Process for preparing environment-friendly silicon rubber shed or awning cloth

A preparation process and technology of silicone rubber, applied in the direction of rubber layered products, heating/cooling fabrics, layered products, etc., can solve the problems of lack of silicone rubber formula and tape preparation technology, and achieve excellent sealing and mechanical properties, good weather resistance performance, long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The technical solutions of the present invention will be further described in detail below in conjunction with the examples.

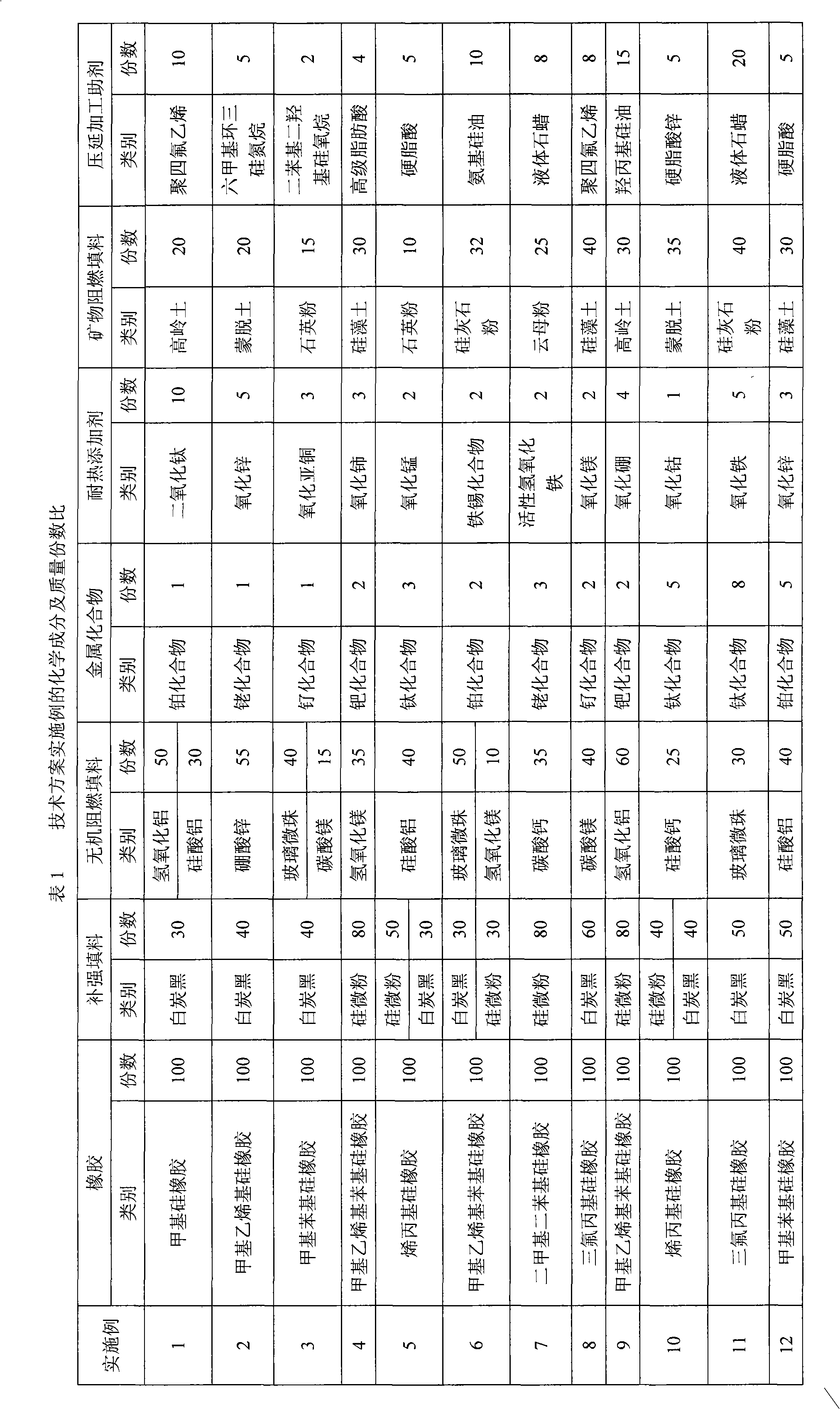

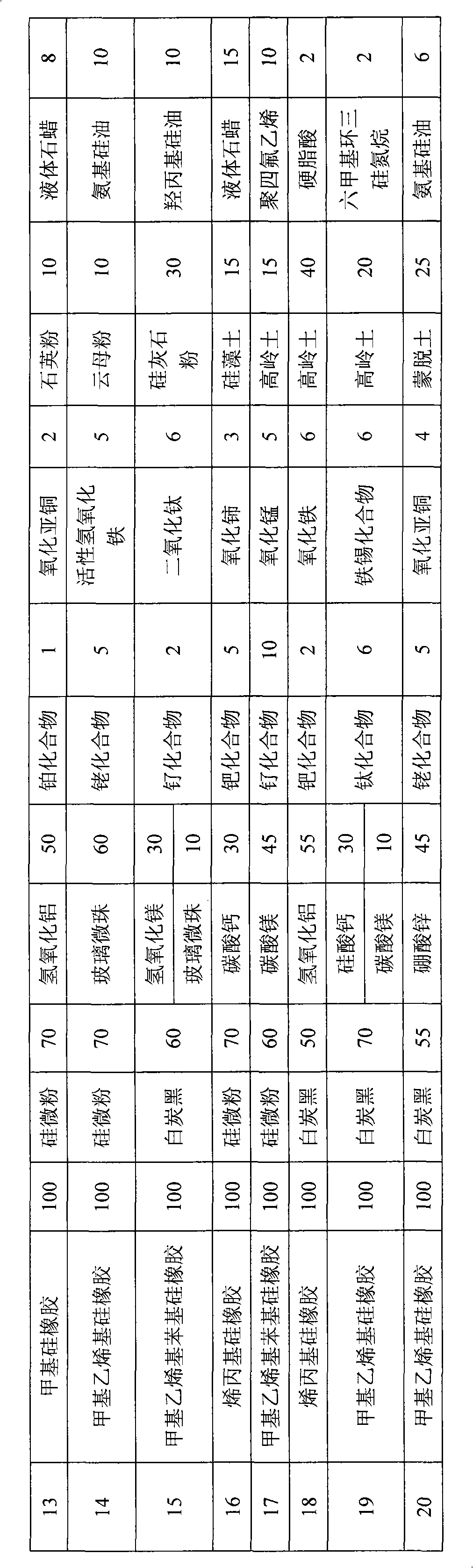

[0048] Table 1 shows the chemical composition and mass parts ratio of the flame-retardant silicone rubber of the technical embodiment of the present invention, wherein the numbers in each formula are mass parts.

