Combusting system, remodeling method for combusting system, and fuel injection method for combusting system

一种燃烧装置、燃料喷射的技术,应用在燃烧方法、燃烧器安全装置、燃气轮机装置等方向,能够解决着火失败等问题,达到提高可靠性、提高环境性能的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

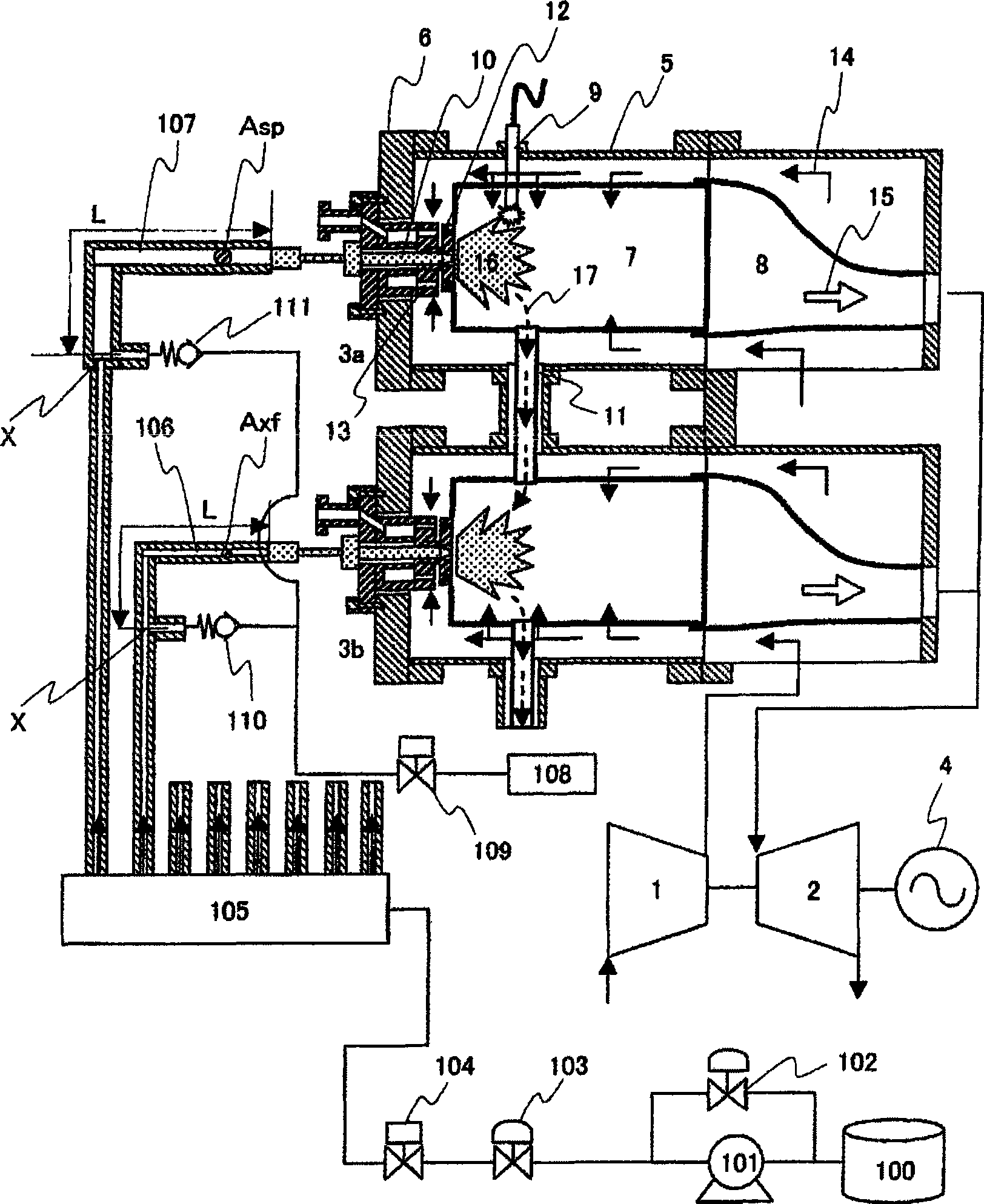

[0022] Below, refer to Figure 1 to Figure 4 with Figure 8 Example 1 will be described. This embodiment is an example where the combustion device is applied to a gas turbine.

[0023] figure 1 It is a schematic configuration diagram schematically showing the overall configuration of a gas turbine plant including the gas turbine combustor of the first embodiment. Such as figure 1 As shown, the gas turbine plant mainly includes: a compressor 1 that compresses air to generate high-pressure combustion air; a plurality of burners 3a that generate combustion gas 15 by mixing combustion air 14 introduced from the compressor 1 with fuel; 3b; and the turbine 2 that introduces the combustion gas 15 generated by the burners 3a, 3b. In addition, in figure 1 In the brief structural diagram, only two are represented in the 10 burners described later. Also, the shafts of the compressor 1 and the turbine 2 are connected.

