NdFeB magnetic steel surface plating method

A technology of NdFeB and magnetic steel, which is applied in the field of electroplating on the surface of NdFeB magnetic steel, which can solve the problems of large loss of magnetic properties and poor anti-corrosion ability, and achieve the effects of strong anti-corrosion ability, improved quality, and reduced porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

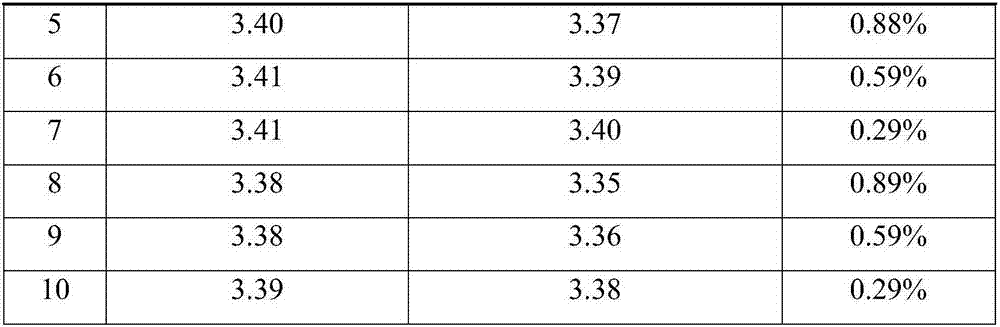

Image

Examples

Embodiment 1

[0032] (1) Pre-treatment: After degreasing 1.5KG of rough black chips, put them into the grinding drum together with 8KG of corundum abrasives, add appropriate amount of water, chamfer and grind for 2 hours. Pickling with nitric acid for 1 to 2 minutes, after ultrasonic cleaning, put it into hydrofluoric acid with a concentration of about 1% to activate for 30 seconds, rinse it clean, and put it into an electroplating barrel plating machine;

[0033] (2) Pre-galvanizing: Put the barrel plating machine into the galvanizing tank, electroplate for 80 minutes at a current of 10 amperes, and transfer it to the zinc-nickel alloy tank after cleaning.

[0034] The composition of the pre-galvanized electroplating solution is: 180 g / L zinc sulfate, 20 g / L boric acid, 50 g / L sodium sulfate, 4 ml BK-38 brightener, pH 5, operating temperature 15°C.

[0035] (3) Zinc-nickel alloy plating: electroplating in a zinc-nickel alloy tank, first electroplating at a current of 15A for 10 minutes, th...

Embodiment 2

[0049] (1) Pre-treatment: After degreasing 1.5KG of rough black chips, put them into the grinding drum together with 8KG of corundum abrasives, add appropriate amount of water, chamfer and grind for 2 hours. Pickling with nitric acid for 1 to 2 minutes, after ultrasonic cleaning, put it into hydrofluoric acid with a concentration of about 1% to activate for 30 seconds, rinse it clean, and put it into an electroplating barrel plating machine;

[0050] (2) Pre-galvanizing: Put the barrel plating machine into the galvanizing tank, electroplate for 80 minutes at a current of 10 amperes, and transfer it to the zinc-nickel alloy tank after cleaning.

[0051]The composition of the pre-galvanized electroplating solution is as follows: 250 g / L zinc sulfate, 28 g / L boric acid, 110 g / L sodium sulfate, 8 ml BK-38 brightener, pH 4.5, operating temperature 25°C.

[0052] (3) Zinc-nickel alloy plating: electroplating in a zinc-nickel alloy tank, first electroplating at a current of 15A for 1...

Embodiment 3

[0067] (1) Pre-treatment: After degreasing 1.5KG of rough black chips, put them into the grinding drum together with 8KG of corundum abrasives, add appropriate amount of water, chamfer and grind for 2 hours. Pickling with nitric acid for 1 to 2 minutes, after ultrasonic cleaning, put it into hydrofluoric acid with a concentration of about 1% to activate for 30 seconds, rinse it clean, and put it into an electroplating barrel plating machine;

[0068] (2) Pre-galvanizing: Put the barrel plating machine into the galvanizing tank, electroplate for 80 minutes at a current of 10 amperes, and transfer it to the zinc-nickel alloy tank after cleaning.

[0069] The composition of the pre-galvanizing electroplating solution is: 300 g / L zinc sulfate, 35 g / L boric acid, 160 g / L sodium sulfate, 10 ml BK-38 brightener, pH 4, operating temperature 40°C.

[0070] (3) Zinc-nickel alloy plating: electroplating in a zinc-nickel alloy tank, first electroplating at a current of 15A for 10 minutes,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com