High-performance samarium-cobalt magnetic powder and preparation method thereof

A high-performance, samarium-cobalt technology, applied in the direction of magnetic materials, magnetic objects, inorganic materials, etc., to achieve the effect of promoting consistency, reducing magnetic loss, and increasing filling volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

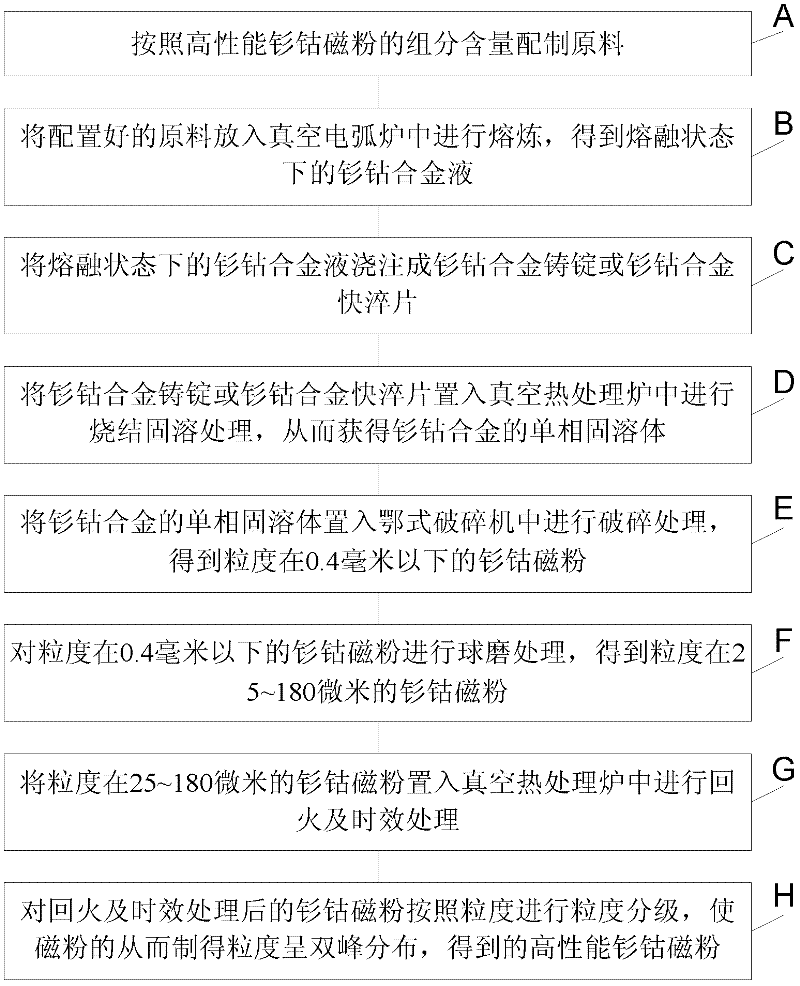

Method used

Image

Examples

Embodiment 1

[0099] As shown in Example 1 in Table 2, a high-performance samarium-cobalt magnetic powder has components including Sm, Co, Fe, Cu, Zr, Gd, V and Cr, and the mass fractions of each component in the total are: Sm accounts for 22 wt%, Co accounts for 47.5 wt%, Fe accounts for 20 wt%, Cu accounts for 5 wt%, Zr accounts for 3 wt%, Gd accounts for 1 wt%, V accounts for 1 wt%, and Cr accounts for 0.5 wt%. The specific preparation process of the high-performance samarium-cobalt magnetic powder includes the following steps:

[0100] In step a, according to the distribution scheme of the samarium cobalt magnetic powder composition listed in Example 1 in Table 2, select Sm, Co, Fe, Cu, Zr, Gd, V and Cr for batching. Wherein, each component in the above-mentioned proportioning scheme should be a pure raw material with an impurity content of no more than 0.01 wt%, so as to avoid the actual component content deviating from the above-mentioned proportioning scheme, so when selecting the ra...

