Non-axis motor

A shaftless and casing-less technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems that the efficiency of the mud pump cannot be exerted, the frictional heat cannot be effectively dissipated, and the normal operation of the mud pump is affected, so as to overcome the inability to synchronize Good operation and cooling effect, low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

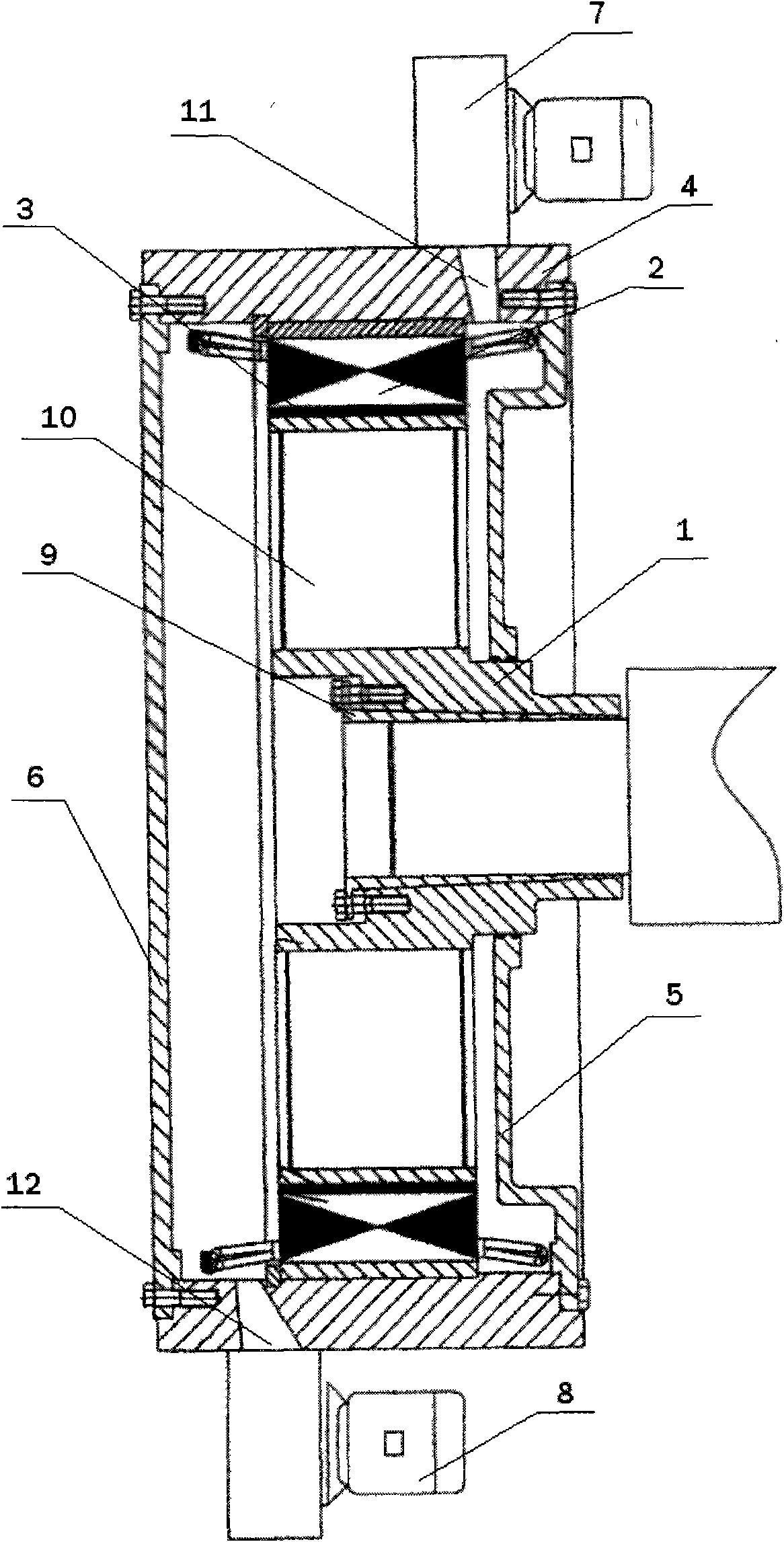

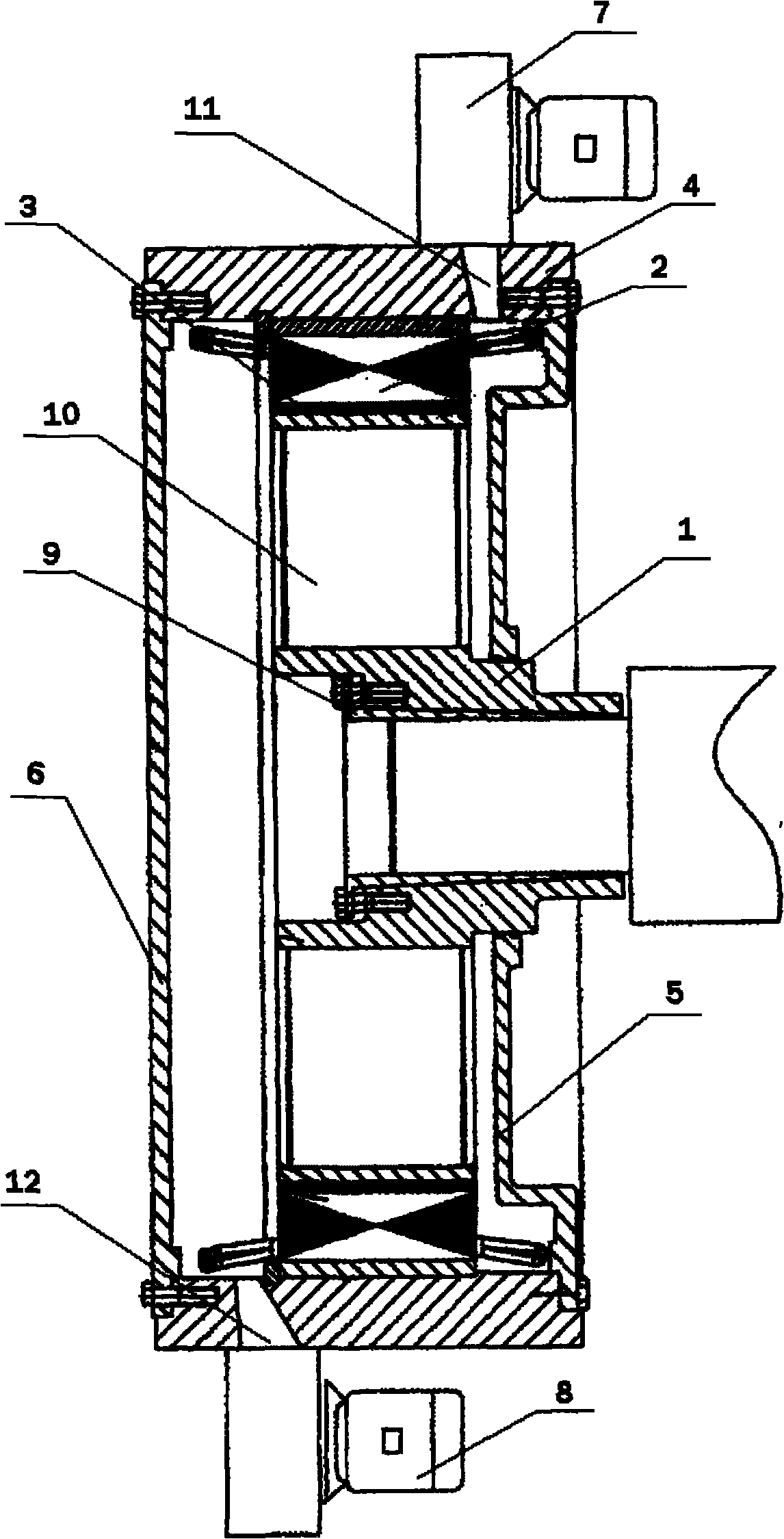

[0010] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0011] As shown in the figure, the shaftless motor is mainly composed of a rotor 1, a stator 2, a permanent magnet block 3, a casing 4, an inner end cover 5, an outer end cover 6, a blower 7 and a suction fan 8. There is an installation cavity in the spoke-type rotor, and a slightly sleeve 9 connected thereto can be arranged in the installation cavity, so that the rotor and the shaft of the mud pump are closely matched. Rotor auxiliary iron 10 is arranged on the outside of the rotor. On the outer surface of the rotor auxiliary iron, there are permanent magnet blocks evenly spaced according to N and S levels. There is a winding stator outside the permanent magnet block, and an organic casing is installed outside the stator. The two ends are respectively fixedly connected with the inner end cover and the outer end cover, and the inner end cover is fixed on the equipment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com