Isothermal annealing device using gear blank forging waste heat

A technology of forging waste heat and isothermal annealing, used in heat treatment furnaces, manufacturing tools, heat treatment equipment, etc., can solve the problems of less application, less energy saving, low production efficiency, etc., and achieves a simple overall structure, which is conducive to cold finishing and production efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

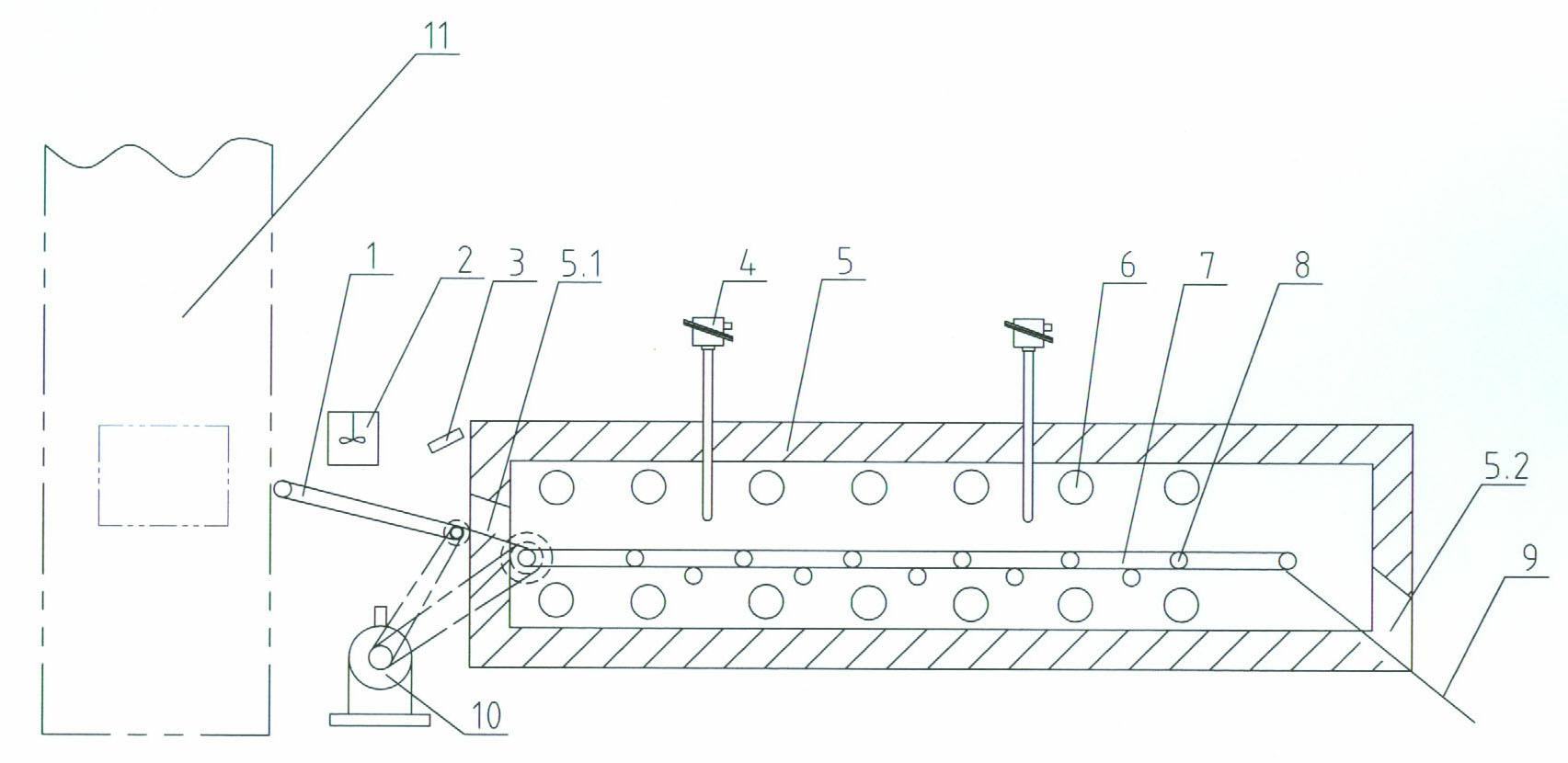

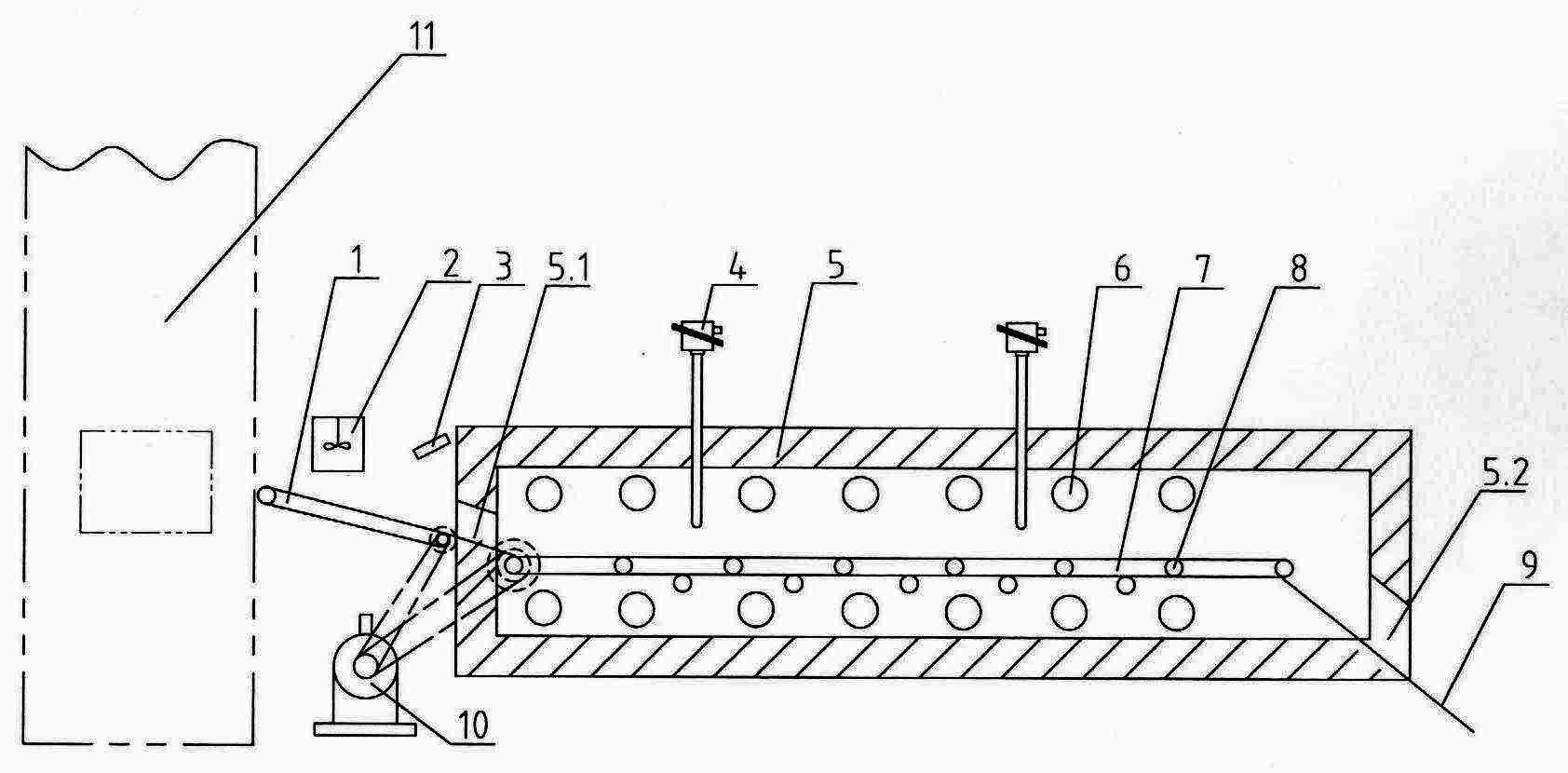

[0014] figure 1 The shown isothermal annealing device utilizing waste heat from tooth blank forging includes a temperature control component, an annealing furnace and a transmission mechanism. The temperature control components include an infrared thermometer 3 installed outside the annealing furnace, a matching fan 2, and a thermocouple 4 installed on the annealing furnace. The transmission mechanism is a belt transmission, which includes a transmission belt 1 driven by a reduction mechanism 10, a mesh belt 7, and an idler roller 8 supporting the mesh belt 7. The annealing furnace is a flat rectangular box-type furnace, and the annealing furnace is located next to the forging press 11. The end of the inlet 5.1 faces the forging press 11, and the other end is provided with an outlet 5.2 inclined downward. The upper and lower inner wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com