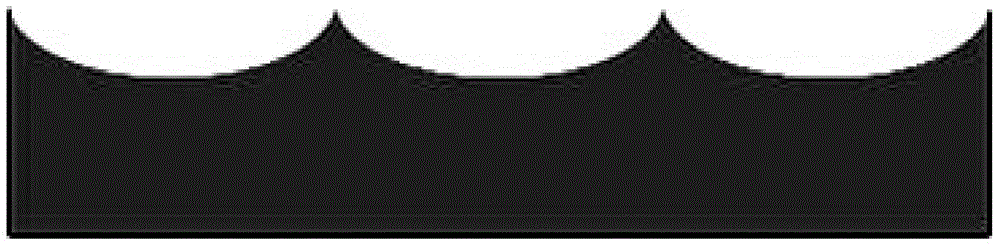

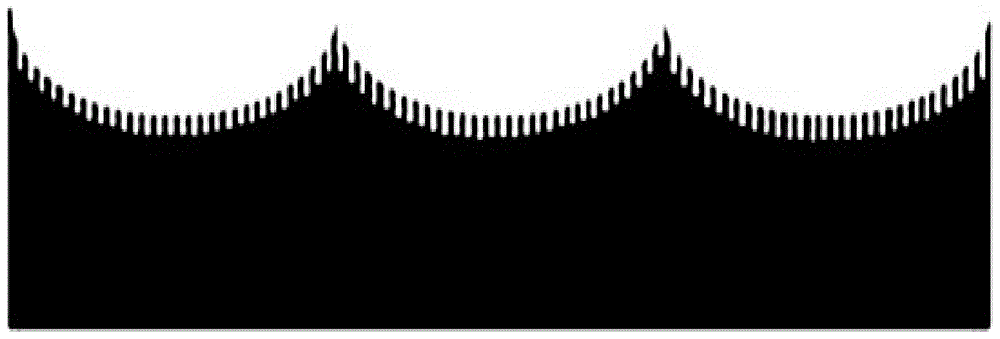

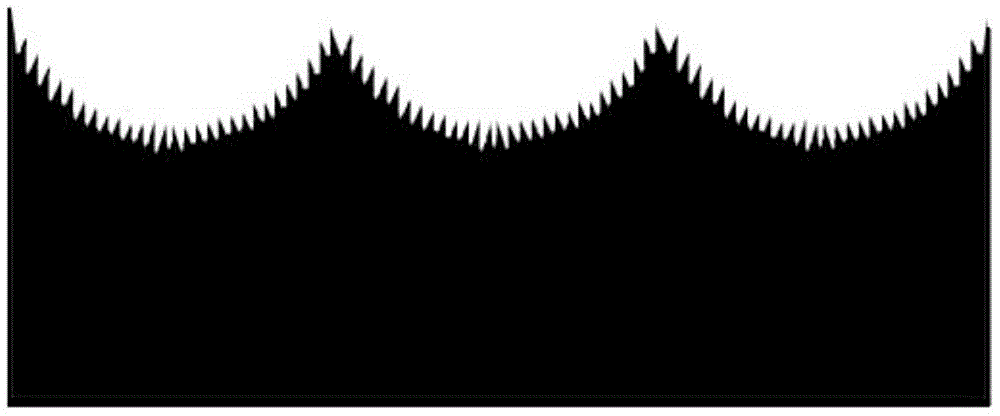

Preparation method of polycrystalline black silicon of micro-nano composite suede structure

A micro-nano composite, polycrystalline silicon wafer technology, applied in chemical instruments and methods, crystal growth, final product manufacturing, etc., can solve the problems of fast reaction speed, single, difficult to control reaction process, etc., to reduce the surface reflectivity, reduce the surface Compounding, removal-friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] First, the p-type polysilicon wafer was etched in an etching solution composed of hydrofluoric acid and nitric acid. The concentration of hydrofluoric acid was 2.5 mol / L, and the concentration of nitric acid was 7.5 mol / L. After 100 seconds, it was taken out and Cleaning is carried out to prepare a polycrystalline silicon wafer with a micro-textured structure; then, it is placed in a mixed solution of hydrofluoric acid and silver nitrate, wherein the concentration of hydrofluoric acid is 4 mol / L, and the concentration of silver nitrate is 0.005 mol / L, take it out after standing for 60s, and obtain a polysilicon wafer with silver nanoparticles adsorbed on the micron suede surface; then, put it into the etching solution of hydrofluoric acid and hydrogen peroxide, wherein the concentration of hydrofluoric acid was 4 mol / L, the concentration of hydrogen peroxide was 0.4 mol / L, and the etching time was 1 min, then the polycrystalline silicon wafer with micro-nano composite s...

Embodiment 2

[0033] First, the p-type polysilicon wafer is etched in an etching solution composed of hydrofluoric acid and nitric acid. The concentration of hydrofluoric acid is 2.5 mol / L, and the concentration of nitric acid is 7.5%. After 100s, it is taken out and cleaned. , to prepare a polycrystalline silicon wafer with a micron textured structure; then, place it in a mixed solution of hydrofluoric acid and copper nitrate, wherein the concentration of hydrofluoric acid is 4 mol / L, and the concentration of copper nitrate is 0.005 mol / L , take it out after standing for 60s, and obtain a polysilicon wafer with copper nanoparticles adsorbed on the micron suede surface; then, put it into an etching solution of hydrofluoric acid and hydrogen peroxide, wherein the concentration of hydrofluoric acid is 4 mol / L, the concentration of hydrogen peroxide is 0.4 mol / L, and the etching time is 1 min, then take it out to obtain a polycrystalline silicon wafer with a micro-nano composite texture structu...

Embodiment 3

[0035] First, the p-type polysilicon wafer was etched in an etching solution composed of hydrofluoric acid and nitric acid. The concentration of hydrofluoric acid was 2.5 mol / L, and the concentration of nitric acid was 7.5 mol / L. After 100 seconds, it was taken out and Cleaning is carried out to prepare a polycrystalline silicon wafer with a micro-textured structure; then, it is placed in a mixed solution of hydrofluoric acid and silver nitrate, wherein the concentration of hydrofluoric acid is 4 mol / L, and the concentration of silver nitrate is 0.005 mol / L, take it out after standing for 60s, and obtain a polysilicon chip with silver nanoparticles adsorbed on the micron suede surface; then, put it into the etching solution of hydrofluoric acid and hydrogen peroxide, wherein the concentration of hydrofluoric acid was 4 mol / L, the concentration of hydrogen peroxide was 0.4 mol / L, and the etching time was 1 min, then the polycrystalline silicon wafer with micro-nano composite te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com