Patents

Literature

158results about How to "Easy out" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

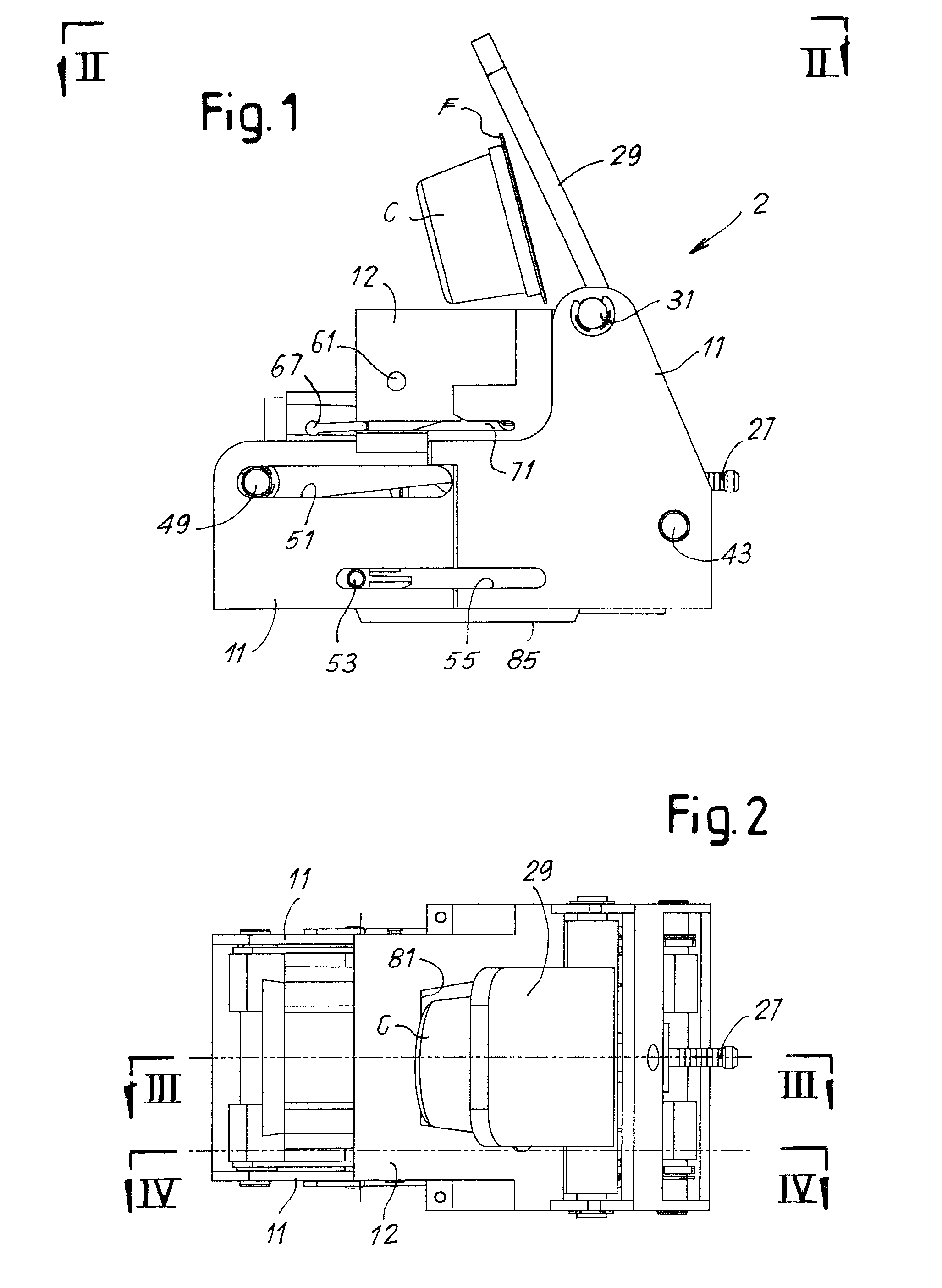

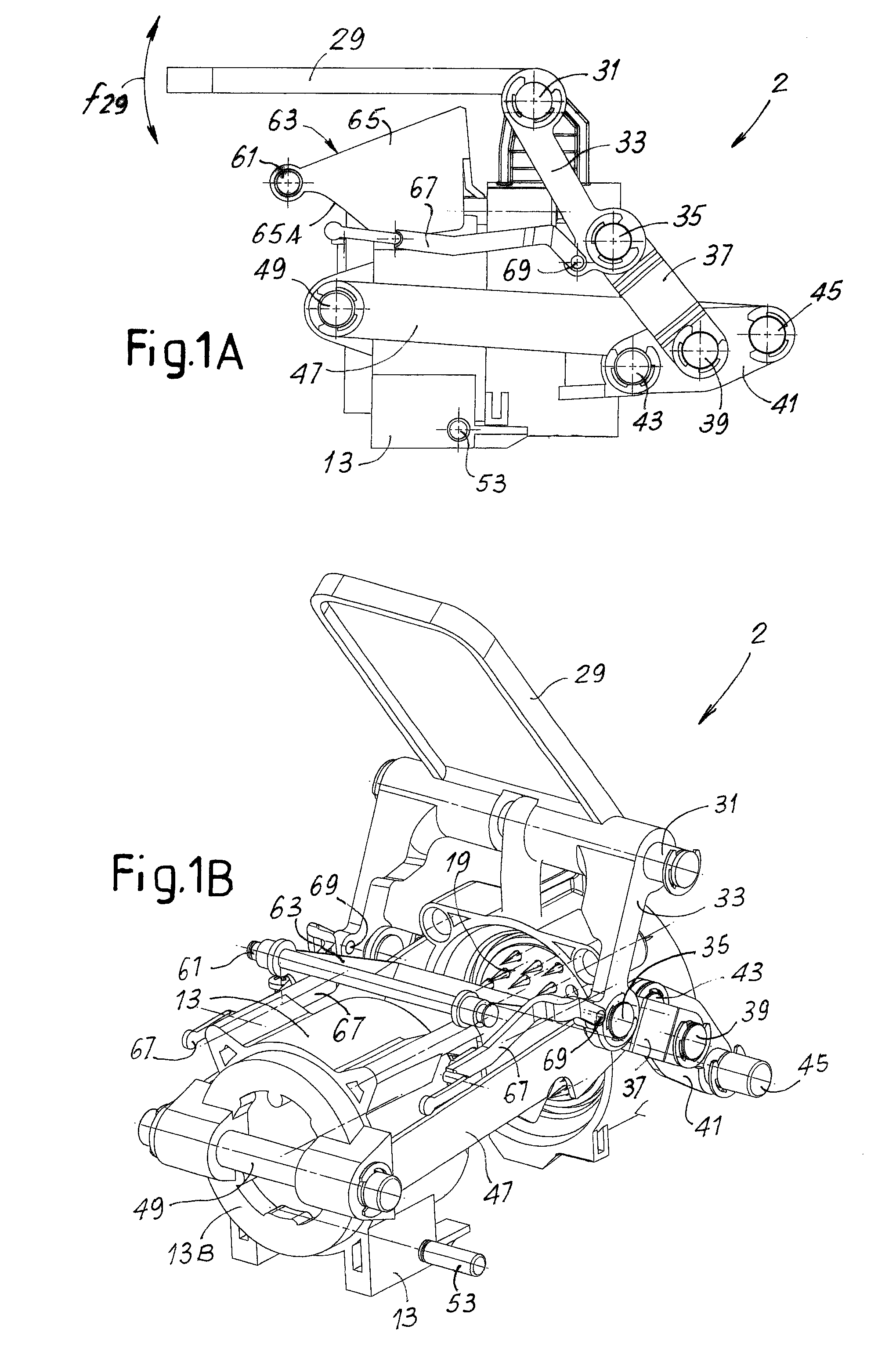

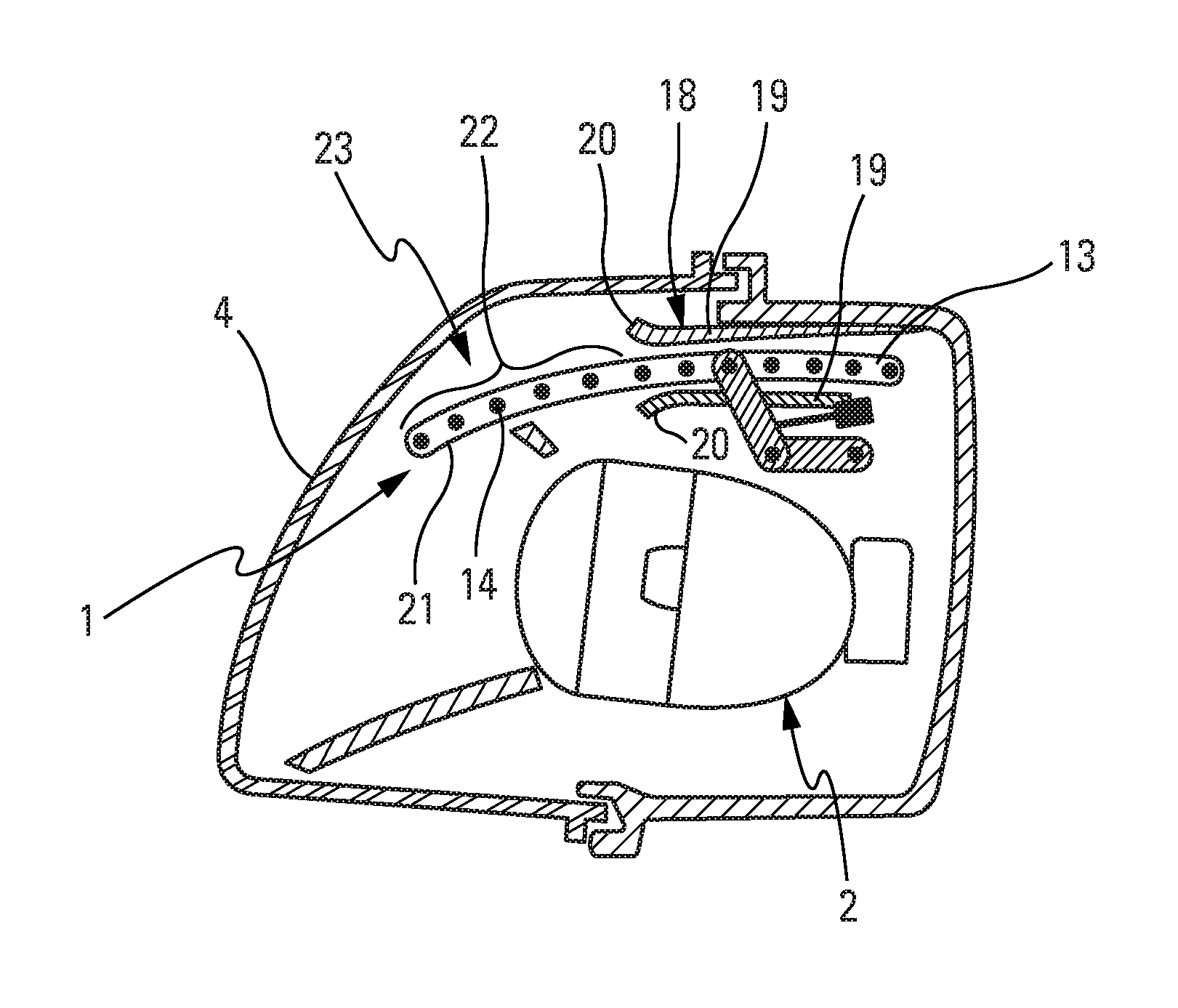

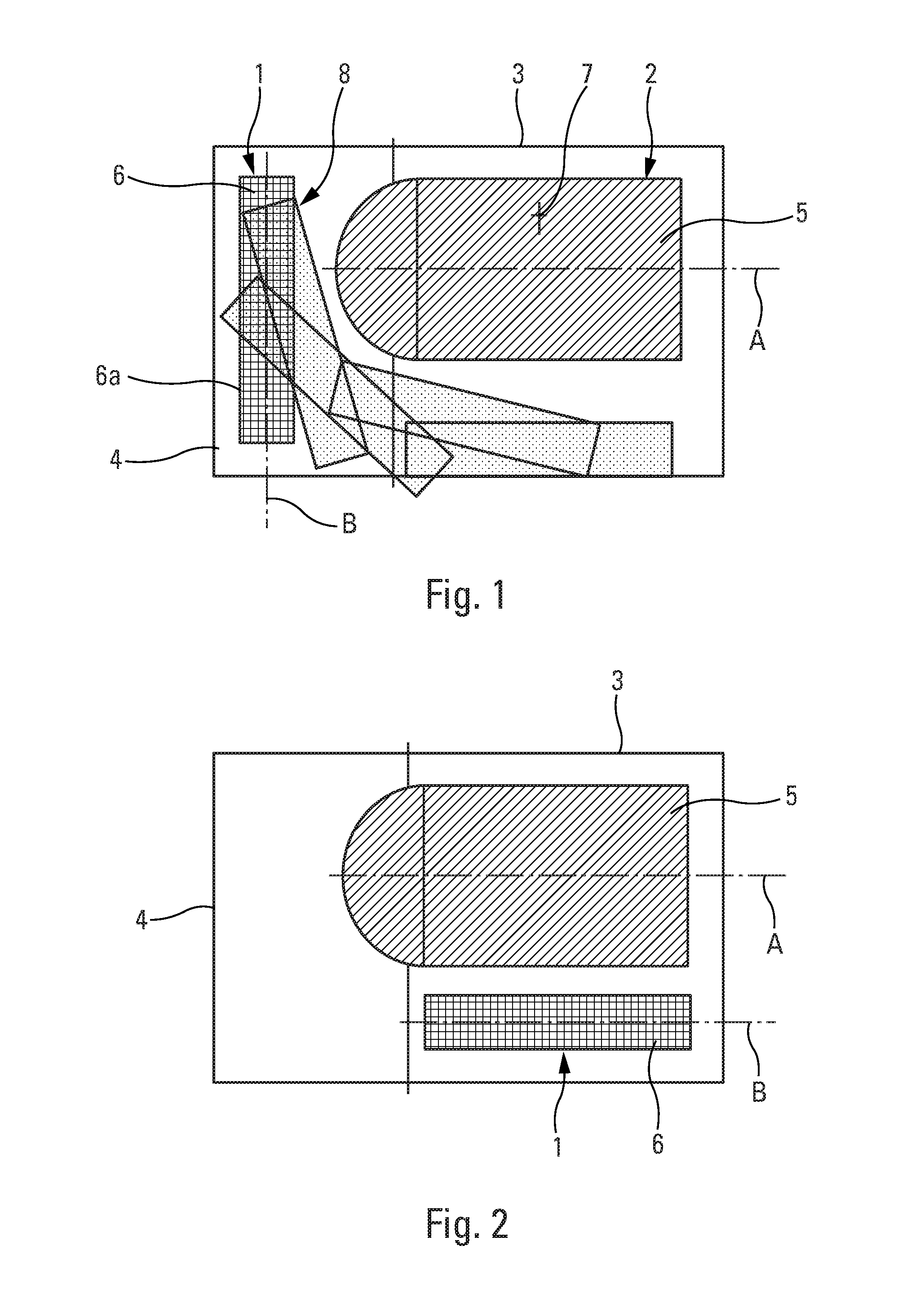

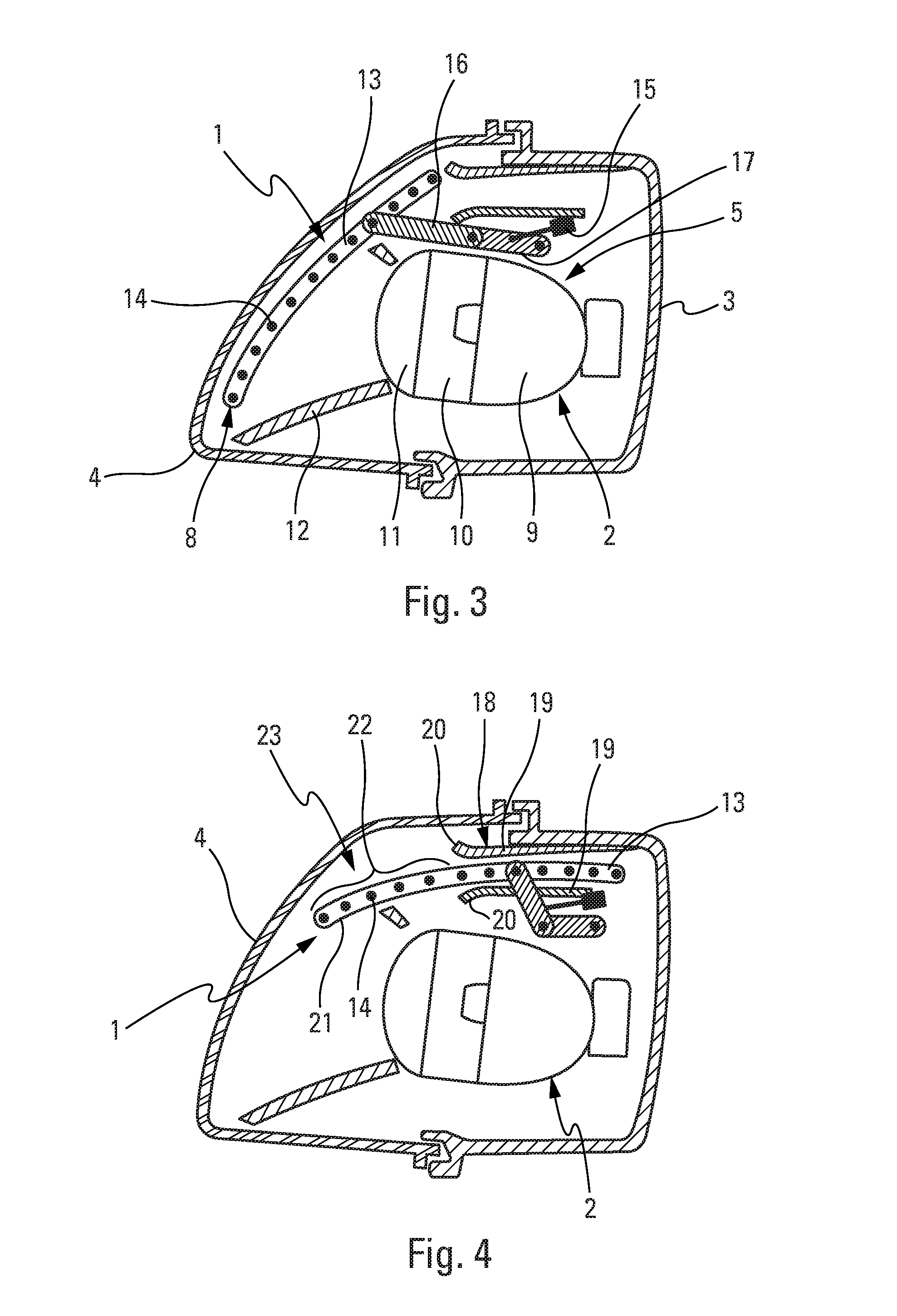

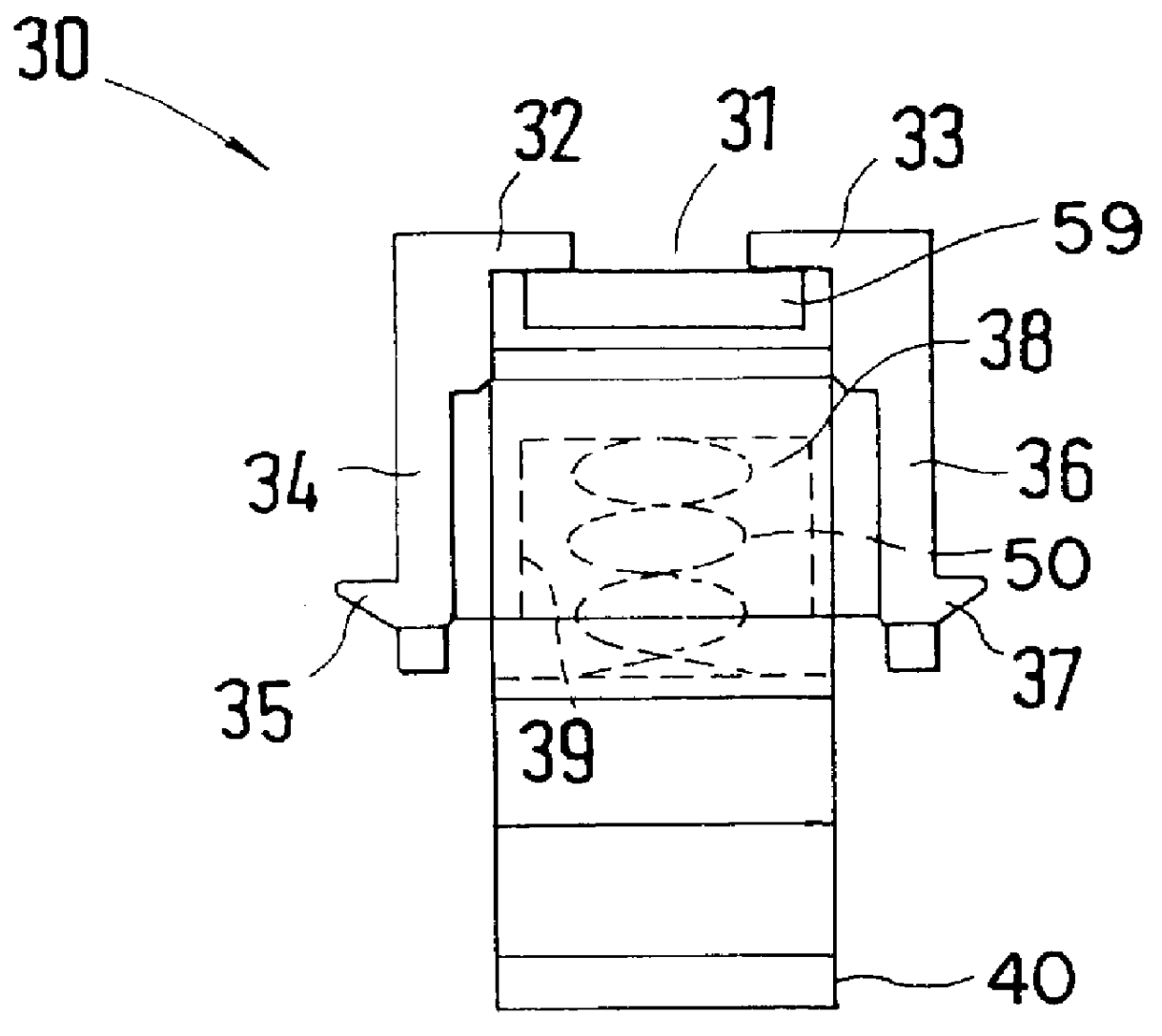

Brewing unit with horizontal motion

ActiveUS20130239820A1Compact and simple to manufactureEasy to useBeverage vesselsEngineeringMechanical engineering

