Preparation method of low-loss amorphous magnetic powder core

A magnetic powder core and low-loss technology, which is applied in the field of preparation of low-loss amorphous magnetic powder cores, can solve problems such as unclear loss, and achieve good DC superposition performance, low loss, and low magnetic loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The Fe-based amorphous strip prepared by the single-roll quick quenching method is subjected to an embrittlement heat treatment. Preferably, the Fe-based amorphous strip is an Fe-Si-B-C amorphous alloy, wherein the atomic mole percentage is: Si (1.5-3.5 at %), B (12-16 at %), C (1-2 at %), and the rest is Fe; the Fe-based amorphous strip is crushed mechanically and jet-milled to obtain Fe-based amorphous soft magnetic alloy powder ; Take 70 grams of amorphous soft magnetic alloy powder with a particle size of 100-200 mesh, 130 grams of 200-300 mesh, stir and mix; add phosphoric acid, nitric acid and chromic acid with a molar ratio of 1:0.8:0.5 and a mass fraction of 0.15% Mix the aqueous solution, stir continuously during the reaction, and react at 150°C for 1 hour; after the reaction is completed, add 0.3% mica powder and stir evenly, then add the mixed aqueous solution of water glass and potassium water glass and stir evenly, at 150°C Keep warm for 1 hour. Then add 2...

Embodiment 2

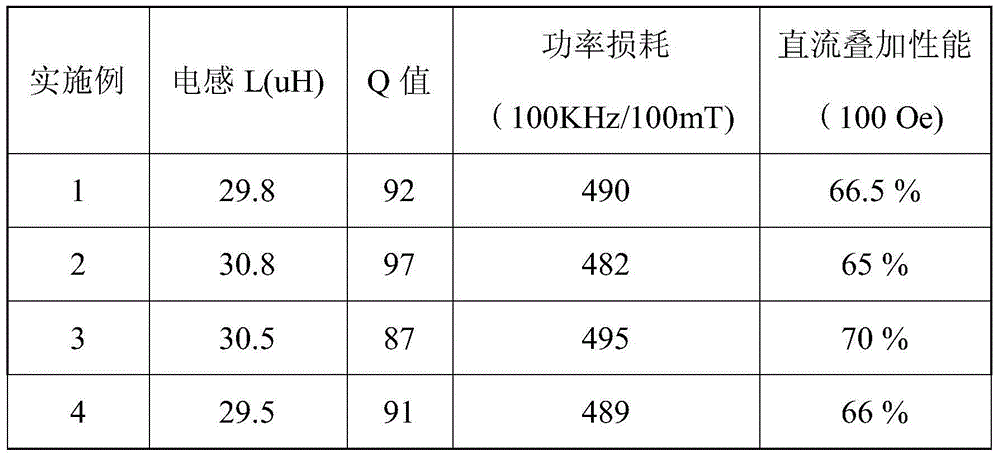

[0032] The preparation method of the amorphous magnetic powder core is the same as in Example 1, except that the mass fraction of the three acids in the formula is reduced to 0.1%, and the additions in the mixed acid solution are changed to 0.2% mica powder and 0.1% alumina powder after the reaction is completed. At the same time, in order to increase the median value of the inductance, the annealing temperature after molding is increased to 500±5°C. It can be seen from Table 1 that the power loss of this amorphous magnetic powder core is 482mW / cm 3 ; DC superposition performance is 65%.

Embodiment 3

[0034] The preparation method of the amorphous magnetic powder core is the same as in Example 1, except that the particle size distribution of the amorphous soft magnetic alloy powder in the formula is changed to 85 grams of 100-200 mesh magnetic powder, 115 grams of 200-300 mesh magnetic powder, stirred and mixed; , nitric acid and chromic acid mixed aqueous solution, at 120 ℃ for 0.5 hours. It can be seen from Table 1 that the power loss of this amorphous magnetic powder core is 495mW / cm 3 ; DC superposition performance is 70%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| core loss | aaaaa | aaaaa |

| core loss | aaaaa | aaaaa |

| core loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com