Mechanical thread tapper

A technology of mechanical tapping and clamping holes, which is applied in the direction of thread cutting machines, metal processing equipment, thread cutting devices, etc., can solve the problems of extremely high requirements on tap materials, large instantaneous force on taps, and high difficulty in coaxial adjustment, so as to improve tapping High efficiency, reduced instantaneous force, and small tapping torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

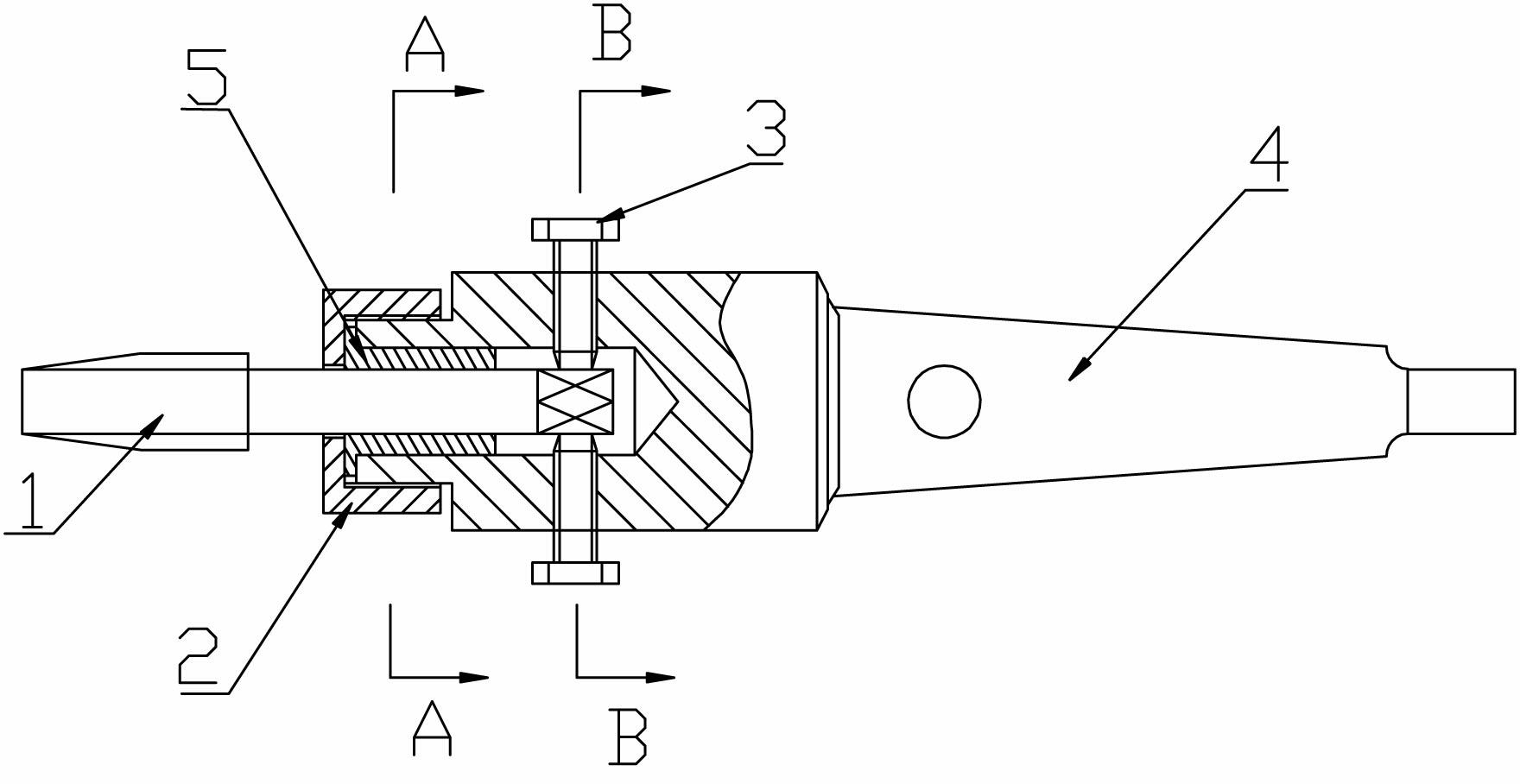

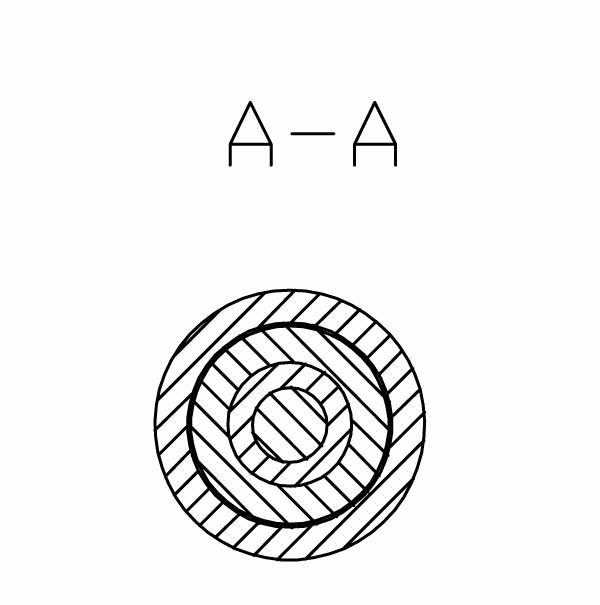

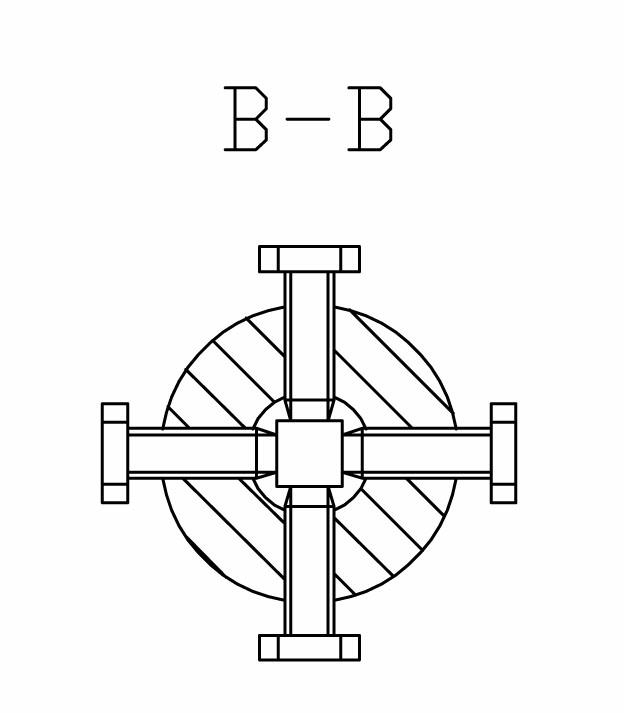

[0013] Such as figure 1 — image 3 Among them, a mechanical tapper, one end of the clamping body 4 is provided with a tapered rod, and one end of the tapered rod is provided with a clamping surface, which is characterized in that: the other end of the clamping body 4 is provided with a clamping hole, and the clamping hole A positioning sleeve 5 is installed through the clamping sleeve 2, and a plurality of positioning bolts 3 are installed at the same section position of the clamping hole.

[0014] The inner hole of the positioning sleeve 5 is coaxial with the outer cylindrical surface, and the outer cylindrical surface forms a clearance fit with the clamping hole.

[0015] The inner hole of the positioning sleeve 5 is in clearance fit with the outer cylindrical surface of the tap 1 .

[0016] There are four positioning bolts 3 .

[0017] The high-precision positioning sleeve 2 and the positioning bolt 3 used in the present invention cooperate to adjust the coaxial structur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com