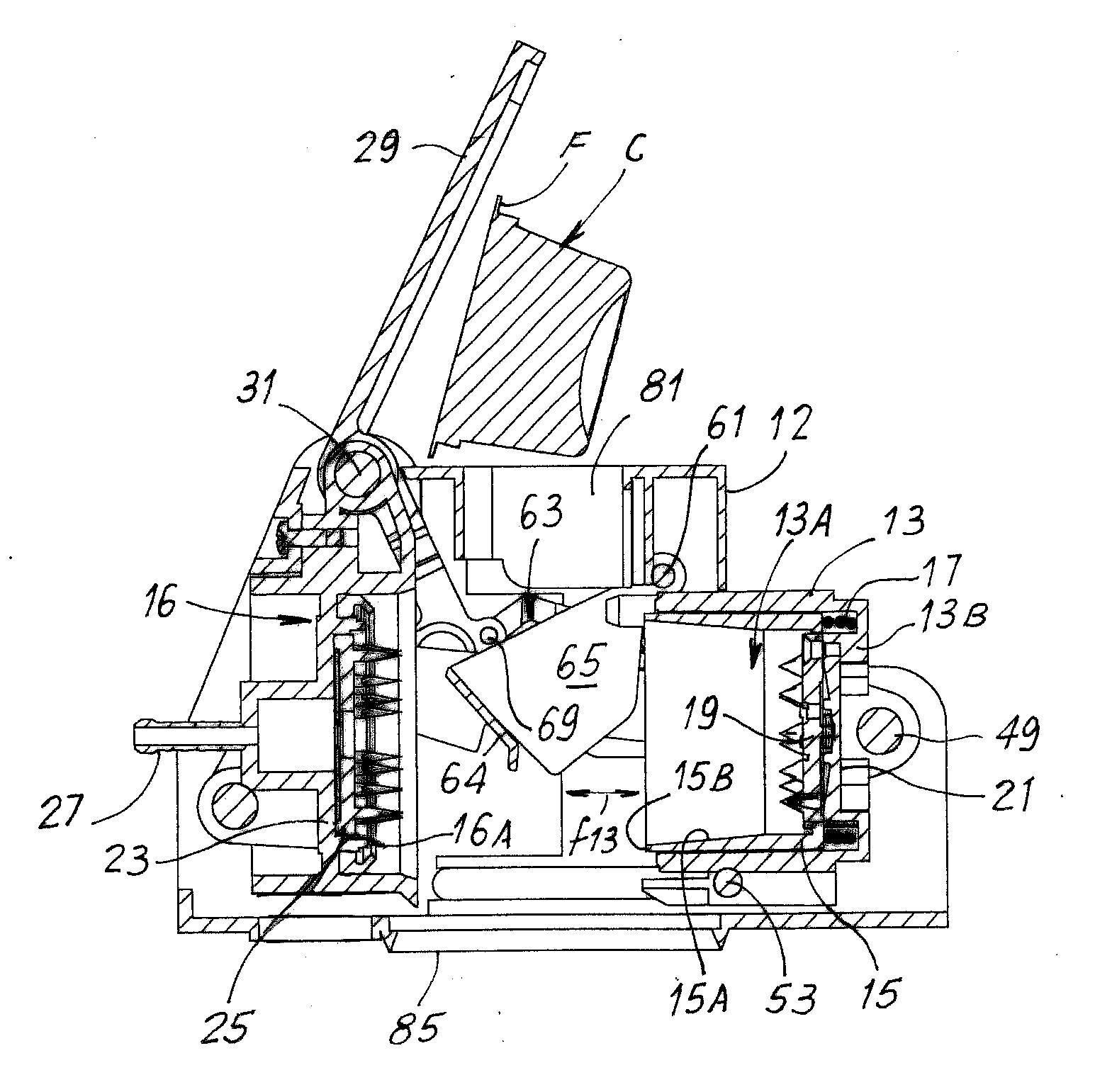

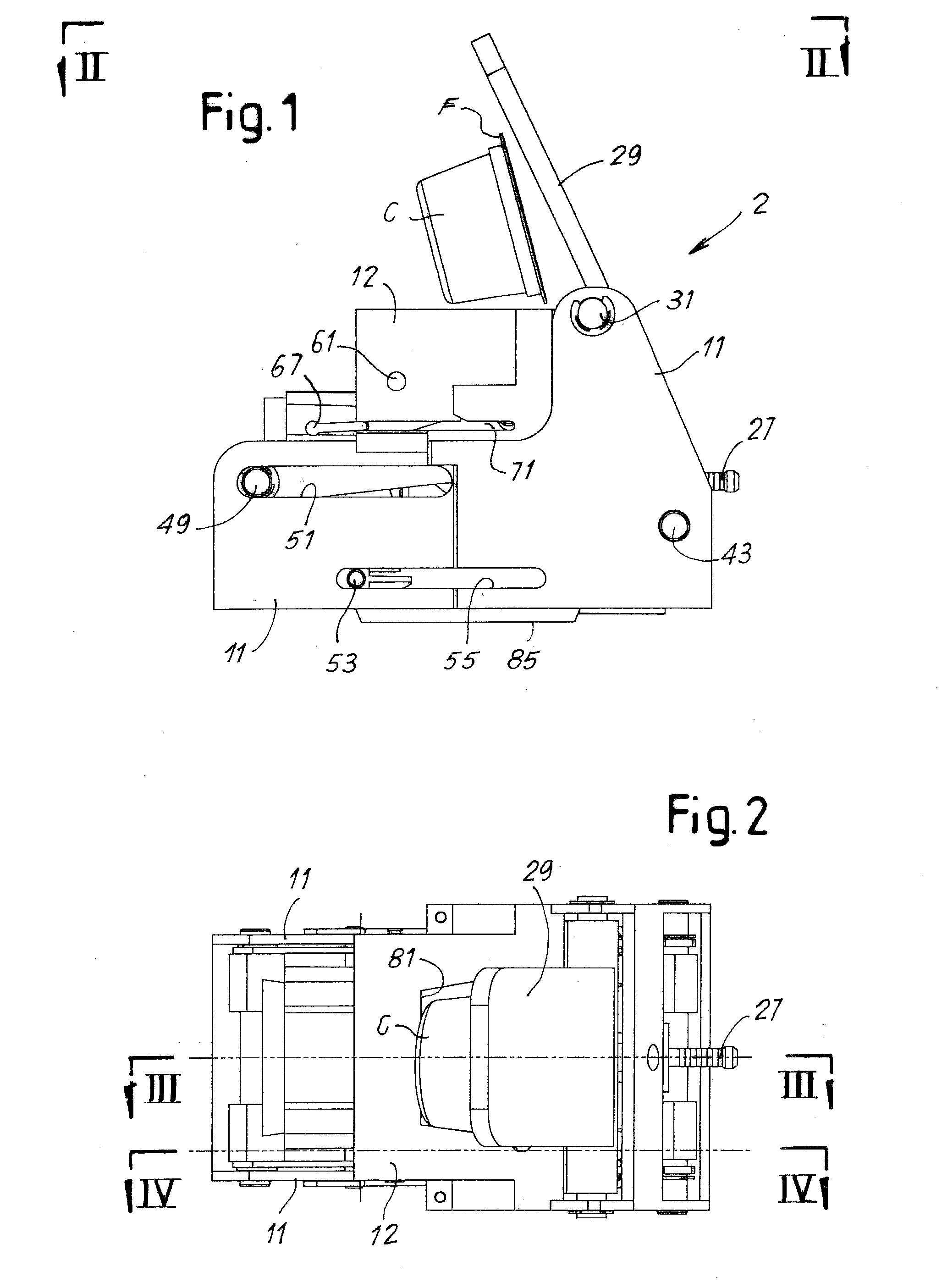

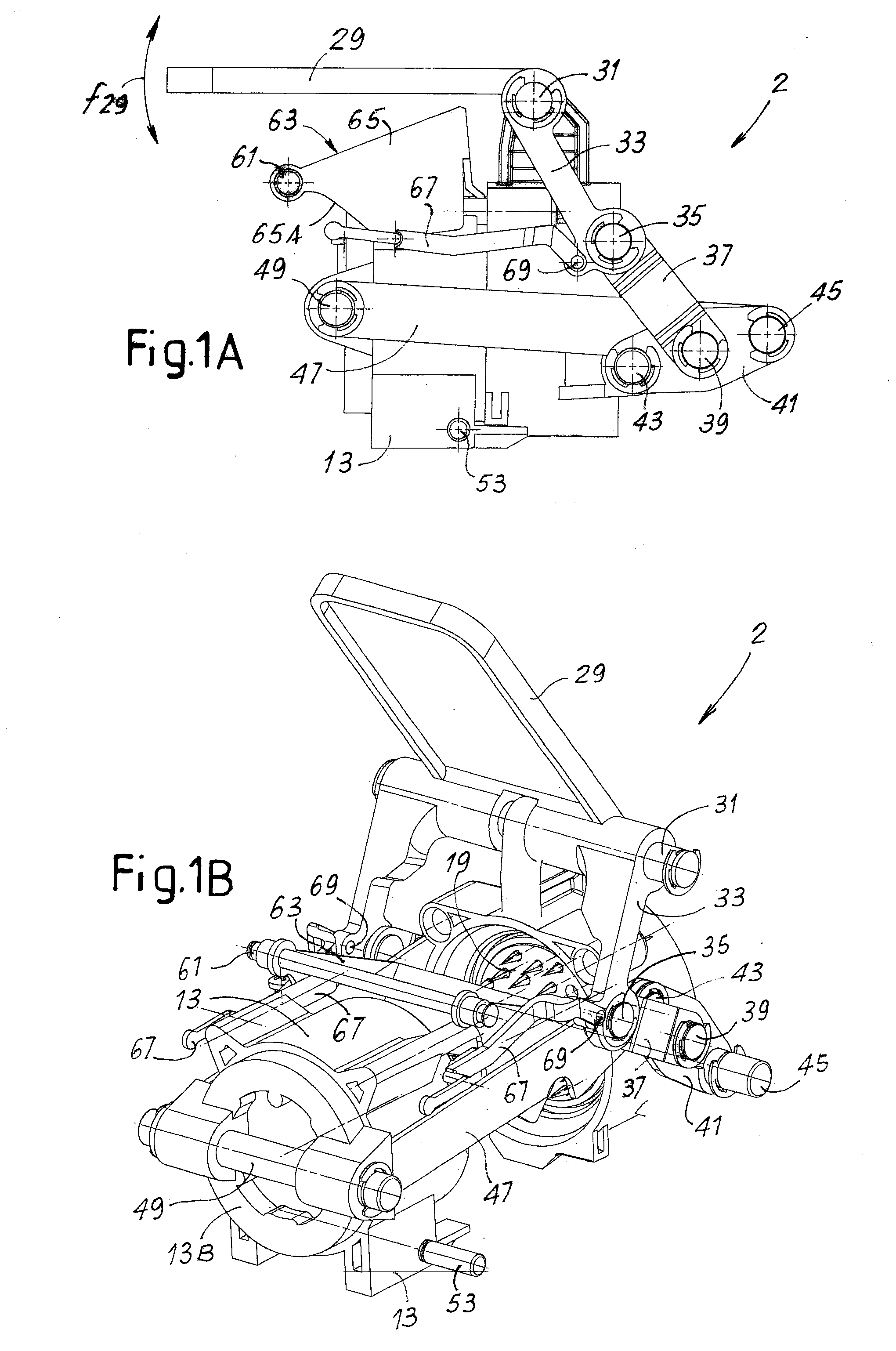

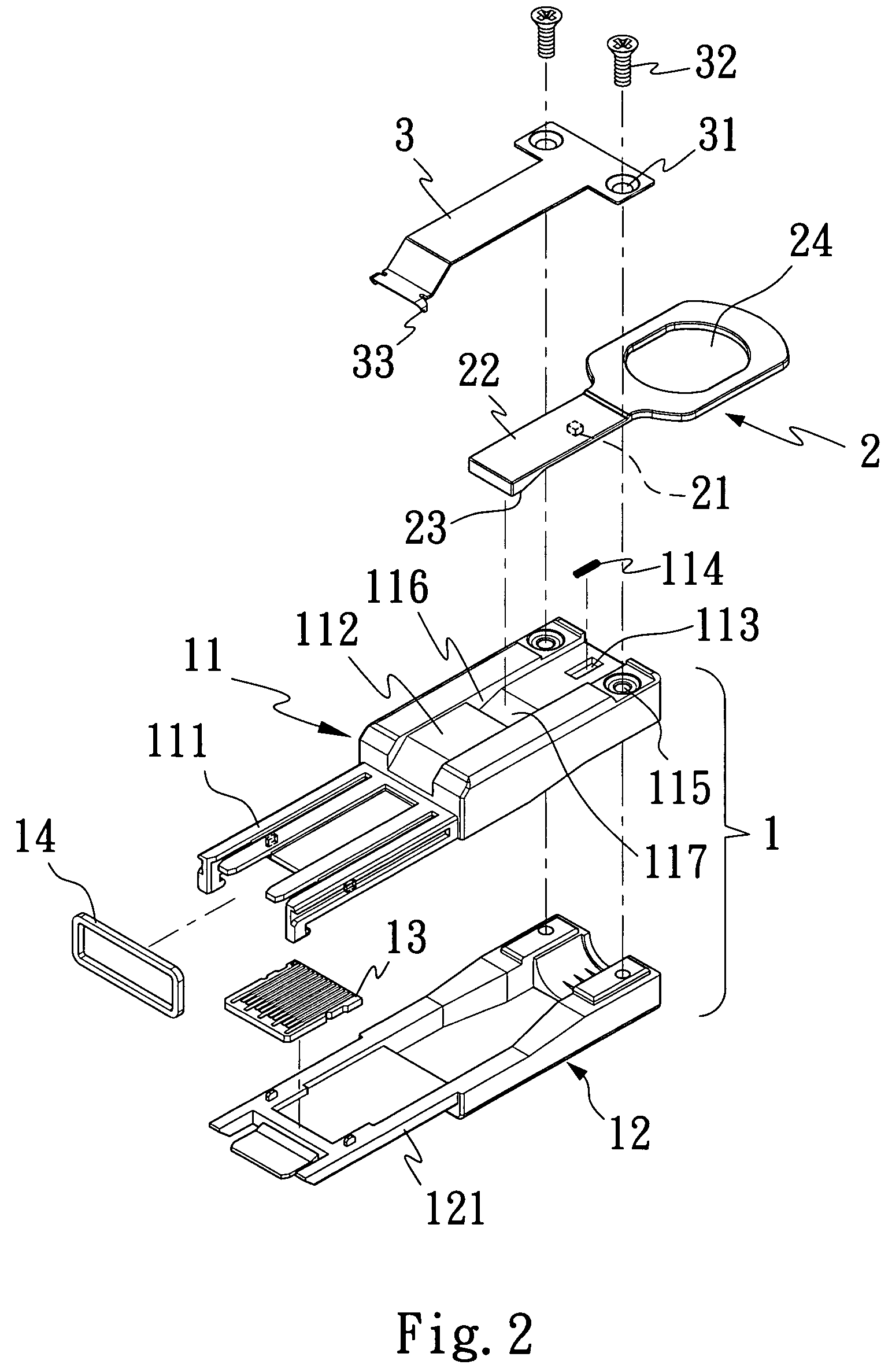

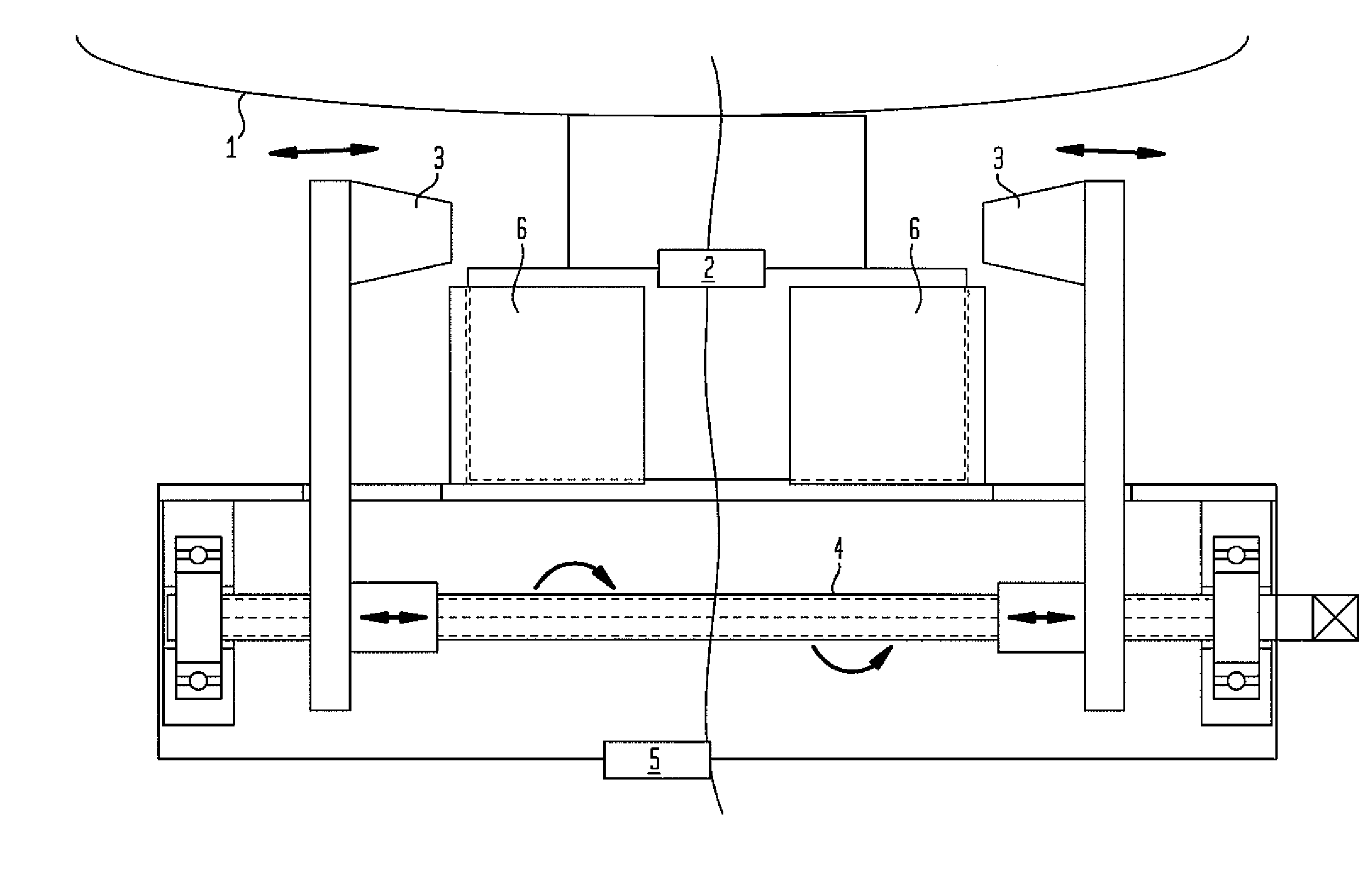

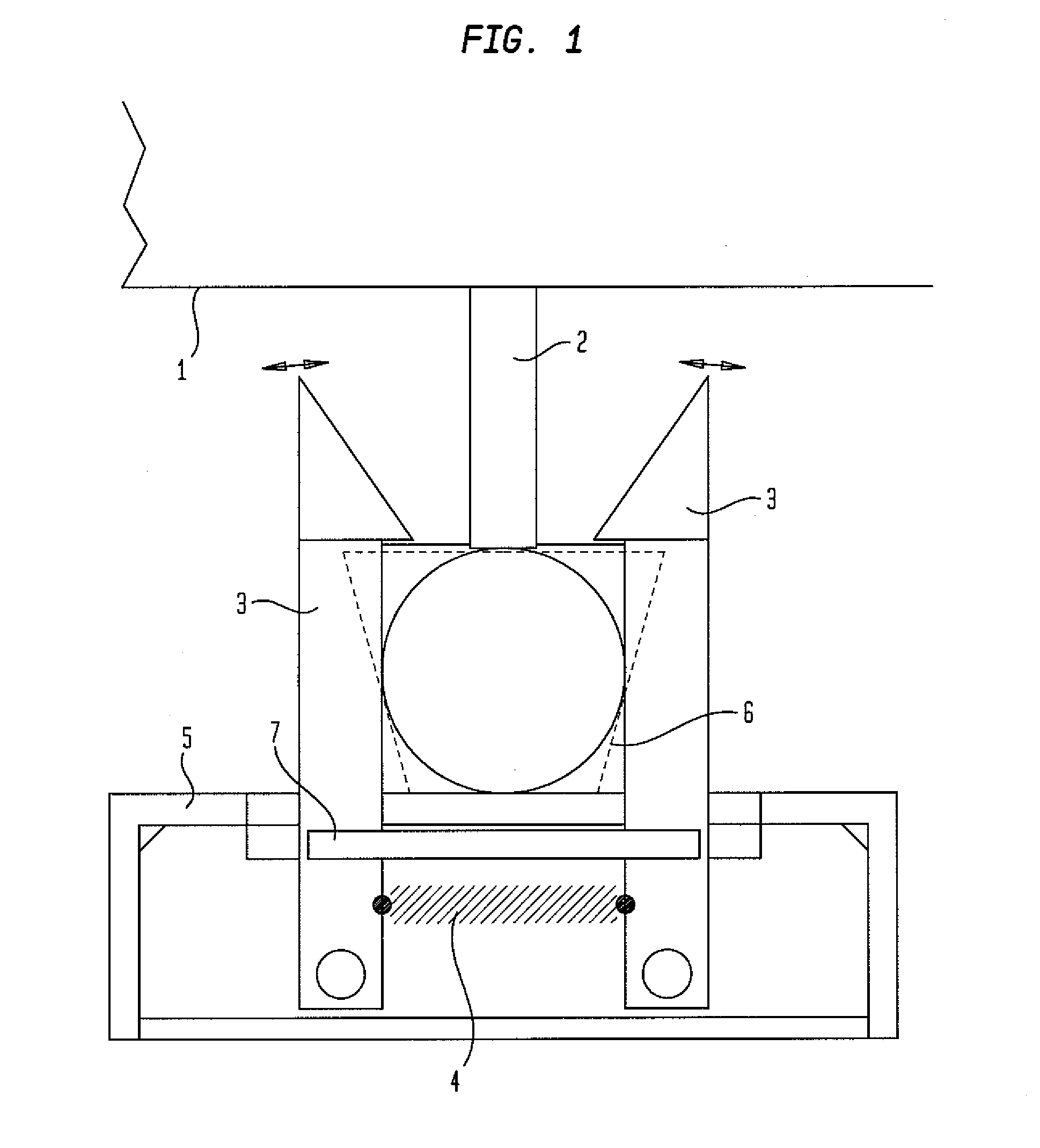

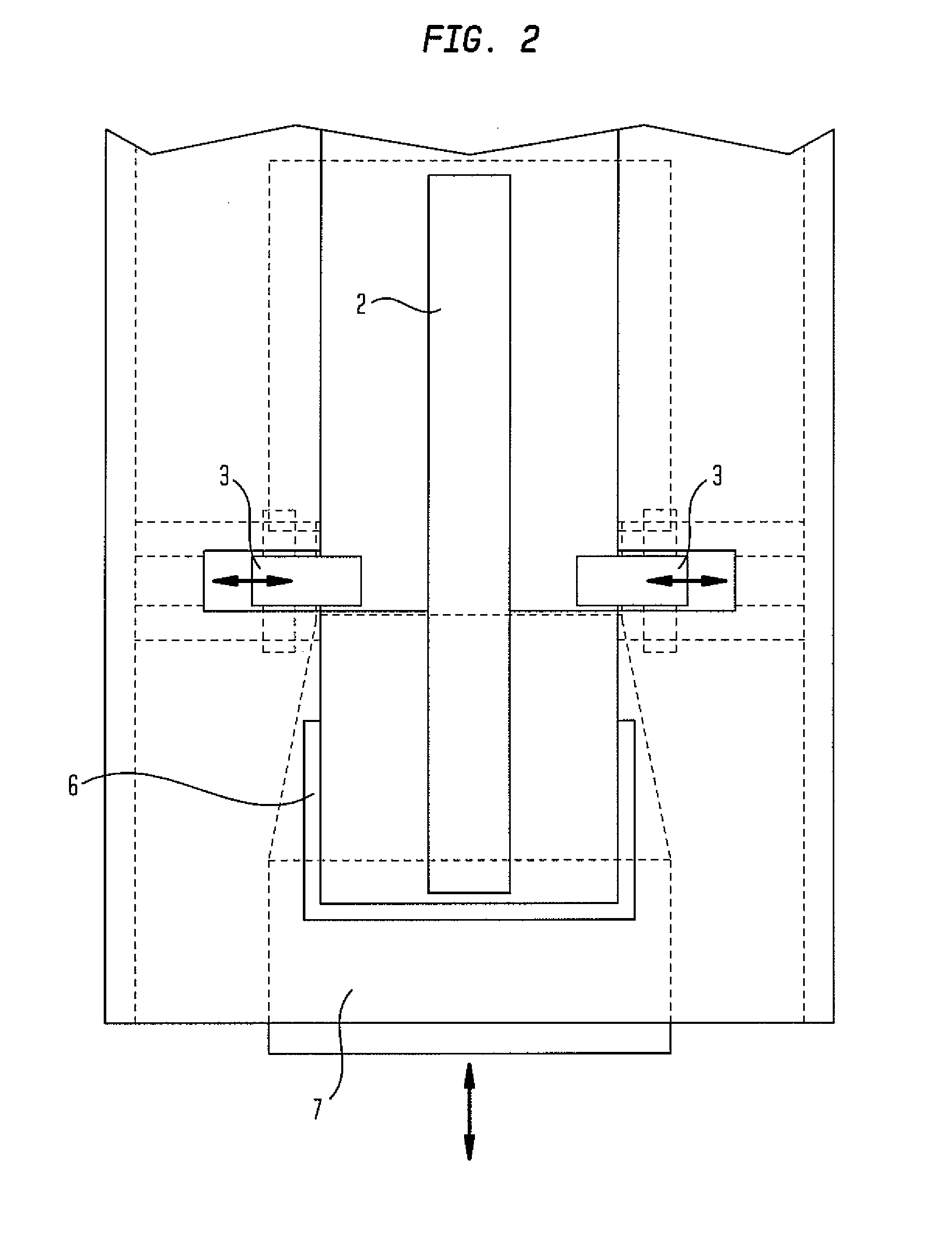

The brewing unit comprises: a brewing chamber (13,16) with a first brewing chamber portion (13) and a second brewing chamber portion (16), mobile one with respect to the other to open and close the brewing chamber; a channel (81) for inserting said capsules (C) towards said brewing chamber; a mobile deviator (63) interposing between said first brewing chamber portion (13) and said second brewing chamber portion (16) to deviate said capsules (C) towards the inside of one of said first and second brewing chamber portions (13, 16) of.

Owner:VERSUNI HLDG BV

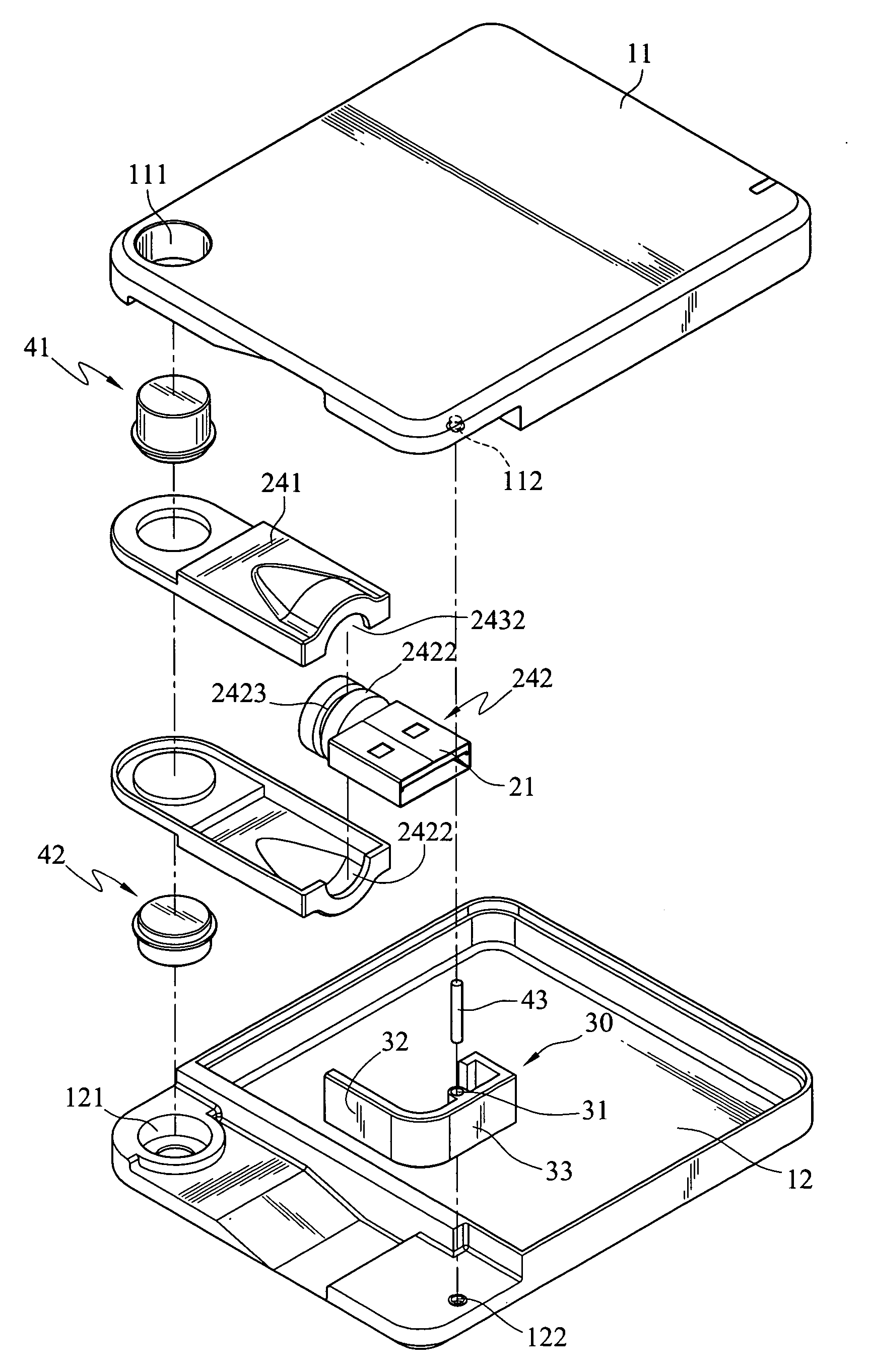

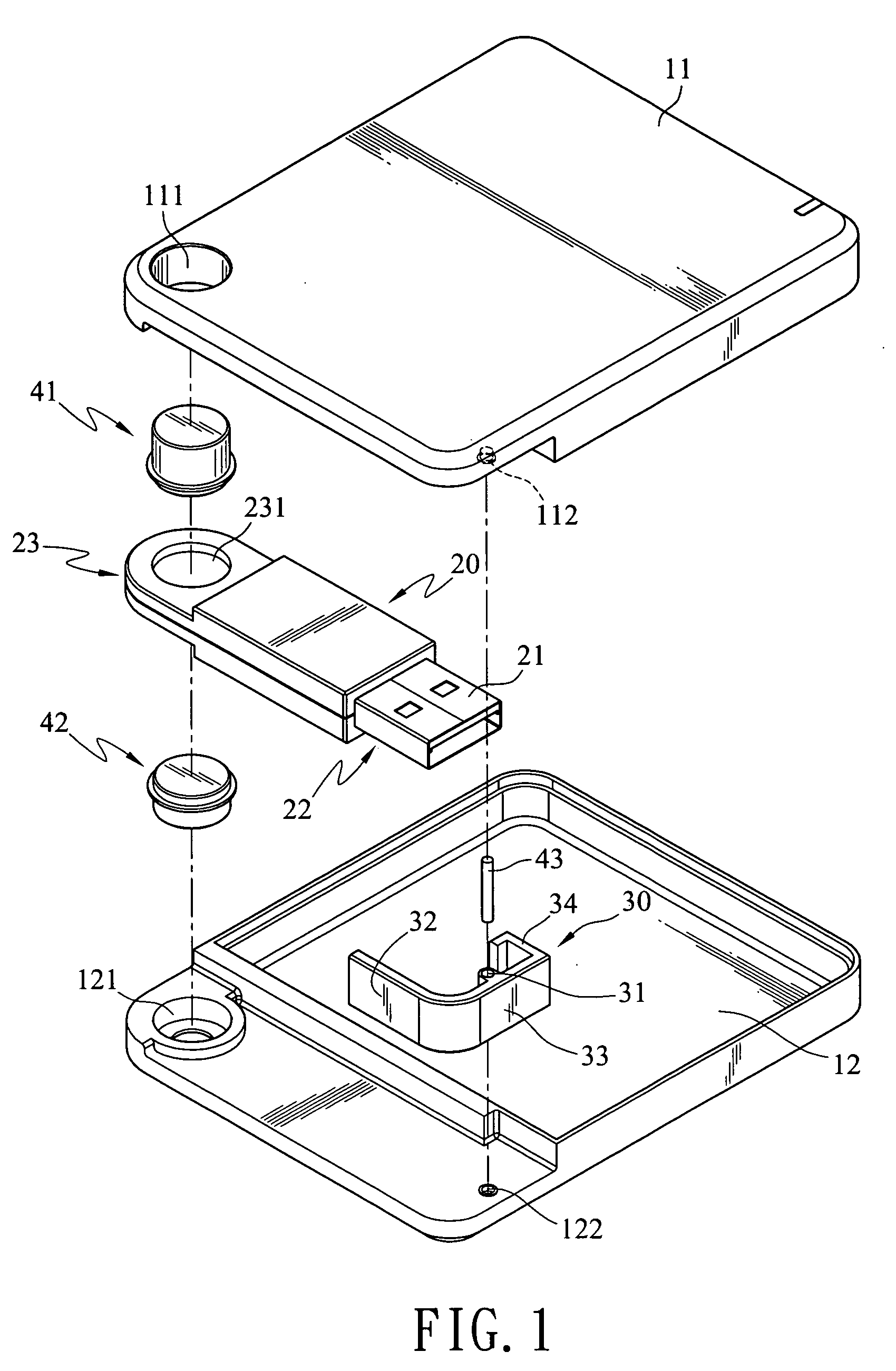

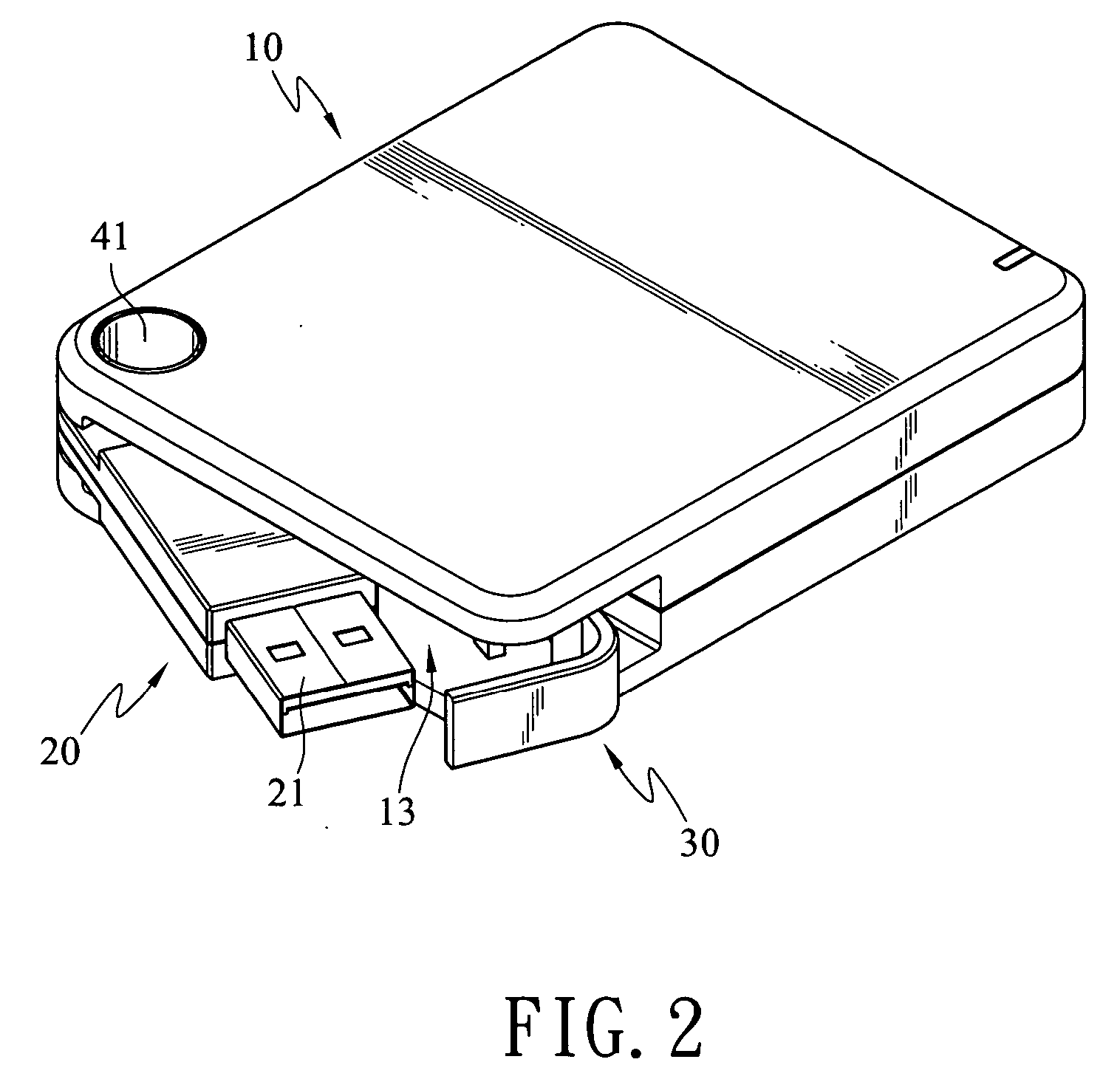

External connecting electronic apparatus

InactiveUS20050161513A1Facilitate carrying and storingEasy outSensing record carriersRecord carriers used with machinesExternal connectionEngineering

