Hot water air conditioning device of sleeve and fin type heat exchanger

A fin heat exchanger and air conditioning equipment technology, applied in lighting and heating equipment, air conditioning systems, heating methods, etc., can solve problems such as low efficiency, increased operating costs, high pollution, etc., to save building space and reduce equipment. Quantitative, energy-efficient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

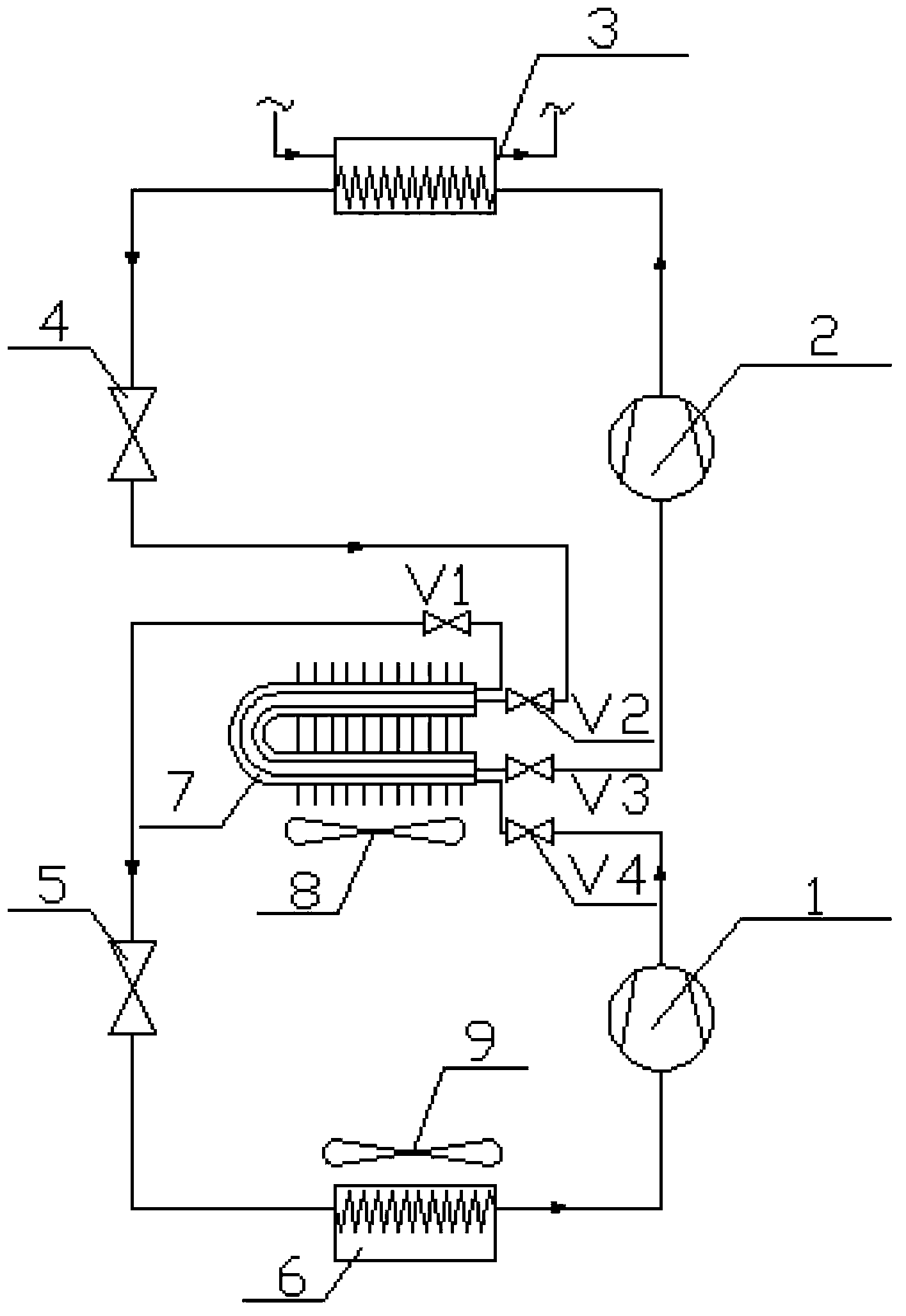

[0018] refer to figure 1 , casing fin heat exchanger hot water air conditioning equipment, including a first compressor 1, an evaporator 6, a first throttling device 5, a casing fin heat exchanger 7, a second compressor 2, and a water heater 3 , the second throttling device 4, the first fan 9, the second fan 8, the second shut-off valve V2, the third shut-off valve V3, the fourth shut-off valve V4, the refrigerant outlet end of the first compressor 1 and the bushing The first port on the refrigerant side of the finned heat exchanger 7 is connected, the third port on the refrigerant side of the casing fin heat exchanger 7 is connected to the inlet end of the first throttling device 5 , and the outlet end of the first throttling device 5 is connected to the evaporator 6 inlet connection, the evaporator 6 outlet is connected to the first compressor 1 inlet; the first fan 9 inlet is connected to the evaporator 6 air side outlet; the second fan 8 is connected to the tube-fin heat e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com