Dead head production equipment

A technology of production equipment and horizontal plates, which is applied in casting molding equipment, metal processing equipment, casting molds, etc., can solve the problems of low production efficiency, uneven product quality, and high labor intensity of operators, so as to reduce labor intensity and improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

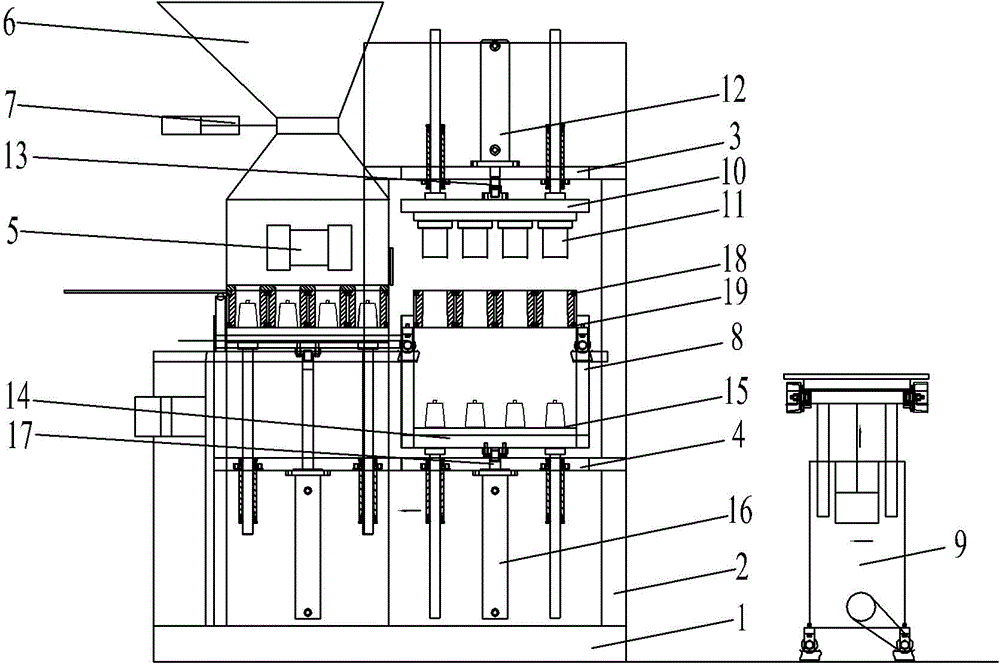

[0010] Such as figure 1 As shown, the present invention includes a base 1, the front portion of the base 1 is provided with a core-connecting trolley 9, the upper end of the base 1 is fixed with an upper die horizontal plate 3 through a column 2, and the lower die horizontal plate 4 is fixed through a column 2 at the bottom of the base 1. The lower part of the upper die horizontal plate 3 is horizontally mounted with a parallel arrangement of the material cylinder 5, the top of the material cylinder 5 is equipped with a hopper 6, the connection between the hopper 6 and the material cylinder 5 is provided with a gate cylinder 7, and the lower end of the upper die horizontal plate 3 The upper mold structure is installed, and the middle mold structure is fixed on the column 2 opposite the upper mold structure and fixed to the base 8. The barrel 5 is provided with an orifice plate corresponding to the middle mold structure, and the base 8 is fixed on the column 2. The lower mold s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com