Owner:MICRO-STAR INTERNATIONAL

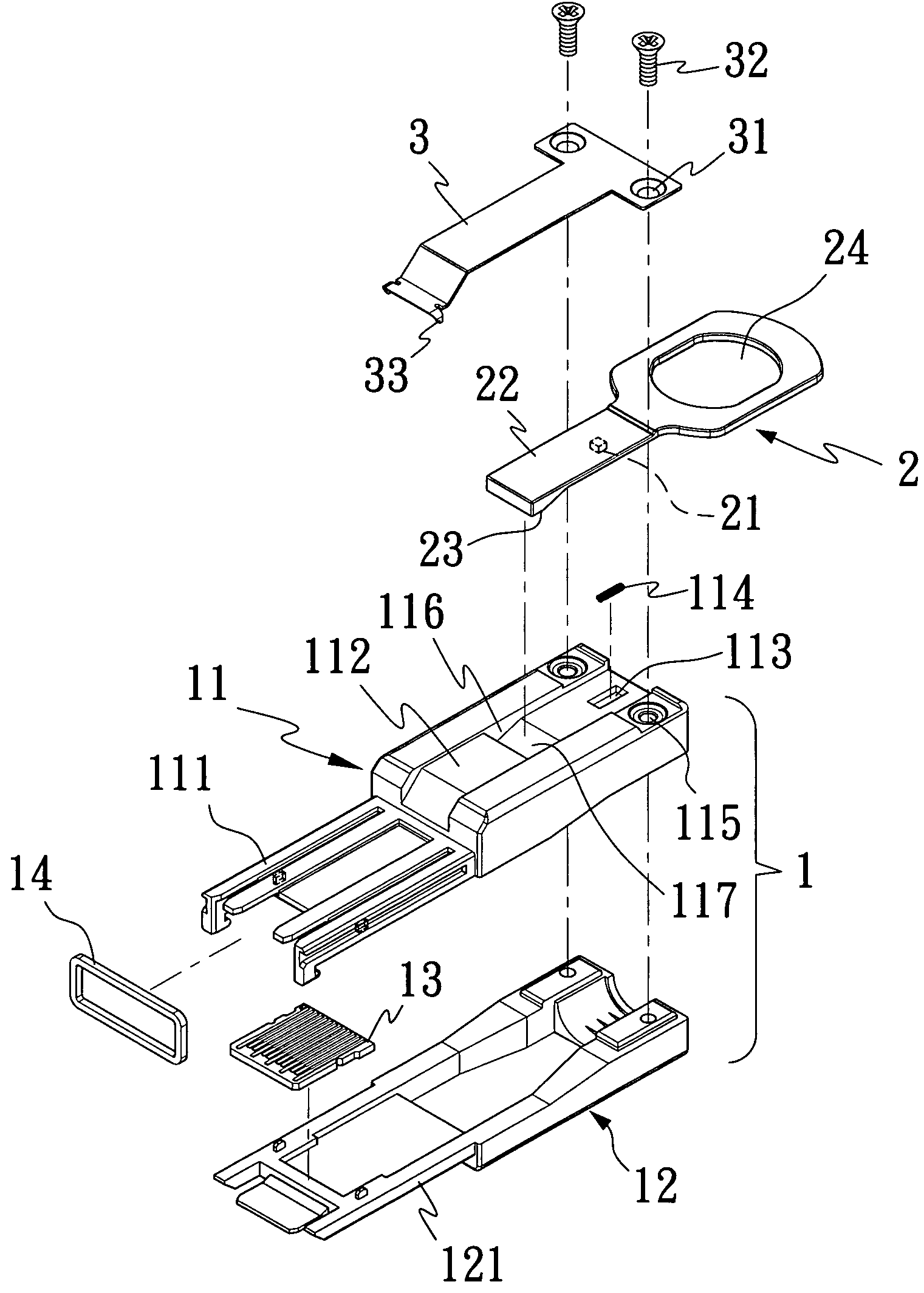

Plug connector

Owner:ALL BEST ELECTRONICS

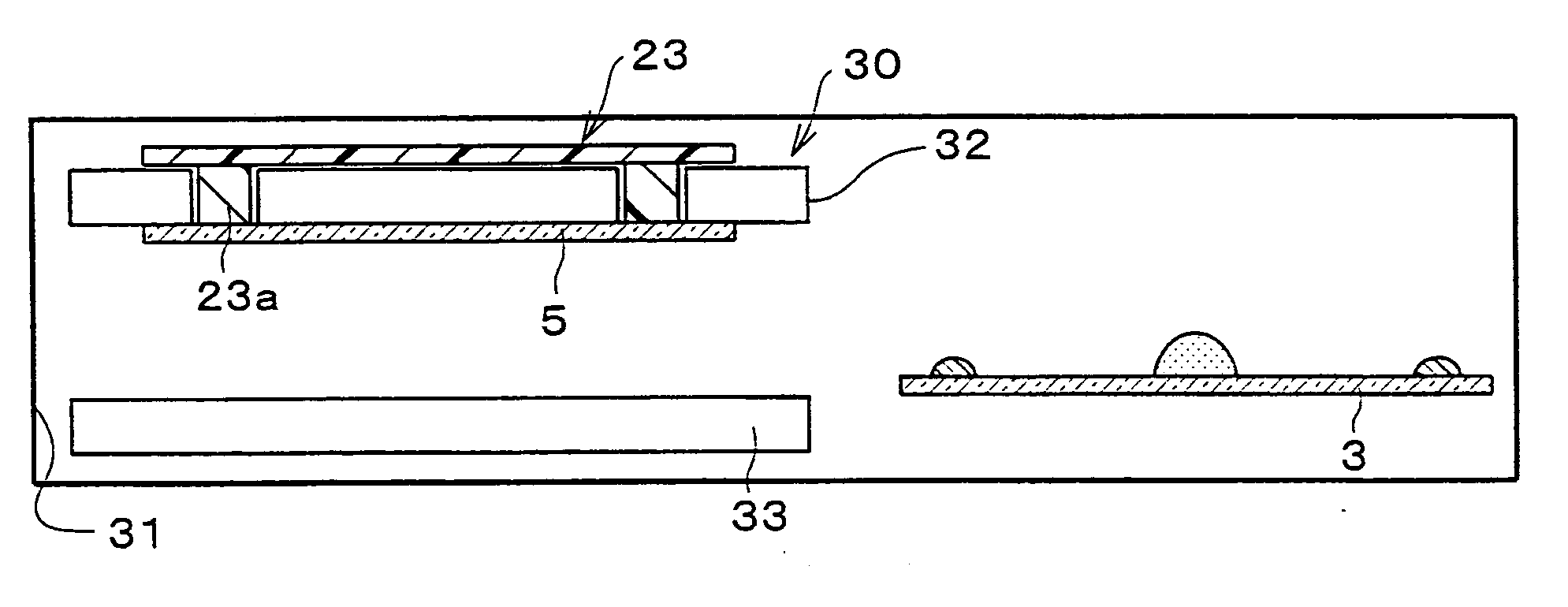

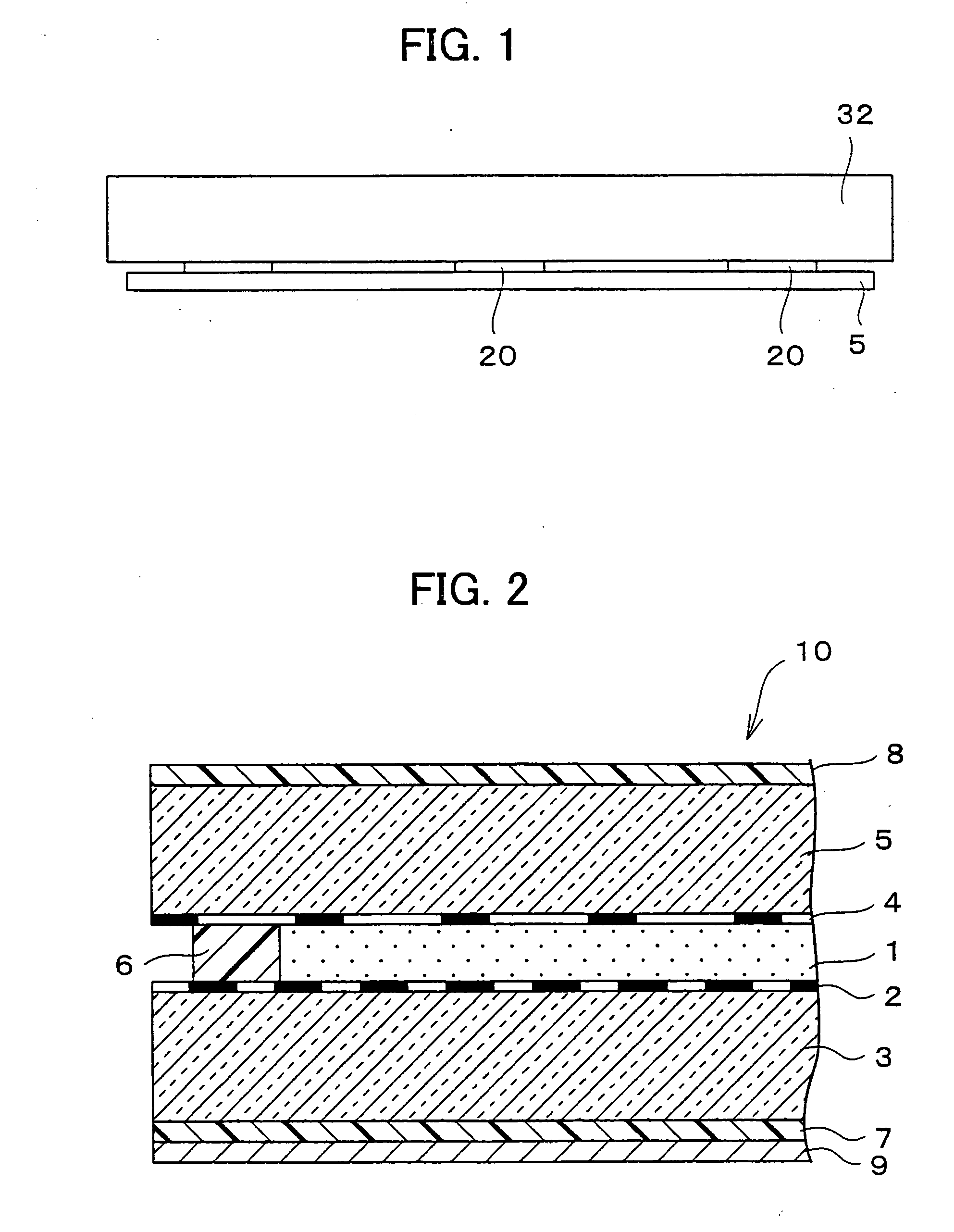

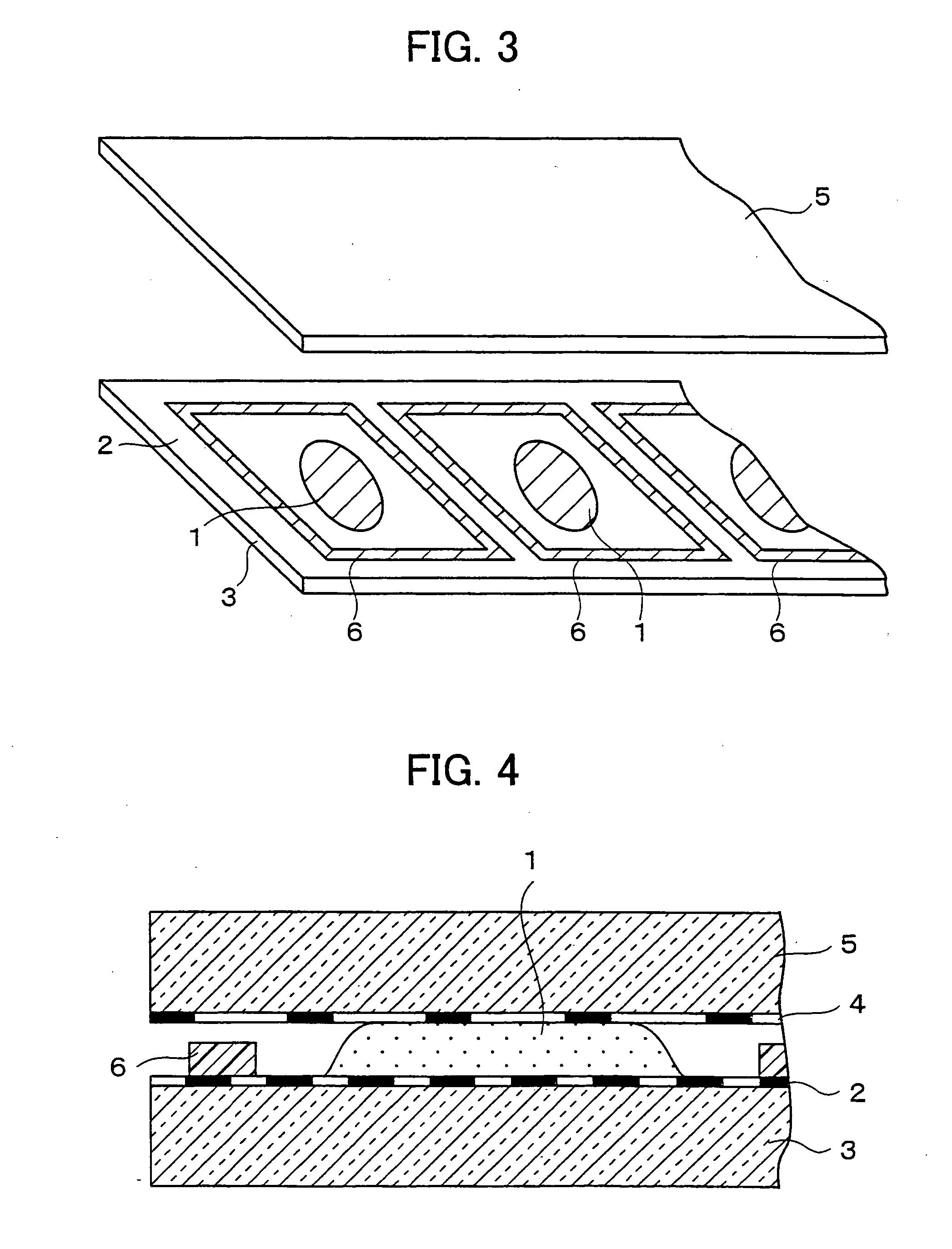

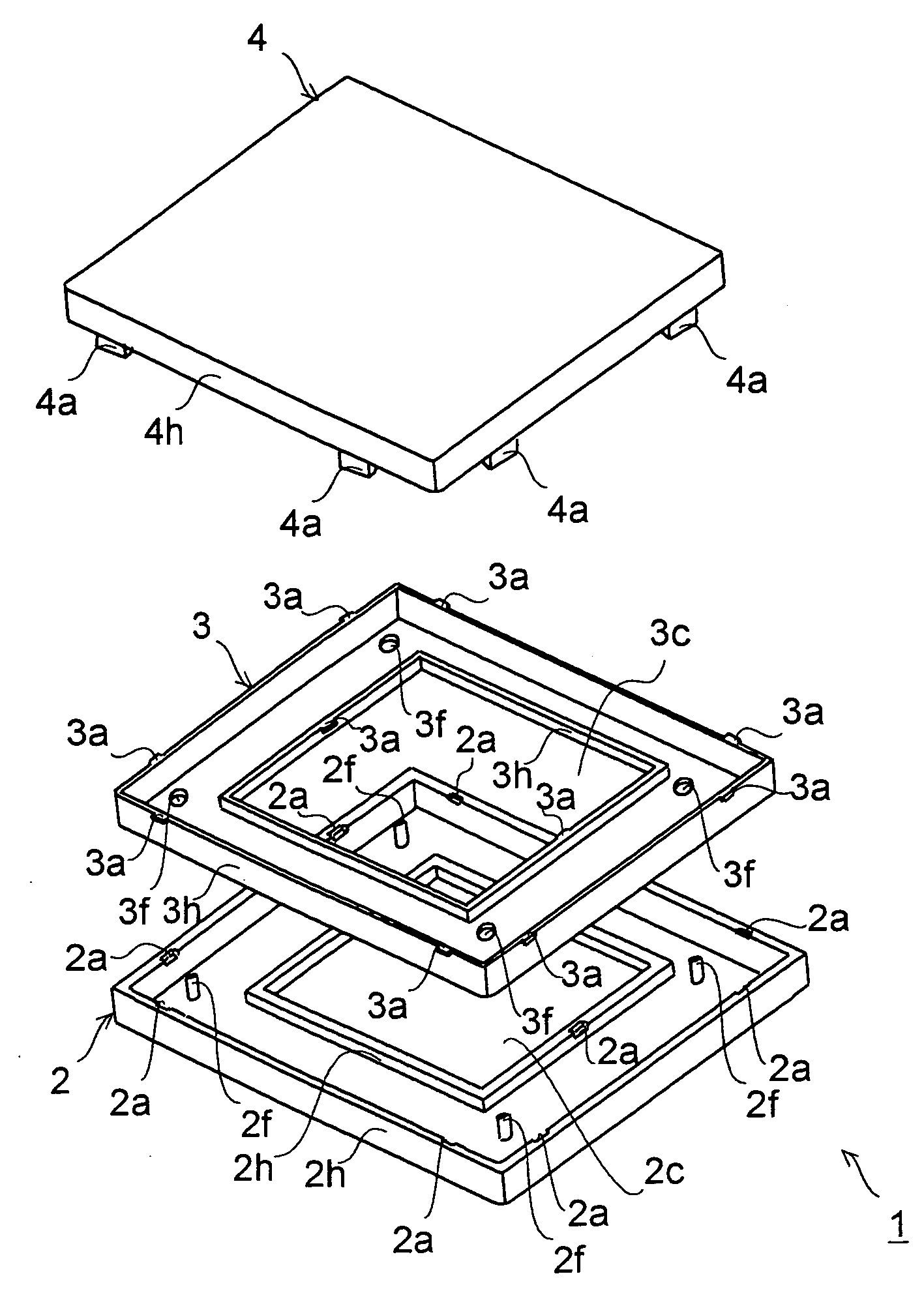

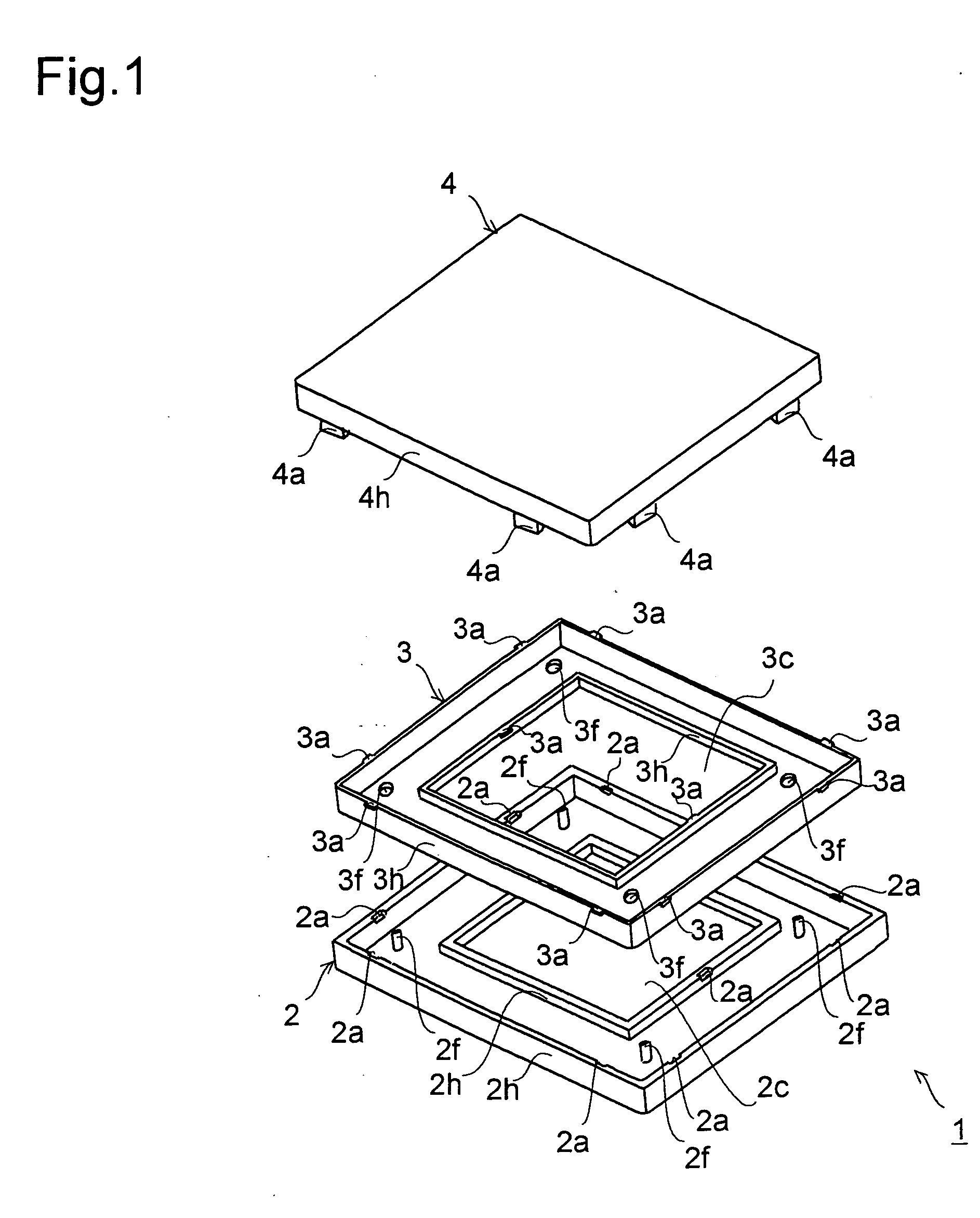

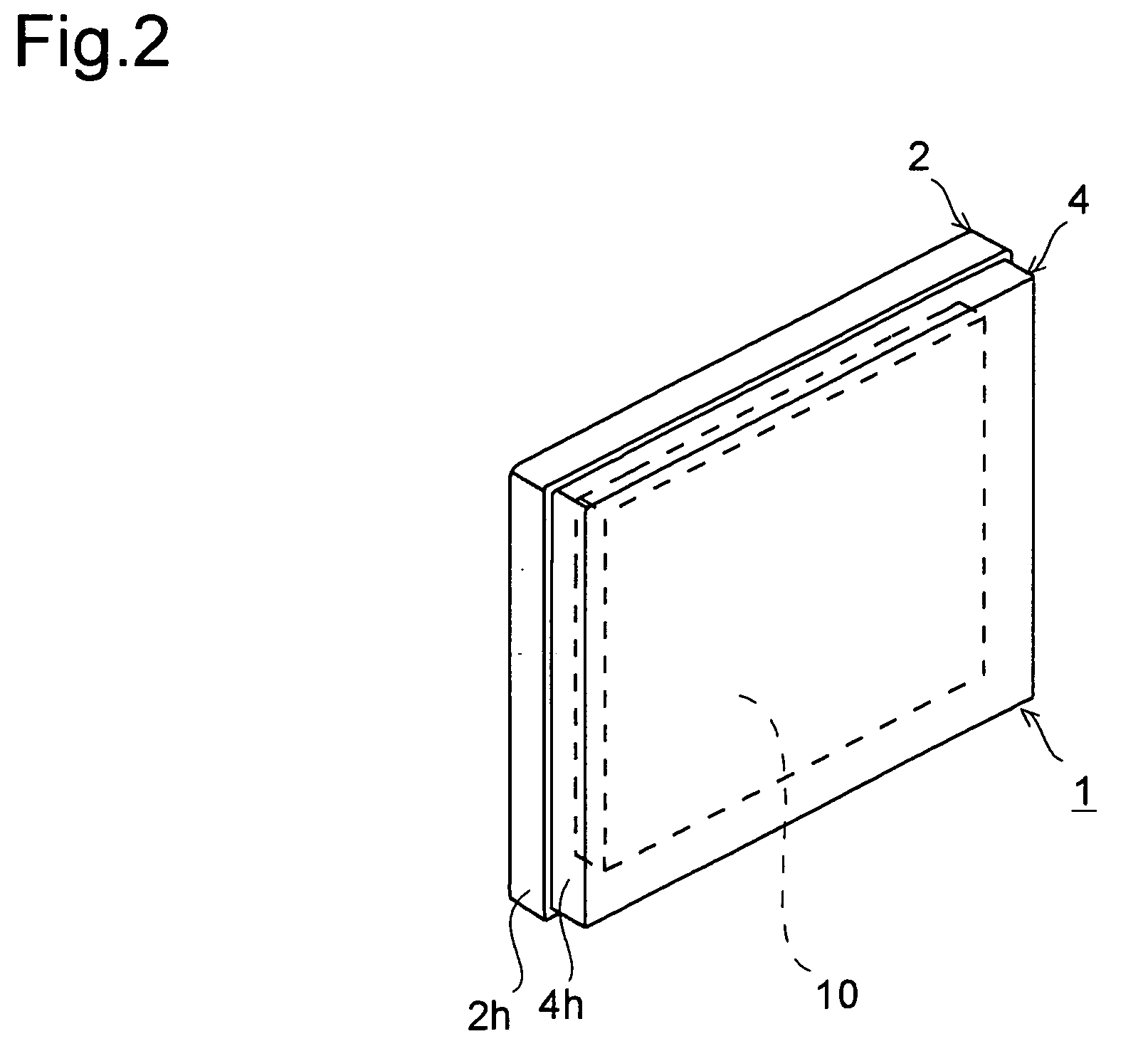

Method for holding substrate in vacuum, method for manufacturing liquid crystal display device, and device for holding substrate

ActiveUS20050167036A1Position registration is easySuitable for useDecorative surface effectsSolid-state devicesLiquid-crystal displayEngineering

In a method of the present invention for holding a substrate in a vacuum, a glass substrate (5) is held by an adhesive pad (20) or an adhesive sheet, both of which are made from a material containing a diene based resin, whereby an adhesive agent is prevented from remaining on the substrate, and the adhesive sheet can be detached with ease from the substrate after assembling the substrates.

