Flexible gear with destressing holes and preparation technology thereof

A preparation process and stress-relieving technology, which is applied to components with teeth, mechanical equipment, belts/chains/gears, etc., can solve the problems of incomplete release of internal stress, low service life of flexible wheels, and high processing difficulty, so as to improve the service life. , The effect of increasing the wall thickness of the product and improving the production yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

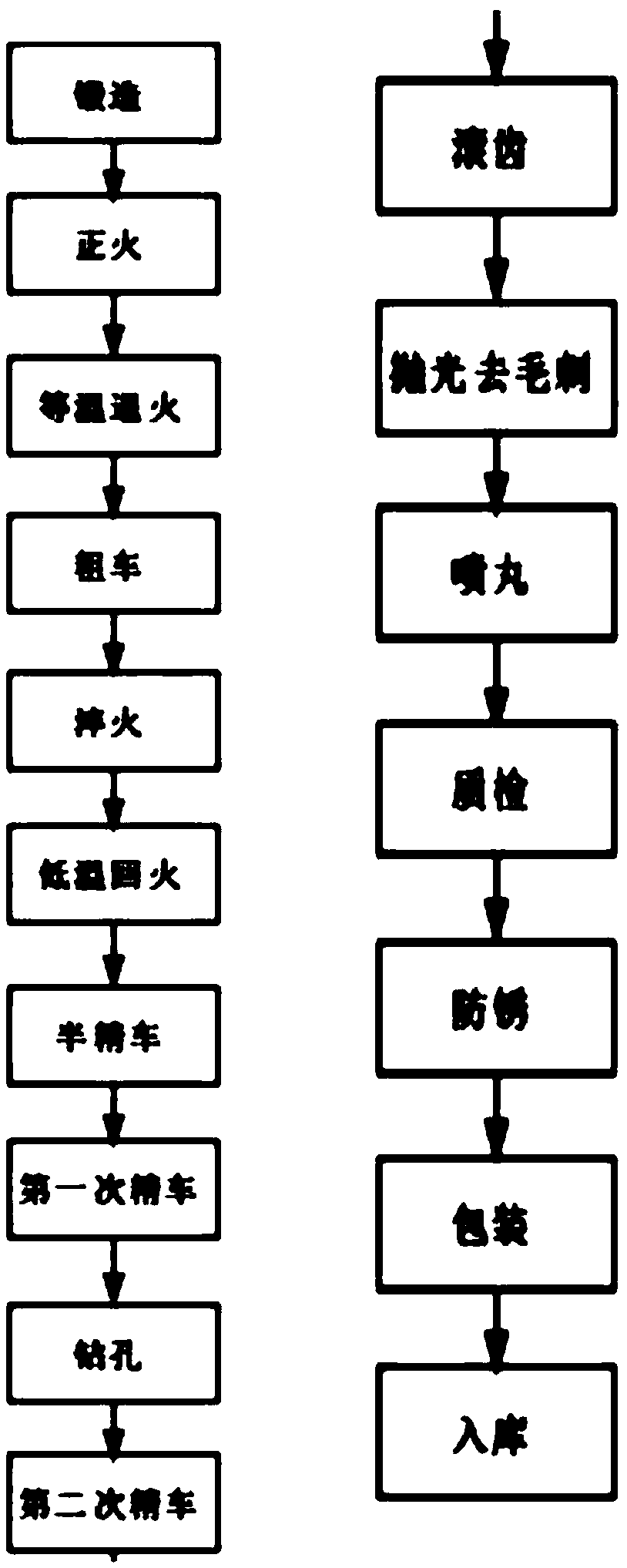

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below, and the exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

