Method for producing temperature-resisting, anti-seismic and antibacterial compound polyethylene water supply pipe

A technology for water supply pipes and production methods, which is applied in the direction of tubular objects, applications, household appliances, etc., can solve the problems of difficult pipe forming and processing, weak impact resistance, poor antibacterial performance, etc., and achieve safe and reliable use, strong impact resistance, Anti-aging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

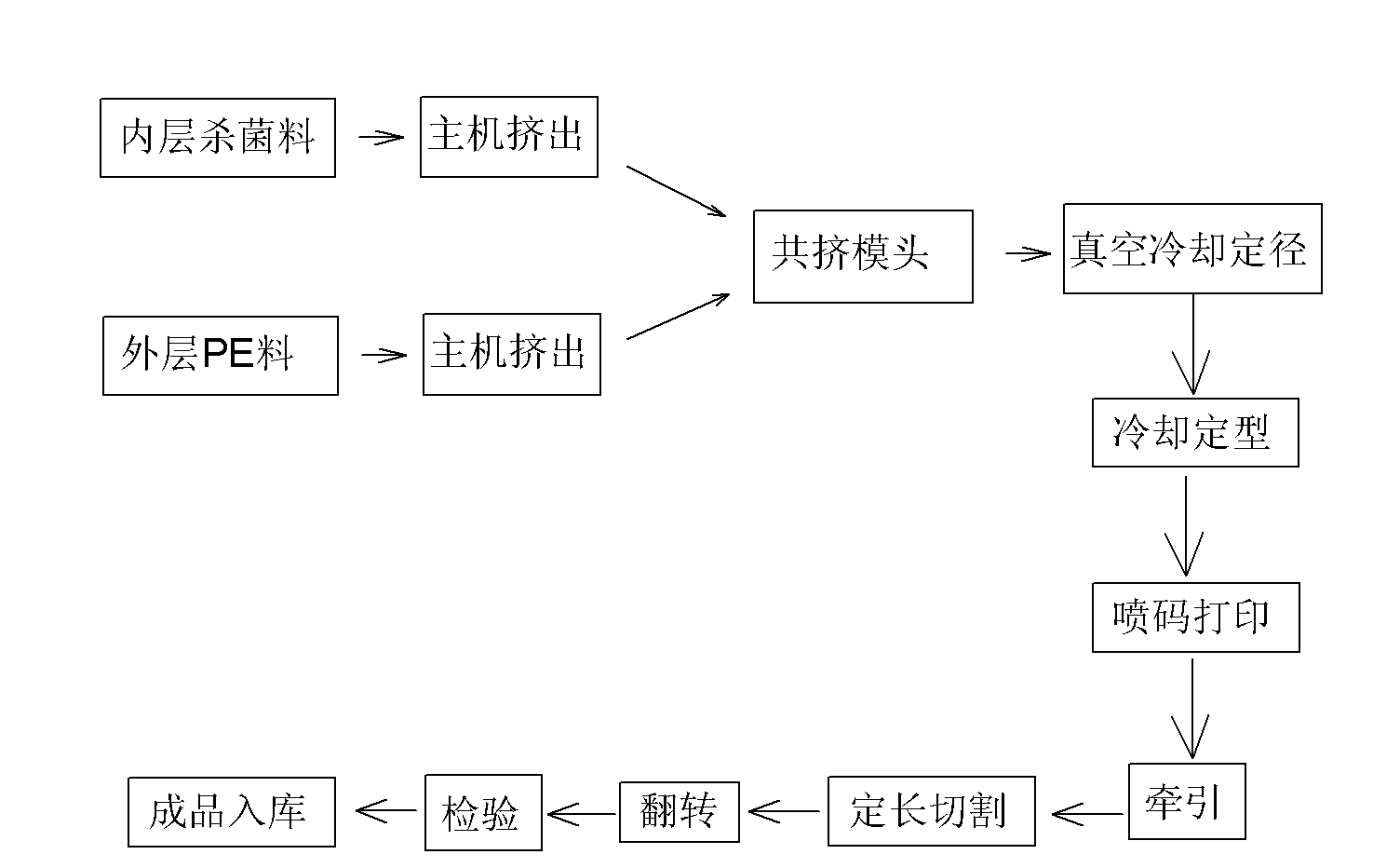

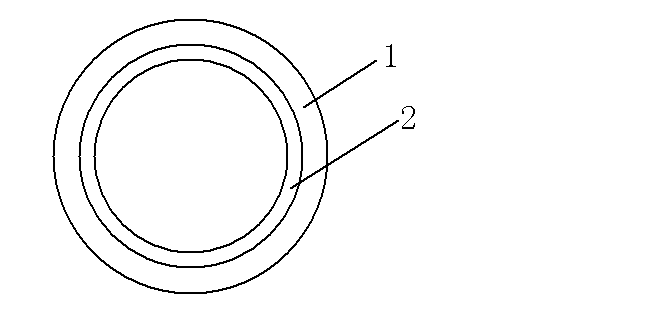

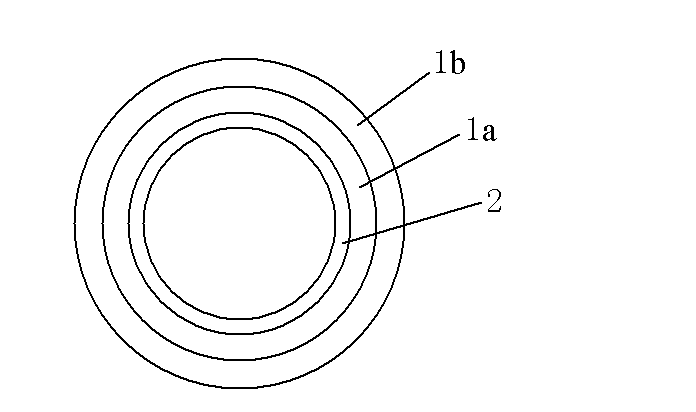

[0013] When the present invention is actually implemented, the polyolefin PE outer layer and the polyolefin PERT inner layer are respectively extruded and heated by an extruder, and then extruded from the same extrusion die by the polyolefin PE outer layer and the polyolefin PERT inner layer. Two-layer co-extruded composite pipe with adjacent layers tightly bonded, in which the length of the barrel area of the extruder for the outer layer of polyolefin PE and the inner layer of polyolefin PERT is divided into 4 sections, and the temperature of each section is: 1st The first section is 168°C, the second section is 173°C, the third section is 178°C, and the fourth section is 180°C. The length of the die head in the die area of the extruder is divided into 7 sections, and the temperature of each section is: Section 1 188°C, 182°C for the 2nd stage, 180°C for the 3rd stage, 190°C for the 4th stage, 195°C for the 5th stage, 200°C for the 6th stage, 205°C for the 7th stage, extru...

Embodiment 2