Owner:AIMECHATEC LTD

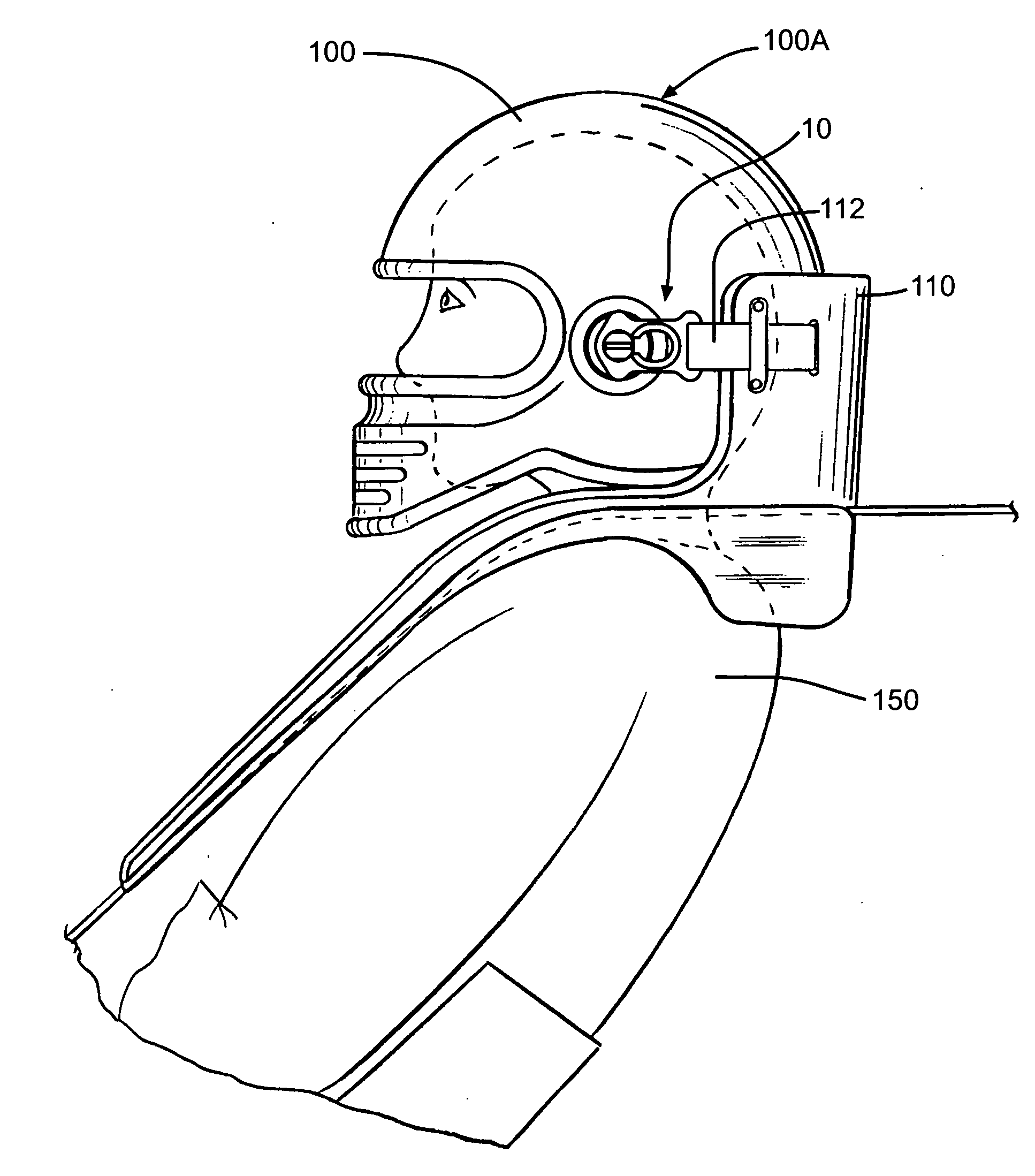

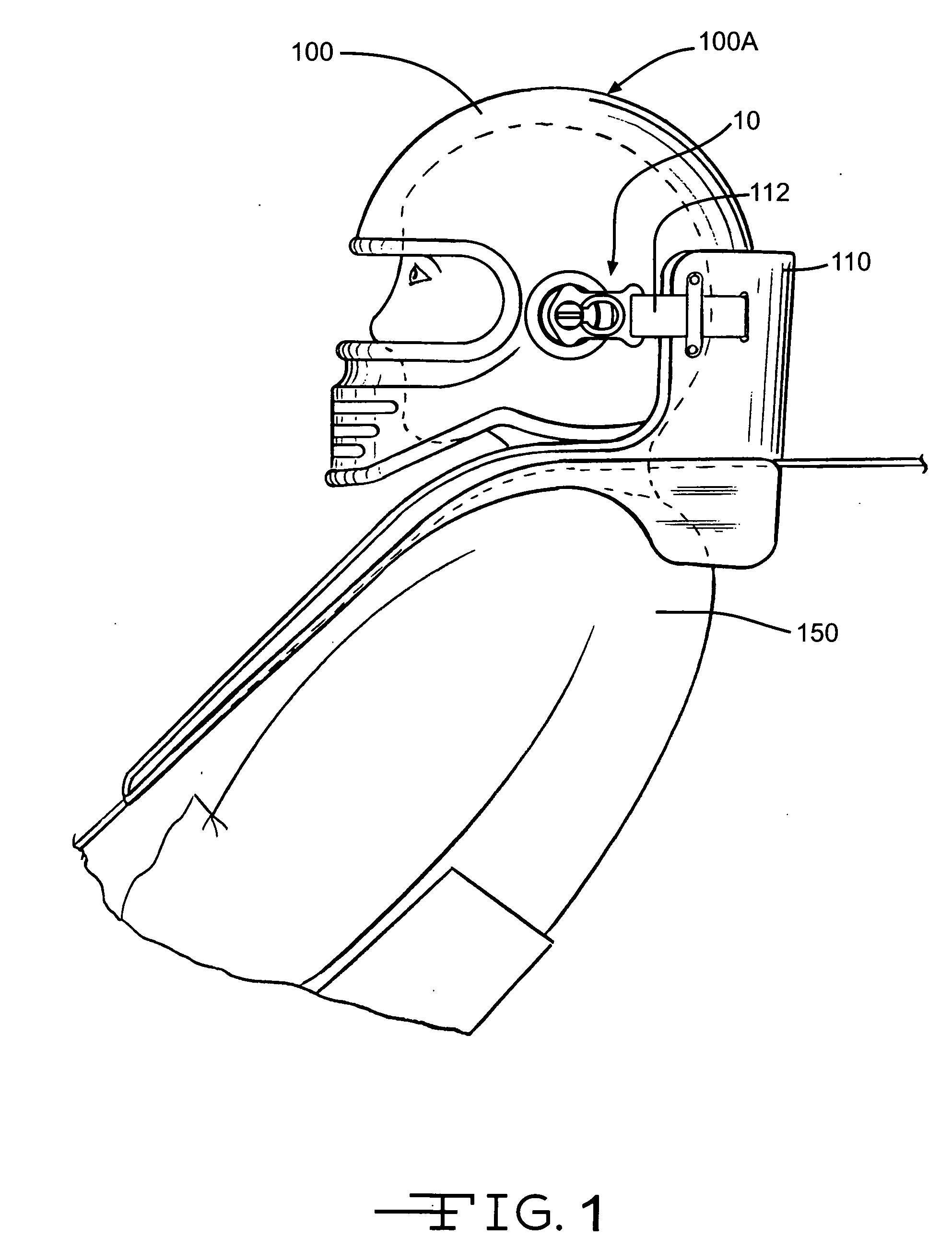

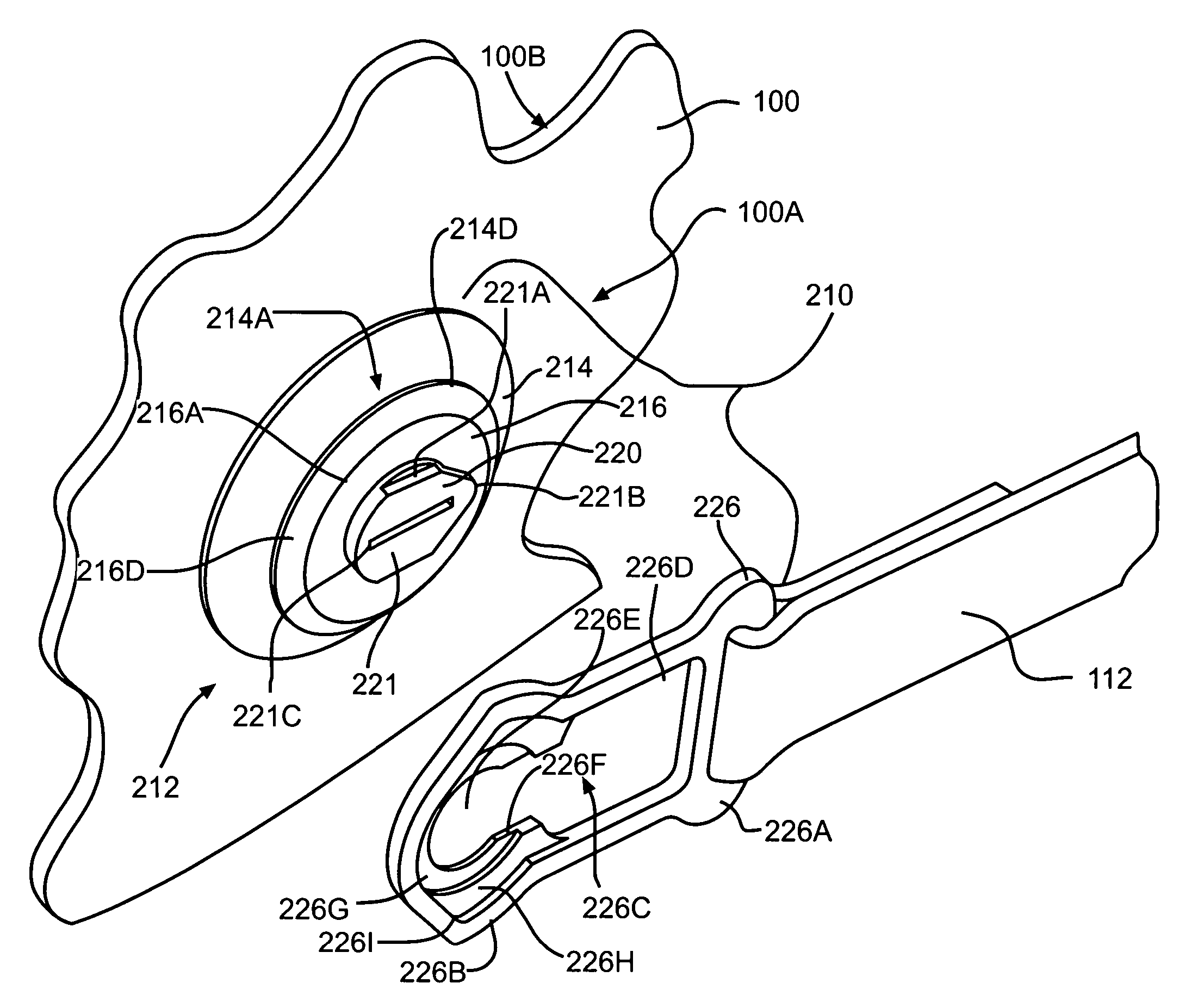

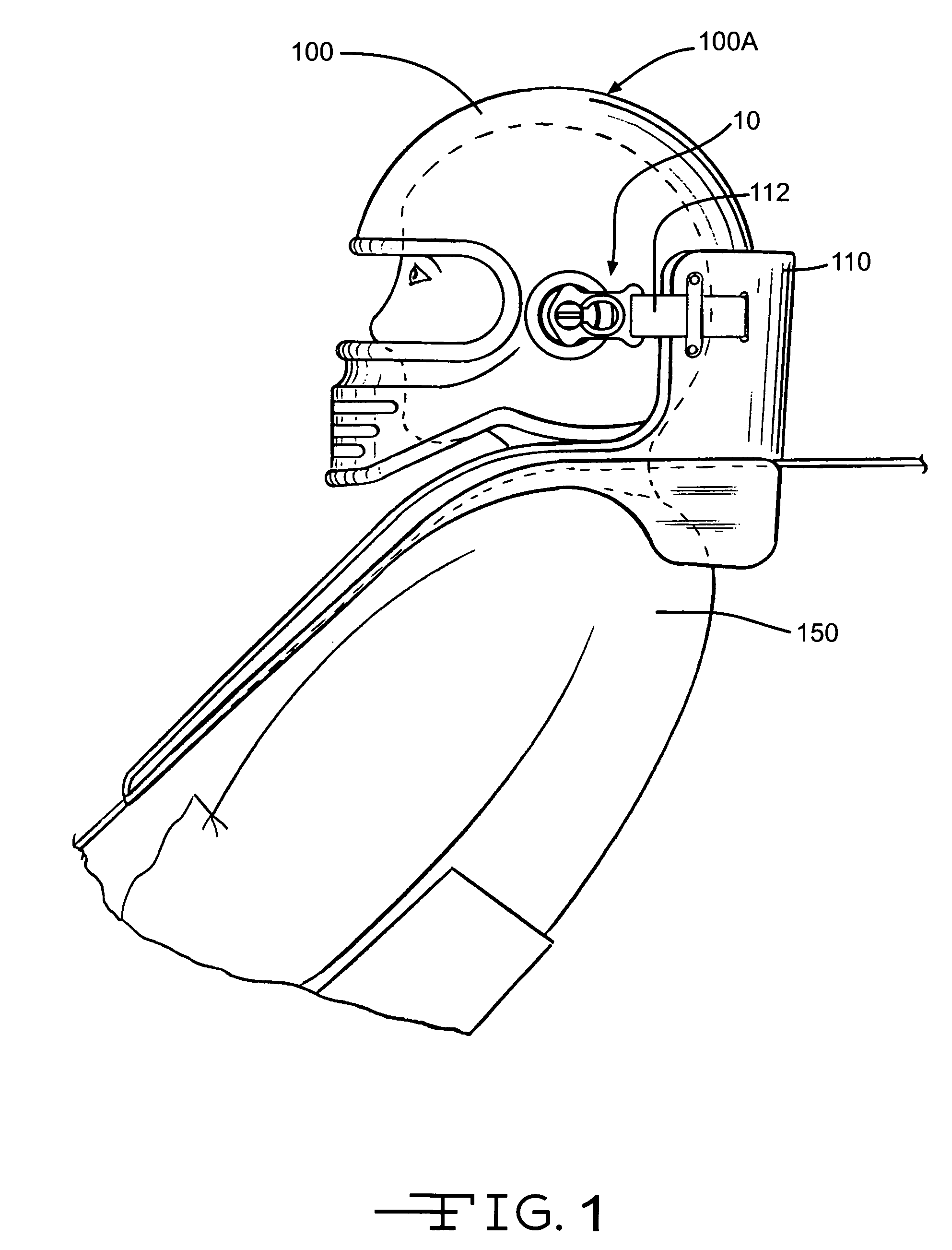

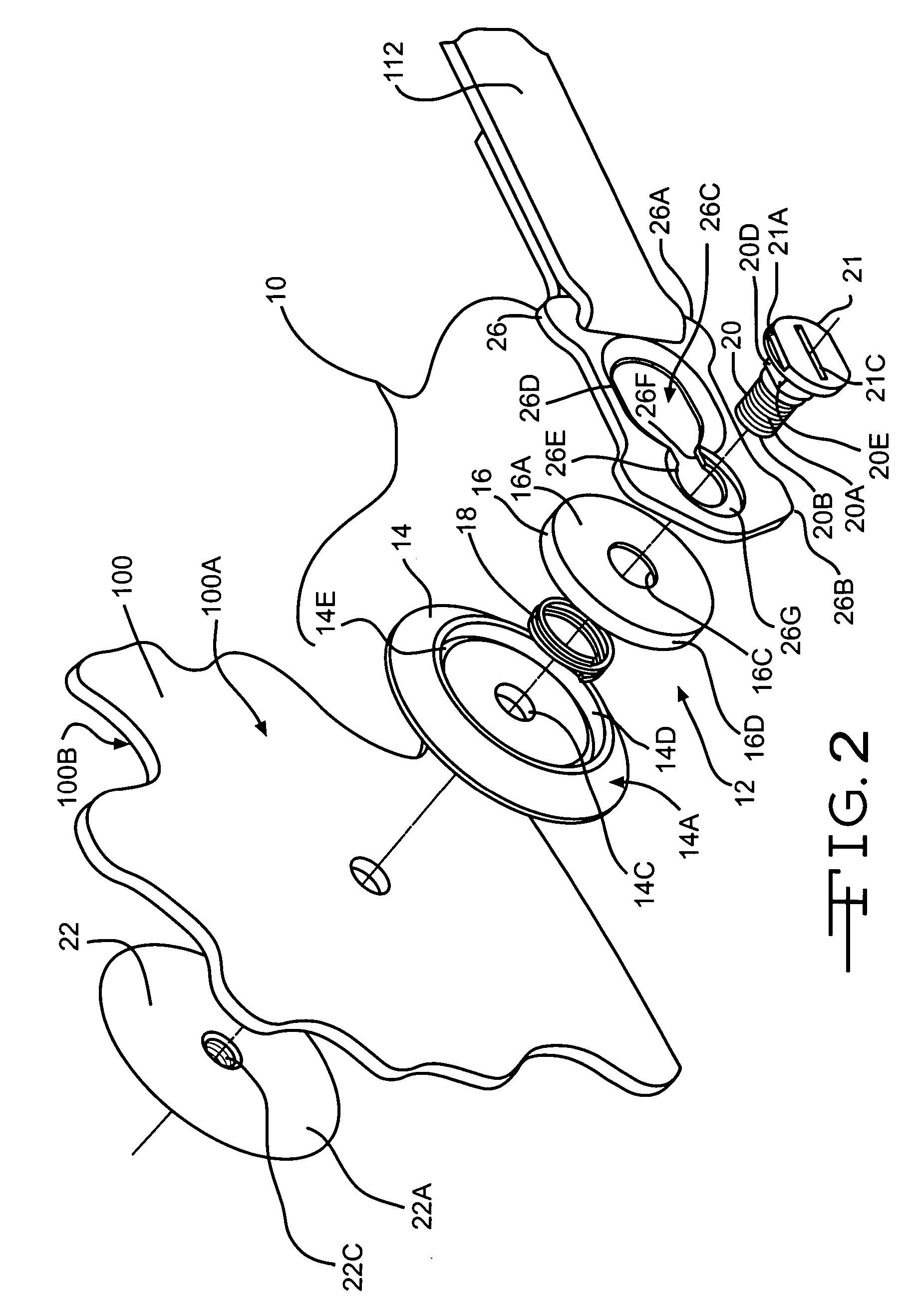

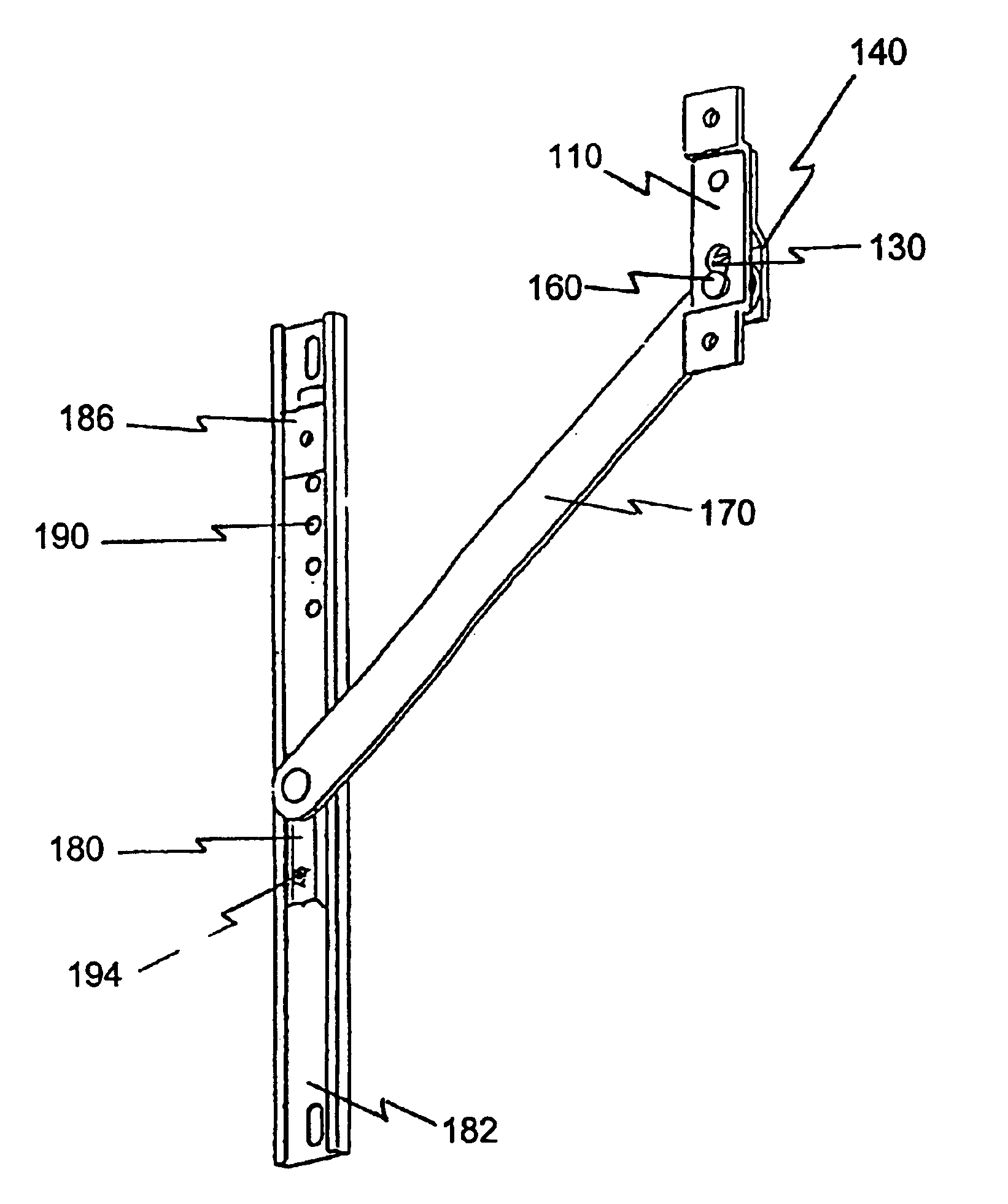

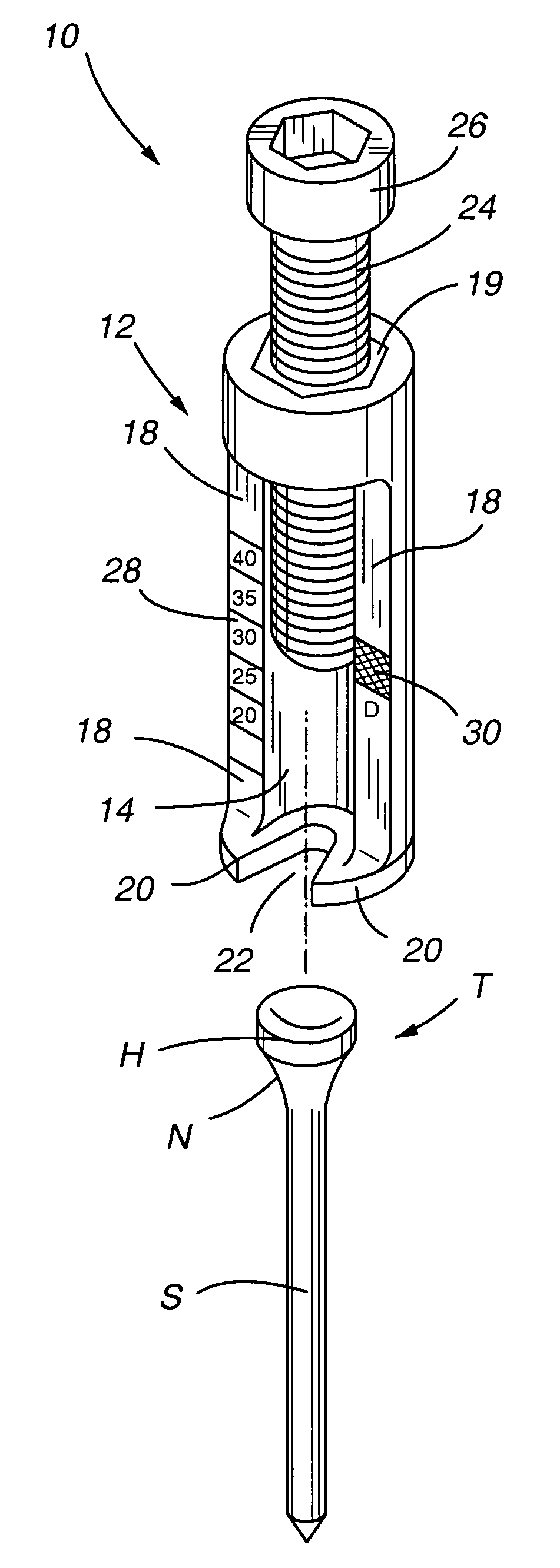

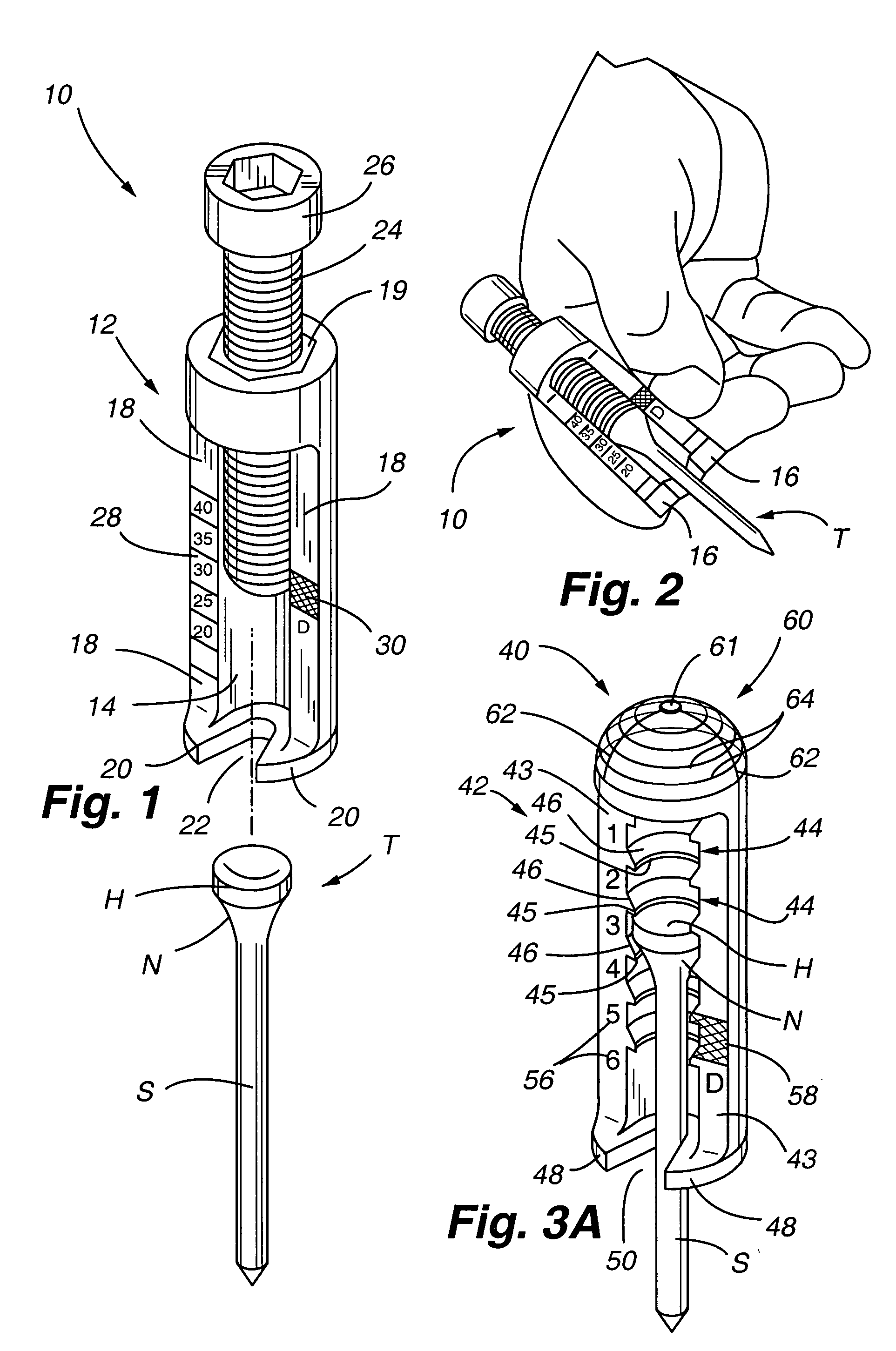

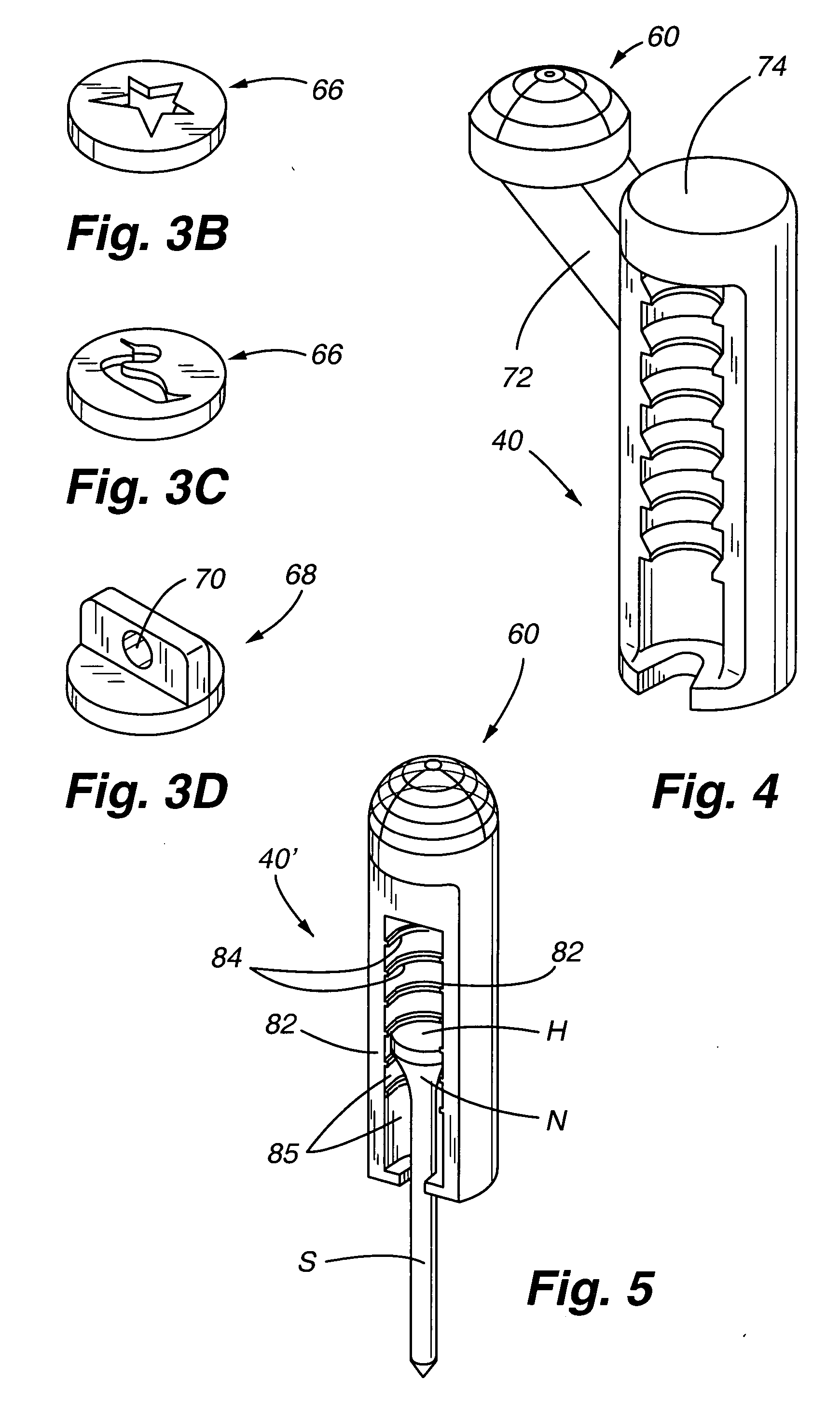

Post attachment device

ActiveUS20050204457A1Reduce distortionEasy outSnap fastenersFasteningsHead and neckMechanical engineering

A post attachment device for connecting a helmet to a head and neck support. The device includes a post anchor having a base, a button, a resilient member, a post, a retainer and a catch having a slot with a larger first section connected by a channel to a smaller second section. The button is positioned in an indention in the base with the resilient member positioned therebetween. The post extends through the button, the base and the helmet. The retainer is secured on the post adjacent the inner surface of the helmet. To secure the post attachment device, the catch is orientated over the post. The button is then pressed into the base while the catch is moved backwards to move the post into the second section of the slot.

Owner:SIMPSON PERFORMANCE PRODUCTS

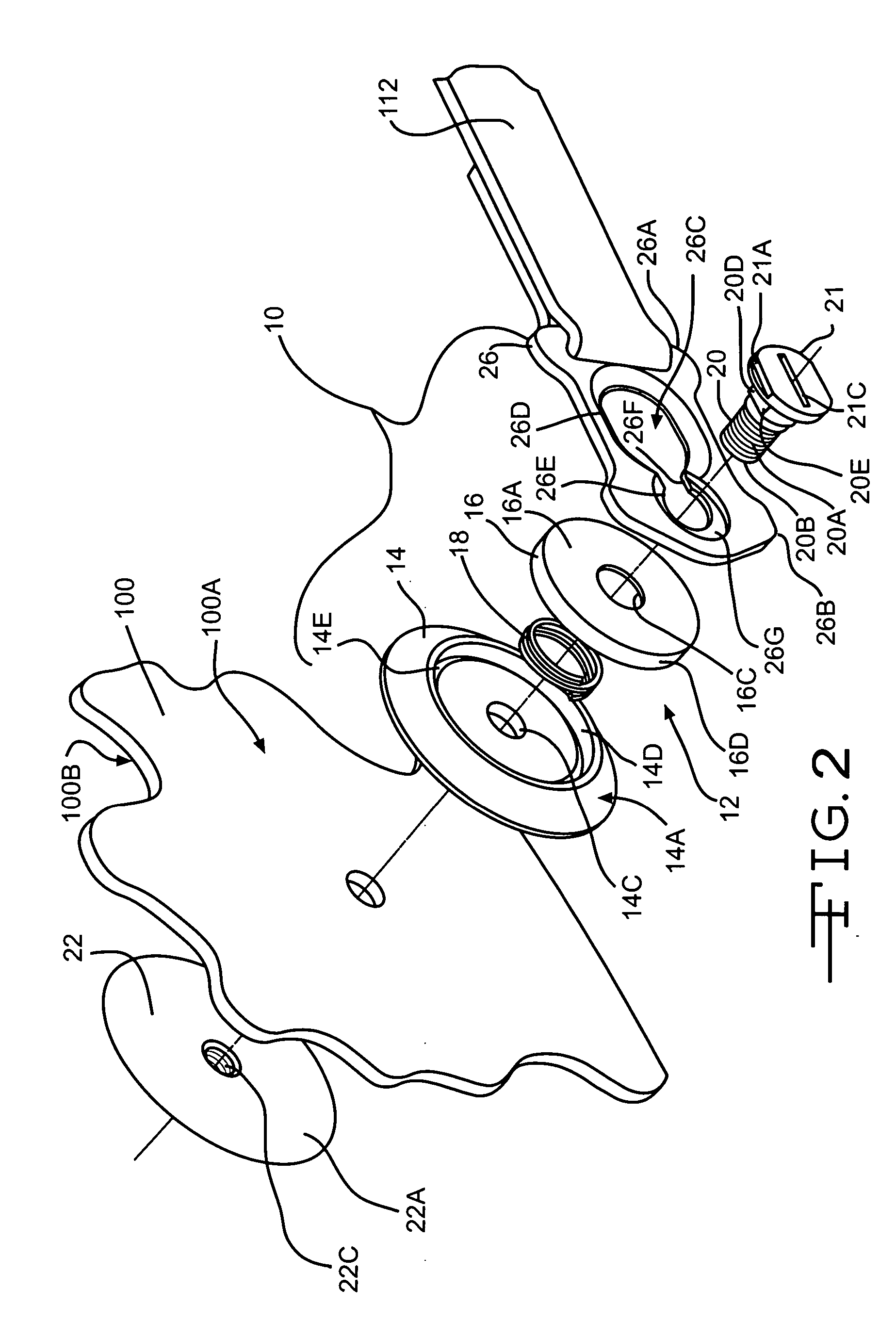

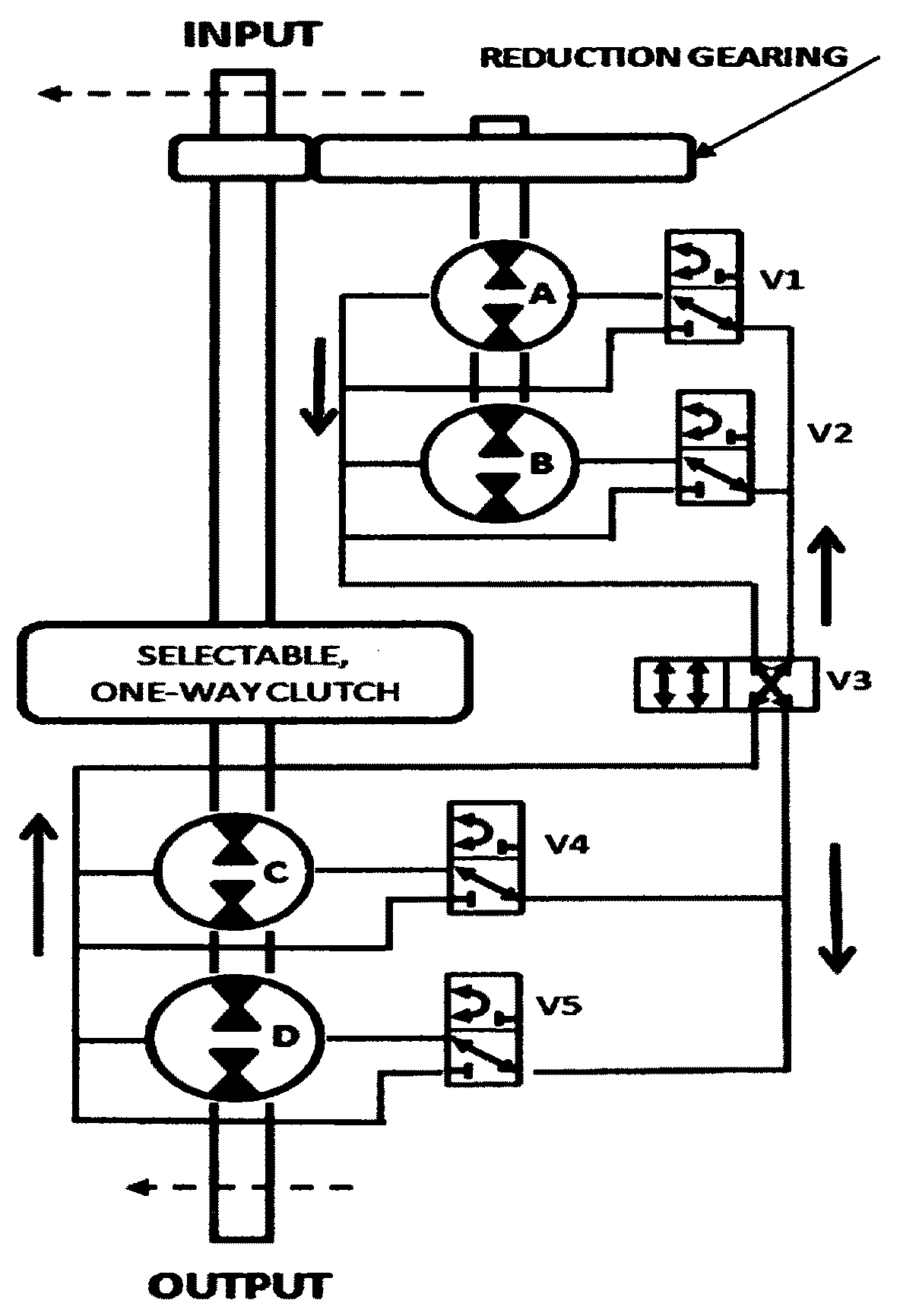

Infinitely-variable, hydro-mechanical transmission using fixed displacement pumps and motors

