Veneer for container base plate

A technology for container floor and plywood, applied in the field of plywood, can solve problems such as difficulty in meeting the requirements for container use, shortage of container timber resources, strength defects, etc., and achieve the effects of low cost, high tensile strength, and reduced production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

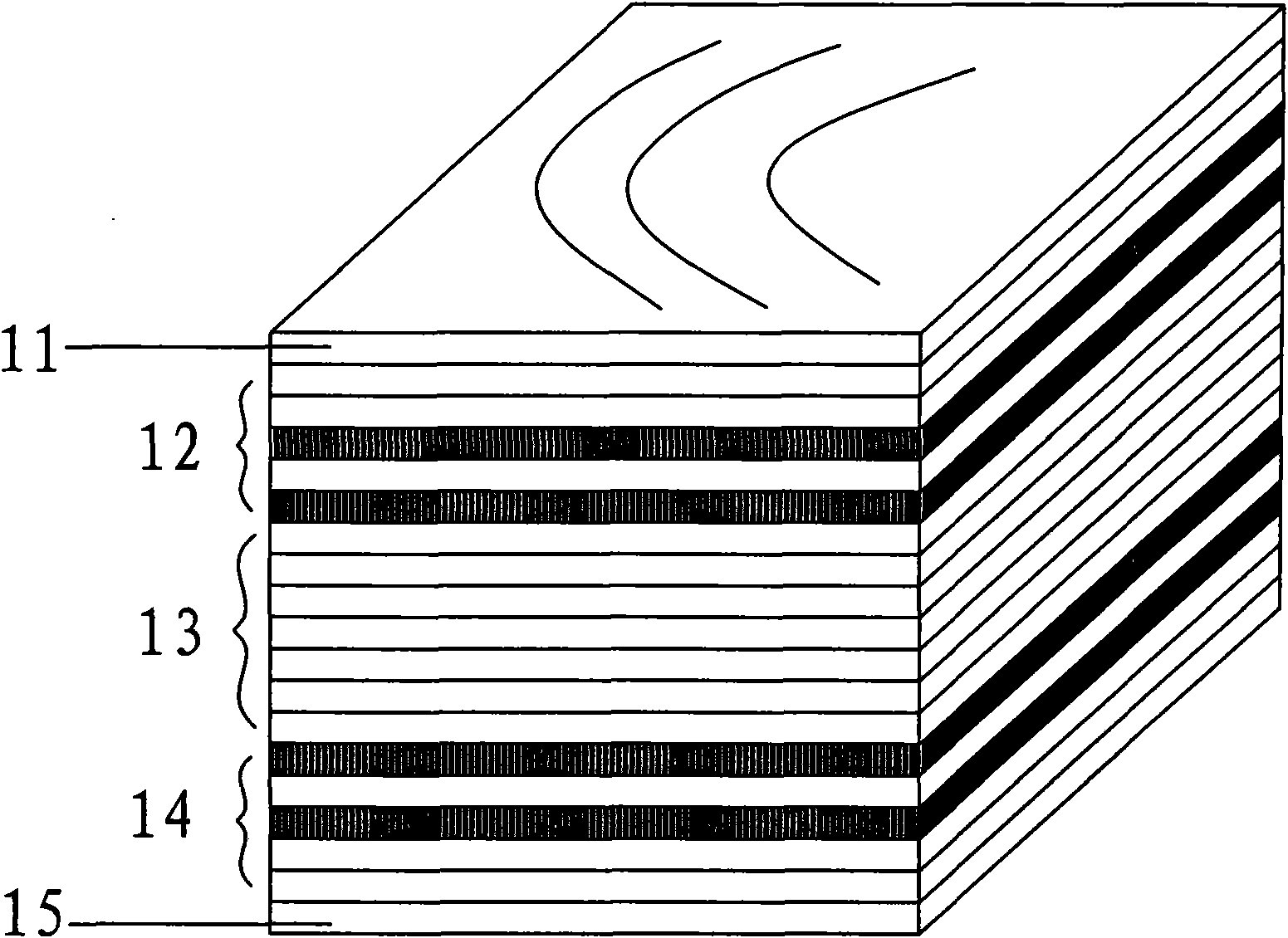

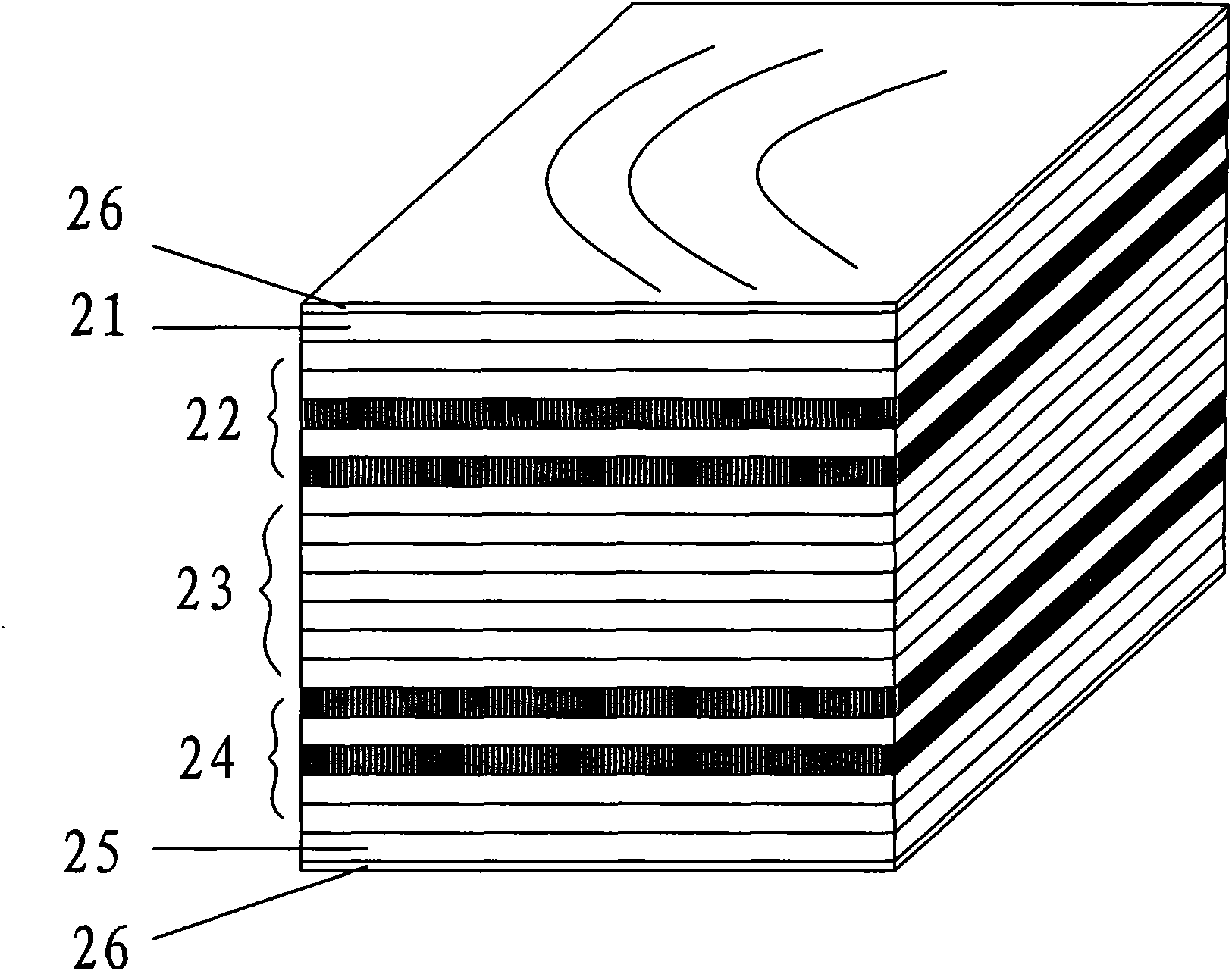

[0034] Such as figure 2 The plywood used for the bottom plate of the container shown has a total of 19 layers, which are processed by dipping, billeting, gluing, hot pressing, etc., and its structure from top to bottom is: surface layer 21, upper sandwich layer 22 , core layer 23, lower sandwich layer 24, bottom layer 25. Wherein the surface layer 21 and the bottom layer 22 are respectively a layer of veneer, adopting a bamboo mat with a thickness of 1.00mm, and the bamboo mat is processed by dipping, wherein the upper layer of the upper surface plate and the lower layer of the lower surface plate are respectively provided with a piece of melamine impregnated paper 26 ; The upper sandwich layer 22 and the lower sandwich layer 24 are each 5 layers, each including 5 layers of bamboo curtains arranged in a criss-cross pattern, and the bamboo curtains are dried after dipping, and their moisture content is less than 10%; Between the core layer 22 and the lower sandwich layer 24, ...

