put 1.3 kg of water and 0.1 kg of admixture (polycarboxylate superplasticizer) into the mixer Stir for 90 seconds to obtain a well-mixed mortar;

[0052] S4 pump the mo...

Embodiment 2

[0054] This embodiment provides a concrete accumulation forming method. Described concrete accumulation molding method comprises the steps:

[0055] S1. Prepare a detachable mold. The assembled mold is a closed cuboid. There is a grouting hole ball valve with a diameter of 50mm on the lower right side of the mold, and a vacuum ball valve with a diameter of 50mm on the upper right side of the mold;

[0056] S2. Put 13 kg of continuously graded basalt coarse aggregate with a particle size of 5-30mm into the mixer, and stir for 90 seconds to obtain evenly mixed coarse aggregate, then spread the coarse aggregate into the mold, spread it flat, and assemble the mold spare;

[0057] S3. Put 5 kg of Portland cement, 2 kg of admixture (mineral powder), and 6 kg of river sand into the mixer and stir for 60 seconds, then put 1.6 kg of water and 0.2 kg of admixture (polycarboxylate superplasticizer) into the mixer Stir for 120 seconds to get a well-mixed mortar;

[0058] S4. Pour the m...

Embodiment 3

[0060] This embodiment provides a concrete accumulation forming method. Described concrete accumulation molding method comprises the steps:

[0061] S1. Prepare a detachable mold. The assembled mold is a closed cuboid. There is a grouting hole ball valve with a diameter of 50mm on the lower right side of the mold, and a vacuum ball valve with a diameter of 50mm on the upper right side of the mold;

[0062] S2. Put 11.5 kg of continuous graded basalt coarse aggregate with a particle size of 5-30 mm into the mixer, and stir for 75 seconds to obtain evenly mixed coarse aggregate, then spread the coarse aggregate into the mold, spread it flat, and assemble the mold spare;

[0063] S3. Put 4 kg of Portland cement, 1.5 kg of admixture (mineral powder), and 5 kg of river sand into the mixer and stir for 45 seconds, then put 1.45 kg of water and 0.15 kg of admixture (polycarboxylate superplasticizer) into the mixer Stir for 115 seconds to obtain a well-mixed mortar;

[0064] S4 pou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com