Magnetic pearlescent pigment with 3D (three-dimensional) effect and preparation method of magnetic pearlescent pigment

A pearlescent pigment, 3D effect technology, applied in inorganic pigment processing, chemical instruments and methods, fibrous fillers, etc., can solve the problems of affecting the color effect of pigments, weak surface magnetism of pigments, difficult to accurately control, etc., and achieve production economic benefits. Good, good magnetic properties, the effect of reducing the loss of ferric oxide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

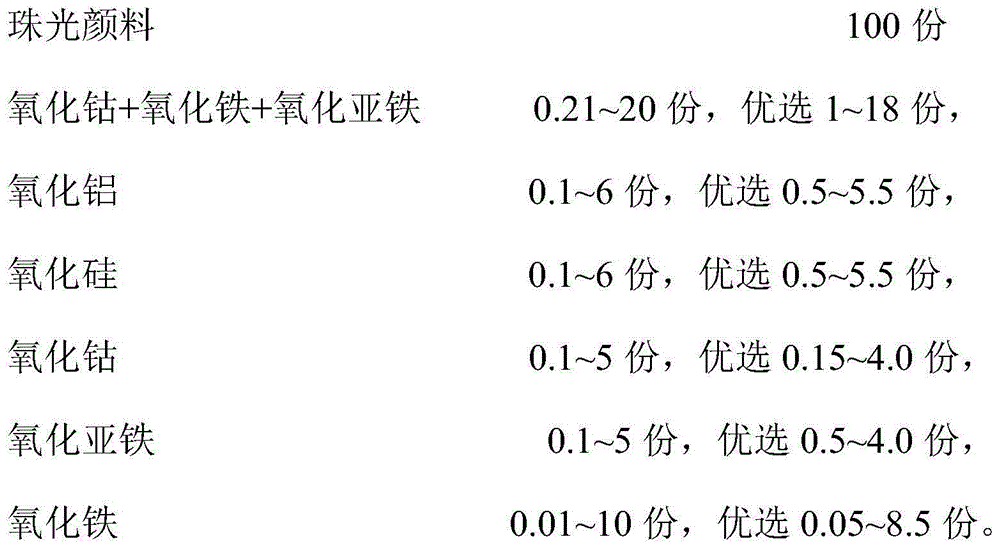

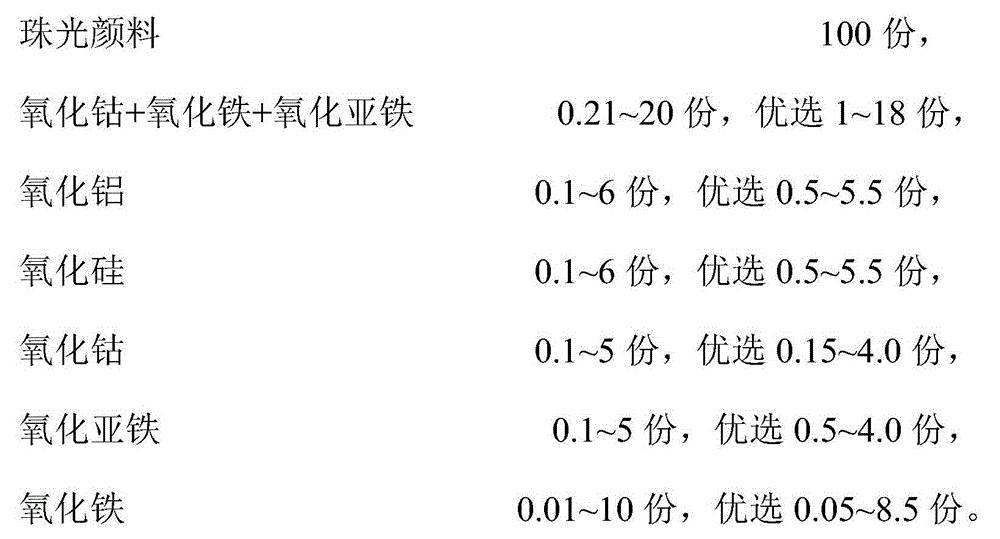

Method used

Image

Examples

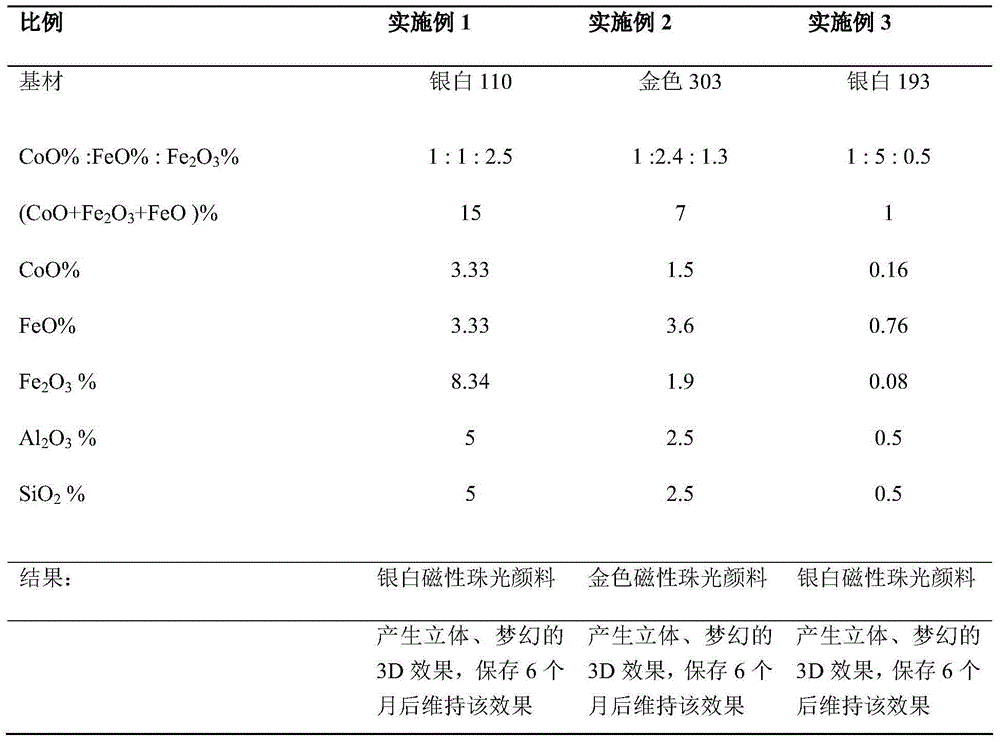

Embodiment 1

[0036] The finished pearlescent pigment is used as the base material to coat cobalt oxide, ferrous oxide and iron oxide in different proportions.

[0037] (1) Weigh 100g of QC110 silver pearlescent pigment (produced by Guangxi Qise Pearlescent Material Co., Ltd.), put it into a 1L reactor, add 800ml of deionized water, stir to make it evenly dispersed into a suspension.

[0038] (2) The suspension was heated in a constant temperature water bath and stabilized at 65°C, and the pH of the suspension was adjusted to 8.5 with a mass fraction of liquid caustic soda (liquid sodium hydroxide) of 31%.

[0039] (3) Adjust the temperature of the suspension to 75°C and the pH to 9.0. 10.93g CoCl 2 ·6H 2 O, 409.0mL FeCl 3 ·6H 2 O(75g / L) and 9.51g FeCl 2 ·4H 2 O is mixed and stirred to make a mixed solution, which is added dropwise at a rate of 0.75 ml / min while keeping the pH constant with sodium hydroxide solution. When the addition is completed, the pH is increased to 10 and stirred at constant...

Embodiment 2

[0049] The finished pearlescent pigment is used as the base material to coat cobalt oxide, ferrous oxide and iron oxide in different proportions.