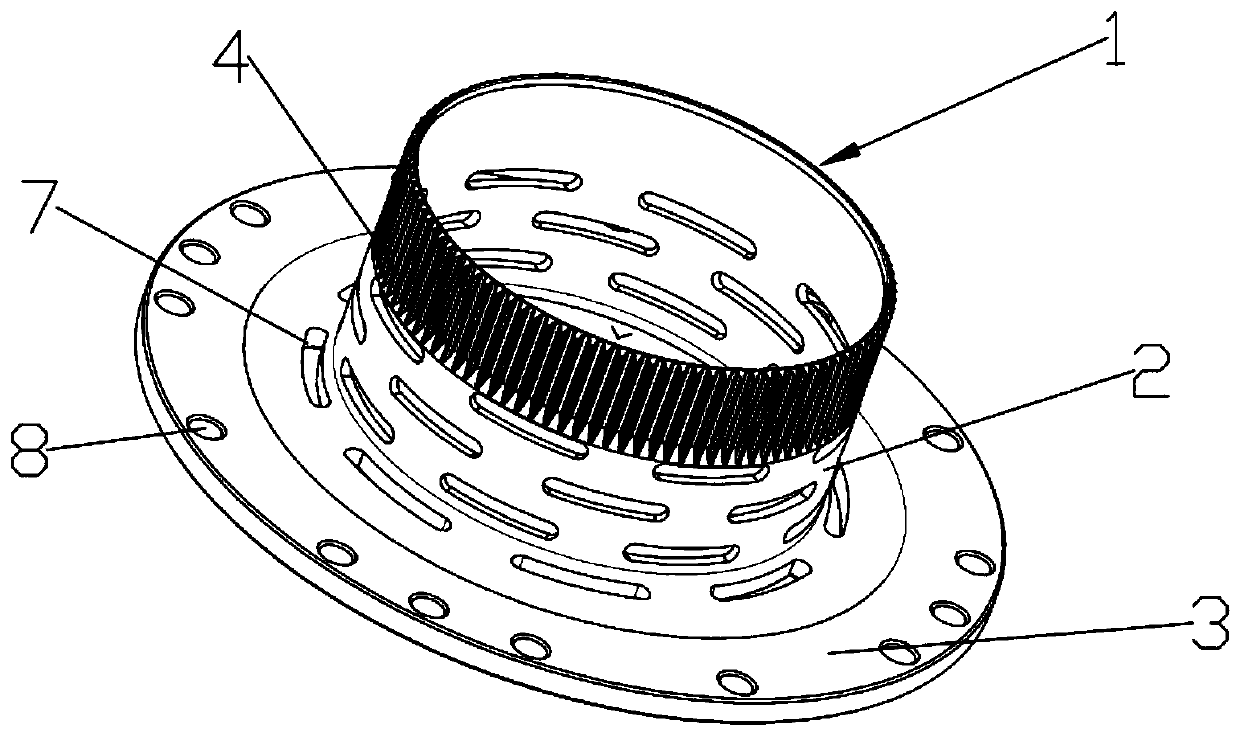

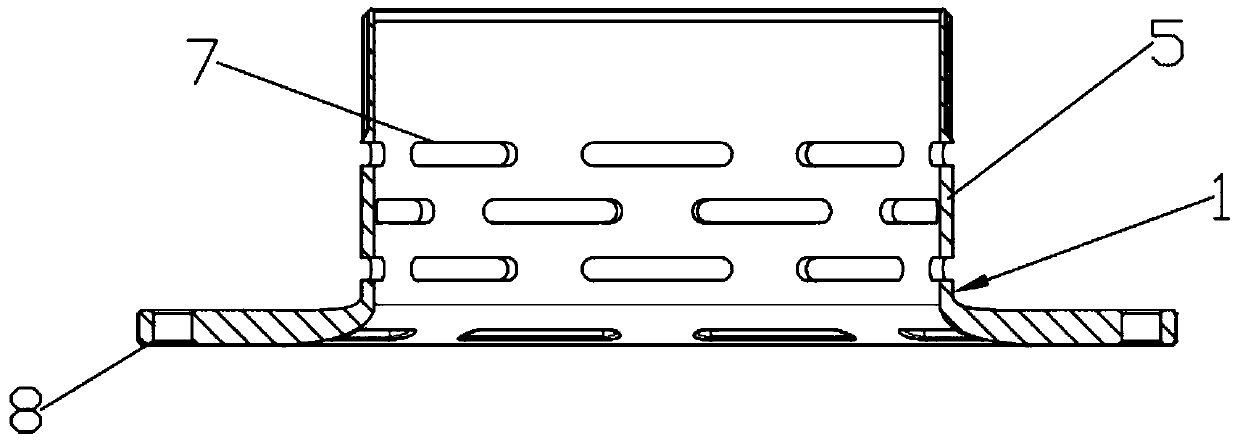

[0033] see figure 1 with figure 2 As shown, the flexspline with stress relief holes of the present invention is used to reduce the stress generated by the flexspline during transmission, and includes a flexspline main body 1, which has a hollow structure, and the flexspline main body 1 includes a cylindrical body 2 and the fixed platform 3, the cylindrical body 2 is located above the fixed platform 3, the cylindrical body 2 is set along the inner diameter of the fixed platform 3, the flexspline main body 1 is provided with a positioning hole 8 and a stress relief hole 7, and the positioning hole 8 is located on the fixed platform 3 and along the edge of the fixed table 3, the flexible spline can be positioned on the harmonic reducer. It should be noted that ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com