Hot work die steel and production method thereof

A technology of hot work die steel and steel plate, which is applied in the field of high alloy steel production, can solve the problems that the hardness and transverse and longitudinal performance ratio cannot meet the strict requirements of high-quality hot work die steel, and achieve the effect of excellent comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following examples are used to specifically illustrate the contents of the present invention, and these examples are only general descriptions of the contents of the present invention, and do not limit the contents of the present invention.

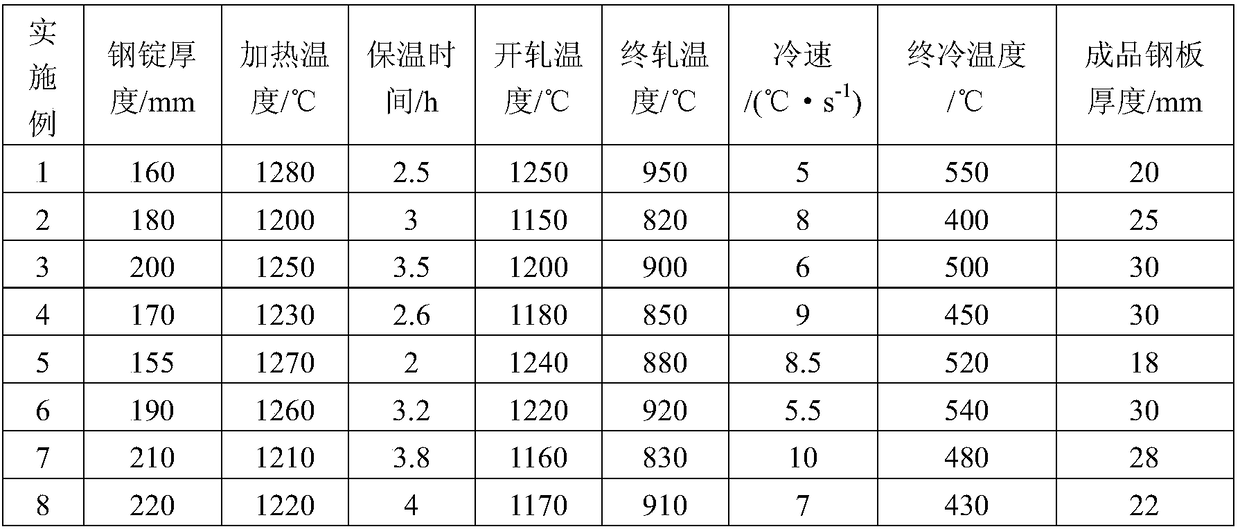

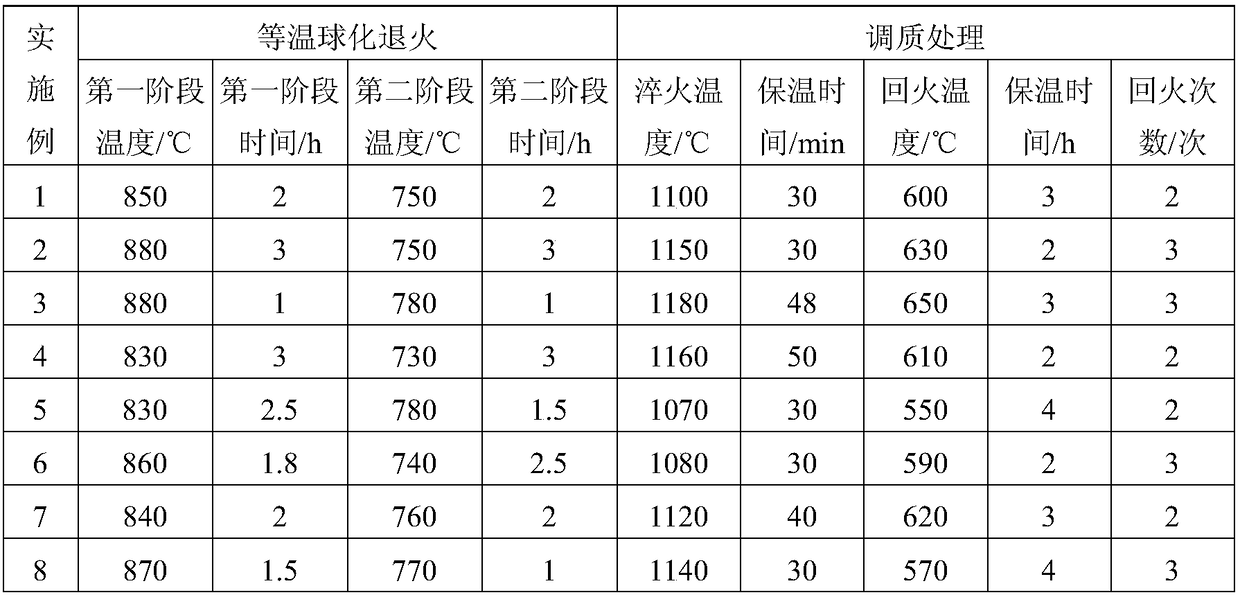

