Manufacturing method of high-temperature jet steel

A manufacturing method and high-performance technology, applied in the manufacturing field of high-performance jet steel, can solve the problems of steel ductility, anti-chipping and anti-cracking performance, affecting the quality of die steel, etc., to achieve excellent toughness and wear resistance, impact The effect of toughness improvement and overall performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

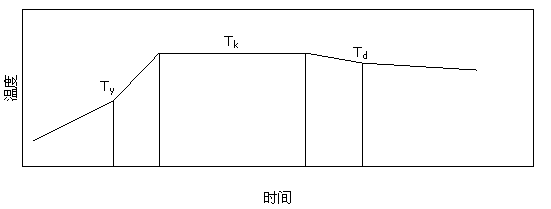

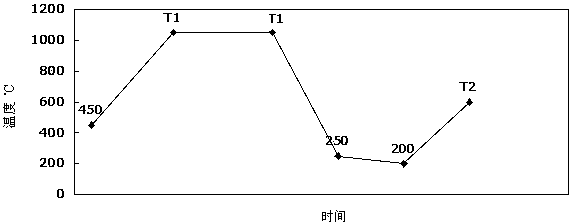

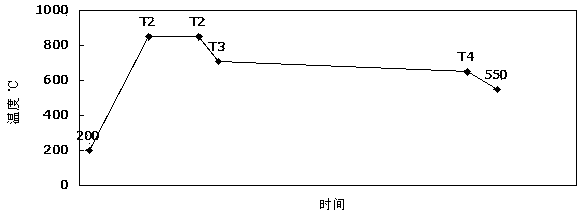

[0027] The manufacturing method of the high-performance sprayed steel involved in the present invention has a design idea that in the subsequent processing steps of the sprayed steel, there is a homogenization treatment step for eliminating the nitrogen in the internal voids of the sprayed steel. In this embodiment, however, the steps of subsequent treatment of sprayed steel include an isothermal annealing step, a strong forging step and a complete annealing step, and the homogenization step is arranged between the isothermal annealing step and the strong forging step. In addition, in this embodiment, in order to further improve the performance of sprayed steel and solve the problem of coarse grains caused by long-time high temperature, a grain refinement step is also set between the strong forging step and the complete annealing step.

[0028] Based on the above description, the overall process flow of the high-performance spray steel manufacturing method of the present embodi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com