[0024] The combustors 3a, 3b seal the following parts with th...

Embodiment 2

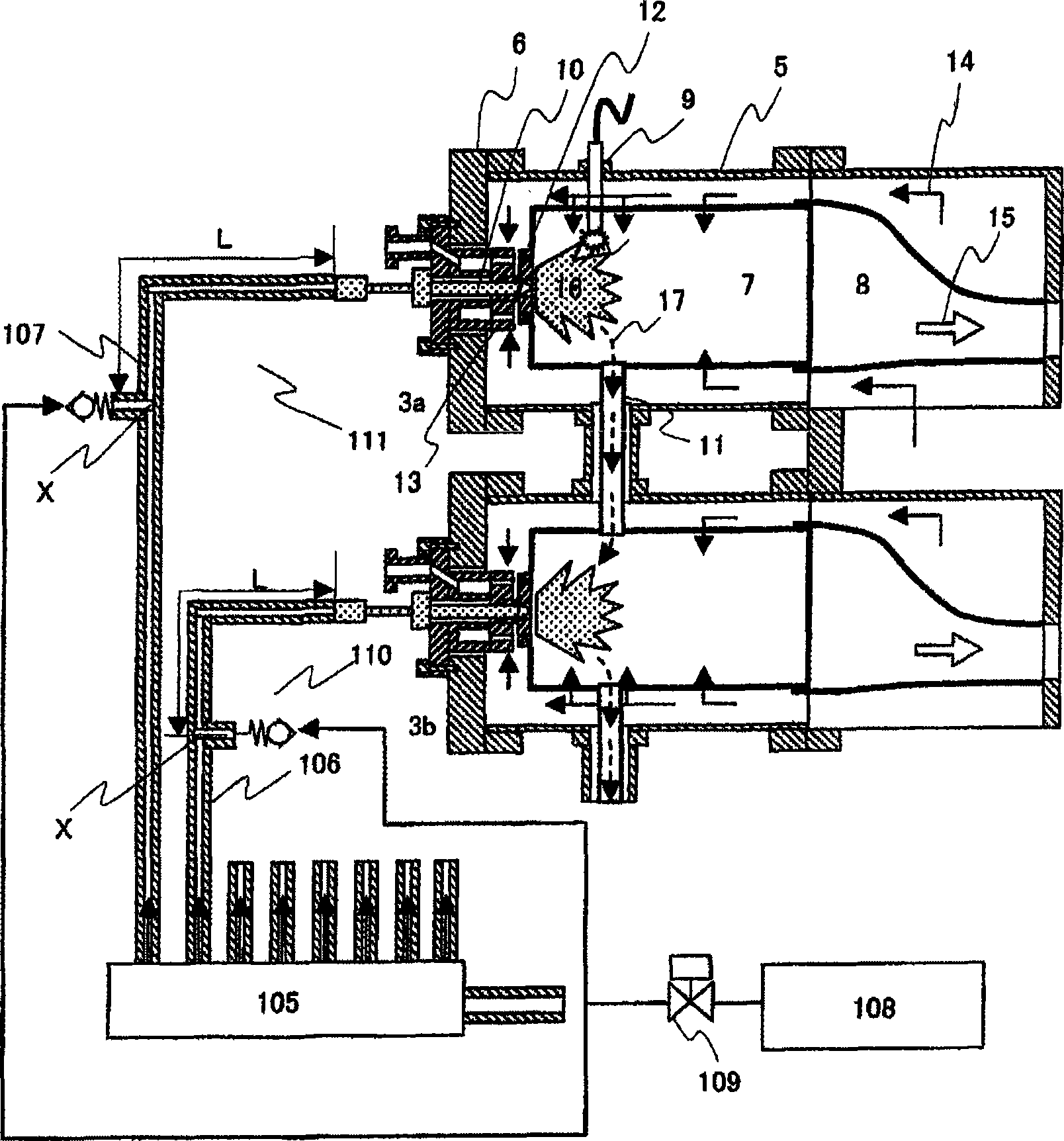

[0053] Below, refer to Figure 5 Example 2 will be described.

[0054] The basic components of the burner of the present embodiment have the same structure as that of the first embodiment. In the present embodiment, by forming the point X2 on the upstream side of the point X1, the fuel pipe 107 from the connection portion (point X2) of the fuel purification system of the burner 3a provided with the spark plug 9 to the inlet of the fuel nozzle The length L2 of is made longer than the length L1 of the fuel pipe 106 from the connection portion (X1 point) of the fuel purification system of the burner 3b without a spark plug to the fuel nozzle inlet.