[0050] (1) Weigh 100g of QC303 Royal Golden Finished Pearlescent Pigment, put it into a reactor with a volume of 1L, add 800ml of deionized water, stir to make it evenly dispersed into a suspension.

[0051] (2) The suspension was heated in a constant temperature water bath and stabilized at 65°C, and the pH of the suspension was adjusted to 8.5 with 31% liquid caustic soda.

[0052] (3) Adjust the temperature of the suspension to 75°C and the pH to 9.0. 4.833g CoCl 2 ·6H 2 O, 87.2mL FeCl 3 ·6H 2 O(75g / L) and 10.311g FeCl 2 ·4H 2 O was mixed and stirred to prepare a mixed solution. The mixed solution was added dropwise at a rate of 0.5ml / min while keeping the pH constant with an aqueous sodium hydroxide solution. When the addition was completed, the pH was raised to 10 and stirred at constant temperature for 15 minutes.

[0053] (4) Adjust...

Embodiment 3

[0062] The finished pearlescent pigment is used as the base material to coat cobalt oxide, ferrous oxide and iron oxide in different proportions.

[0063] (1) Weigh 100g of QC193 silver white pearlescent pigment, put it into a 1L reactor, add 800ml of deionized water, stir to make it evenly dispersed into a suspension.

[0064] (2) The suspension was heated in a constant temperature water bath and stabilized at 65°C, and the pH of the suspension was adjusted to 8.5 with 31% liquid caustic soda.

[0065] (3) Adjust the temperature of the suspension to 75°C and the pH to 9.0. 0.51g CoCl 2 ·6H 2 O, 4.5mL FeCl 3 ·6H 2 O(60g / L) and 2.12g FeCl 2 ·4H 2 O mix and add water to dilute to 10ml, add this mixture dropwise at a rate of 0.4ml / min while keeping the pH constant with an aqueous sodium hydroxide solution. When the addition is complete, raise the pH to 10 and stir at constant temperature for 15 minutes.

[0066] (4) Adjust the temperature of the suspension to 75°C, and adjust the pH to 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com