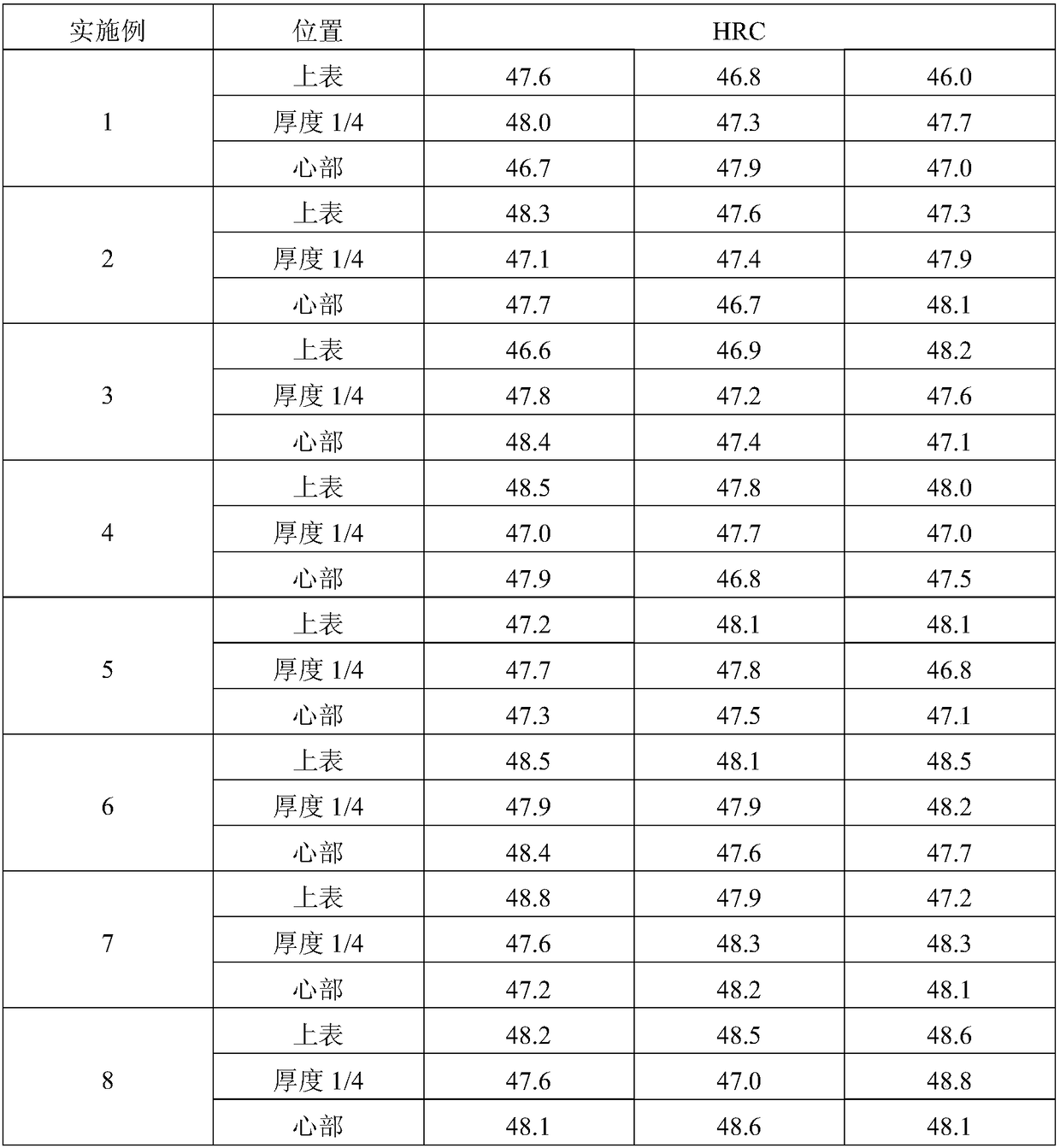

[0031] Table 1 is the chemical composition of the steel of the embodiment; Table 2 is the hot rolling process of the steel of the embodiment; Table 3 is the heat treatment process of the steel of the embodiment; Table 4 is the Rockwell hardness performance of the final steel plate; Table 5 is the hot work die steel Impact performance and isotropic performance.

[0032] Table 1 Chemical composition of the embodiment of the present invention, wt%

[0033] Example

C

Cr

Si

mn

Mo

V

P

S

Gd

La

Y

1

0.50

6.0

0.90

0.40

1.30

0.80

0.012

0.02

0.20

0.12

0.14

2

0.48

5.8

1.00

0.50

1.20

0.90

0.013

0.03

0.25

0.15

0.15

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com