A method and an arrangement for reducing the weight and optimizing the longitudinal strength of a water-craft

A technology of longitudinal strength and ships, applied in ship construction, ship design, ship parts, etc., can solve the problems of increasing ship weight, disadvantages, etc., and achieve the effect that is beneficial to management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

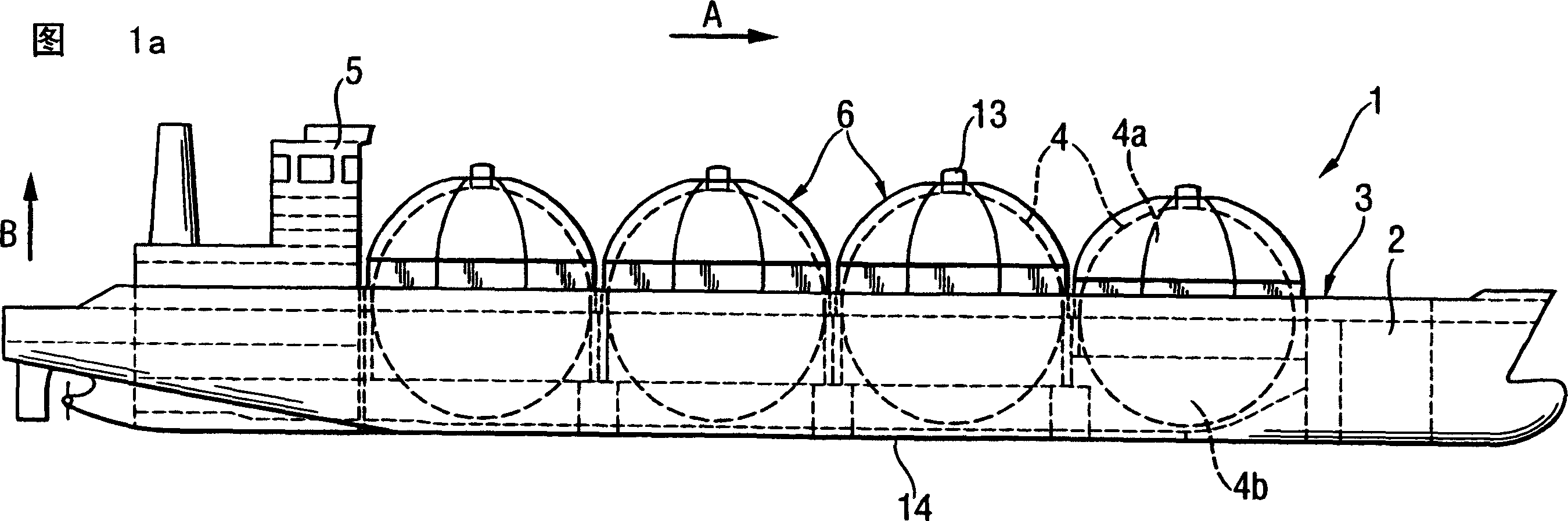

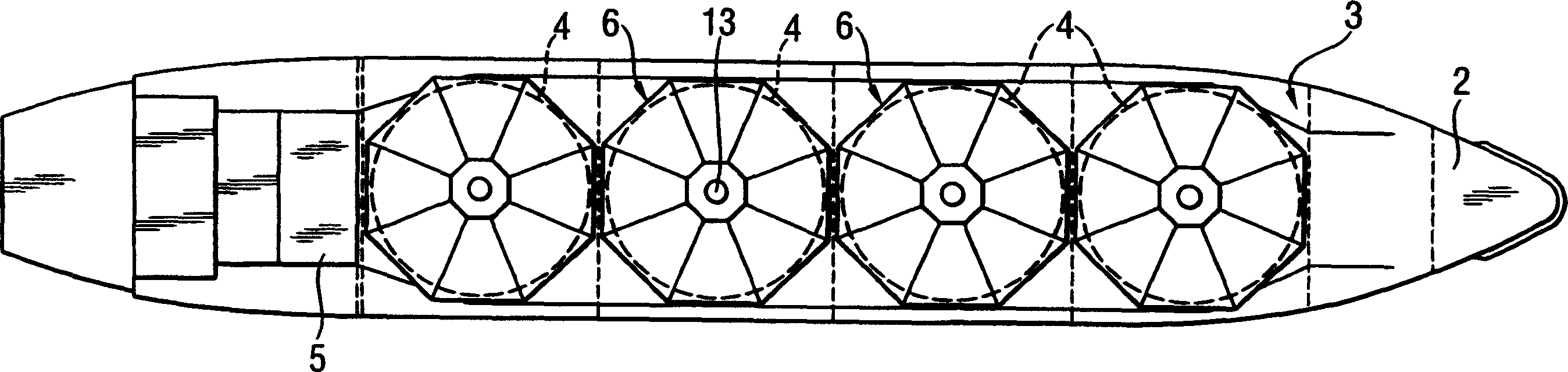

[0024] In Figures 1a and 1b, reference numeral 1 denotes a vessel (or water craft). The figures also show the hull 2 and deck 3 of the vessel, and the cargo tanks 4 each covered by a protective hull structure 6 . Furthermore, in this case the deckhouse 5 is shown located at the stern of the vessel 