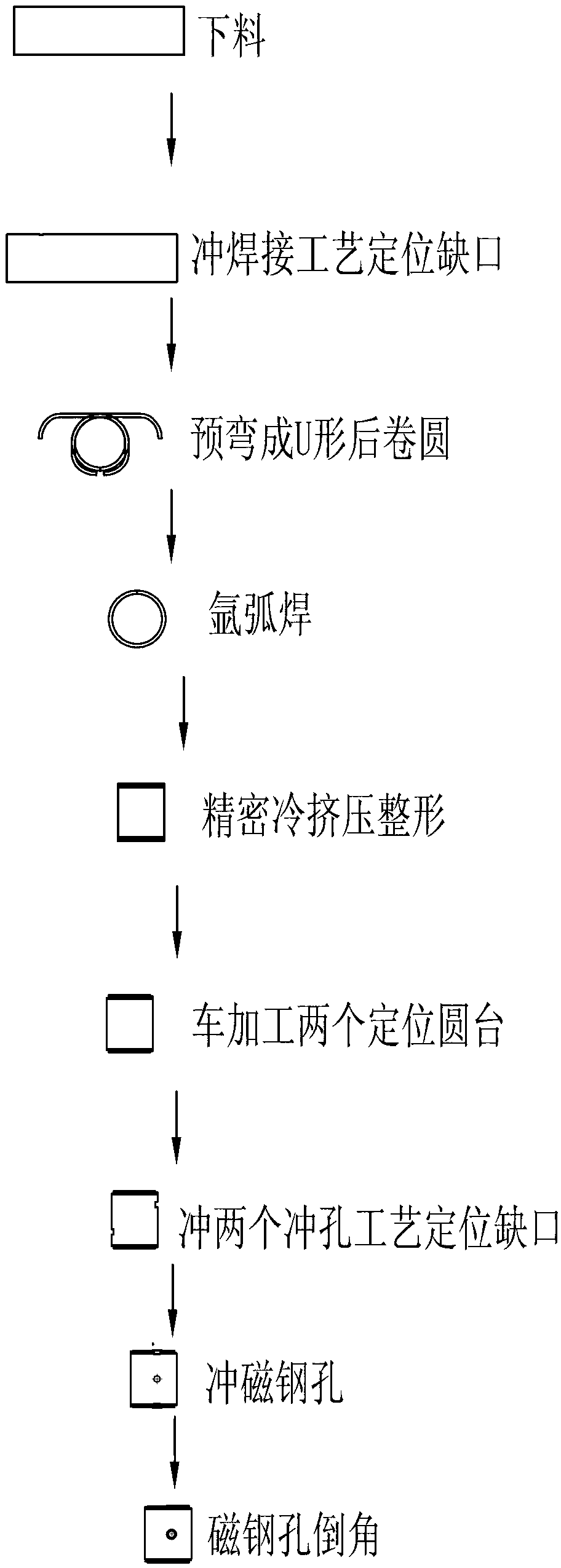

Machining process of automotive starter motor cases

A technology for starting motors and processing technology, which is applied in the direction of metal processing equipment, perforating tools, manufacturing tools, etc., which can solve the problems of numerous processing equipment, reduced starting efficiency, and high manufacturing cost, so as to improve automation level and work efficiency, and reduce residual magnetism coefficient, effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