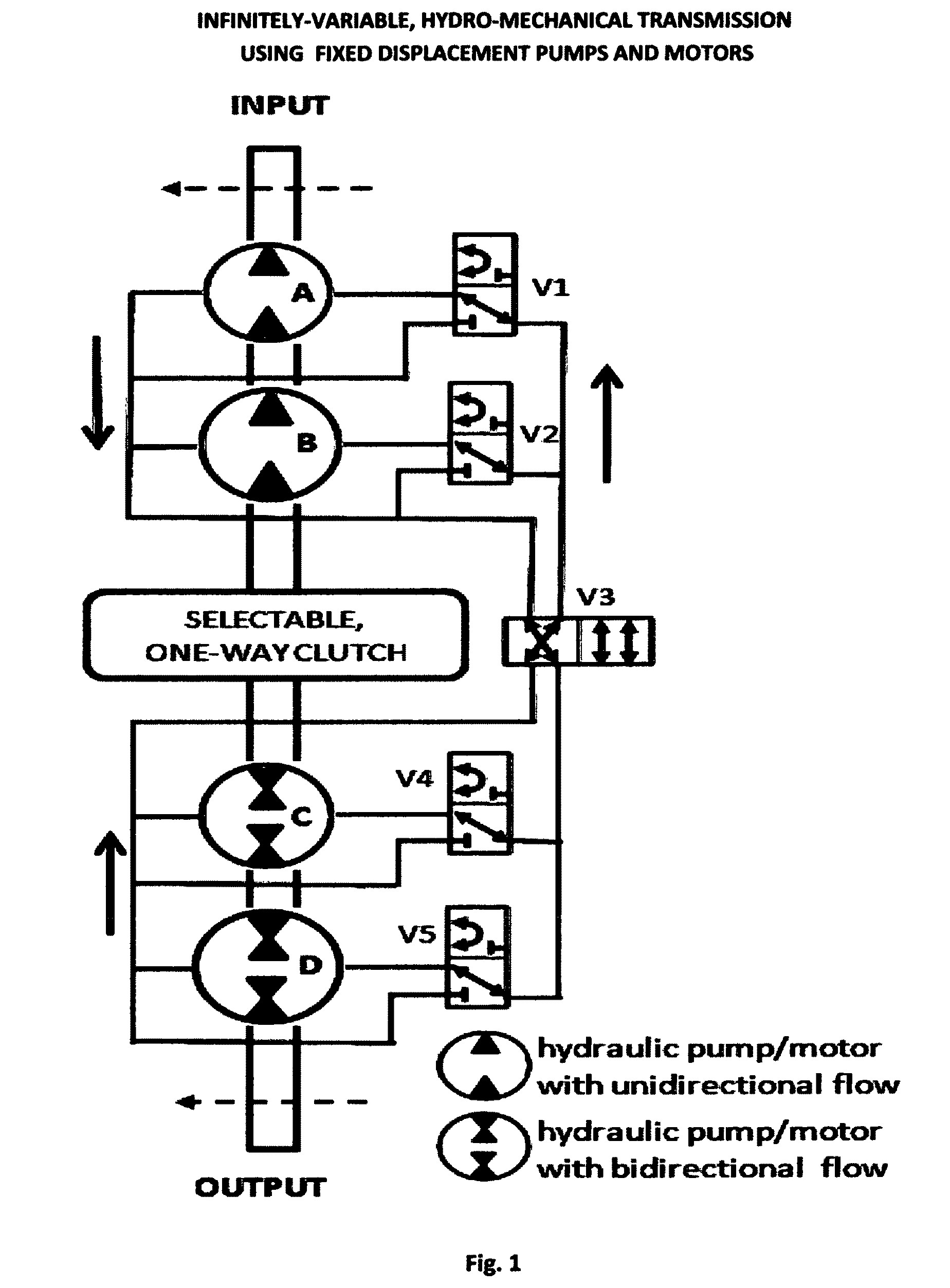

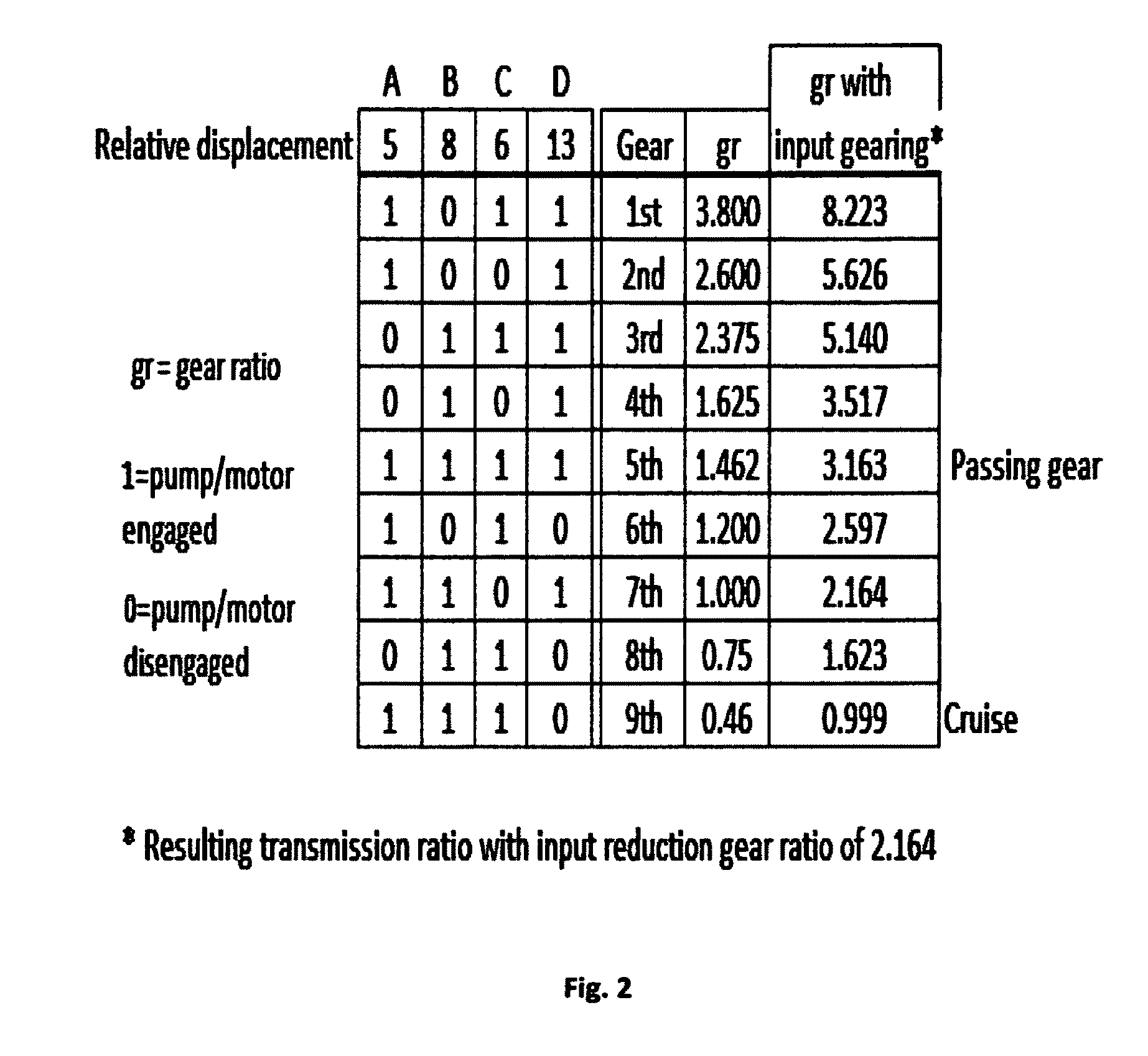

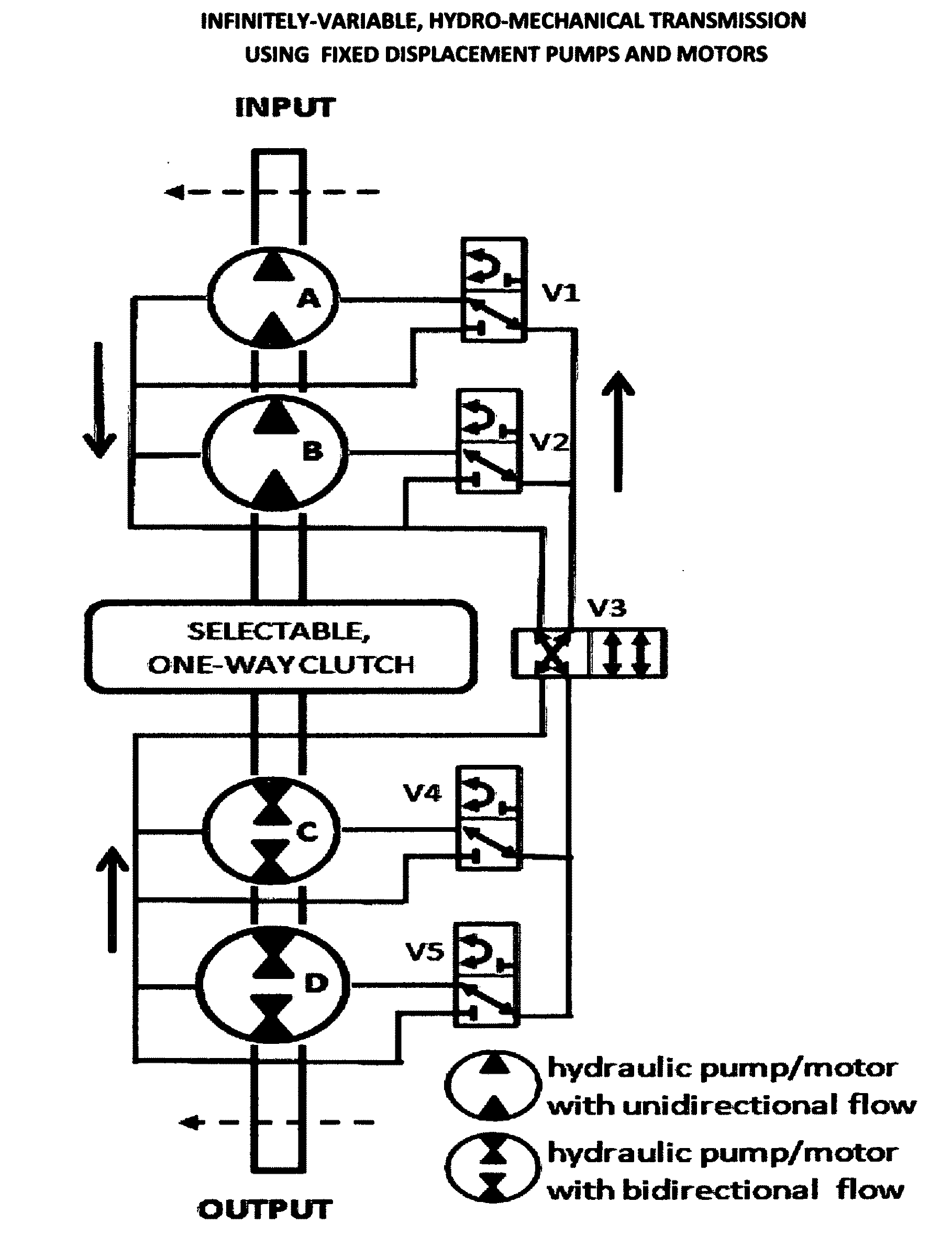

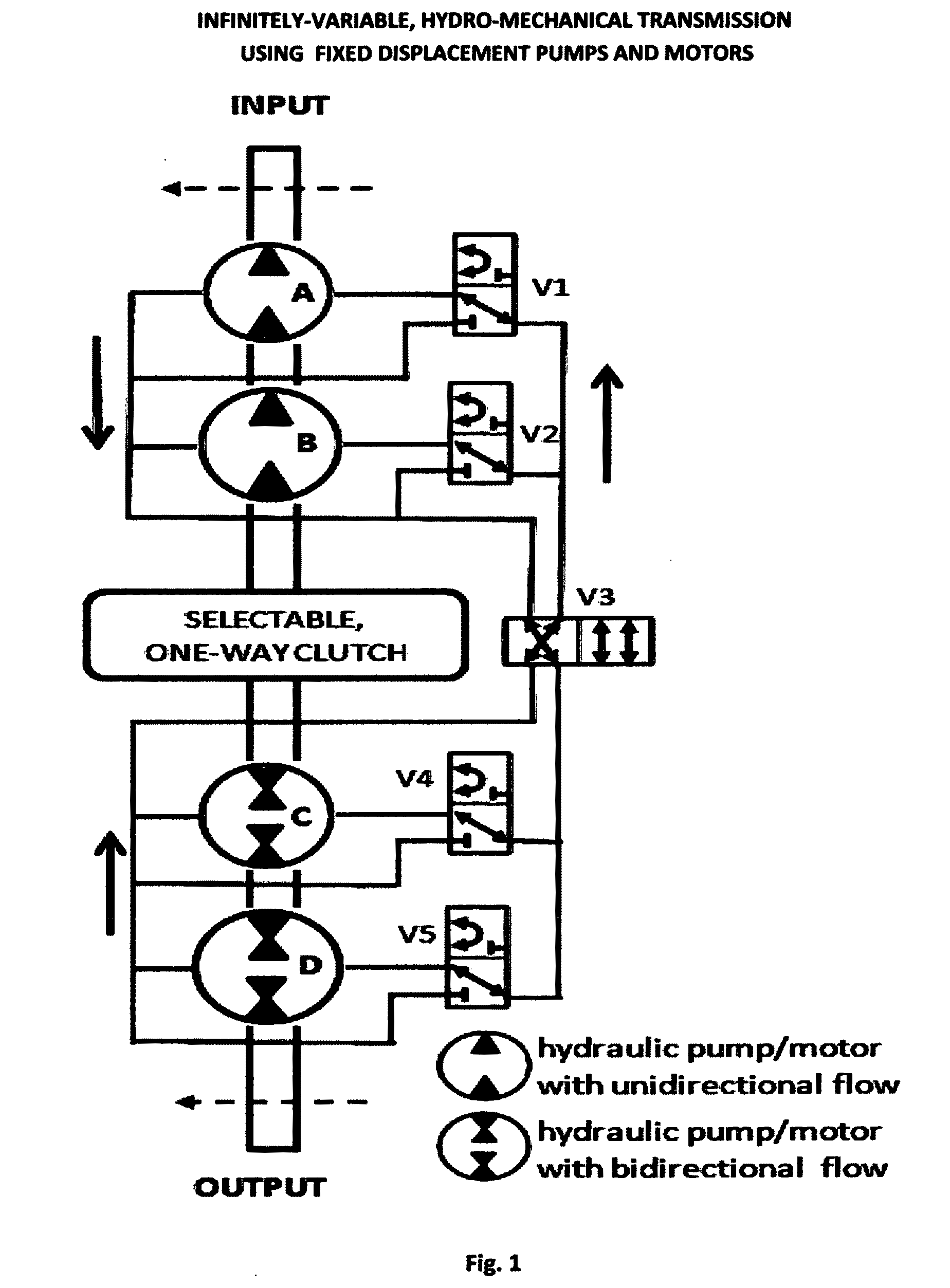

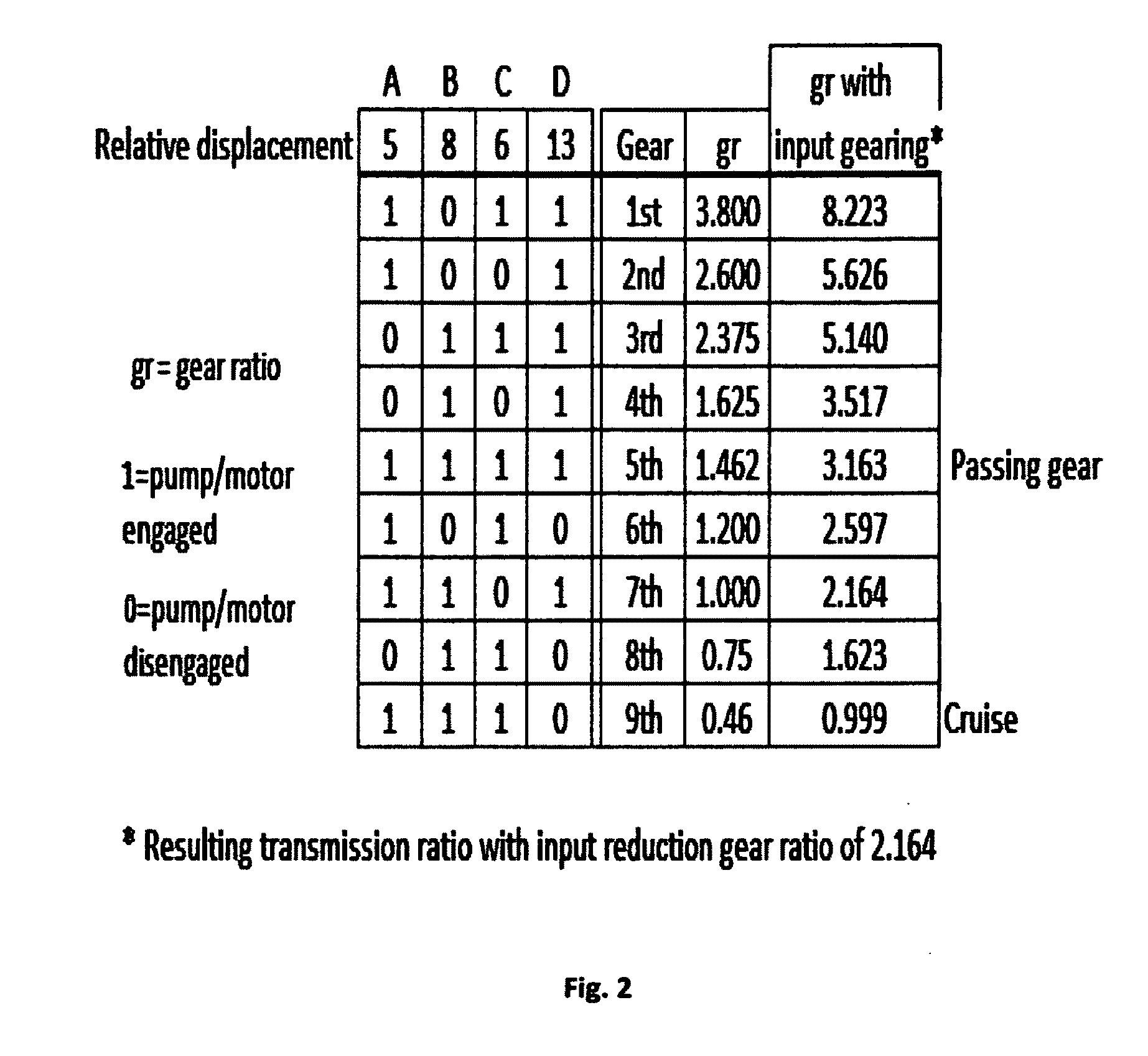

This invention consists of two or more fixed displacement hydraulic pump / motors mounted on a common input shaft hydraulically connected to two or more fixed hydraulic pump / motors mounted on a common output shaft. The relative displacements of the pump / motors are chosen such that by selectively activating the individual pump / motors, the transmission ratio can be changed in the case when the input devices and acting as pumps driving the output devices as motors (conversely when driving the vehicle in reverse). Further, a hydraulic accumulator and reservoir are attached in a manner that allows the pressurized fluid to augment the flow produce by the input pumps in order to increase the transmission ratio. Similarly, the transmission ratio can also be reduced by causing the input pumps to pump fluid into the accumulator at the same time they are pumping fluid through the output motors. The transmission also contains a single speed all mechanical by-pass for use when cruising and an input reduction gear to increase the torque and power capacity of the transmission.A further feature of the transmission is a valve arrangement that allows the transmission to generate a continuously variable braking torque when the transmission is used to supply braking force to the vehicle.In addition, the transmission includes a selectable, one-way clutch that connects the input directly to the output. When engaged, this clutch provides an all mechanical by-pass to the hydraulic transmission for use when cruising in order to improve the efficiency.

Owner:LLOYDCO

Ostomy appliance

InactiveUS20140128826A1Good peeling effectEasy to peelNon-surgical orthopedic devicesBodily discharge devicesEngineeringOstomy appliances

Owner:COLOPLAST AS

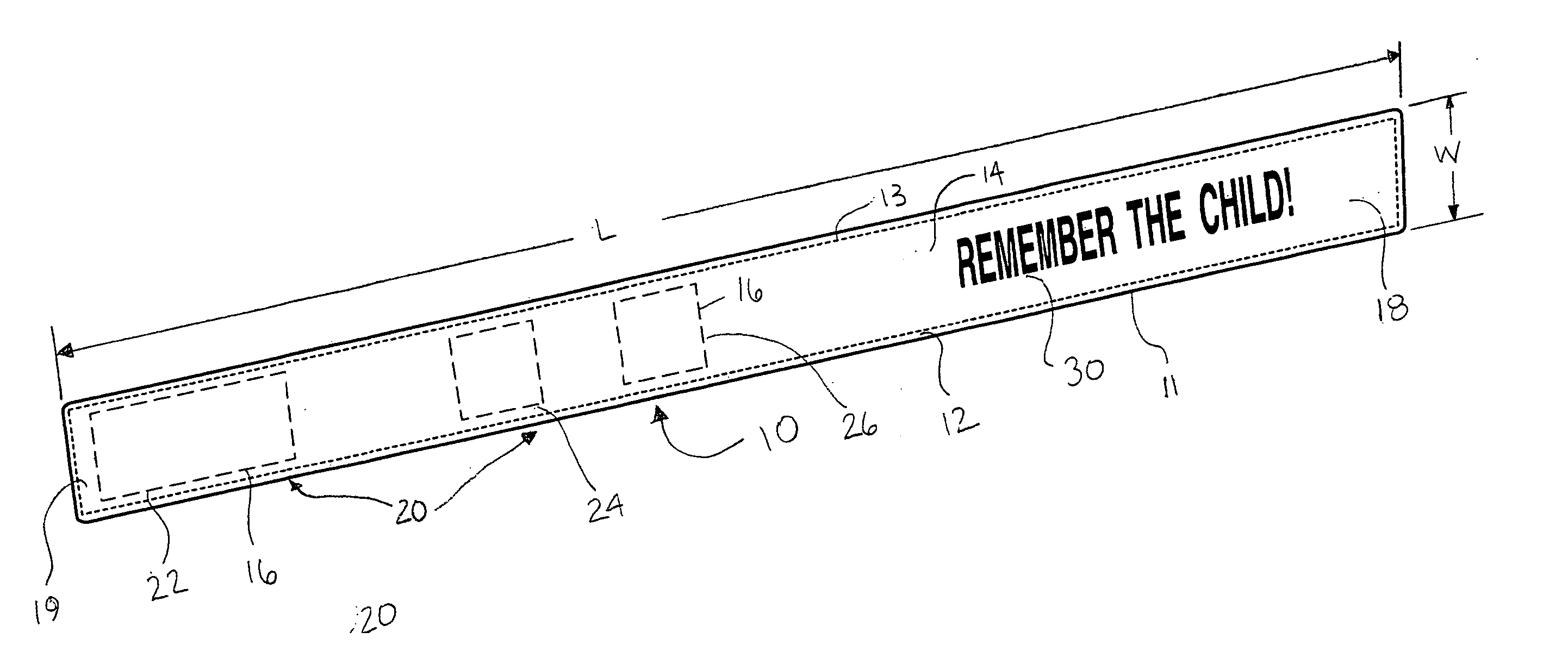

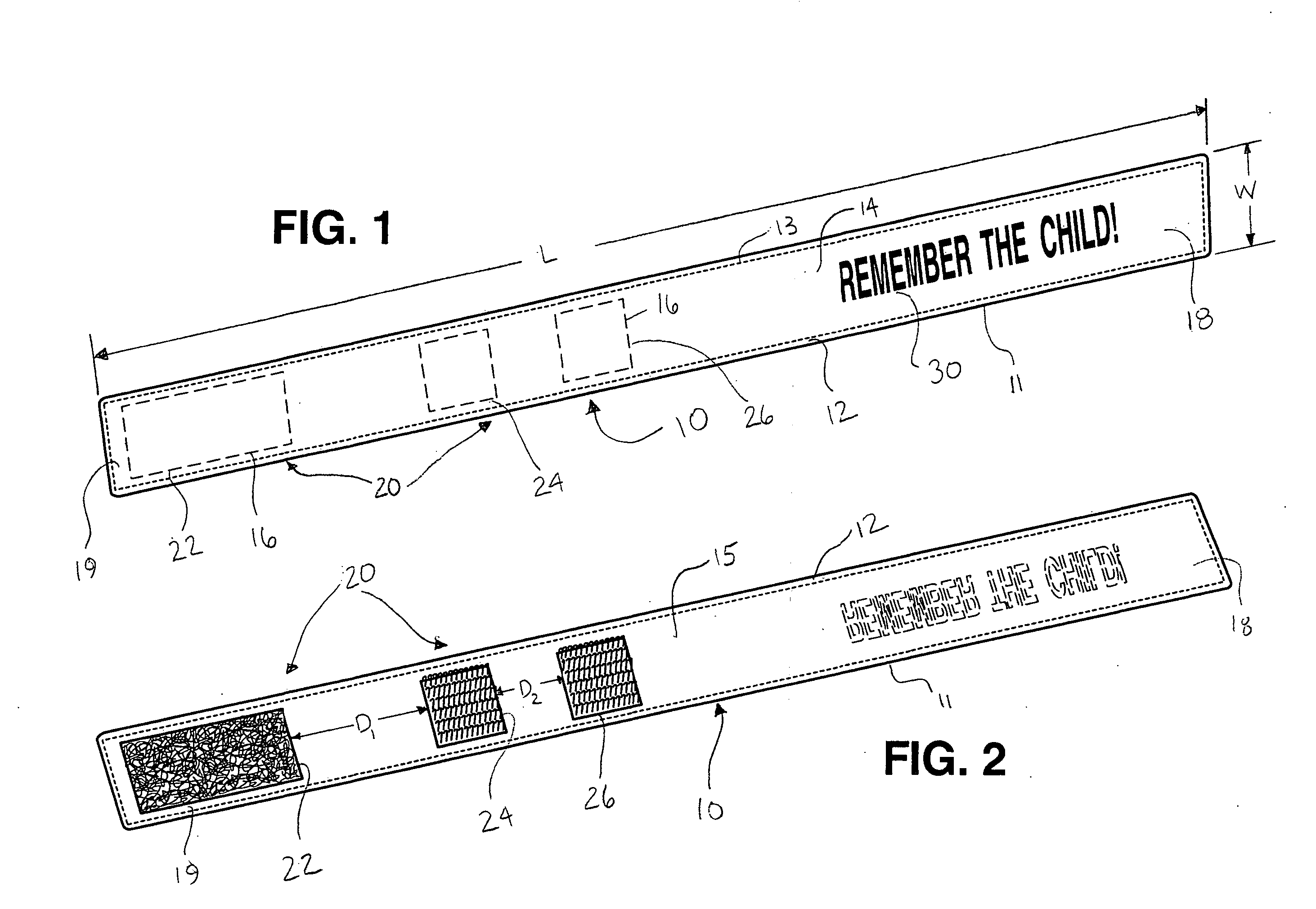

Memory triggering device and method of use for the same

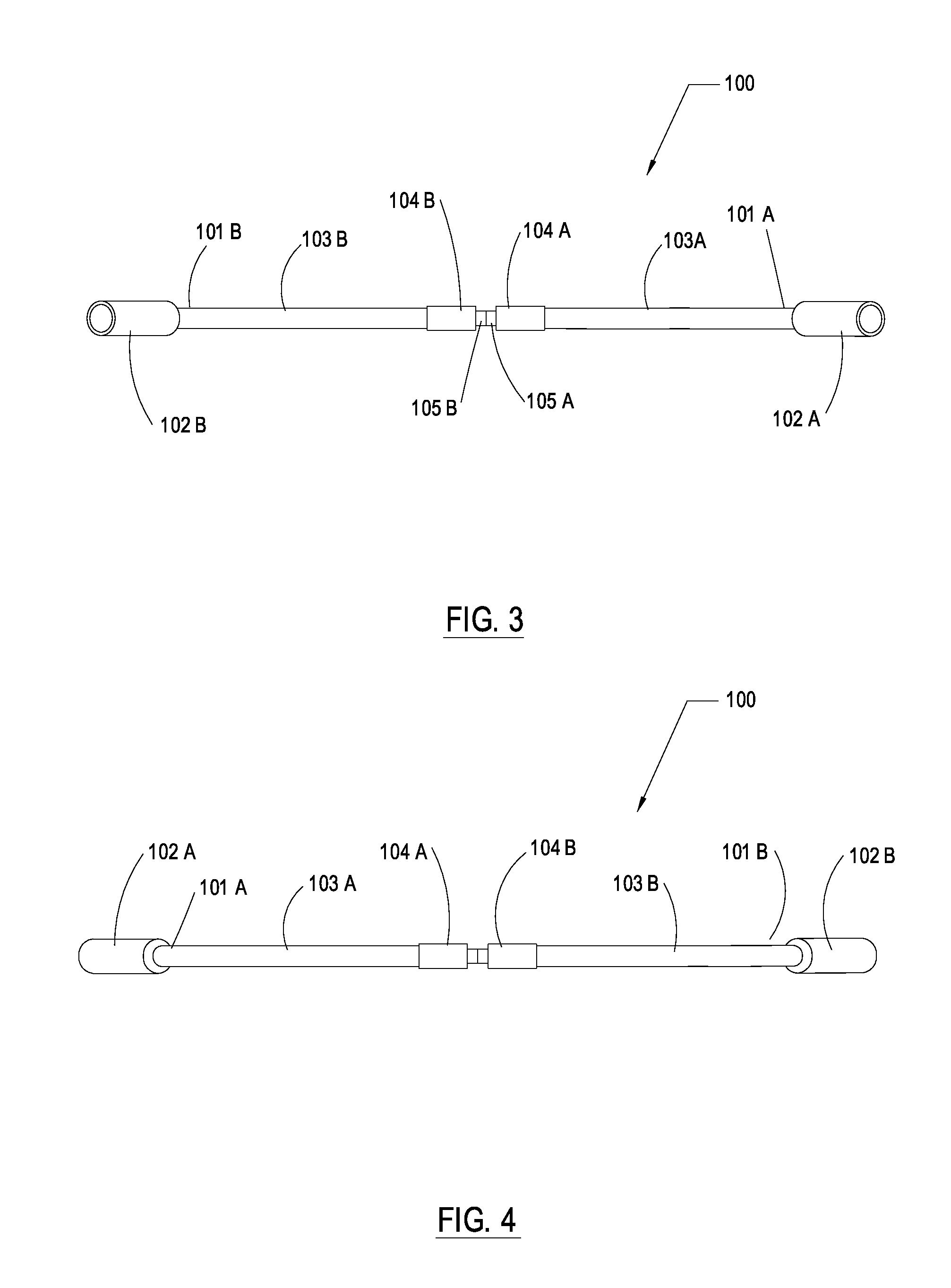

A device for triggering the memory of a primary caregiver of the presence of a child is provided. The memory triggering device includes a band of material having a front side and a back side. The band of material has a length that is longer than its width with the band of material having a first end and a second end that is distal from the first end along its length. A fastener is disposed on one of the sides of the band of material for enabling the band of material to be secured around an appendage of a wearer. The length of the band of material permits the second end to hang from the appendage of the wearer at a length that draws the attention of the wearer without becoming a hindrance to the mobility of the appendage or the wearer to remind the wearer of the presence of a child.