[0055] According to the embodiment of the present invention constituted in this way, the volume of the fuel pipe 107 of the burner 3a having an ignition device can be made larger than the volume of the fuel pipe 106 of the burner 3b without an ignition device. 1 to the same effect.

[0056] In addition, in Embodiment 1, since the ...

Embodiment 3

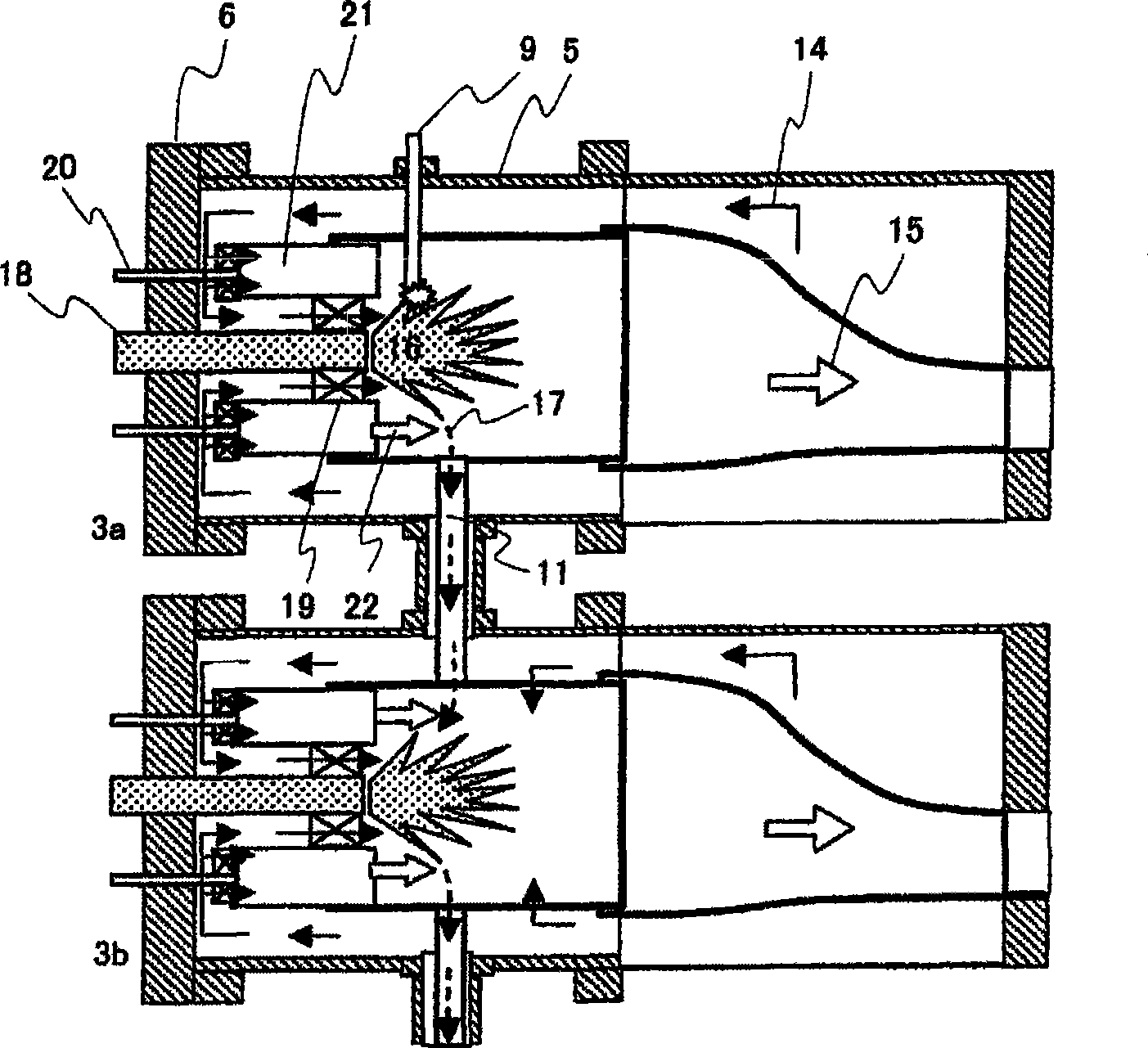

[0059] Below, refer to Image 6 Embodiment 3 of the present invention will be described.

[0060] The burner of this embodiment is the same as that of Embodiment 2, and the cross-sectional areas of the fuel pipes 106, 107 of all the burners 3a, 3b are the same. The present embodiment is different in that the connection position for connecting the fuel purification system to the fuel piping is also the same. Let the piping distance from the connecting portion of the fuel purification system and the fuel piping to the fuel nozzle inlet be L3. Furthermore, in this embodiment, the three-way valve 113 is provided only on the upstream side of the fuel pipe 107 of the burner 3a provided with the spark plug 9 at a distance L4 (L3

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com