Embodiment 2

[0120] As shown in Example 2 in Table 2, a high-performance samarium-cobalt magnetic powder has components including Sm, Co, Fe, Cu, Zr, Er, Mn and Cr, and the mass fractions of each component in the total are: Sm accounts for 26 wt%, Co accounts for 48.5 wt%, Fe accounts for 16 wt%, Cu accounts for 6 wt%, Zr accounts for 2 wt%, Er accounts for 0.5 wt%, Mn accounts for 0.5 wt%, and Cr accounts for 0.5 wt%. The specific preparation method of the high-performance samarium-cobalt magnetic powder is consistent with the samarium-cobalt magnetic powder method described in Example 1.

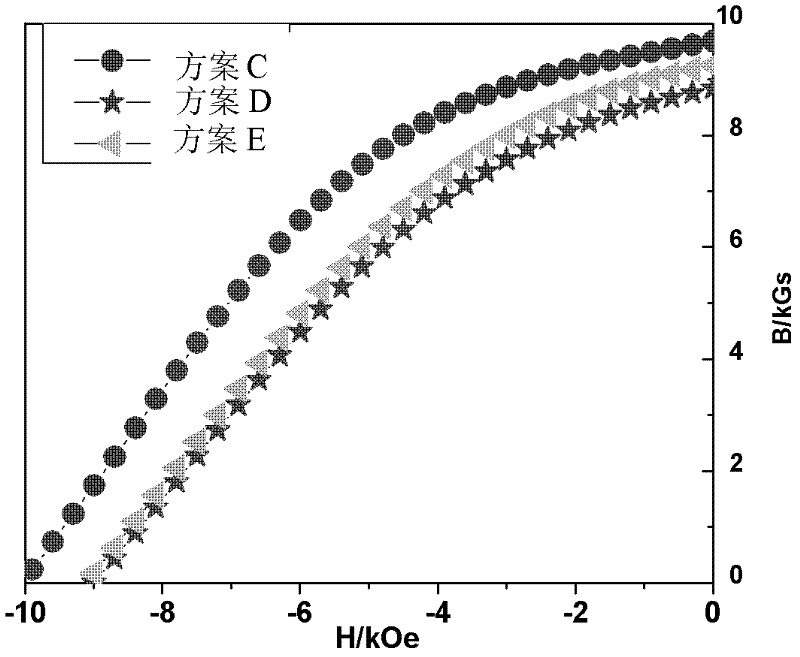

[0121] Multiple comparative experiments show that: as shown in Table 4 and image 3 As shown, scheme C adopts the samarium-cobalt magnetic powder composition ratio scheme and samarium-cobalt magnetic powder preparation method provided in this example; the samarium-cobalt magnetic powder composition ratio scheme of scheme D is the same as scheme C, but the samarium-cobalt magnetic powder preparation met...

Embodiment 3

[0126] As shown in Example 3 in Table 2, a high-performance samarium-cobalt magnetic powder has components including Sm, Co, Fe, Cu, Zr, Ho, Mn and V, and the mass fractions of each component in the total are: Sm accounts for 25 wt%, Co accounts for 47.6 wt%, Fe accounts for 20 wt%, Cu accounts for 5 wt%, Zr accounts for 1 wt%, Ho accounts for 0.4 wt%, Mn accounts for 0.3 wt%, and V accounts for 0.7 wt%. The specific preparation method of the high-performance samarium-cobalt magnetic powder is consistent with the samarium-cobalt magnetic powder method described in Example 1.

[0127] Multiple comparative experiments show that: as shown in Table 5, Figure 4 and Figure 5 As shown, scheme F adopts the composition ratio scheme of samarium cobalt magnetic powder and the preparation method of samarium cobalt magnetic powder provided in this embodiment; the composition ratio scheme of samarium cobalt magnetic powder of scheme G is the same as scheme F, and the preparation method o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com