Hyperbranched concrete tackifier as well as preparation method and application thereof

A tackifier and concrete technology, which is applied in the field of hyperbranched concrete tackifier and its preparation, can solve the problems of inter-molecular entanglement and segregation, and achieve the effects of good compatibility, simple synthesis method, and improved workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

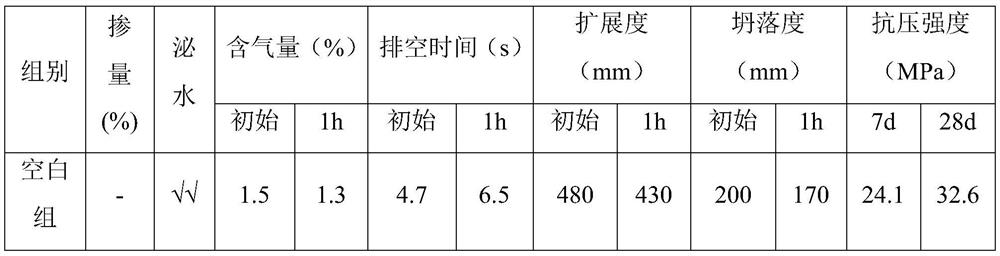

Examples

Embodiment 1

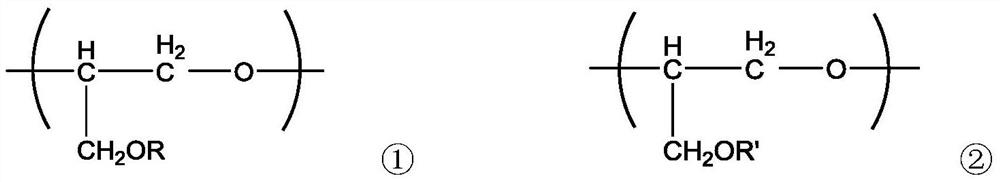

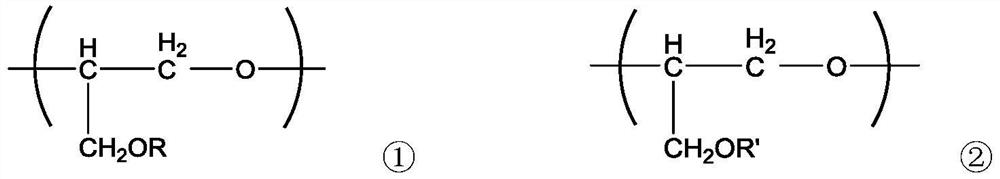

[0040] The hyperbranched concrete tackifier of the present embodiment consists of hyperbranched polymer A, N-hydroxysuccinimide acrylate, polyethylene glycol maleic acid diester and 2-propionamido-2-methylpropanesulfonate The acid is prepared by free radical polymerization; the hyperbranched polymer A is prepared by ring-opening polymerization of propenyl glycidyl ether.

[0041] The preparation method of described concrete tackifier specifically comprises the following steps:

[0042] S1. Add 150ml of DMAC solution and 68.48g of propenyl glycidyl ether into a four-necked flask equipped with an electric stirrer, dropping device, thermometer and nitrogen circulation, set the temperature of the oil bath to 60°C and stir well; then add 1.14g After the trimethylolpropane is completely dissolved, add 2.85g of potassium carbonate; the temperature rises to 120°C, and then use a peristaltic pump to slowly add 45.66g of propenyl glycidyl ether into the four-necked flask; after the addi...

Embodiment 2

[0045] The hyperbranched concrete tackifier of the present embodiment consists of hyperbranched polymer A, N-hydroxysuccinimide methacrylic acid, diethylene glycol diester maleate and methacrylamidopropyl-N, N dimethylpropanesulfonic acid is prepared by radical polymerization; the hyperbranched polymer A is prepared by ring-opening polymerization of propenyl glycidyl ether.

[0046] The preparation method of described concrete tackifier specifically comprises the following steps:

[0047] S1. Add 150ml of DMAC solution and 57.07g of propenyl glycidyl ether into a four-necked flask equipped with an electric stirrer, dropping device, thermometer and nitrogen circulation, set the temperature of the oil bath to 60°C, and stir well; then add 1.71g After the trimethylolpropane is completely dissolved, add 2.85g of potassium carbonate; the temperature rises to 120°C, and then use a peristaltic pump to slowly add 57.07g of propenyl glycidyl ether into the four-necked flask; after the ...

Embodiment 3

[0050] The hyperbranched concrete tackifier of the present embodiment consists of hyperbranched polymer A, N-hydroxysuccinimide methacrylic acid, diethylene glycol diester maleate and methacrylamidopropyl-N, N dimethylpropanesulfonic acid is prepared by radical polymerization; the hyperbranched polymer A is prepared by ring-opening polymerization of propenyl glycidyl ether.

[0051] The preparation method of described concrete tackifier specifically comprises the following steps:

[0052] S1. Add 150ml of DMAC solution and 89.69g of methacryl glycidyl ether into a four-necked flask equipped with an electric stirrer, dropping device, thermometer and nitrogen circulation, set the temperature of the oil bath to 60°C, and stir well; then add 1.71g of trimethylolpropane, add 2.85g of potassium carbonate after it is completely dissolved; the temperature rises to 120°C, and then slowly add 38.44g of methacryl glycidyl ether into the four-necked flask by using a peristaltic pump; drop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com