1 . The upper part of the cargo tank comprises an extension 13 in which all piping components of the cargo tank are arranged (not shown more precisely). The lower part of the hull is indicated with reference number 14 .

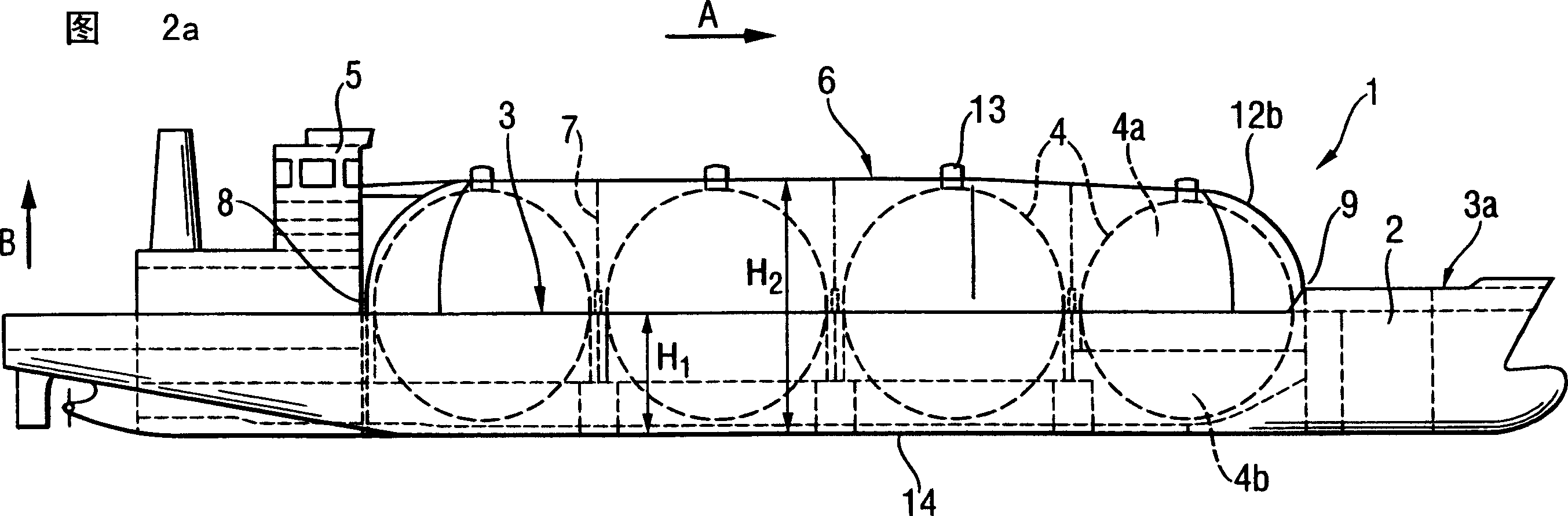

[0025] Figures 2a and 2b show an advantageous embodiment of the structure according to the invention, in which a continuous protective shell structure 6 is arranged above the hull 2 and deck 3 of the vessel, which is formed by hemispherical elements 4a and 4b The spherical cargo tank 4 provides an integral covering. Furthermore, the figure shows a deckhouse 5 located at the stern of the vessel 1, from which deckhouse, above the protective shell structure 6 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com