Concrete forming construction method based on concrete segregation degree testing device

A technology of testing device and construction method, which is applied in the directions of measuring device, analyzing materials, and analyzing materials by electromagnetic means, can solve the problems of difficult distribution of aggregates, reduced economic benefits, cumbersome testing process, etc., so as to improve concrete quality, Improve detection efficiency, convenient and quick test effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

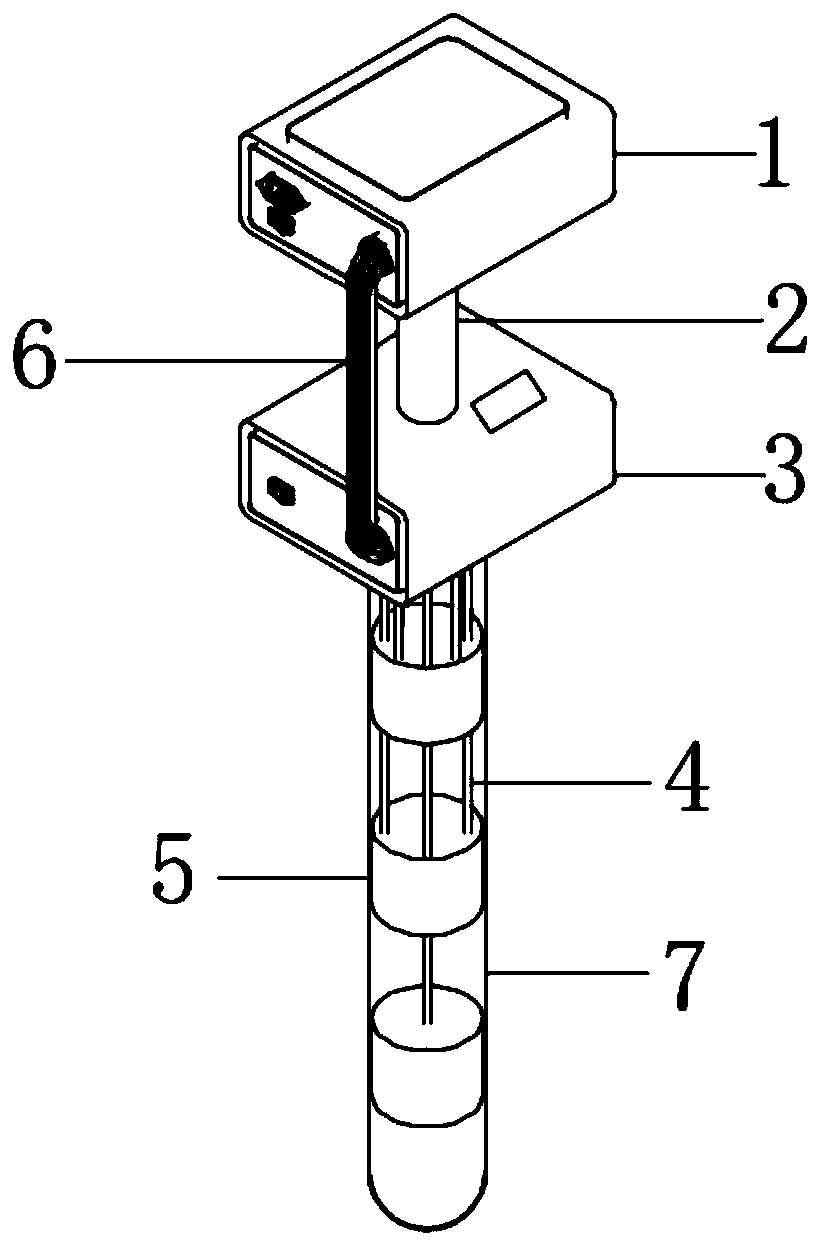

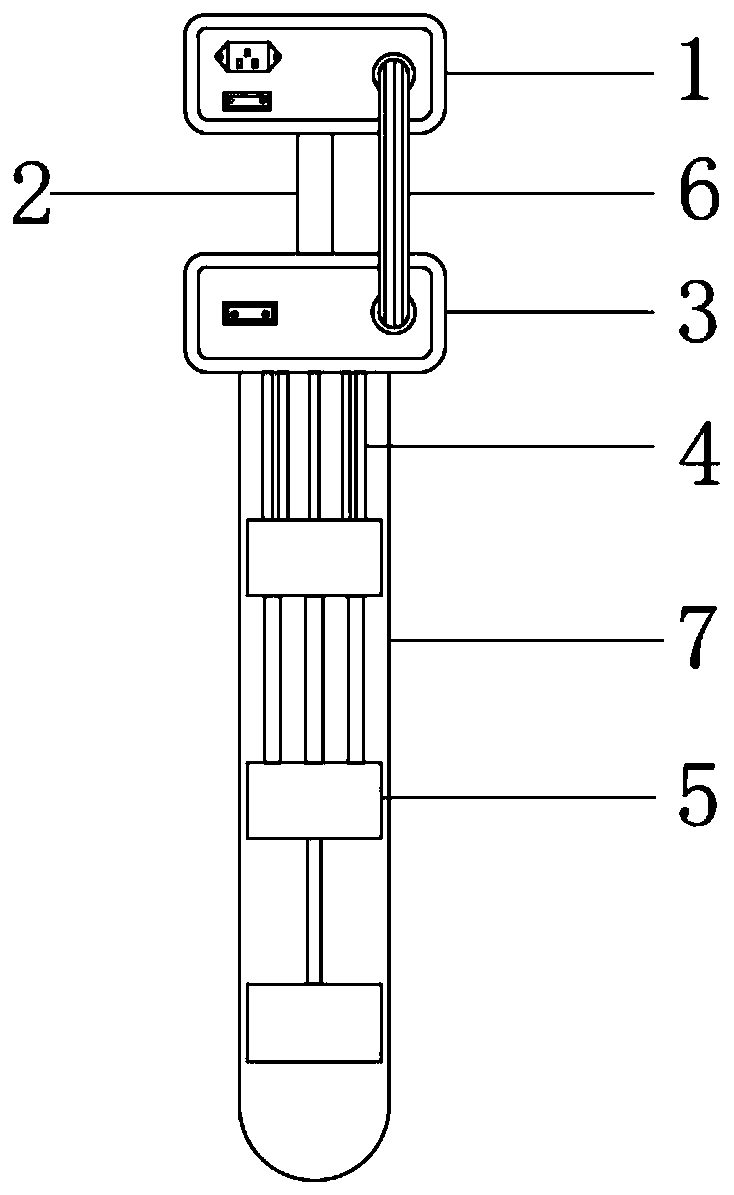

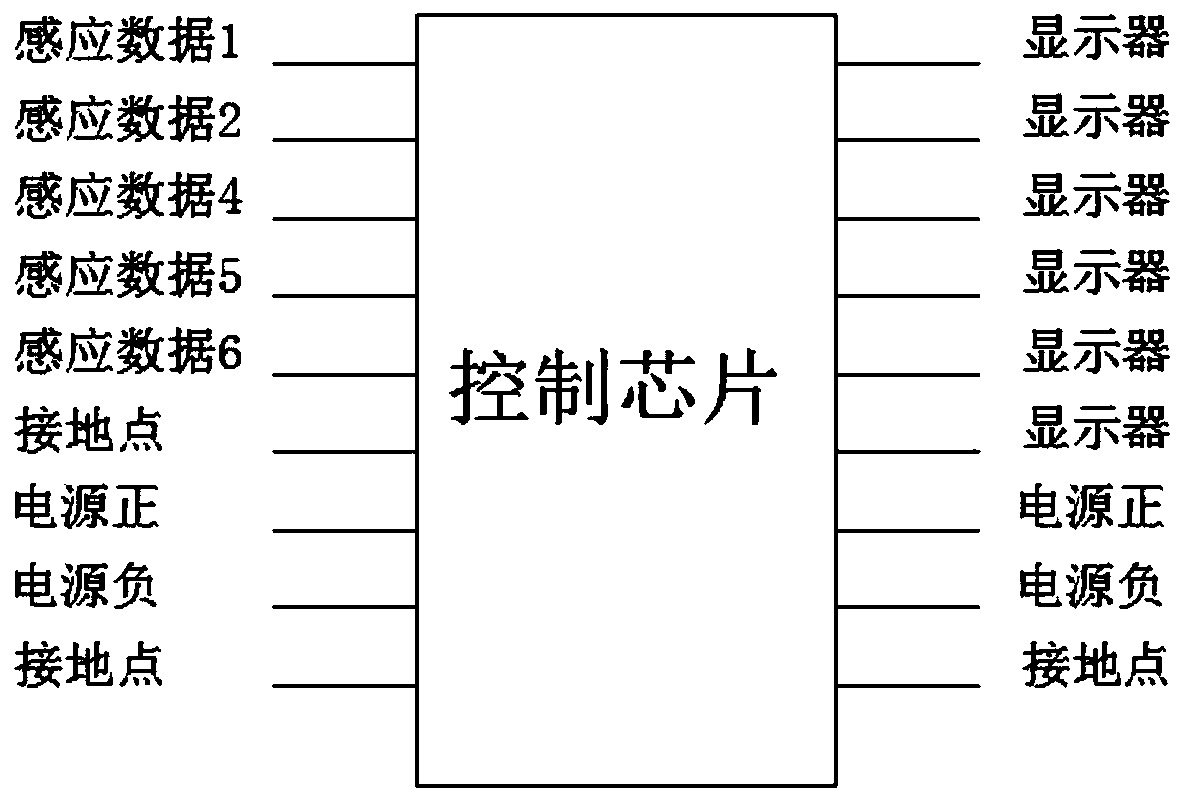

[0030] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0031] A concrete forming construction method based on a concrete segregation degree testing device, characterized in that: the forming construction method is based on the resistance value of the newly poured concrete at a relative height measured by the testing device at different time periods, specifically including the following step:

[0032] S1, get ready to need pouring material (concrete), prepare a plurality of segregation degree test devices, place described test devices respectively on the top of the formwork of the slab, beam, column and beam-column node of the freshly mixed concrete member formwork, test device Suspended on the top of the fresh concrete t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com