Planar sawing machine

A sawing machine and plane technology, which is applied to metal sawing equipment, sawing machine devices, metal processing equipment, etc., can solve the problems of waste of raw materials, easy to produce defective products, and lower yield rate, and achieve low labor intensity, stable output, and good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

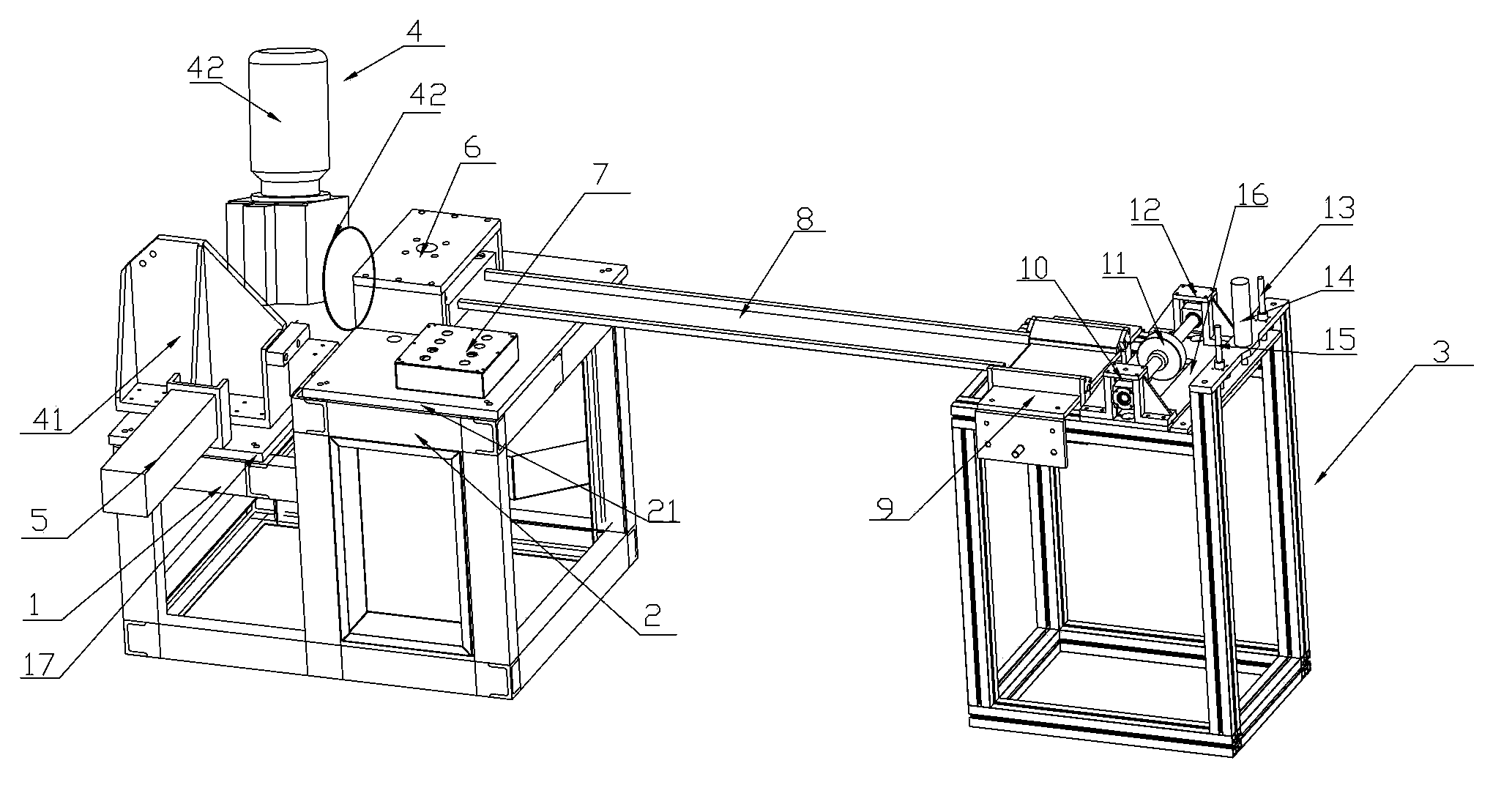

[0016] Embodiment 1: as figure 1 Shown a kind of planar sawing machine, comprise first support 1, second support 2, the 3rd support 3, sawing device 4, steel plate 8 and transmission device; Said sawing device 4 is arranged on the first support 1, The sawing device 4 includes a guide rail 5, a bracket 41, a motor 43 and a sawing machine 42; The guide rail 5 is arranged in the bracket 41; the sawing machine 42 is driven by a motor 43 arranged on the upper end of the sawing machine 42, and the supporting plate is divided into a first supporting plate 17, a second supporting plate 21 and a third supporting plate 16. The first supporting plate 17 is set on the first support 1, the second supporting plate 21 is set on the second support 2, the third supporting plate 16 is set on the first support 3, and the second supporting plate 21 is set on the first support 3. A pallet 17 is provided with a bracket 41; the transfer device is arranged on the third pallet 16 of the third support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com