Owner:JETTON JAMES STEVEN

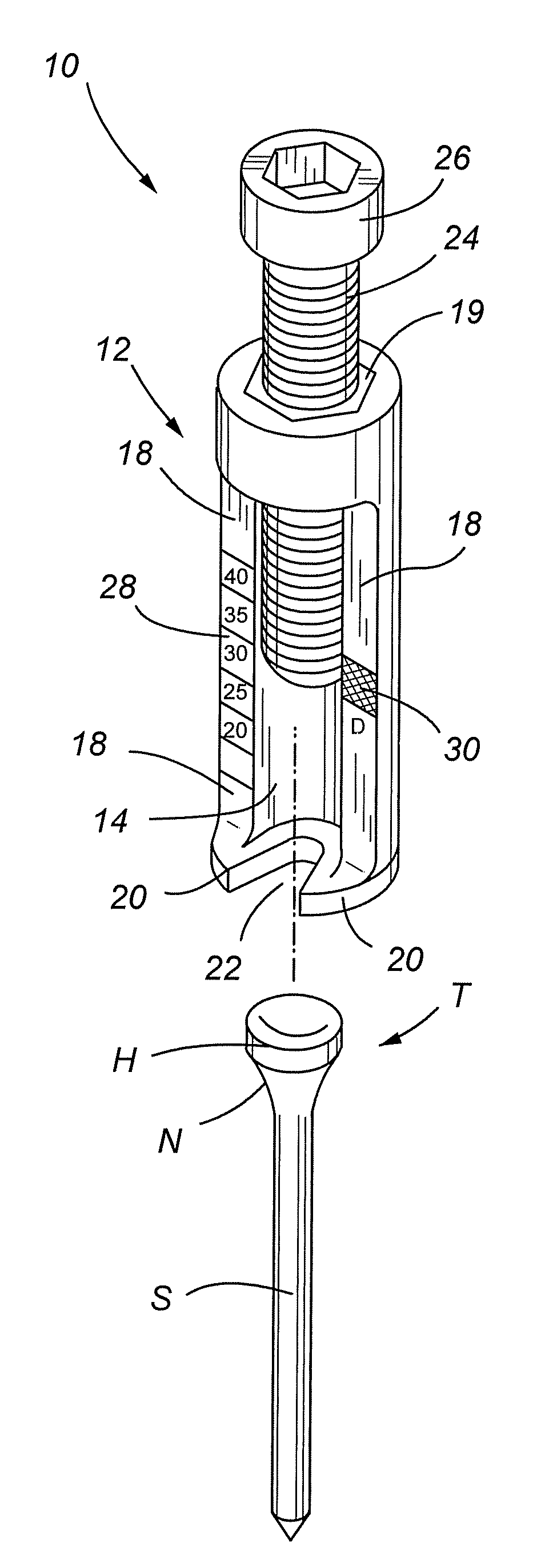

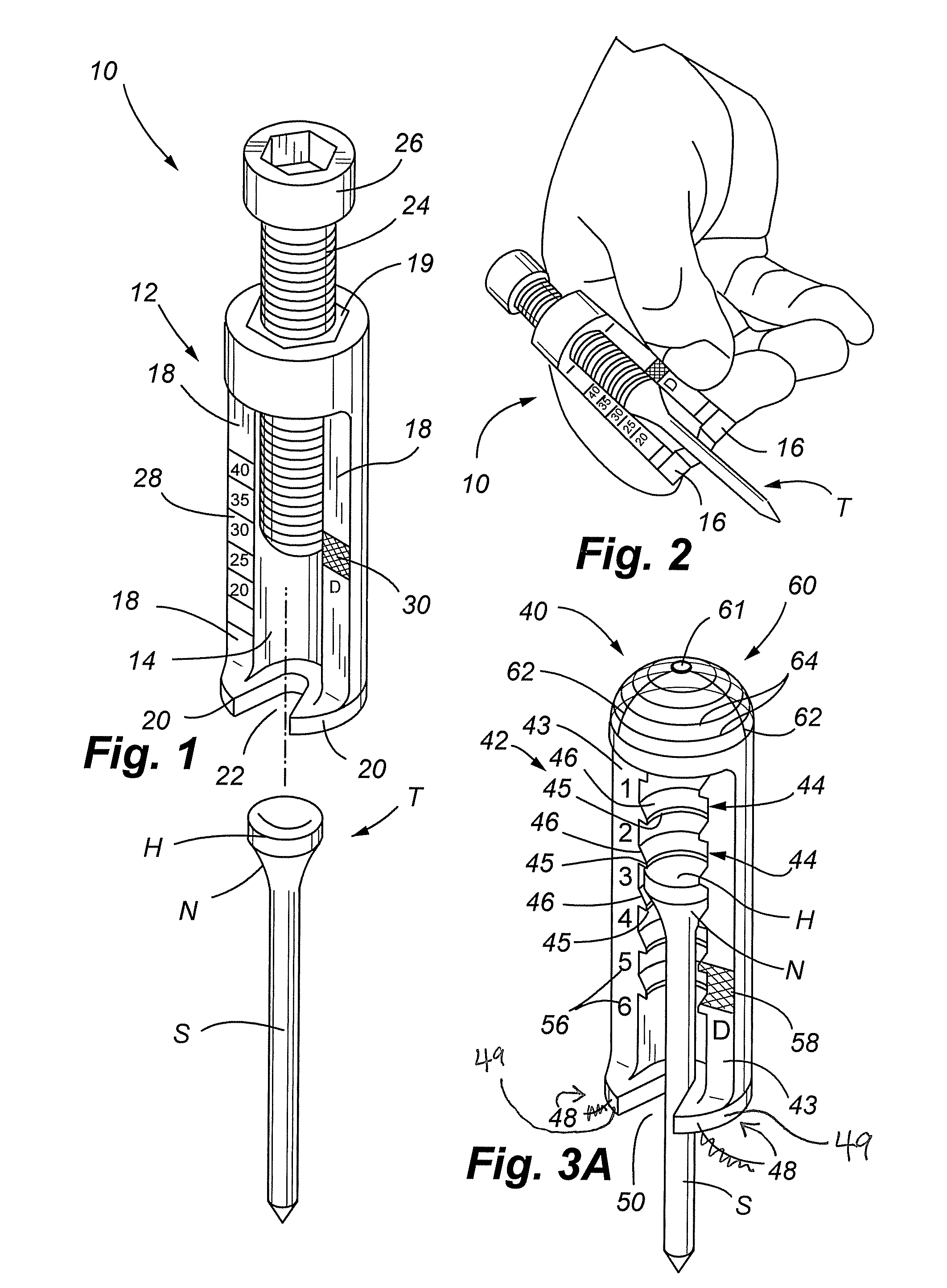

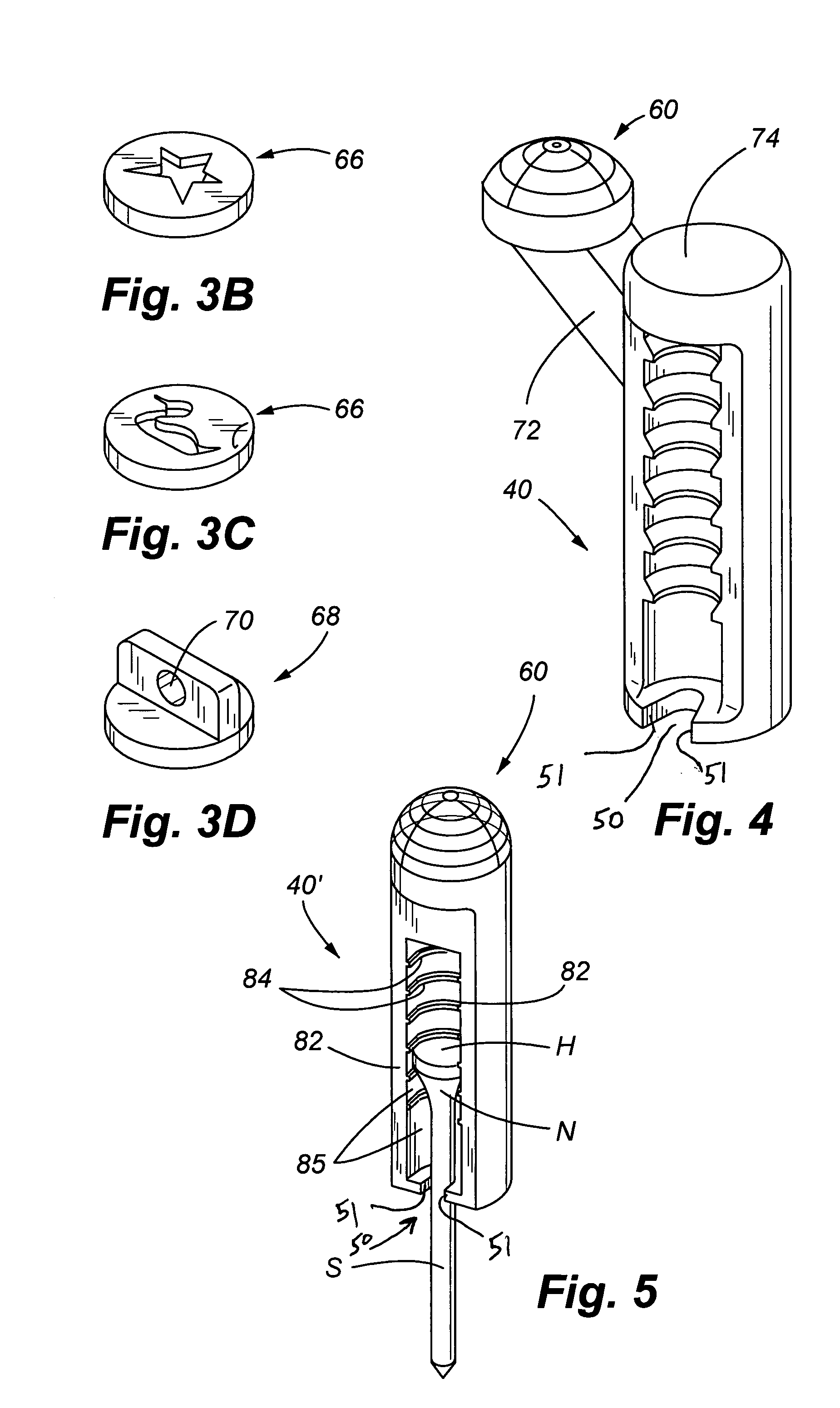

Golf tee setting device and method

InactiveUS7223184B2Simple structureEfficient settingsGolfing accessoriesGolf BallElectrical and Electronics engineering

Owner:SUWITO WANTJINARJO

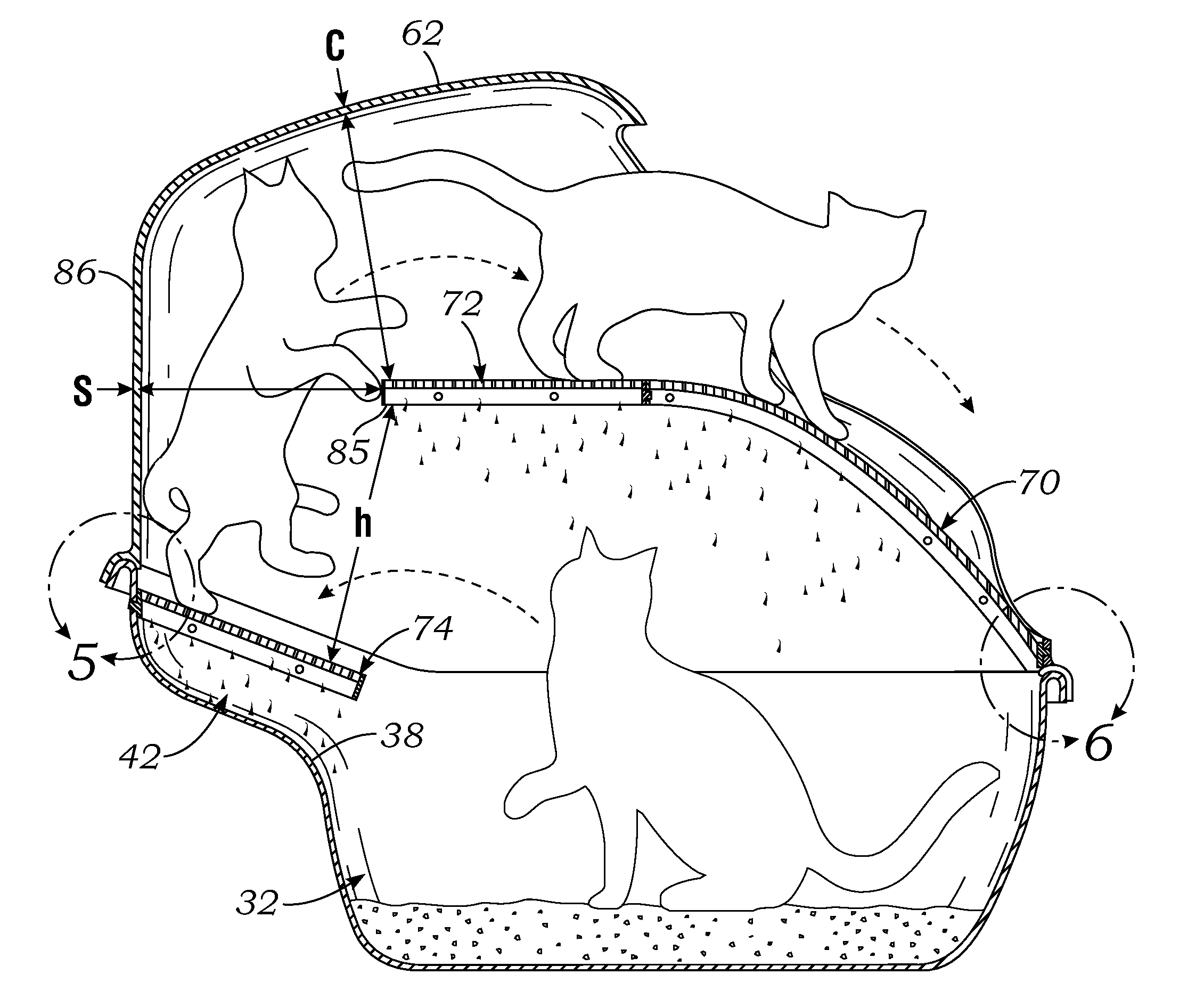

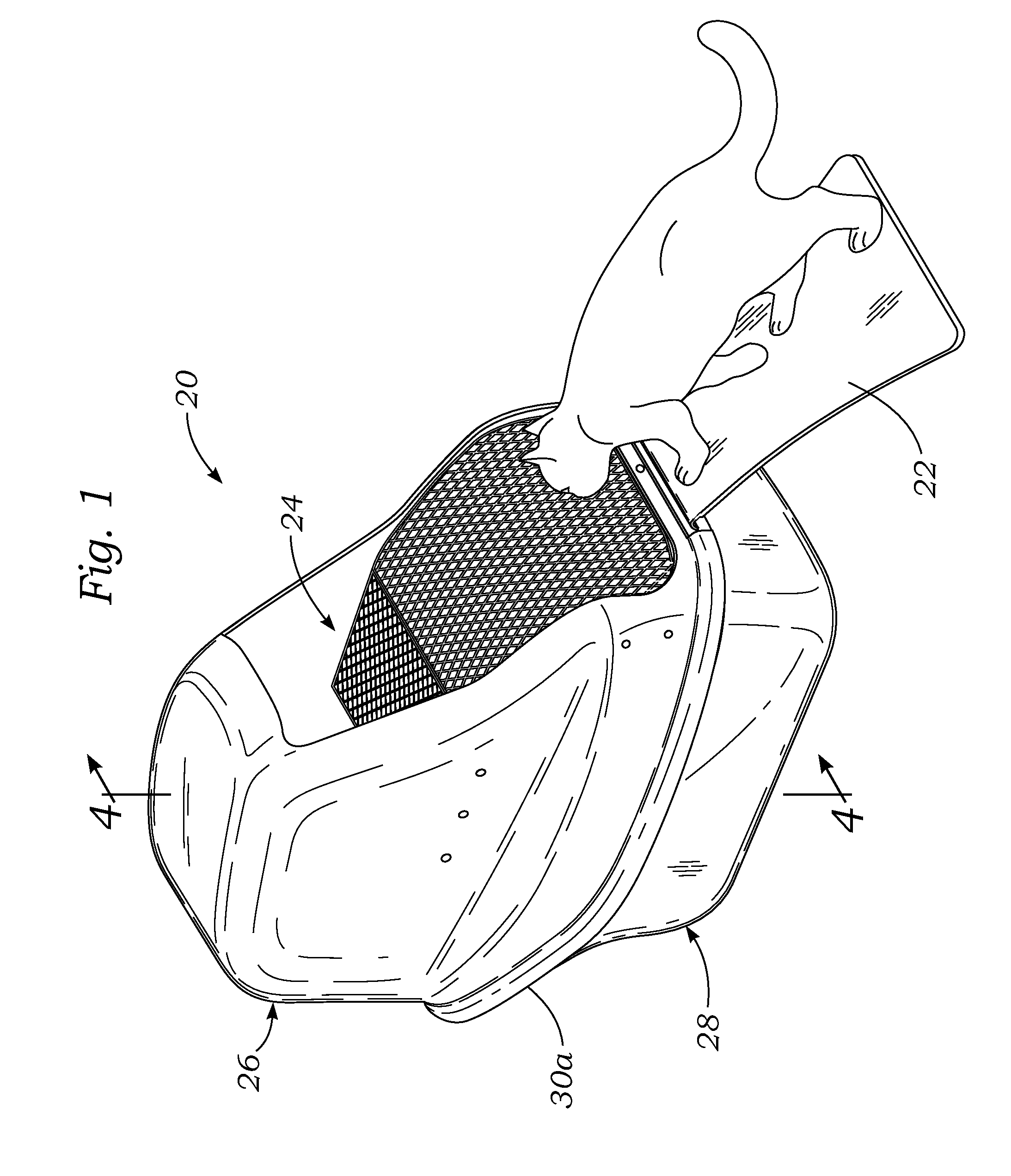

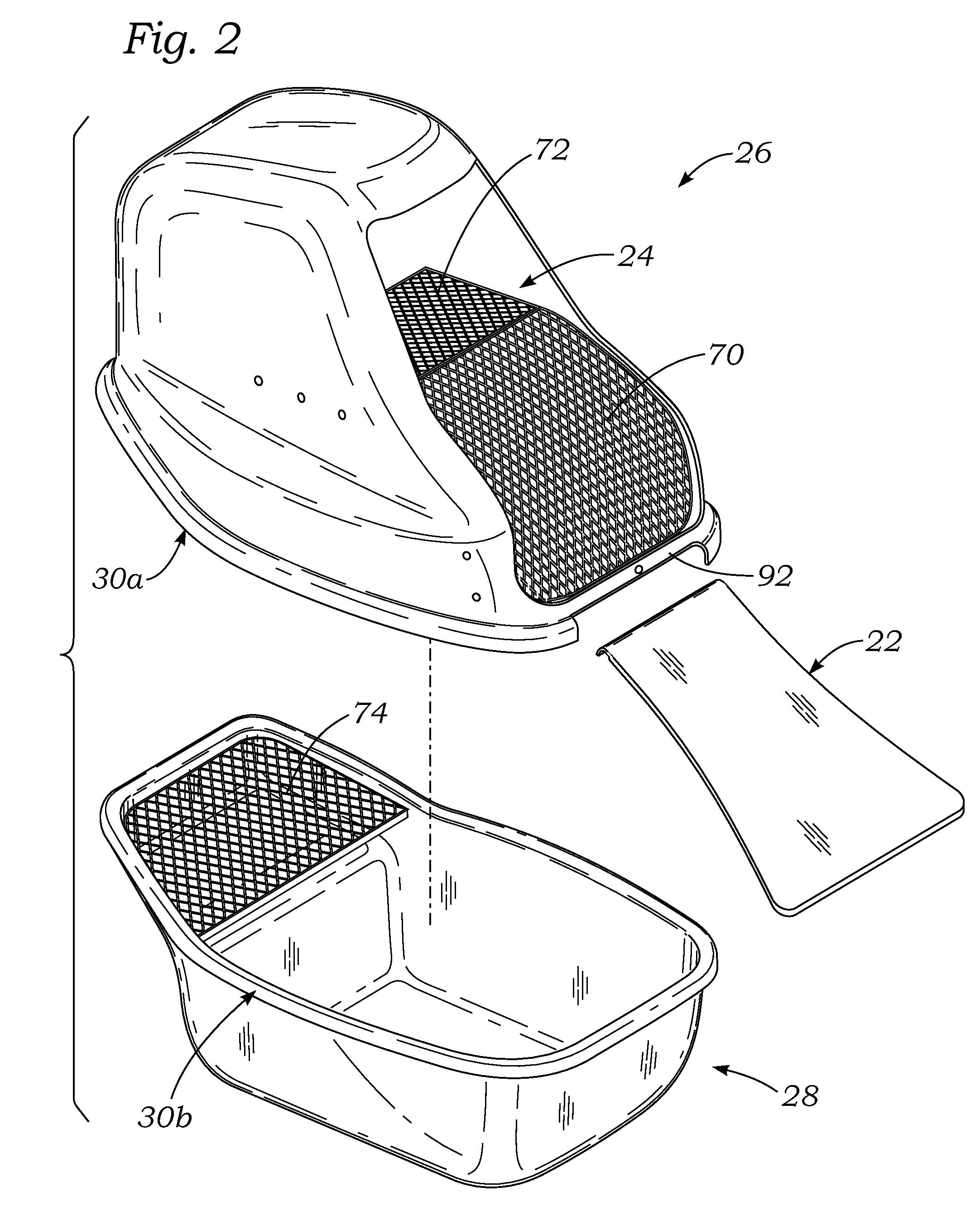

Tidy cat litter box

ActiveUS20140069342A1Easily get intoEasy outAnimal housingOther apparatusEngineeringCompanion animal

A tidy pet litter box having a plurality of internal screens across which the pet must traverse when entering or leaving a main basin of the litter box. An upper lid fits over a lower tray, the upper lid having a large front opening. The lower tray defines a large main basin in which litter is placed, and a secondary basin at a rear end thereof. An entrance screen mounted laterally across side walls of the upper lid extends from a lower end of the front opening substantially over the entire main basin and permits passage of a pet to a rear screen located above the secondary basin. To exit, the pet must jump up to the rear screen, then over the entrance screen which dislodges any litter sticking to its paws so that it falls back into the main basin. A method of training a cat to use the litter box by first removing the entrance screen is also disclosed.

Owner:KHALILI KEVIN

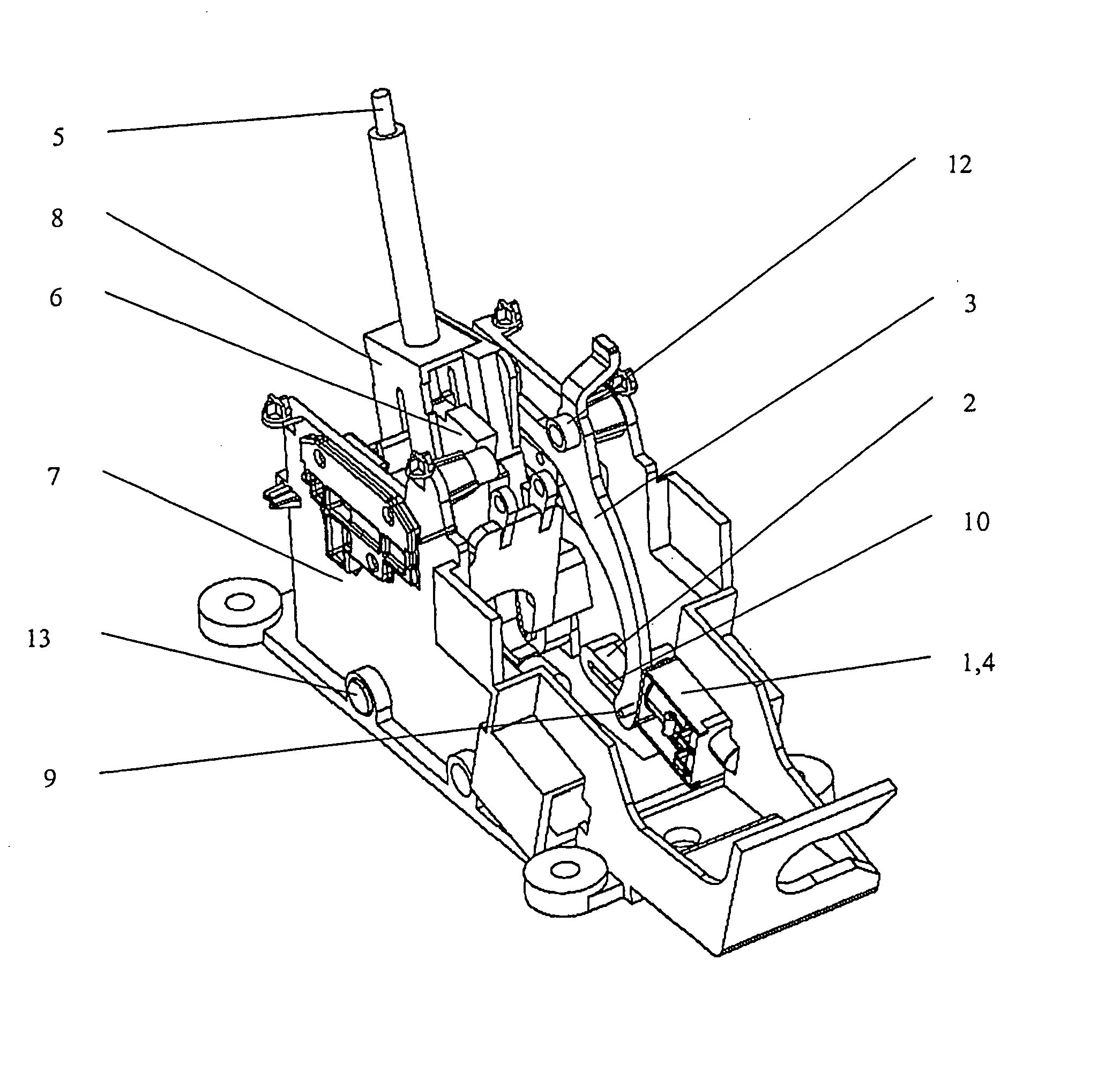

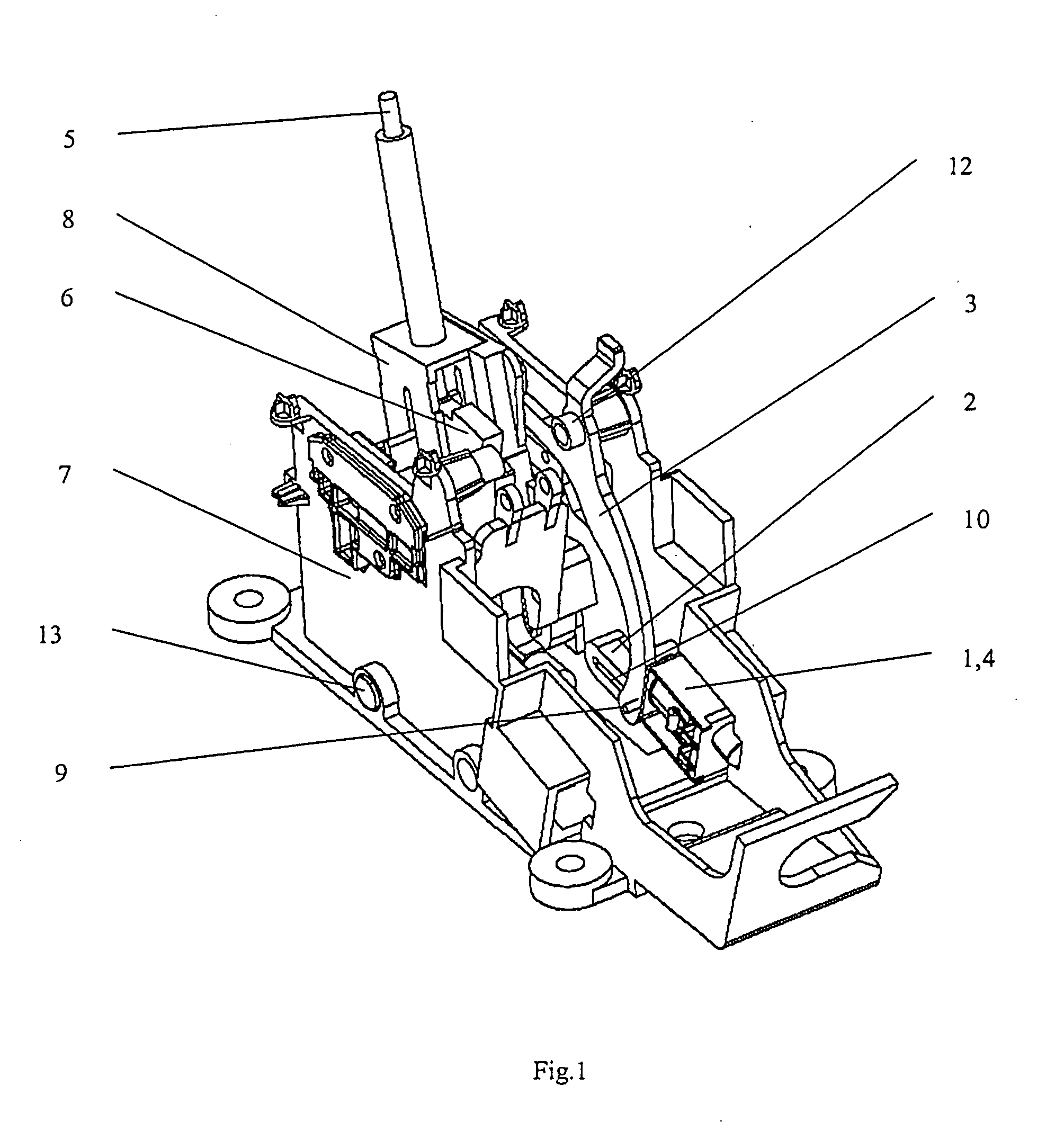

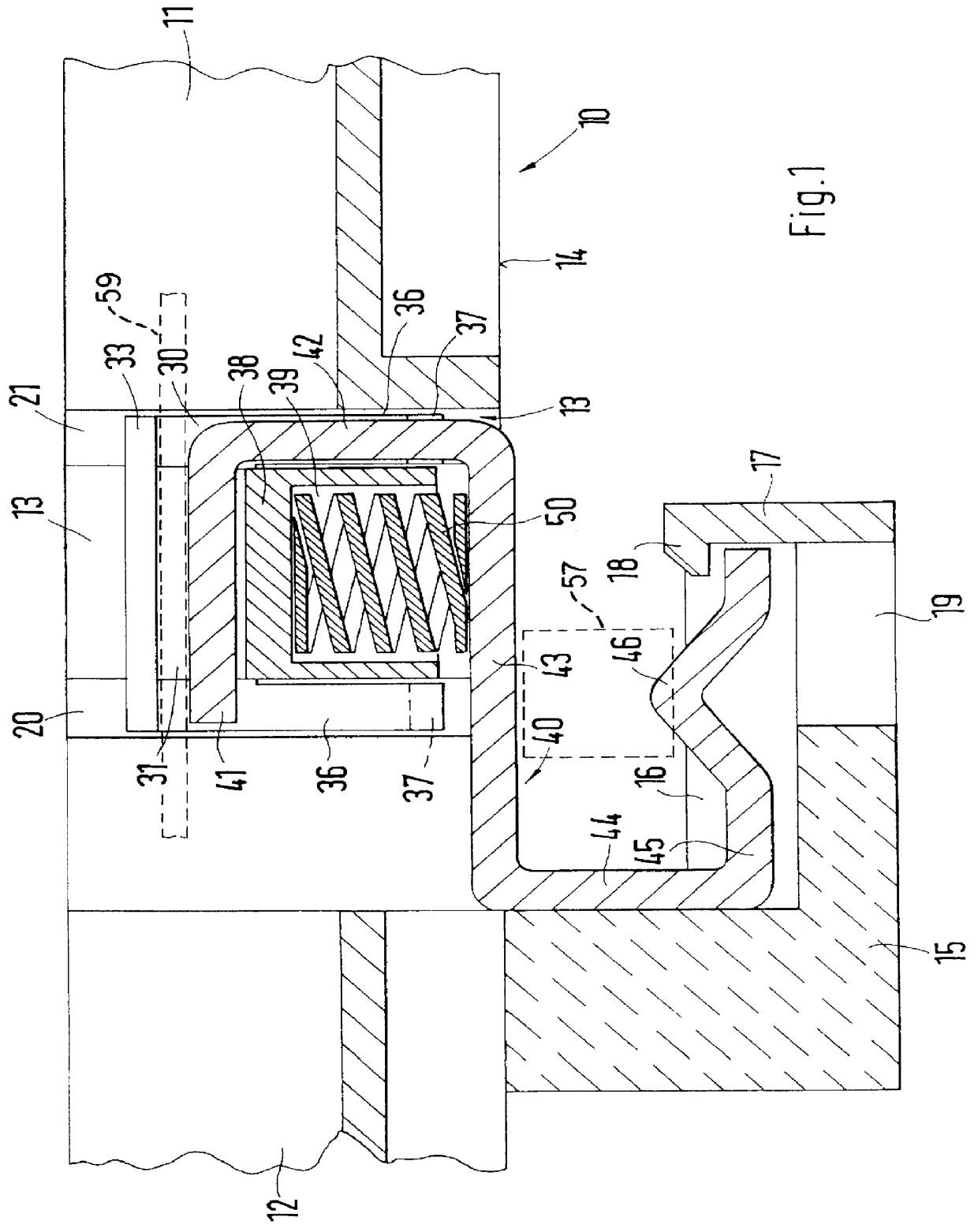

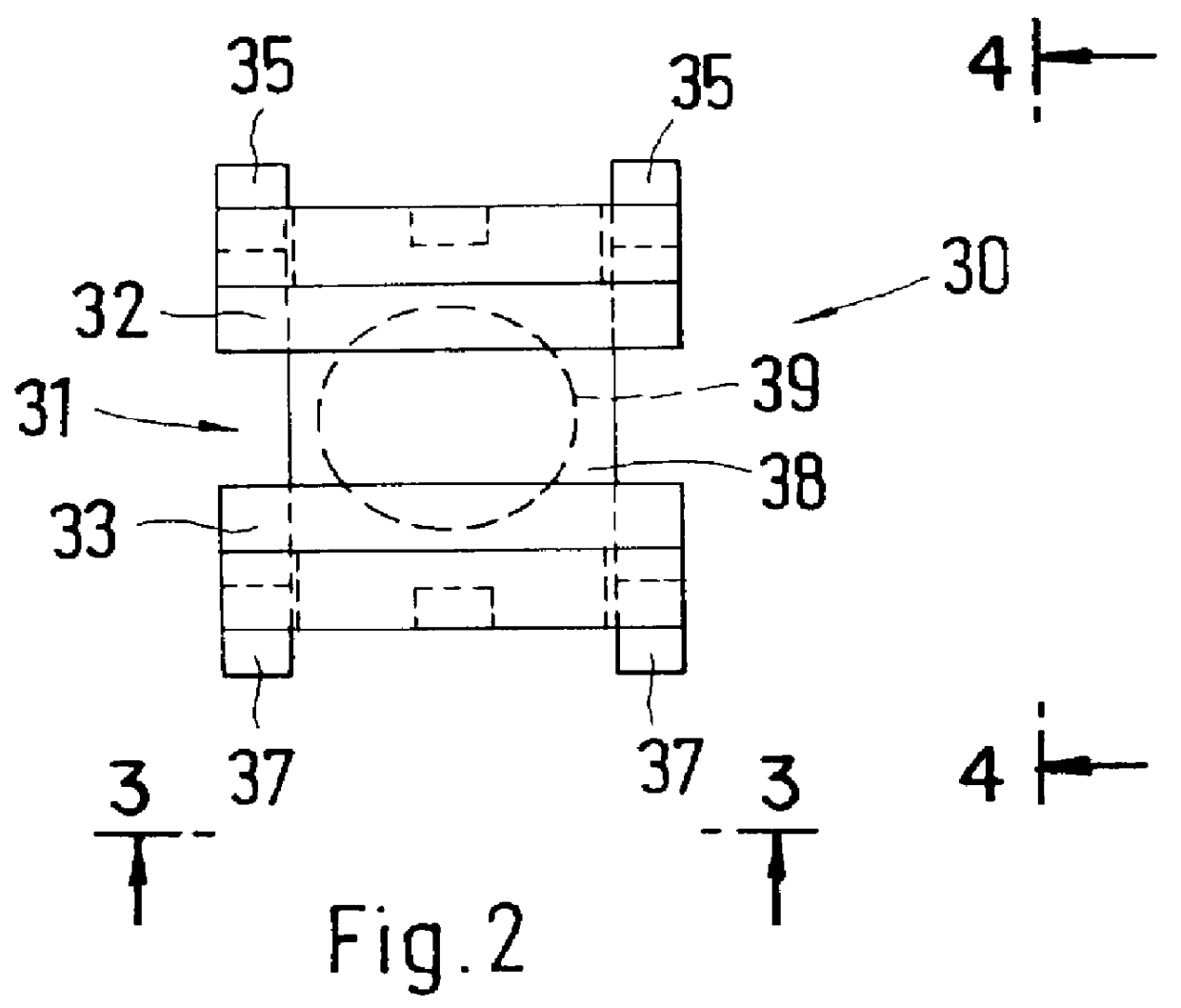

Device to switch over a mechanical shifting means

InactiveUS20050160859A1Reduce noiseLow costManual control with multiple controlled membersGearing controlAutomatic transmissionEngineering

A device to switch over a mechanical shifting means between at least two shifting states, particularly for purposes of switching on and off a parking lock of an external selector for an automatic transmission, whereby a shifting gate that can be actuated via a shift gear lever having a connecting rod such as a pull rod or push rod is arranged in a housing and the parking position is held by a locking magnet, whereby a locking lever having an axis of rotation is provided inside the housing, said lever interacting with the locking magnet, whereby the locking lever is connected via a bell crank having a blocking pin and having an axis of rotation to the pull rod or push rod having an axis of rotation, and to a link slide that can be moved relative to a shifting gate.