Embodiment 3

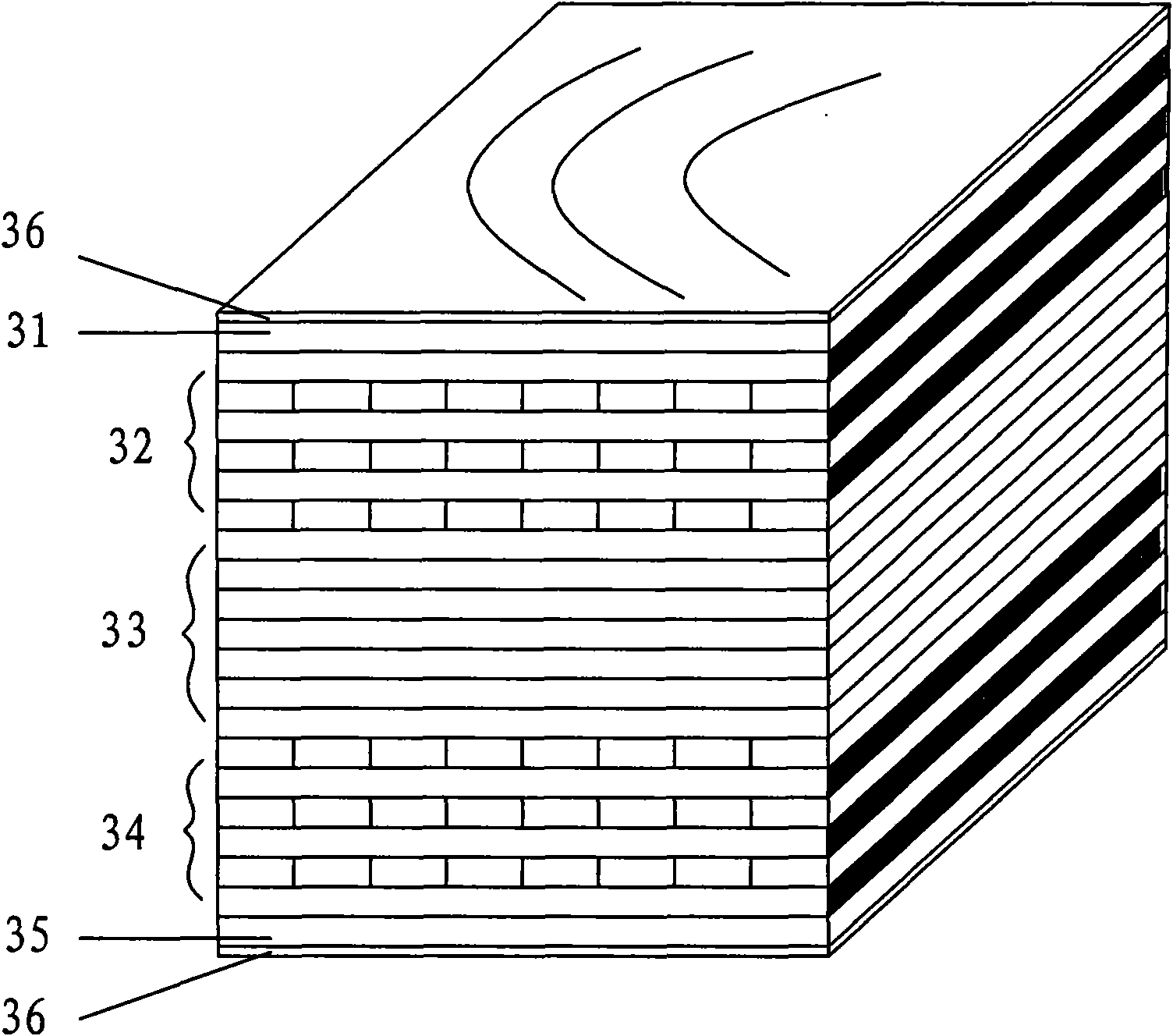

[0039] Such as image 3 The plywood used for the bottom plate of the container shown has a total of 21 layers, which are processed by forming blanks, gluing, and hot pressing. The structure from top to bottom is: surface layer 31, upper sandwich layer 32, core layer 33, lower sandwich layer 34, bottom layer 35. Wherein the surface layer 31 and the bottom layer 35 are respectively a layer of veneer, adopting a bamboo mat with a thickness of 1.00mm, and the bamboo mat is processed by dipping, wherein the upper layer of the upper surface plate and the lower layer of the lower surface plate are respectively provided with a piece of melamine impregnated paper 36 ; The upper sandwich layer 32 and the lower sandwich layer 34 are each 6 layers, each including 6 layers of bamboo curtains arranged in a criss-cross pattern, and the bamboo curtains are dried after dipping, and their moisture content is less than 10%; Between the core layer 32 and the lower sandwich layer 34, 7 poplar lon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com