Magnetic element and its manufacture, power supply module therewith

A technology of magnetic components and magnetic components, applied in the direction of inductance with magnetic core, inductance/transformer/magnet manufacturing, coil manufacturing, etc., can solve the problems of lack of mass production and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

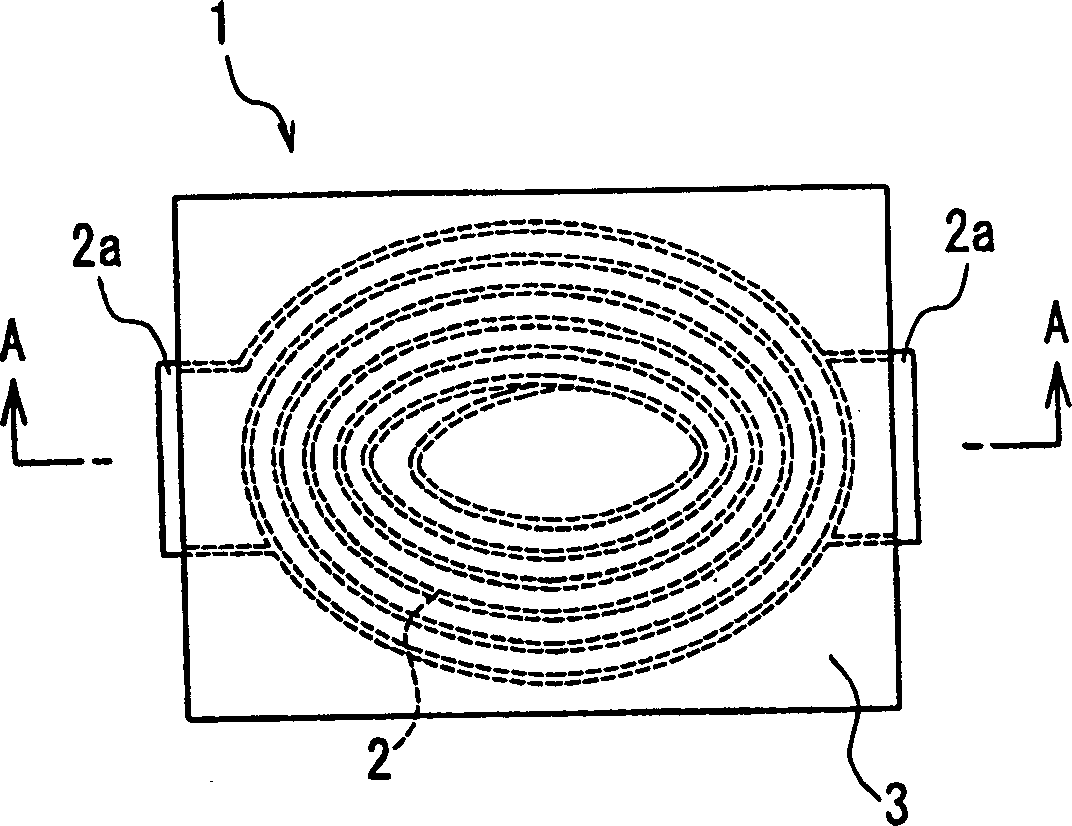

Embodiment 1

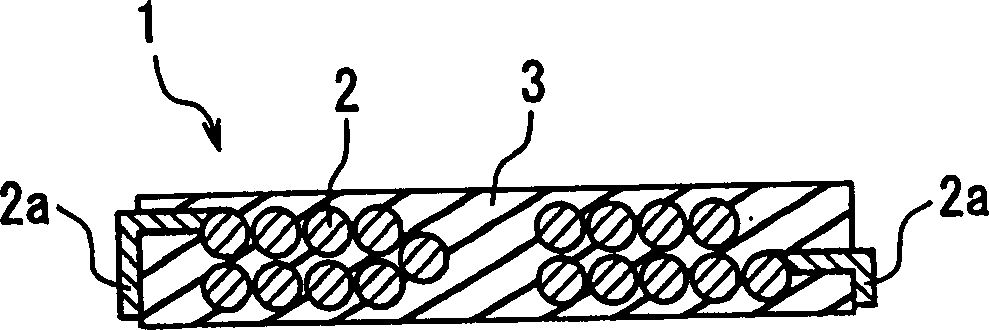

[0114] Two Fe-based amorphous thin bodies (METGLAS-26055C (manufactured by Hanewell Corporation, USA)) having a corner of 4 mm and a thickness of 20 μm were prepared as the first magnetic member 4 . As the second magnetic member 5, 14 wt. % After being made into a paste, shape it into a sheet with a doctor blade, heat and dry at 80° C. for 1 hour, and prepare a composite sheet with a thickness of about 310 μm. The chip coil 1 is a chip coil formed as follows: a tape with an outer diameter of 4.0mmφ, an inner diameter of 0.5mmφ, a thickness of 300μm, a conductor diameter of about 100μm, and a DC resistance of 170mΩ produced by an insulating material embedding plating method. Two stacked 18-turn conductor coils covered in insulation, formed into a sheet. The chip coil covers the conductor coil with an insulating substance having a lower magnetic permeability than the composite sheet used in the second magnetic member 5. In this embodiment, epoxy resin (based on bisphenol A) is ...

