Molded running board

a running board and molded technology, applied in the direction of transportation and packaging, vehicle components, step arrangement, etc., can solve the problems of high manufacturing cost, high manufacturing cost, and high cost of manufacturing and coating of the structural support portion, and achieve the effect of adequate rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

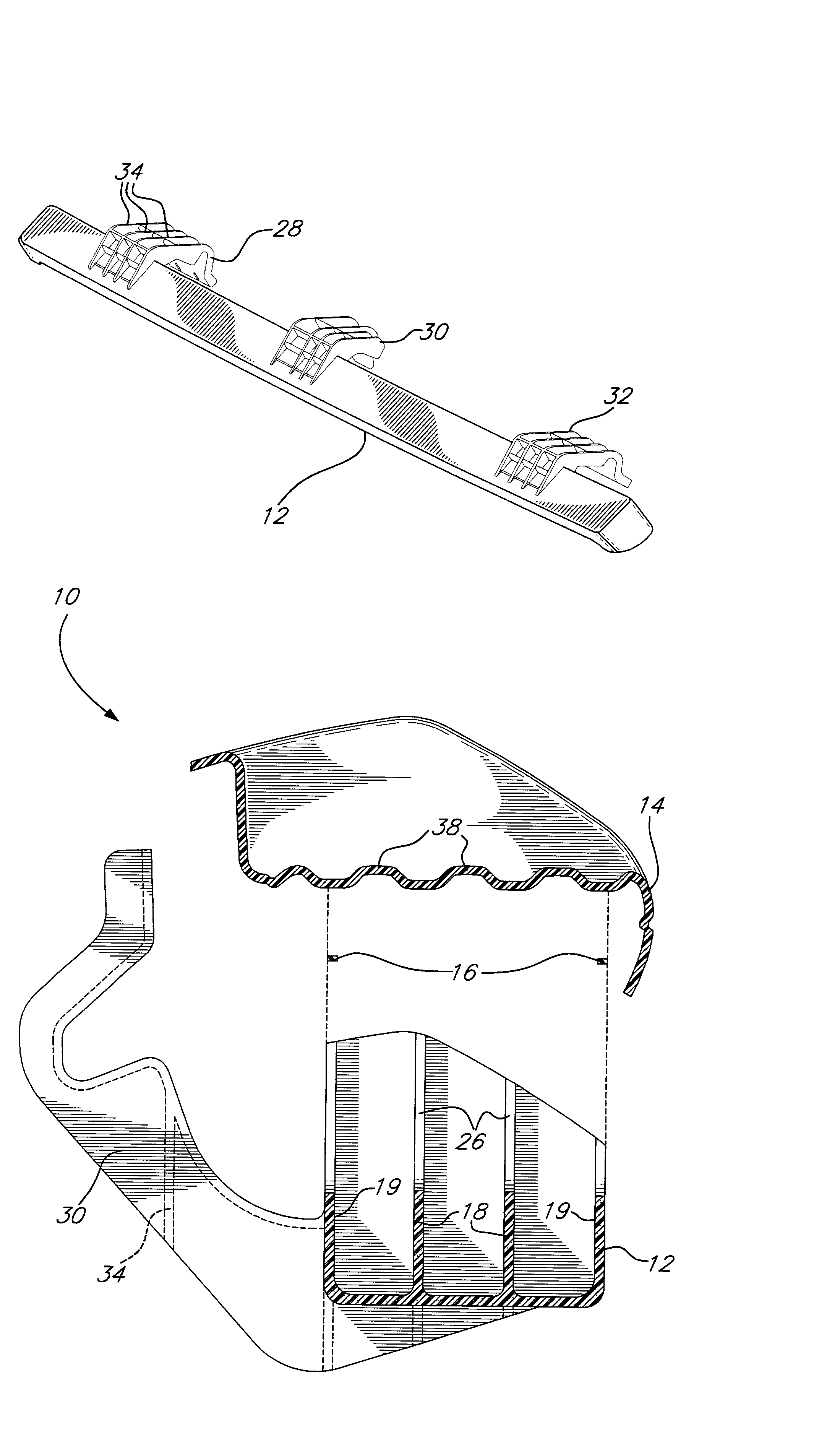

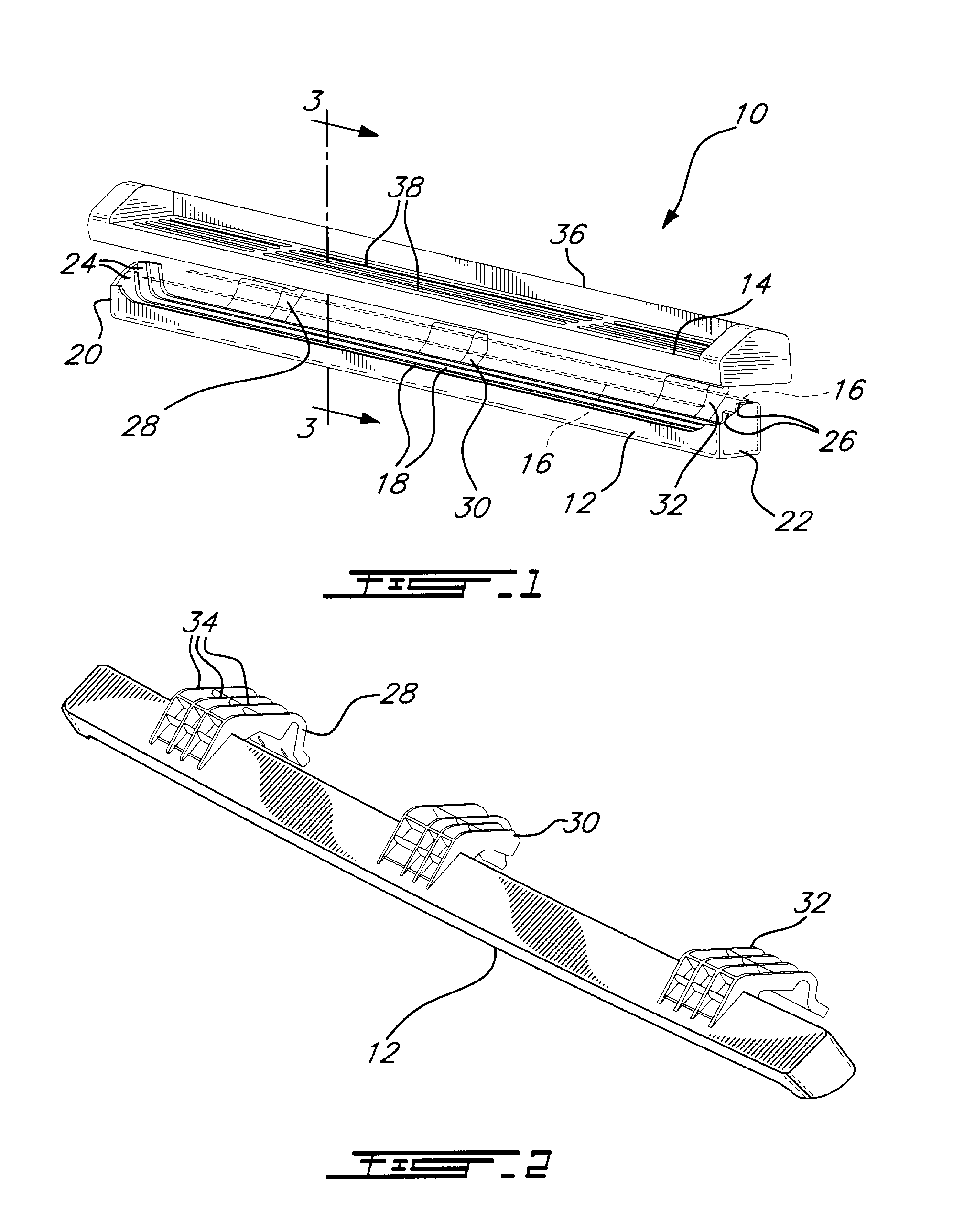

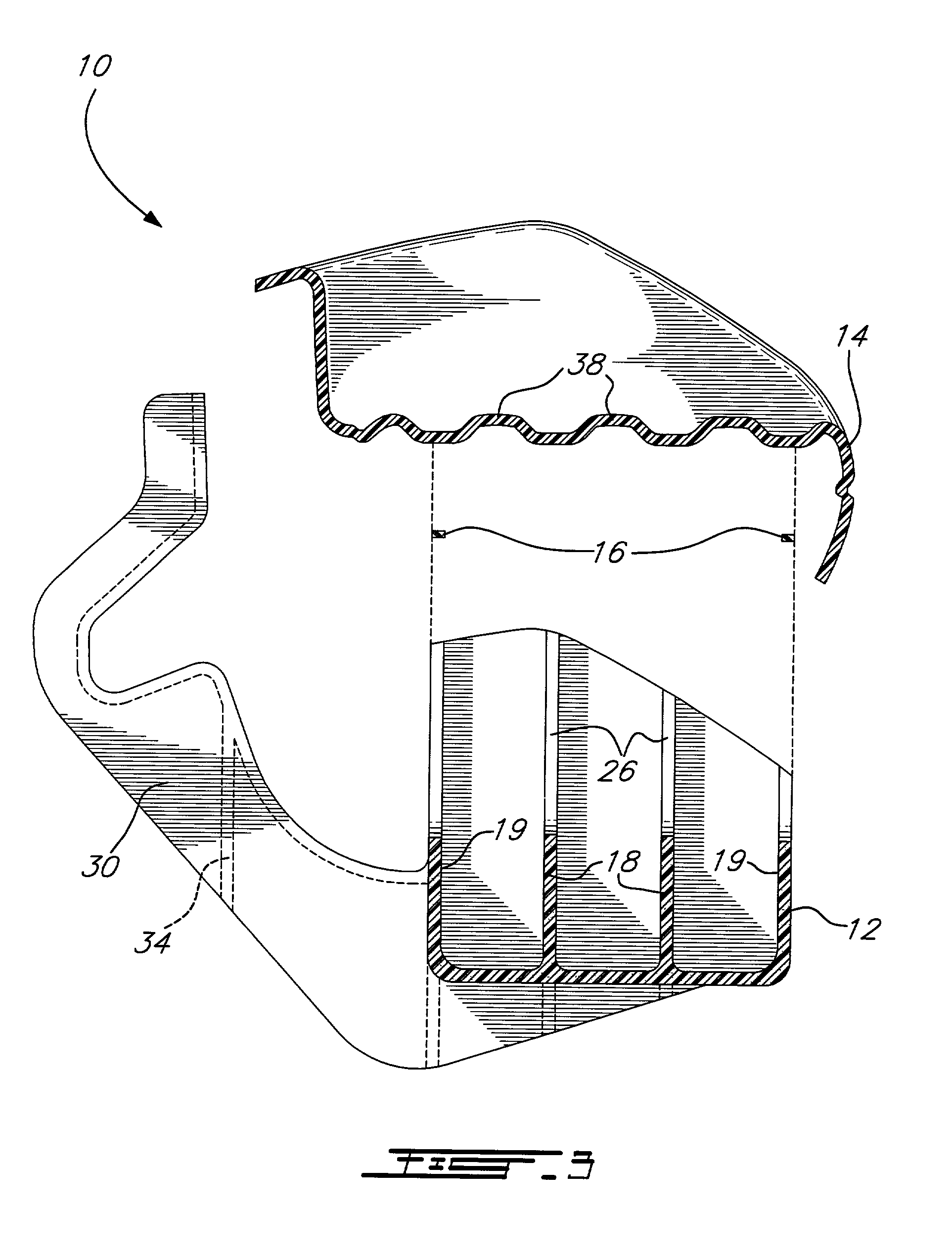

[0042]Turning now more specifically to FIGS. 1 to 3 of the appended drawings, a molded running board 10 according to the present invention will be described.

[0043]The molded running board 10 comprises a structural support portion 12; a top portion 14; and thin strands of an electromagnetic adhesive material 16 provided between the support portion 12 and the top portion 14.

[0044]As can be seen from FIG. 1, the support portion 12 is generally open and comprises reinforcing ribs 18 running lengthwise and transverse (not shown), and front and rear ends 20, 22 respectively provided with reinforcing ribs 24 and 26.