Owner:TELEFLEX AUTOMOTIVE GERMANY

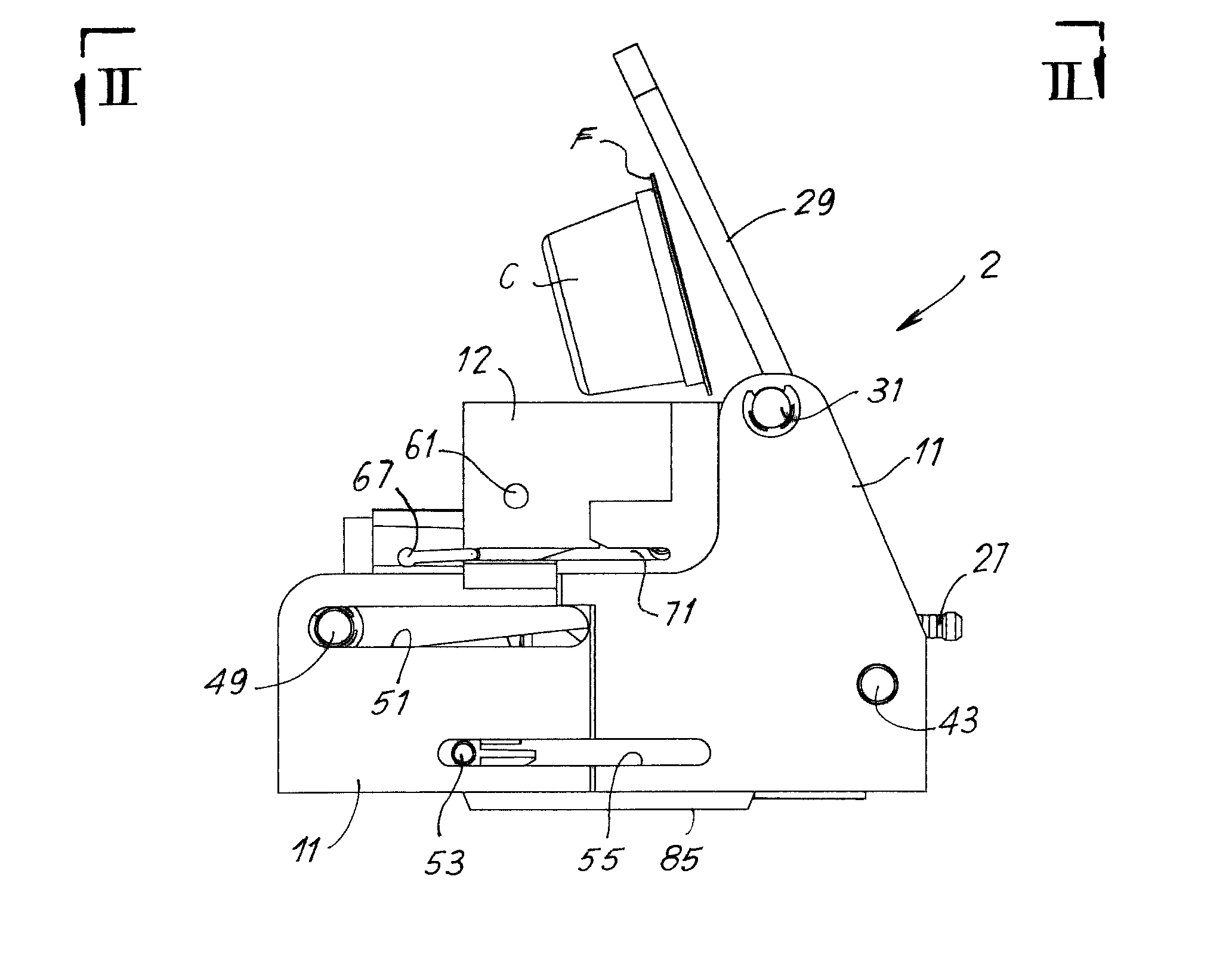

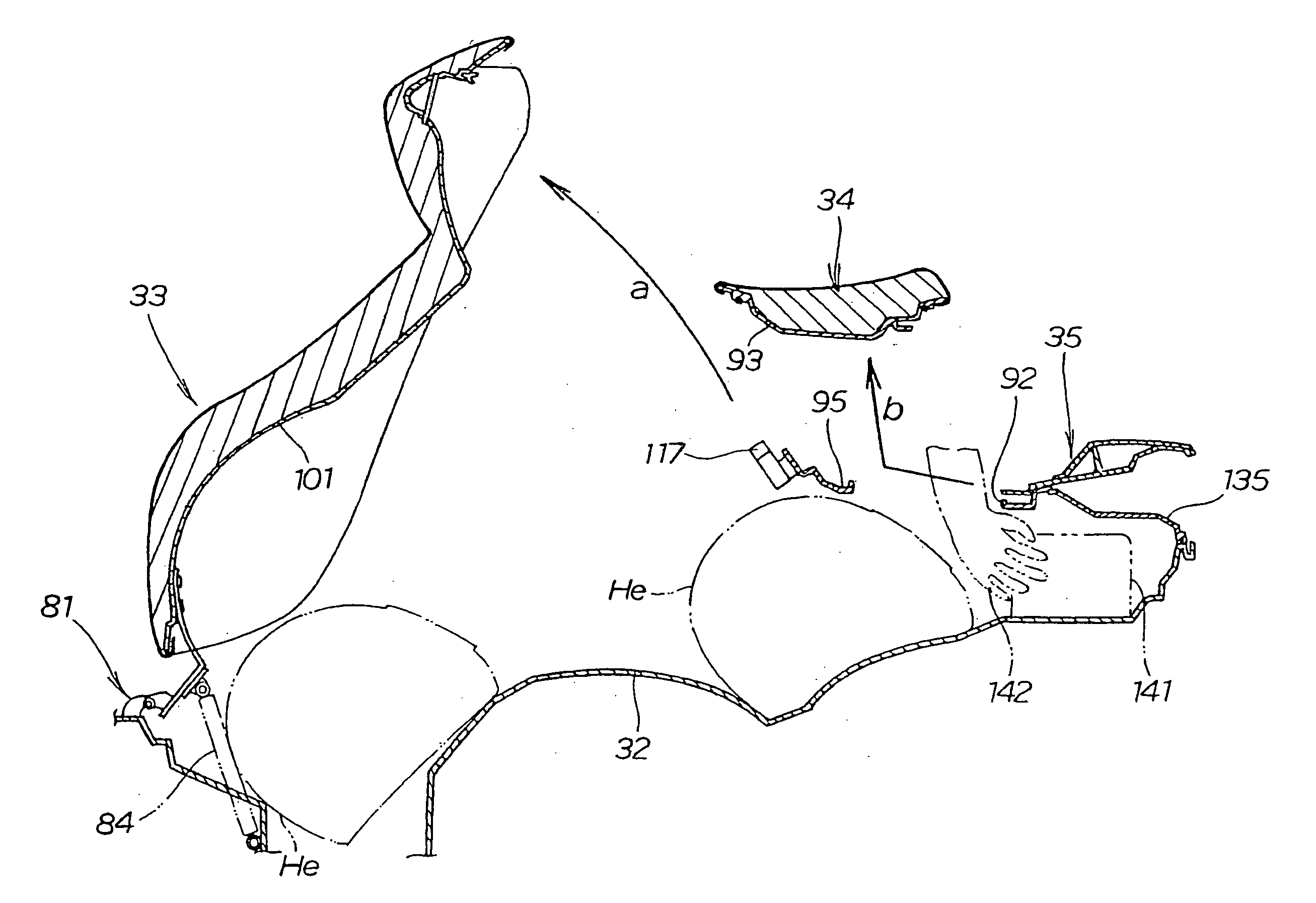

Brewing unit with horizontal motion

ActiveUS9486102B2Compact and simple to manufactureEasy to useBeverage vesselsBrewingElectrical and Electronics engineering

A brewing unit including a first brewing chamber portion and a second brewing chamber portion; a channel for inserting capsules towards said brewing chamber; a mobile deviator interposing between said first brewing chamber portion and said second brewing chamber portion when said first brewing chamber portion and second brewing chamber portion are open, to deviate said capsules towards one of said first and second brewing chamber portions; an actuation mechanism for closing and opening said brewing chamber, wherein said actuation mechanism is connected to open and close said brewing chamber; said actuation mechanism is further connected to said mobile deviator such that said actuation mechanism controls said mobile deviator to remove said mobile deviator from a trajectory of mutual motion of said first and second brewing chamber portions during closure of the brewing chamber.

Owner:VERSUNI HLDG BV

Post attachment device

A post attachment device for connecting a helmet to a head and neck support. The device includes a post anchor having a base, a button, a resilient member, a post, a retainer and a catch having a slot with a larger first section connected by a channel to a smaller second section. The button is positioned in an indention in the base with the resilient member positioned therebetween. The post extends through the button, the base and the helmet. The retainer is secured on the post adjacent the inner surface of the helmet. To secure the post attachment device, the catch is orientated over the post. The button is then pressed into the base while the catch is moved backwards to move the post into the second section of the slot.

Owner:SIMPSON PERFORMANCE PRODUCTS

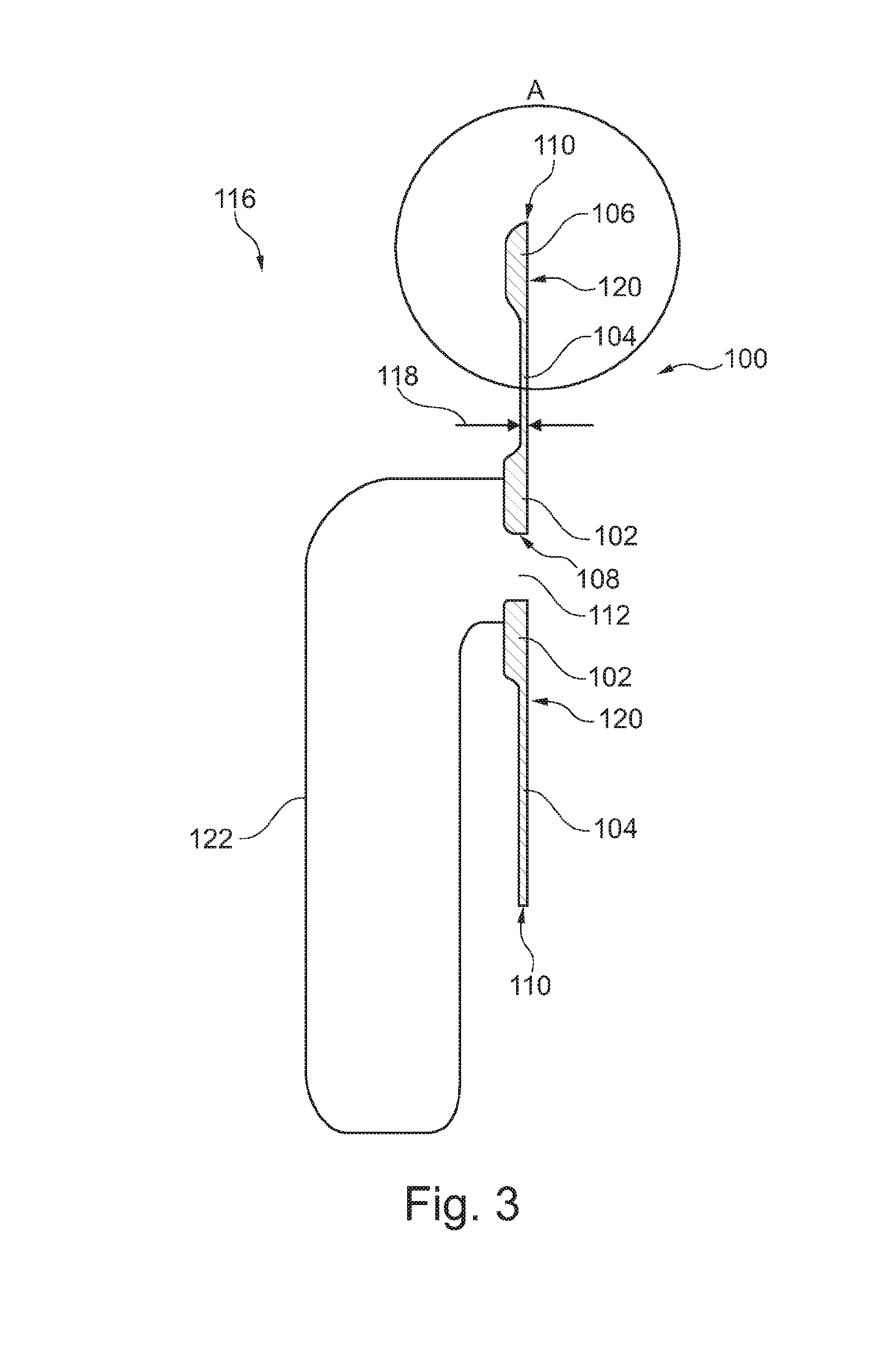

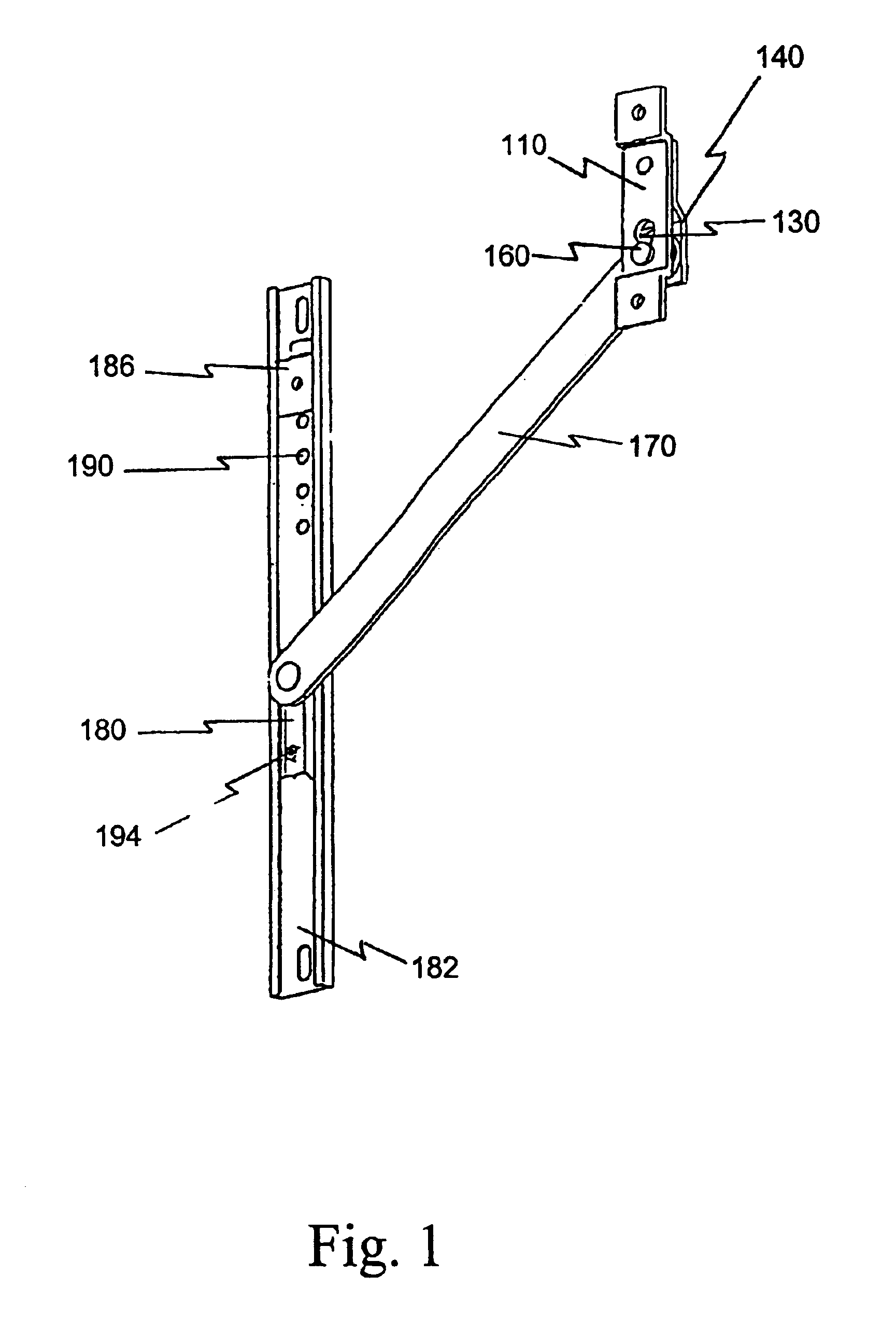

Detachable arm limiting assembly

InactiveUS6880792B2Quickly and easily be openLimited degreeMan-operated mechanismWing fastenersFastenerEngineering

A mechanism which selectably limits the opening of a hinged window vent. The mechanism has a releasable arm that permits the vent to be conveniently opened beyond the selected limit. An assembly is disclosed for limiting travel of a vent relative to a frame. The assembly includes a security fastener for restricting transition of the assembly between a locked configuration and an unlocked configuration. An arm is pivotally connected to a mounting bracket by a locking plate and a loading pin.

Owner:CALDWELL MFG NORTH AMERICA

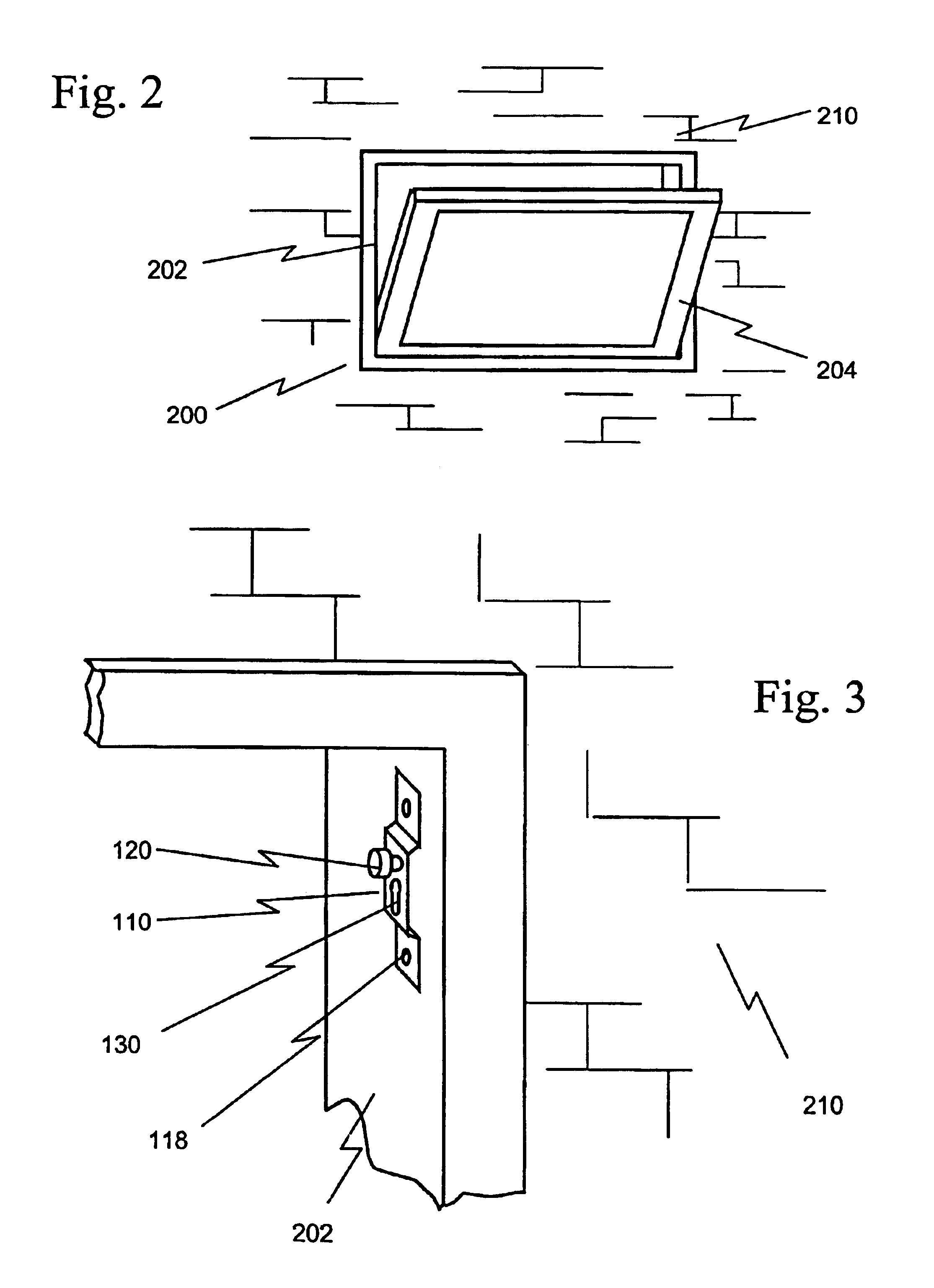

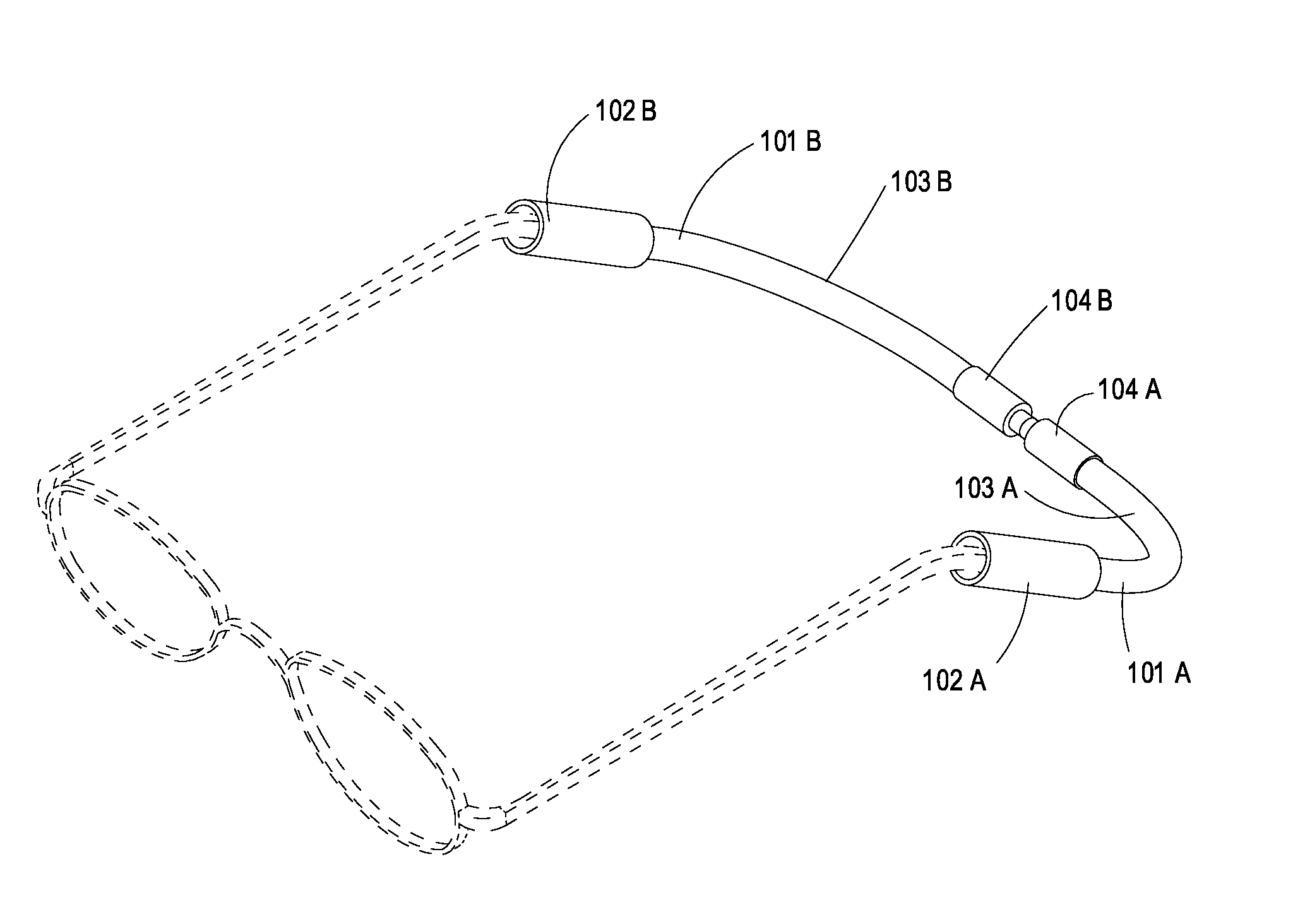

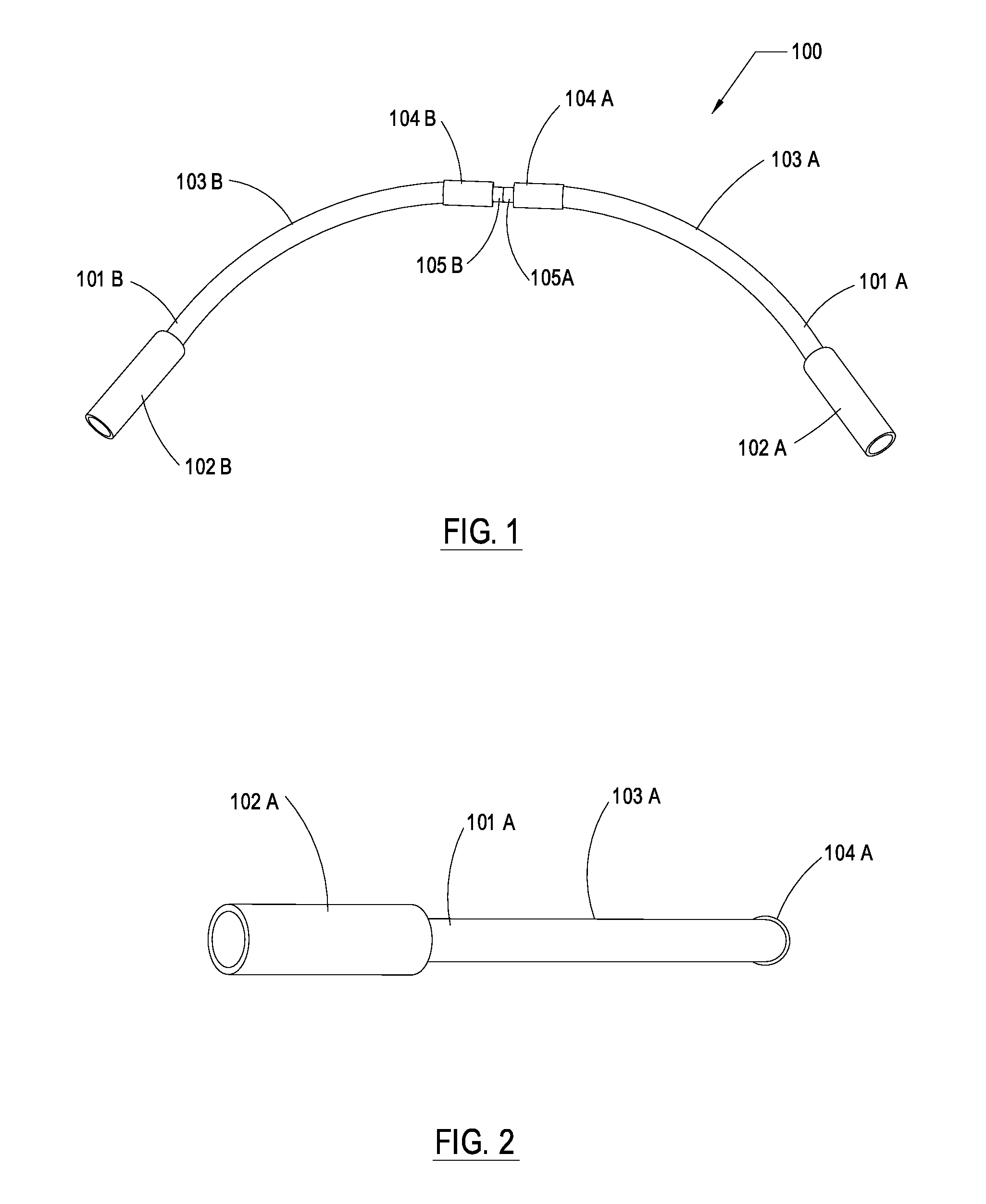

Eyeglass retainer devices

An eyewear retention device that comprises two elongate members, each having a receiving end for receiving an end of a temple member of said eyewear, a connecting end having a magnetic fastener, and an elongate portion for wrapping around said human head is disclosed. The magnetic fasteners of the elongate members may be magnetically engaged to each other behind said human head and snuggly hold the eyewear at the bridge of the nose.