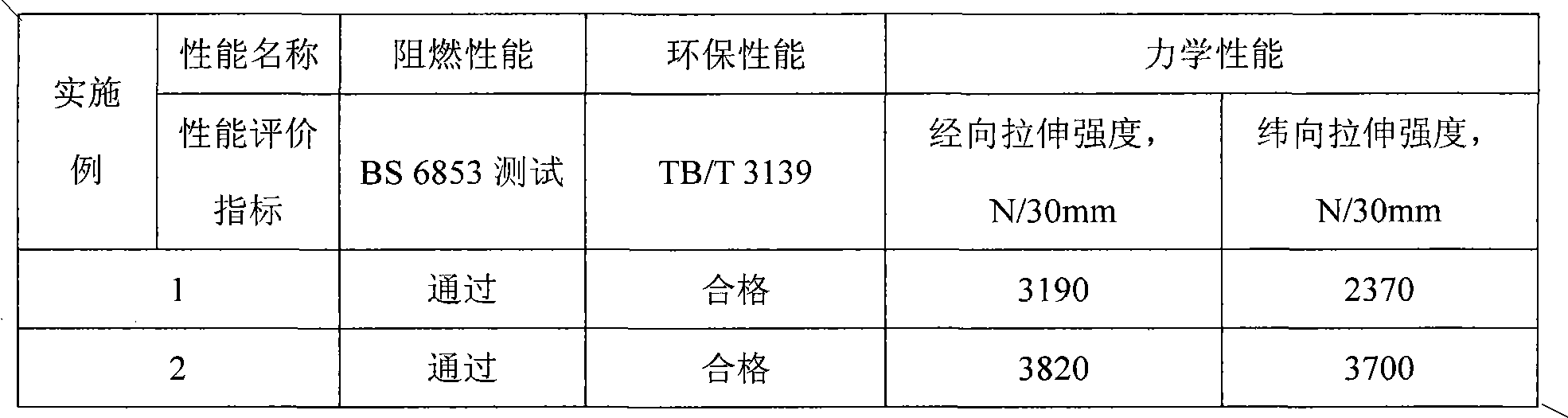

[0049] Table 2 shows the reinforcing fabric, coupling agent and shed (canopy) cloth forming process of the technical embodiment of the present invention.

[0050] The environment-friendly flame-retardant silicone rubber shed (canopy) cloth of the present invention follows the steps of the process: each component of the rubber material is weighed in parts by mass, mixed evenly on an open mill or an internal mixer, and the flame-retardant silicone rubber is prepared. Rubber material; prepare a coupling agent, and use the coupling agent to treat the reinforced fabric for use; the flame-retardant silicone rubber material is released on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com