Embodiment 2

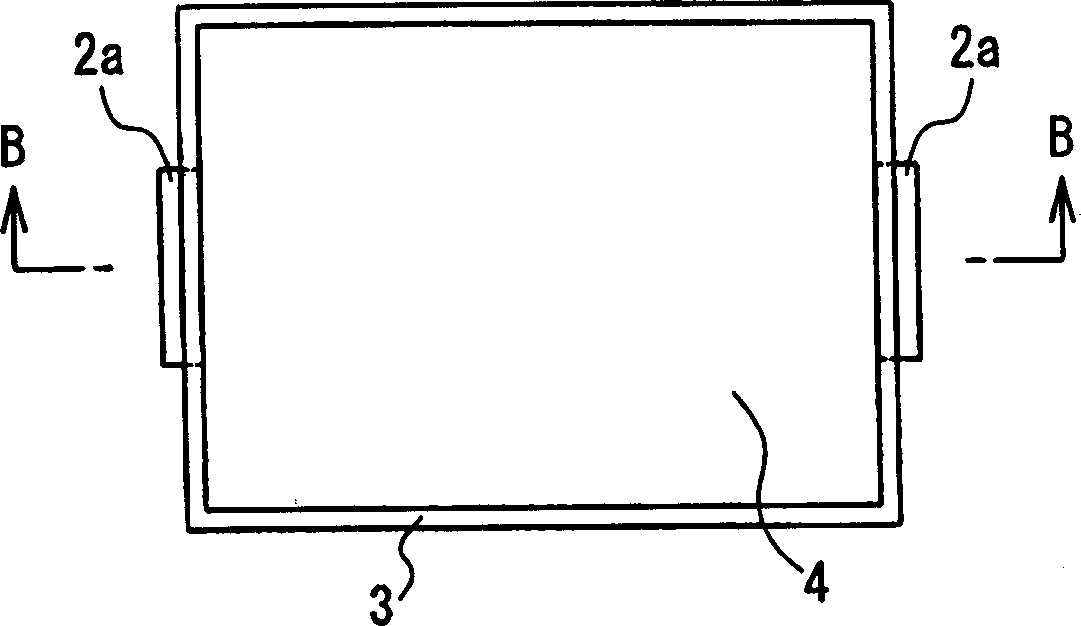

[0118] As the first magnetic member 4 , two MnZn-based ferrite sintered bodies with a length of 10 mm and a thickness of 0.5 mm were prepared. One of them was configured to have a protrusion with a diameter of 4.0 mm and a height of 0.6 mm at the center. In the same manner as in Example 1, an uncured composite sheet having a thickness of about 310 μm was prepared as the second magnetic member 5 . As the chip coil 1, a chip coil manufactured by an insulating material embedding plating method with an outer diameter of 7.5mmφ, an inner diameter of 4.5mmφ, a thickness of 600μm, a conductor diameter of about 250μm, and a DC resistance of 100mΩ is used. Two stacked coils of 14 turns of conductor with insulation covering, formed into sheet form. The insulating substance used is the same as in Example 1. Holes for fitting protrusions provided on the ferrite sintered body are provided at the center of the chip coil, and holes for arranging the second magnetic member 5 are provided at...

Embodiment 3

[0122] As the first magnetic member 4, a NiZn ferrite sintered body with a thickness of 0.2 mm was prepared. Prepare the second magnetic member 5 by mixing 16% by weight of epoxy-based curable resin (epoxy resin with bisphenol A as the main ingredient) in carbonyl (carbonyl) Fe powder with an average particle size of about 5 μm, and prepare a paste. . As the chip coil 1, a chip coil manufactured by an insulating material embedding plating method with an outer diameter of 2.8mmφ, an inner diameter of 0.8mmφ, a thickness of 250μm, a conductor diameter of about 100μm, and a DC resistance of 350mΩ is used. Two stacked coils of 16 turns of conductor with insulation covering, formed into sheet form. The insulating substance used is the same as in Example 1. In this embodiment, a large sheet forming a plurality of such sheet-like coils is prepared. The conductor coil has a structure in which its terminals are formed in the same plane, and its outer shape has a size of 3 mm×4 mm. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Inductance value | aaaaa | aaaaa |

| Dc resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com