Manufacturing method of magnetic grinder and magnetic grinder thereof

A magnetic grinding and manufacturing method technology, which is applied in the direction of machine tools, grinding machines, and manufacturing tools suitable for grinding the edge of workpieces, can solve the problem of reducing the grinding efficiency and effect of magnetic grinding machines, the operation of magnetic grinding machines is not humanized enough, and the increase in Problems such as the difficulty of magnet replacement, to achieve good promotion value, increase the magnetic action area, and the effect of fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

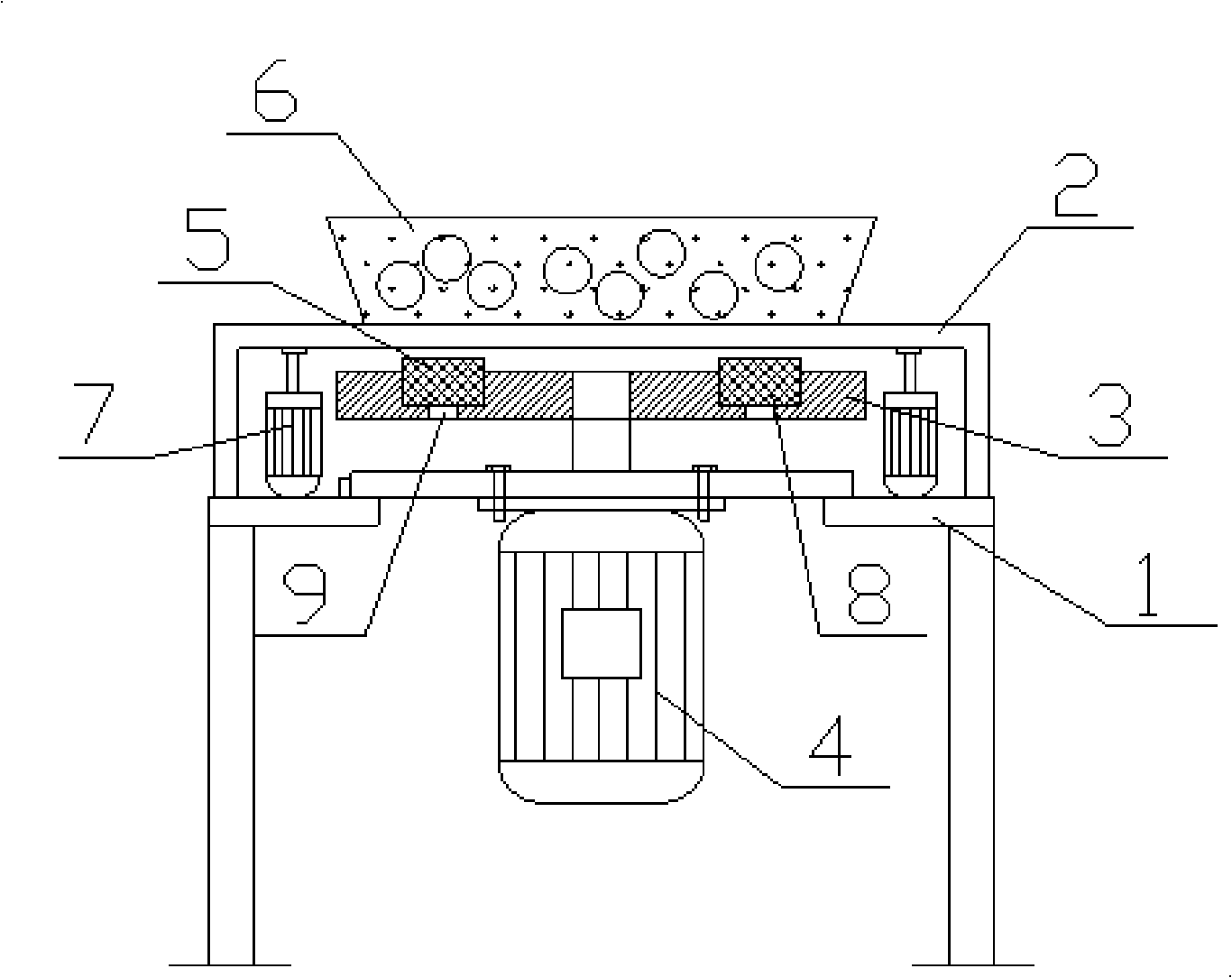

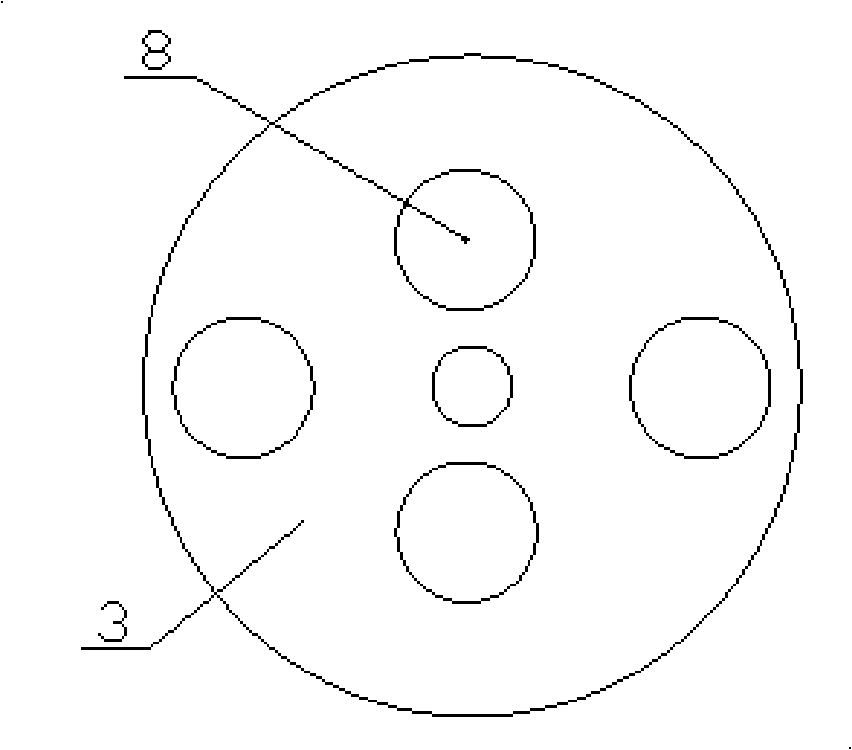

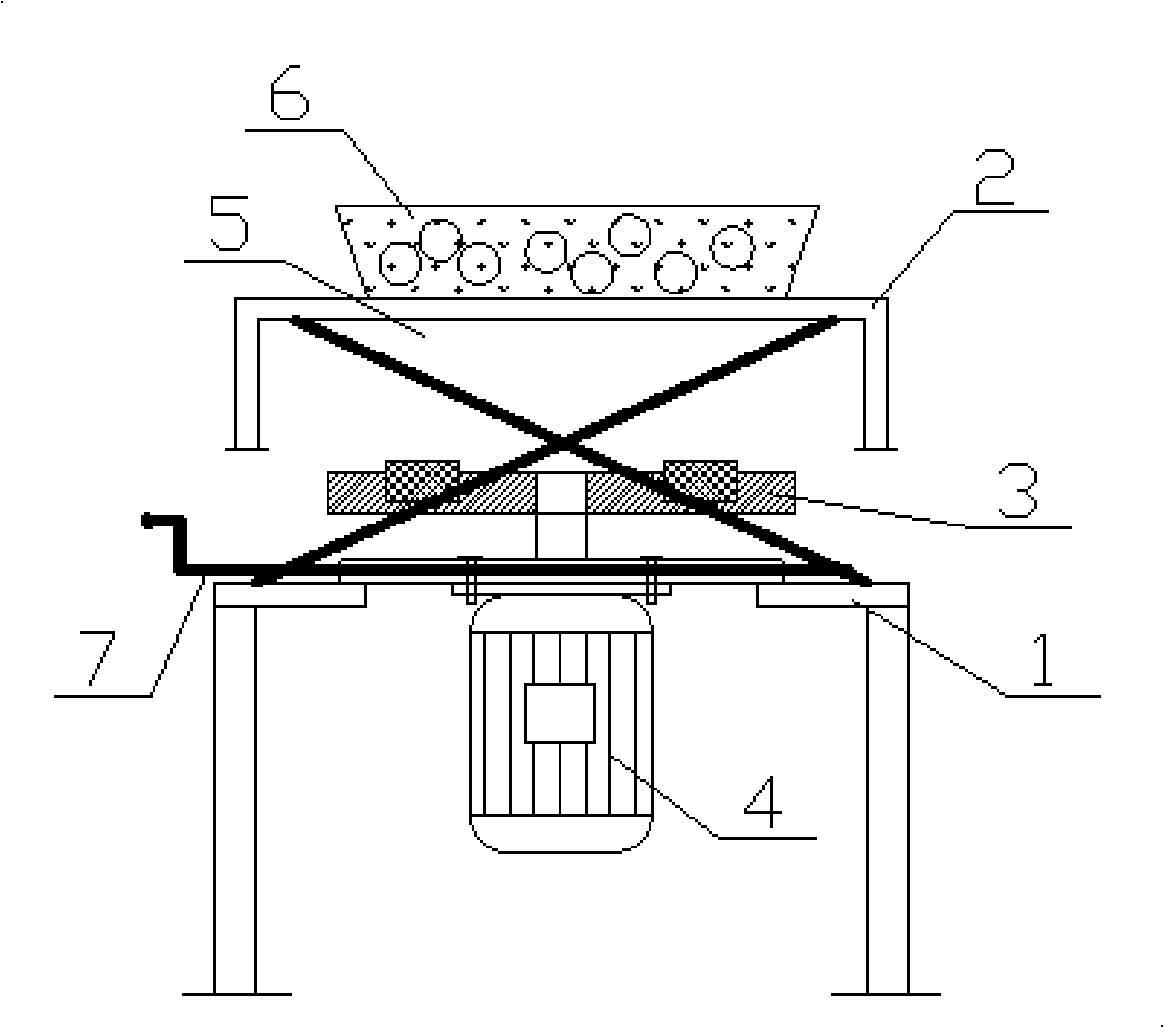

[0020] Embodiment: the structure of the present invention is as figure 1 , figure 2 As shown, the frame 1 and the supporting platform 2 are welded by profiles, a motor 4 with a rotating shaft facing upwards is installed in the middle of the frame 1, and a rotating tray 3 that can rotate along the center of the circle is placed on the upper end of the frame 1. The center of the rotating tray 3 is connected with the rotating shaft of the motor 4. The rotating tray 3 is made of iron plate. The rotating tray 3 is provided with a magnet installation slot 8 for installing a strong magnet 5. In the magnet installation slot 8, there are also slots for Disassemble the magnetic unloading hole 9 of the strong magnet 5, so that the strong magnet 5 can be directly fixed on the rotating tray 3 through the magnet installation slot 8, without fixing devices such as screws or pressure plates, reducing the magnetic loss of the strong magnet 5, and can improve Installation speed, the setting o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com