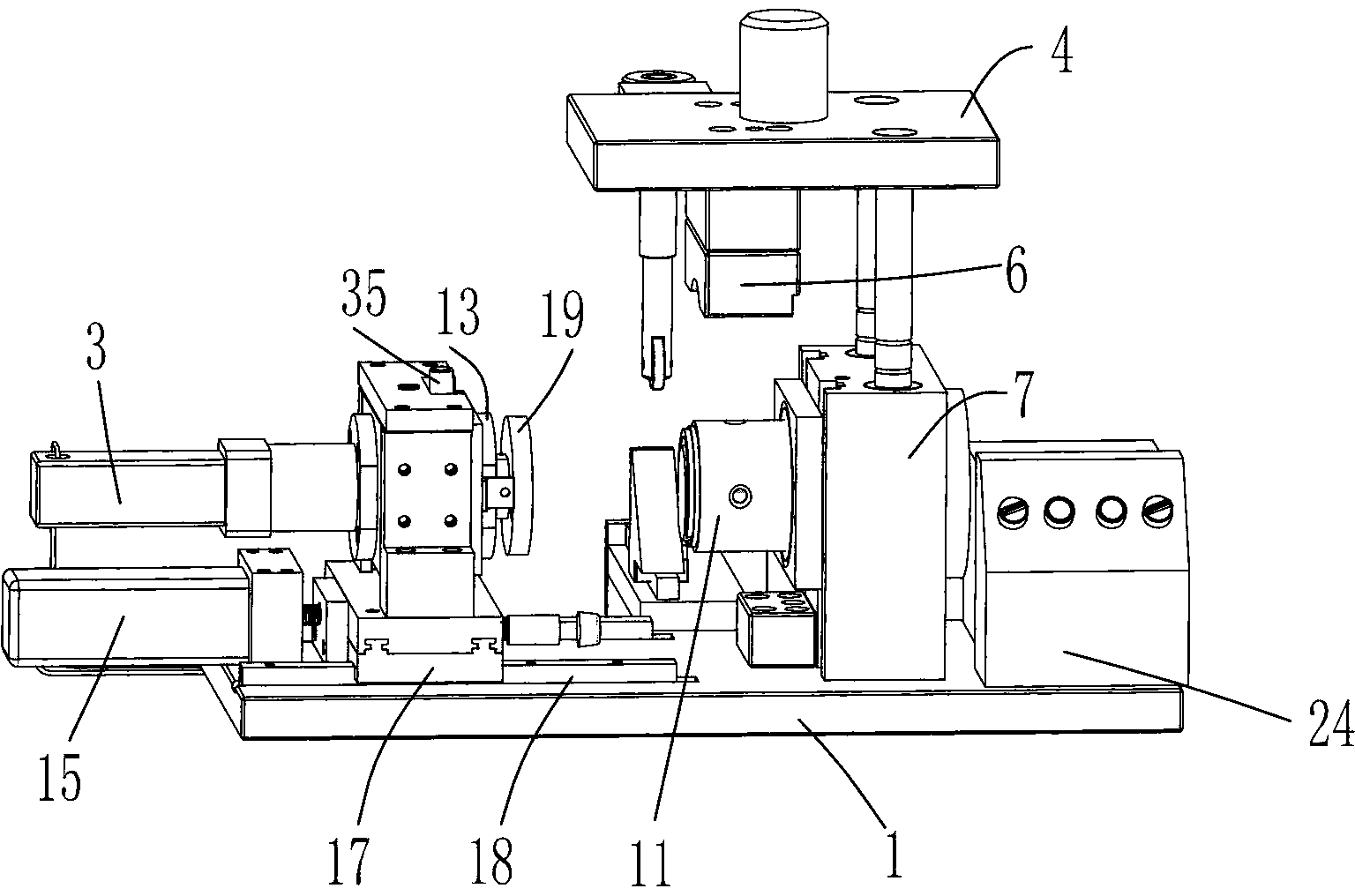

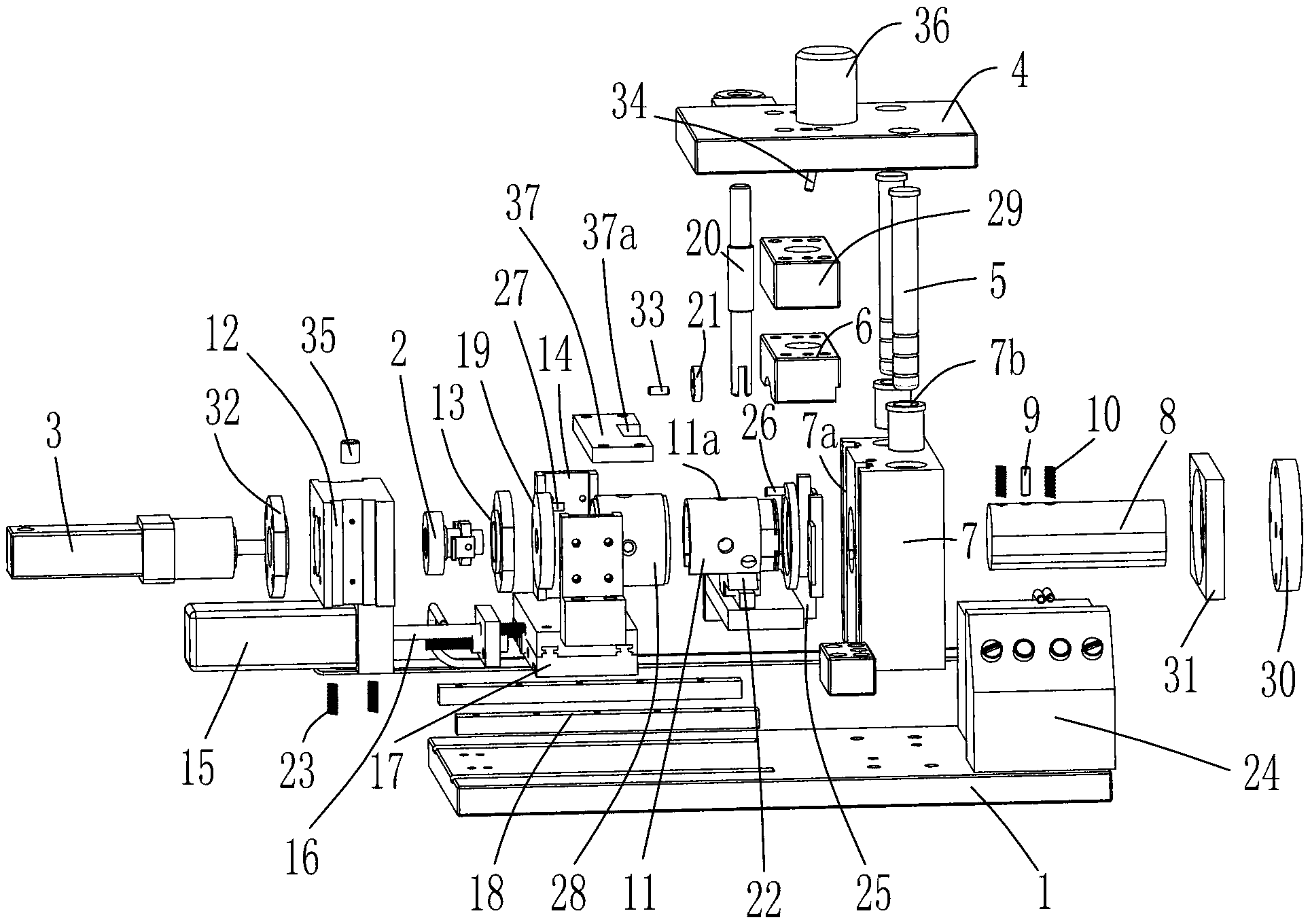

[0038] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0039] Such as Figure 4 ——The housing of the starter motor for vehicles shown in 7 is a cylinder with welded seams F rolled from hot-rolled steel plates, and four radial holes A uniformly distributed in the circumferential direction are punched on the cylinder for installing magnets. Steel, and the outer end of each radial hole A is provided with a chamfer. A left positioning round platform B is arranged on the outer circumference of the left end of the cylinder, and a left positioning notch C is punched on the left positioning round platform B. A right positioning round table D is arranged on the outer circumference of the right end of the cylinder, and a right positioning notch E is punched on the right positioning round table D. The number of radial holes A is not limited to four, and can be set as required. The left positioning round table B and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com