Composite spunlaced nonwoven fabric and preparation method thereof

A technology of non-woven fabrics and spunlace, which is applied in the direction of non-woven fabrics, textiles, and papermaking. It can solve the problems of unfavorable application of high-grade wiping cloths, low transverse strength, and large elongation, and achieve good wiping effects and extended service life. , Improve the effect of performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

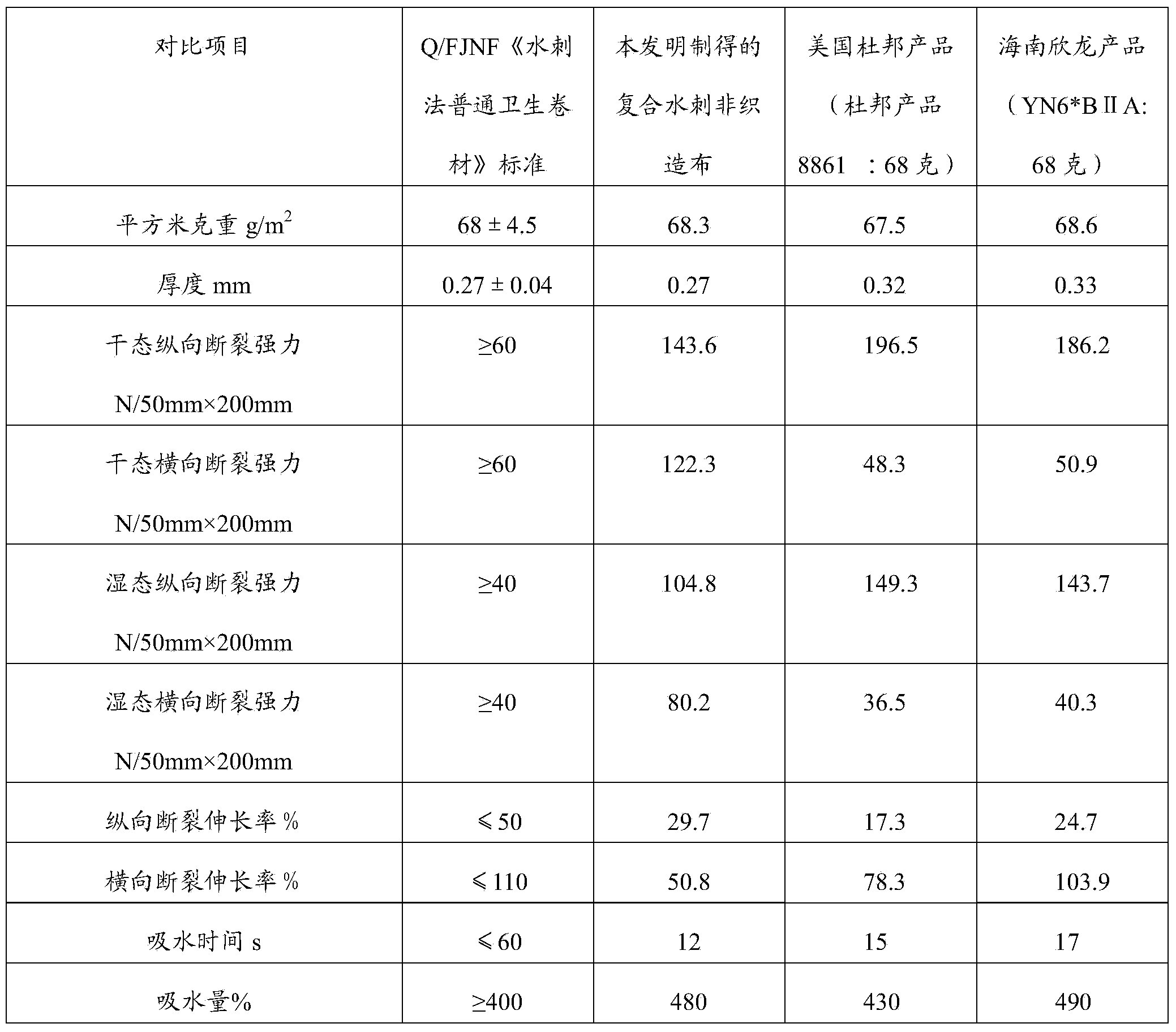

[0030] A method for preparing a composite spunlaced nonwoven fabric of the present invention, the 100% polyester fiber is sequentially fed through unpacking, coarse opening, fiber mixing, fine opening, carding, cross-lapping, drafting and the first Spunlace to obtain a non-wiping layer, and then composite the non-wiping layer with a wiping layer composed of 100% wood pulp paper material for the second time to obtain a composite spunlace nonwoven fabric.

[0031] The beneficial effect of the preparation method of composite spunlace nonwoven fabric of the present invention is:

[0032] (1) Feed 100% polyester fiber through bale opening, coarse opening, fiber mixing, fine opening, carding, cross-lapping, drafting and the first spunlace, so that the CD transverse strength of the non-wiping layer obtained Up to 100N / 5CM has the characteristics of high strength, and then the wiping layer and the non-wiping layer are spunlace compounded for the second time, so that the longitudinal a...

Embodiment 1

[0044] The composite spunlace nonwoven fabric of this embodiment includes a wiping layer and a non-wiping layer, the wiping layer is made of 100% wood pulp paper material, and the non-wiping layer is made of 100% 1.2D×38MM polyester fiber material, so The non-wiping layer is made of 100% polyester fibers through cross-laying and the first water entanglement, and the wiping layer and the non-wiping layer are combined through the second water entanglement. The weight of the wiping layer is 38±2g / m 2 ; The weight of the non-wiping layer is 30±3g / m 2 , the weight of the wiping layer and the non-wiping layer after the second spunlace composite is 68±4.5g / m 2 .

[0045] The preparation method steps of the composite spunlace nonwoven fabric of the present embodiment are as follows:

[0046] (1) Preparation of non-wiping layer: 100% 1.2D×38MM Jiangsu Yizheng spunlace special fiber is fed through bag opening, coarse opening, fiber mixing, fine opening, carding, laying and drawing to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Lateral force | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com