Surface crack repairing and nondestructive detection method for levelling roller

A non-destructive testing, surface crack technology, applied in the direction of optical testing flaws/defects, material magnetic variables, etc., can solve problems such as stagnation of leveling rolls, waiting rolls, and unqualified product quality, so as to avoid quality substandard and reduce waiting rolls.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

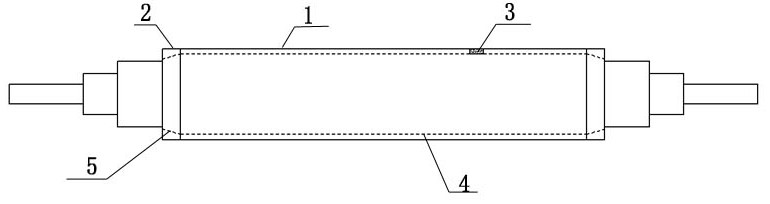

[0015] The final process of cold-rolled stainless steel strip needs to pass through the tempering machine to level the surface of the stainless steel. If the leveling roll in the tempering machine has some defects, the stainless steel surface after the tempering machine will still be uneven and cannot meet the requirements. .

[0016] In the actual use process, if there are some tiny cracks and other defects on the surface of the leveling roller, it is difficult to detect them, resulting in unqualified product quality.

[0017] This embodiment provides a method for non-destructive detection and repair of cracks on the surface of the leveling roll, specifically as follows

[0018] First, eddy current flaw detection is used to detect whether there is a crack in the middle of the leveling roll surface. The middle part of the leveling roll surface refers to the area composed of points on the effective surface of the leveling roll to the edge of the effective surface with a distanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com