[0015] In the present invention, the outer layer of polyolefin PE and the inner layer of polyolefin PERT are respectively extruded and heated by an extruder, and then extruded from the same extrusion die by two layers of the outer layer of polyolefin PE and the inner layer of polyolefin PERT. Composite pipes extruded and closely bonded adjacent layers, in which the length of the barrel area of the extruder for the outer layer of polyolefin PE and the inner layer of polyolefin PERT is divided into 4 sections, and the temperature of each section is: the first section is 173 ℃, the second section is 178°C, the third section is 183°C, the fourth section is 185°C, the length of the die head in the die area of the extruder is divided into 7 sections, and the temperature of each section is: the first section is 193°C , the second stage is 187°C, the third stage is 185°C, the fourth stage is 195°C, the fifth stage is 200°C, the sixth stage is 205°C, the seventh stage is 210°C, the ...

Embodiment 3

[0017] In the present invention, the outer layer of polyolefin PE and the inner layer of polyolefin PERT are respectively extruded and heated by an extruder, and then extruded from the same extrusion die by two layers of the outer layer of polyolefin PE and the inner layer of polyolefin PERT. Composite pipes extruded and closely bonded adjacent layers, in which the length of the barrel area of the extruder for the outer layer of polyolefin PE and the inner layer of polyolefin PERT is divided into 4 sections, and the temperature of each section is: the first section is 178 ℃, the second section is 183°C, the third section is 188°C, the fourth section is 190°C, the length of the die head in the die area of the extruder is divided into 7 sections, and the temperature of each section is: the first section is 198°C , the second stage is 192°C, the third stage is 190°C, the fourth stage is 200°C, the fifth stage is 205°C, the sixth stage is 210°C, the seventh stage is 215°C, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com