[0045]Three brackets 28, 30 and 32 are provided to mount the support portion 12 to a vehicle (not shown) for which the running board 10 is intended.

[0046]As can be better seen from FIG. 2, the three brackets 28, 30 and 32 are integrally formed with the support portion 12. It is however to be noted that the brackets 28, 30 and 32 could alternatively be formed separately, out of p...

second embodiment

[0062]Turning now to FIGS. 4 to 6, a molded running board 100 according to the present invention will be described.

[0063]Since the molded running board 100 is very similar to the molded running board 10 illustrated in FIGS. 1 to 3, only the differences therebetween will be discussed in detail hereinbelow.

[0064]The molded running board 100 comprises a support portion 102, a top portion 104 and thin strands of material 106. These three elements being substantially as described in relation to the corresponding ones comprised in the molded running board 10 illustrated in FIGS. 1 to 3.

[0065]A major difference between the molded running board 100 and the molded running boards 10 can be better seen in FIGS. 5 and 6 where it is clearly shown that a bottom portion of the support portion 102 includes apertures 108. These apertures 108 allow both for a reduction in weight and cost of the support portion 102 and for the drainage of liquid that could enter the molded running board 100.

[0066]It i...

third embodiment

[0068]Turning now to FIGS. 7 to 9 of the appended drawings, a molded running board 200 according to the present invention will now be described.

[0069]As can be better seen from FIG. 9, the molded running board 200 comprises a generally U-shaped cross-section support portion 202, a corresponding, also generally U-shaped, top portion 204, a string of material 206 and a step pad 208 that can be mounted onto the top portion 204. Again, the support portion 202 comprises three brackets 210, 212 and 214 (FIGS. 7 and 8) that allow the molded running board 200 to be mounted to a vehicle (not shown).

[0070]The support portion 202 includes reinforcing ribs 216 and edge portions 218 provided with a rectangular channel 220 therein. As can be seen from FIG. 9, the string of material 206 is inserted in the channel 220.

[0071]The top portion 204 includes a generally flat under-surface 222 configured and sized to contact and complementarily fit with the free ends 216a and 216b of the reinforcing ribs ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com