Owner:YRIBARREN RICHARD J

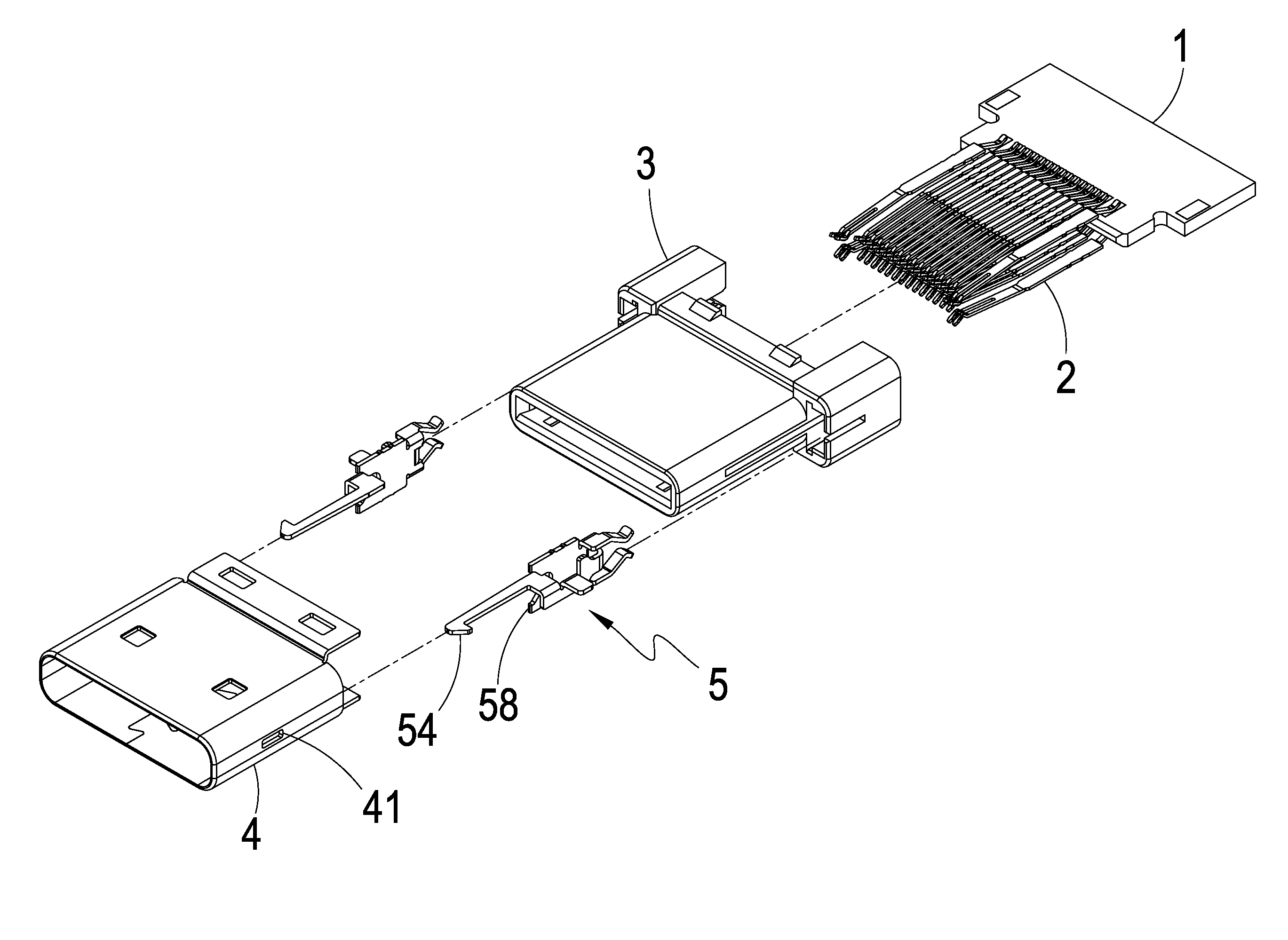

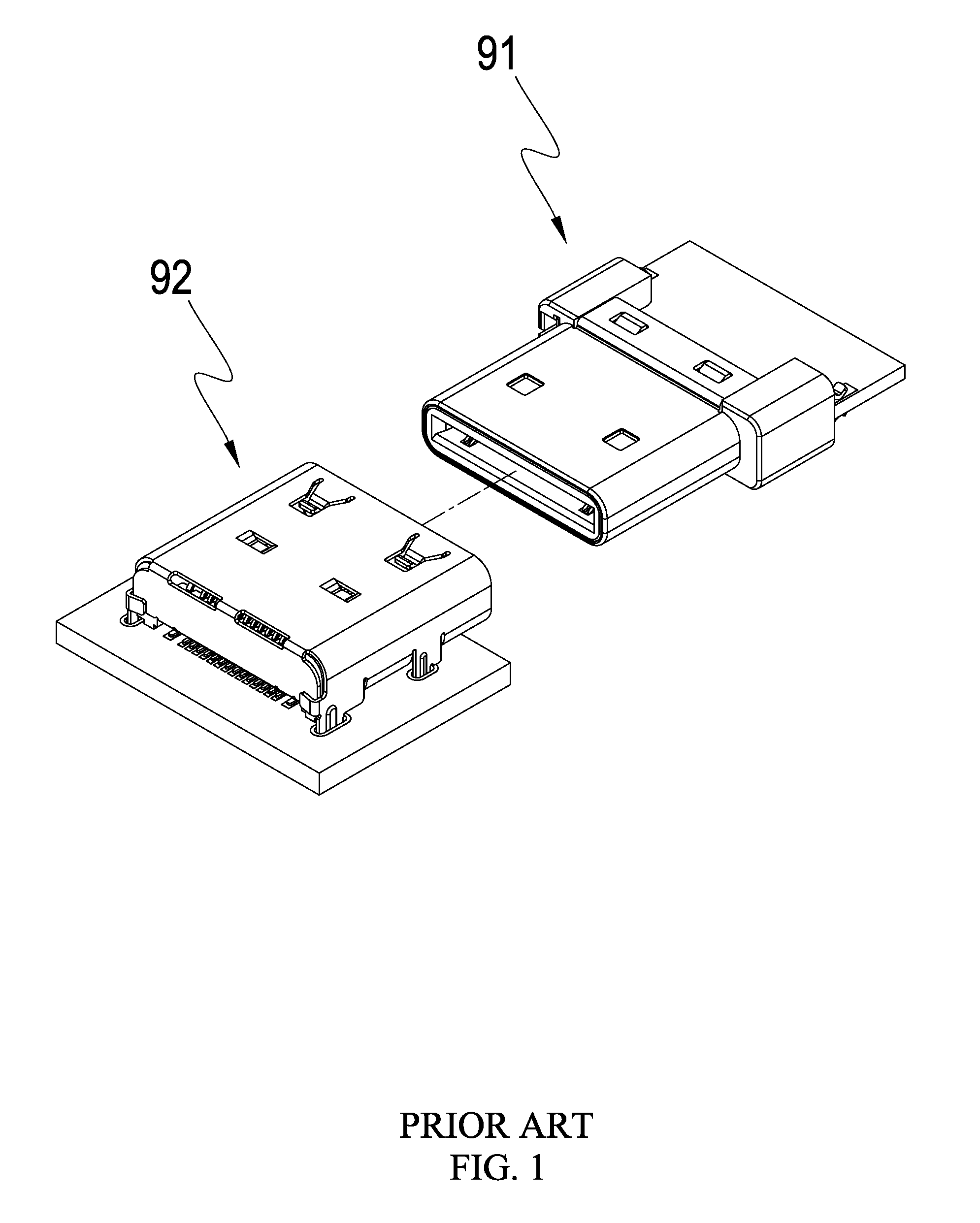

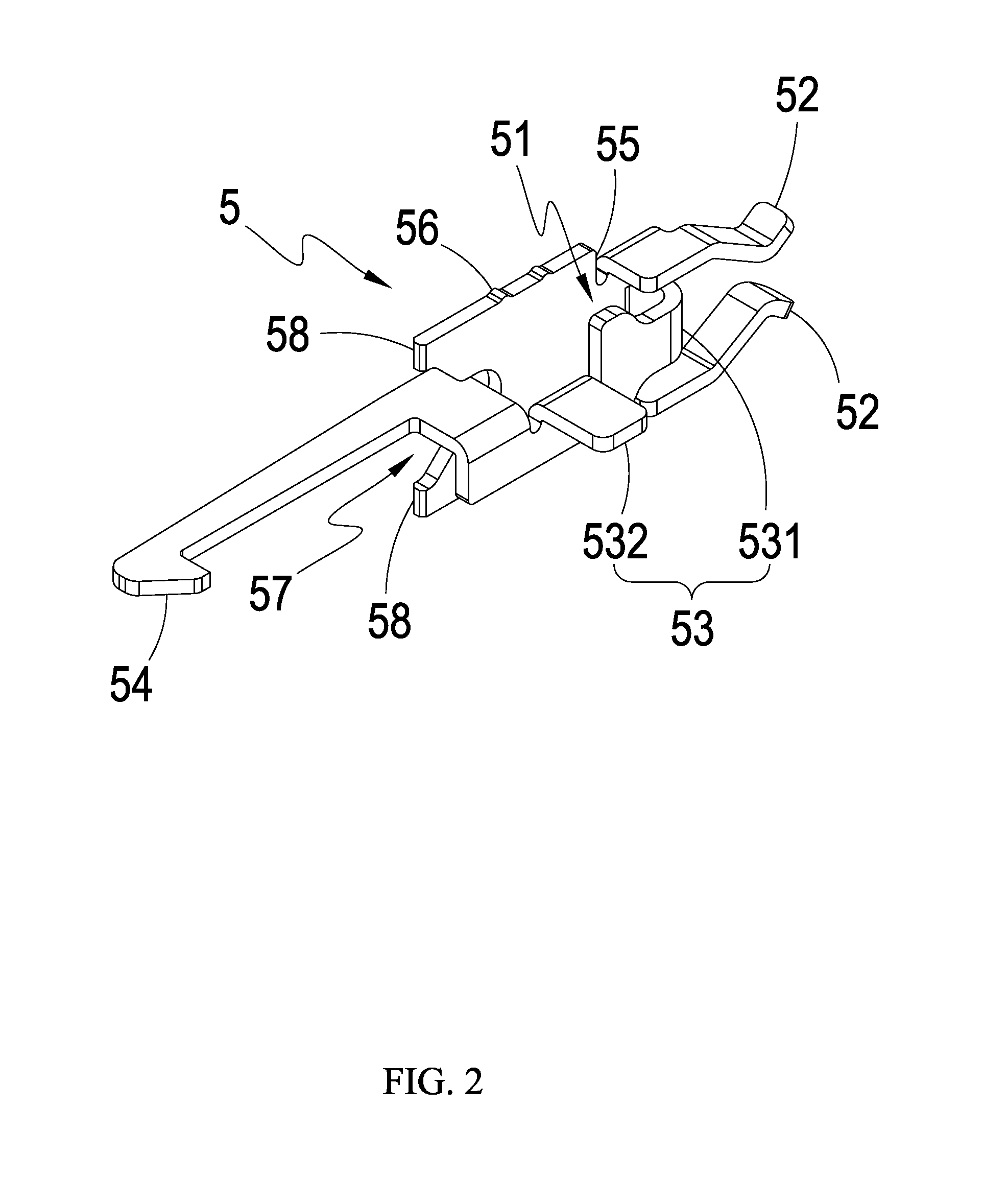

Structure of electrical connector

InactiveUS9425565B1Improve structural strengthEasy outCoupling device detailsTwo-part coupling devicesSolderingElectrical connector

An electrical connector includes a hook-up pin mounted on one lateral side of the electrical connector. The hook-up pin includes a pin body, soldering sections respectively formed on two sides of an end of the pin body, an elastic pressing section formed on an end of the pin body that is adjacent to the soldering sections, and a hook section formed on an end of the elastic pressing section that is distant from the soldering sections. The soldering sections are arranged to clamp and be soldered to opposite sides of the circuit substrate. In inserting male and female parts of the present invention to each other, the soldering sections clamp on and are soldered to two sides of the circuit substrate so as to be resistant to the force of insertion and removal and be protected against damage. Further, the hook section helps prevent undesired detachment.

Owner:KINNEXA

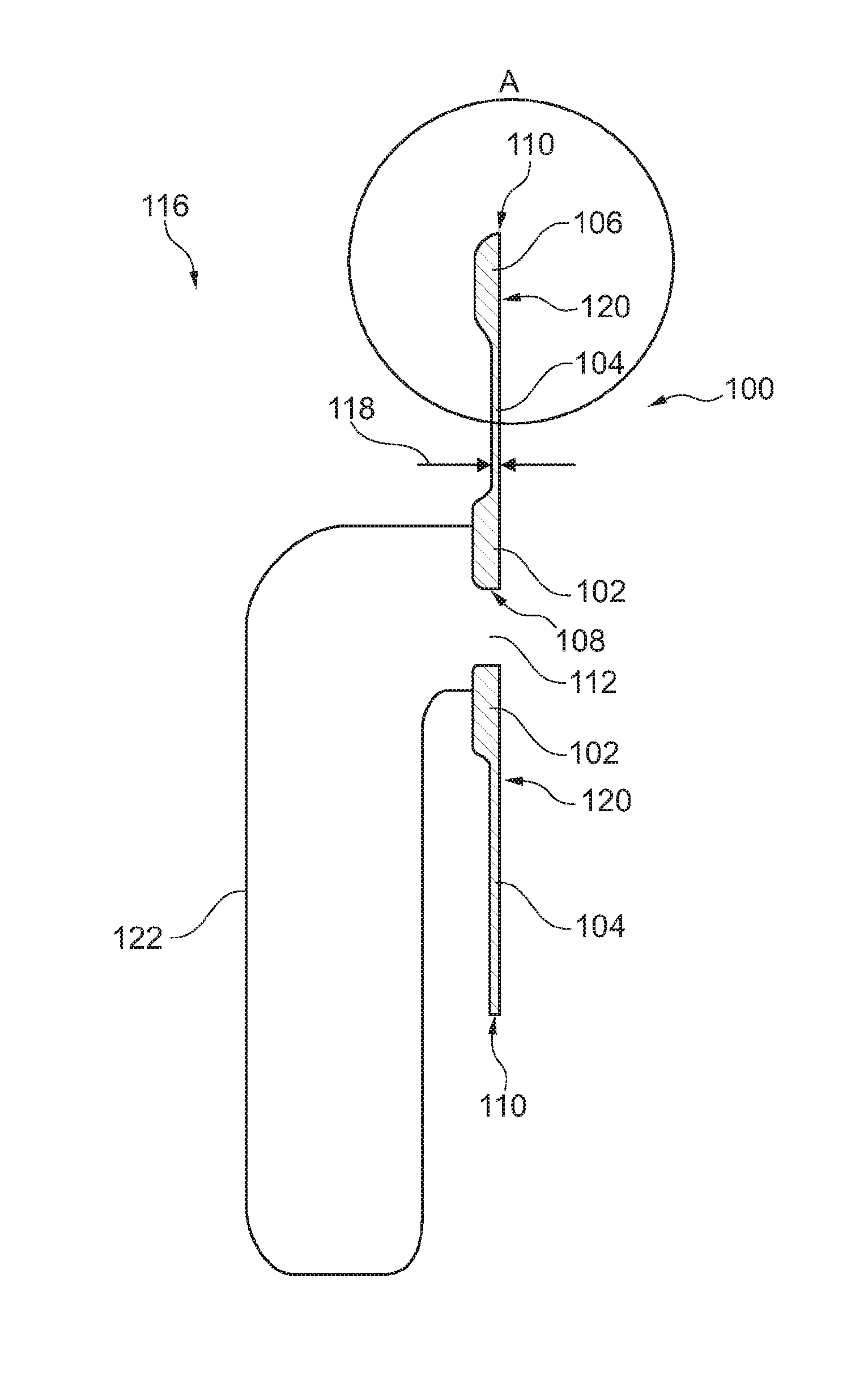

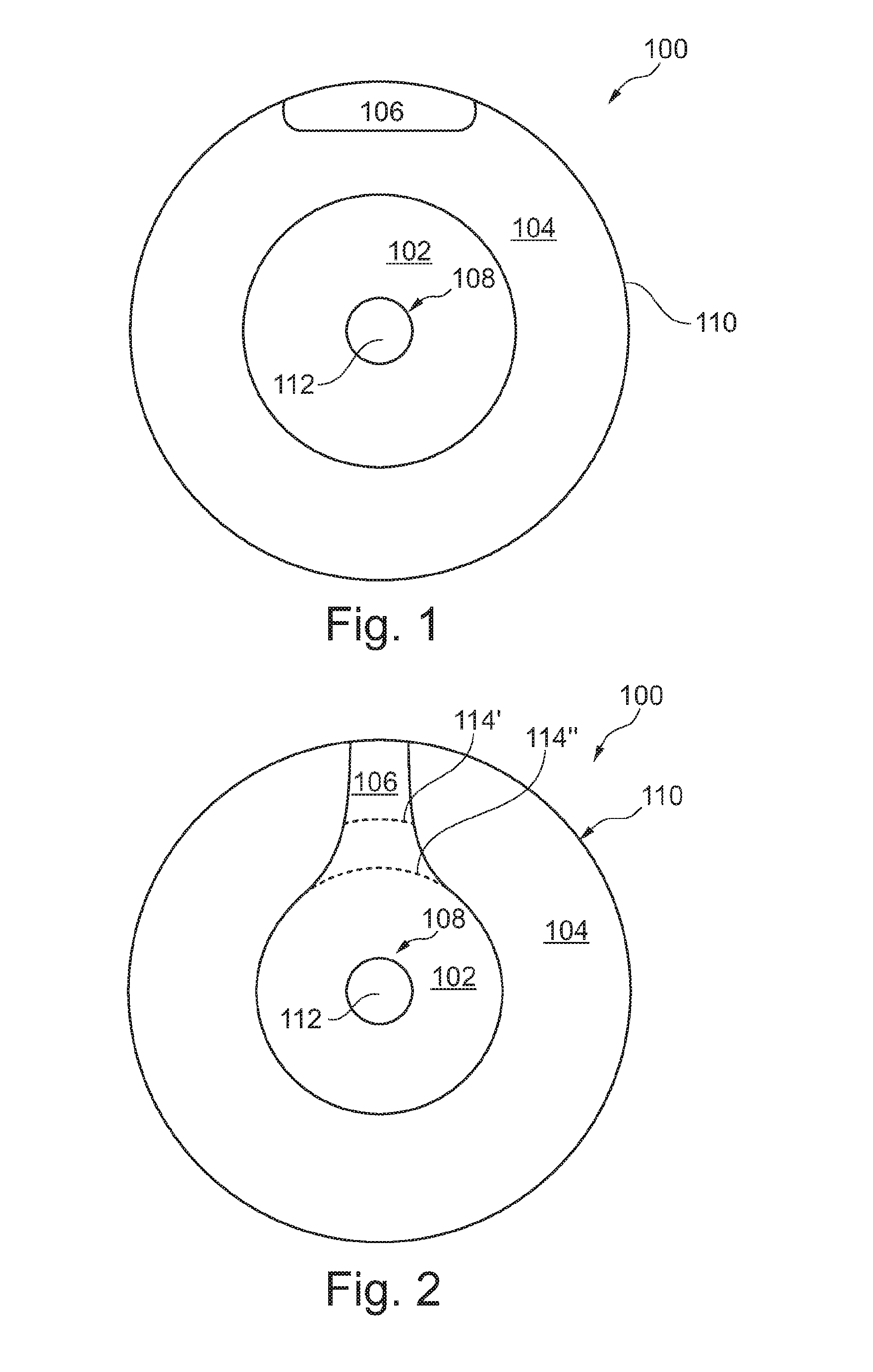

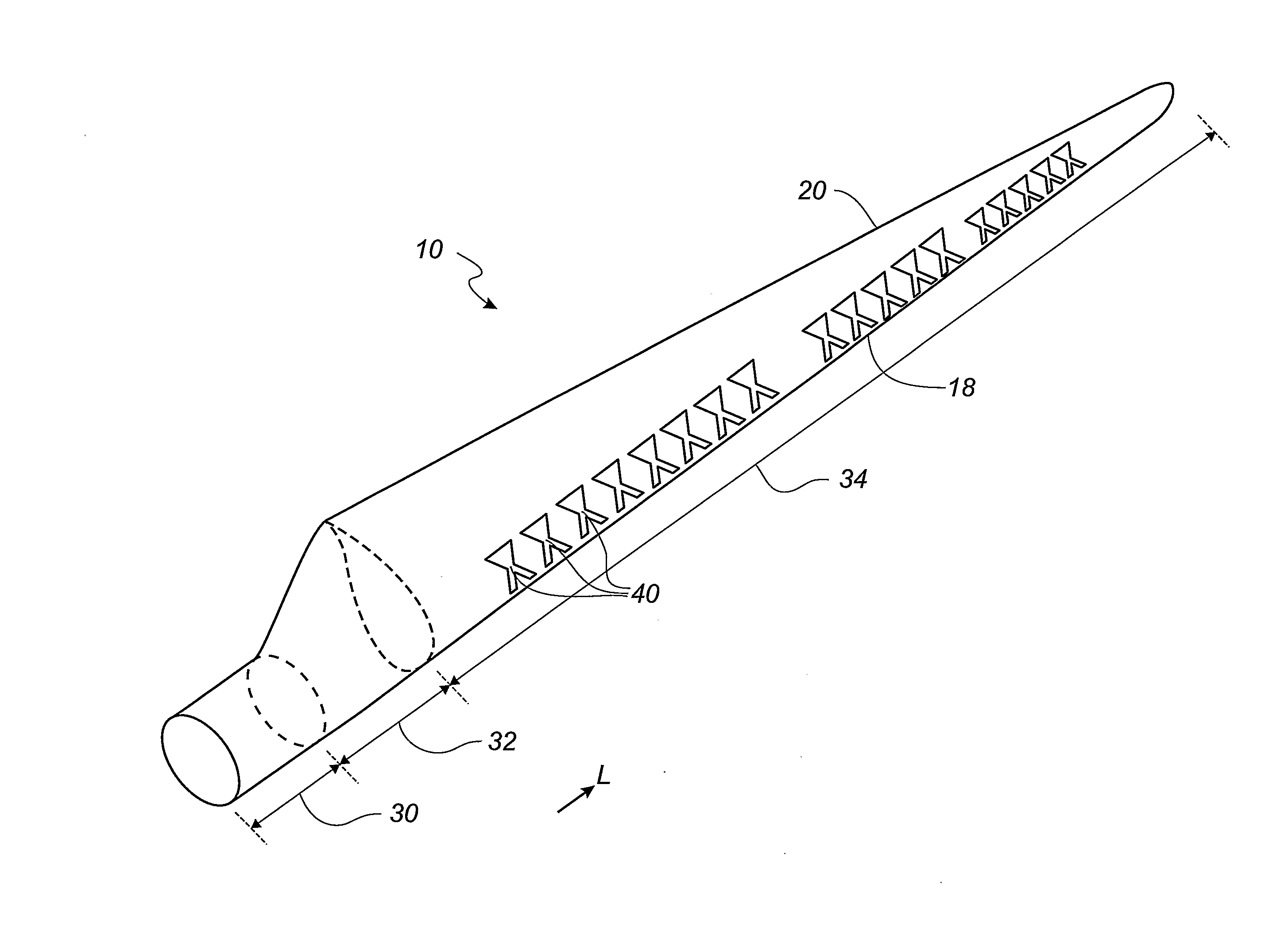

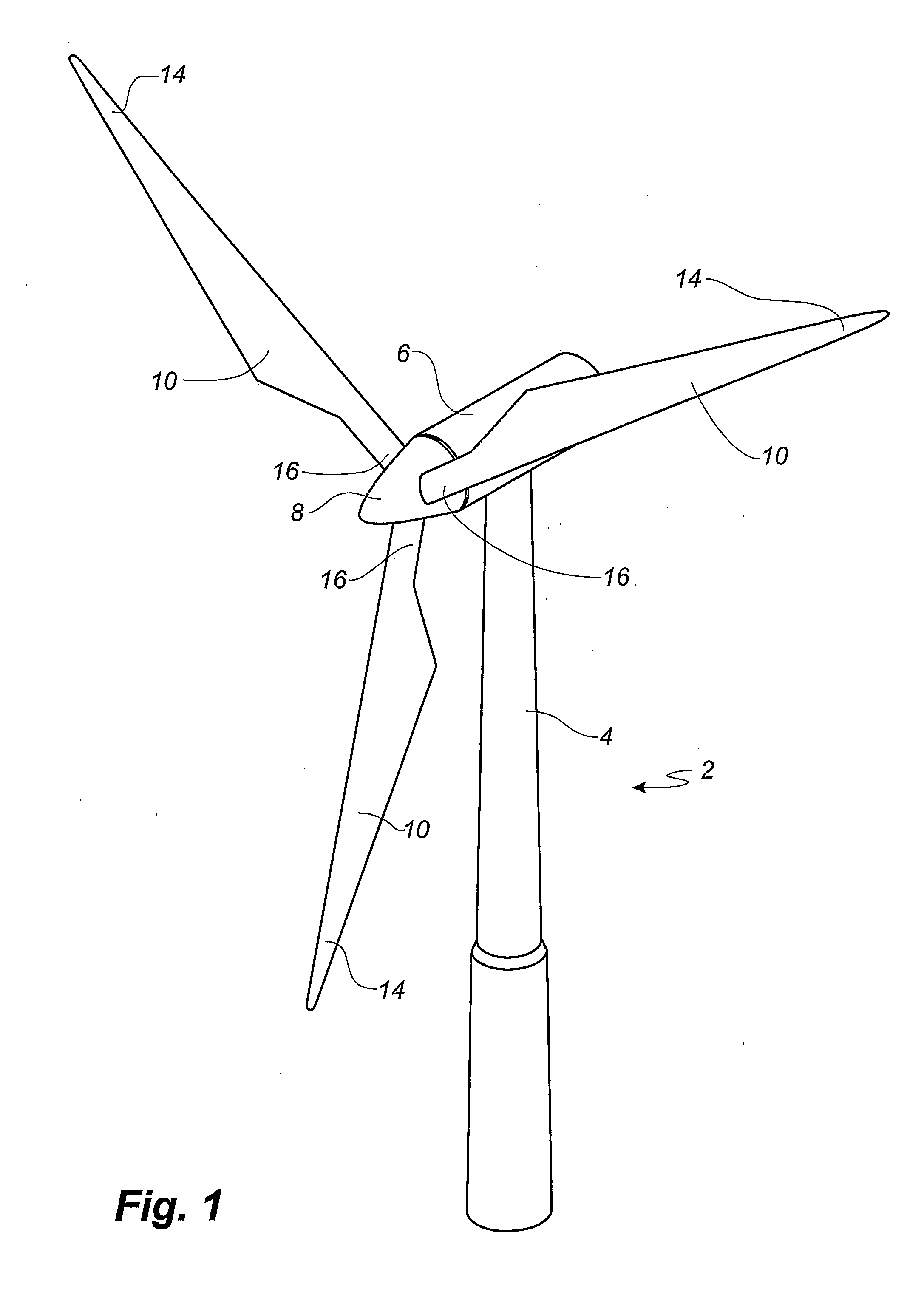

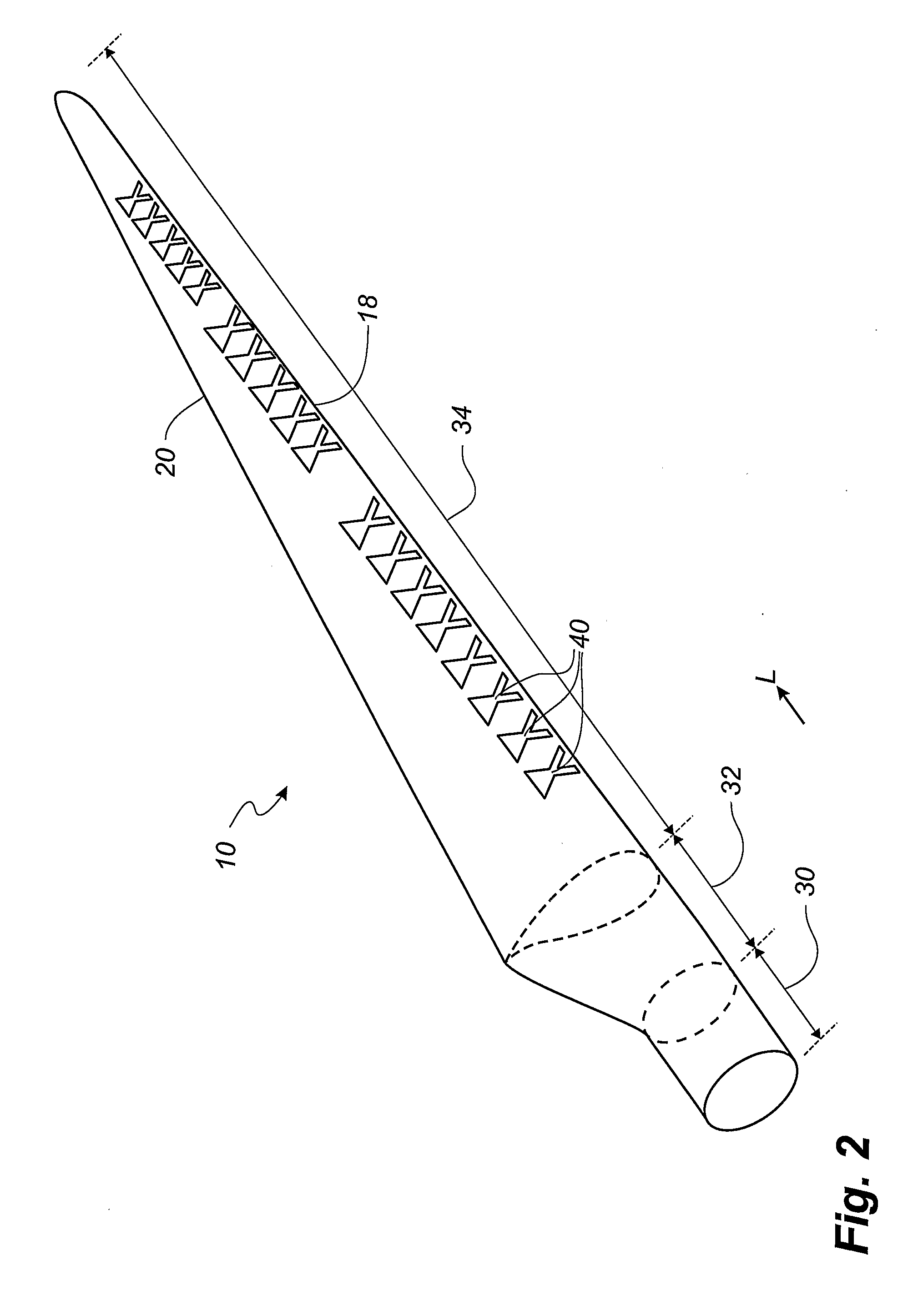

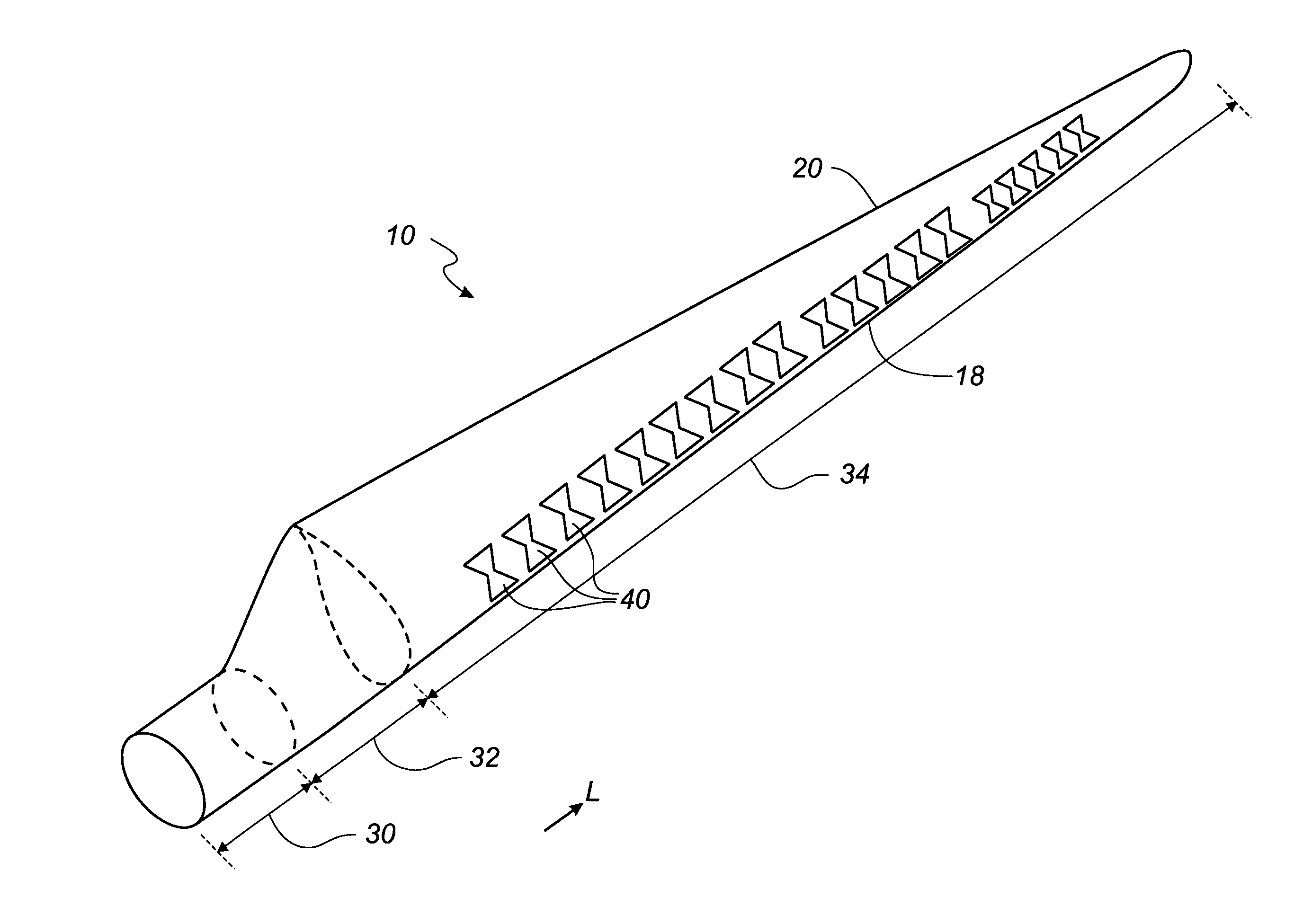

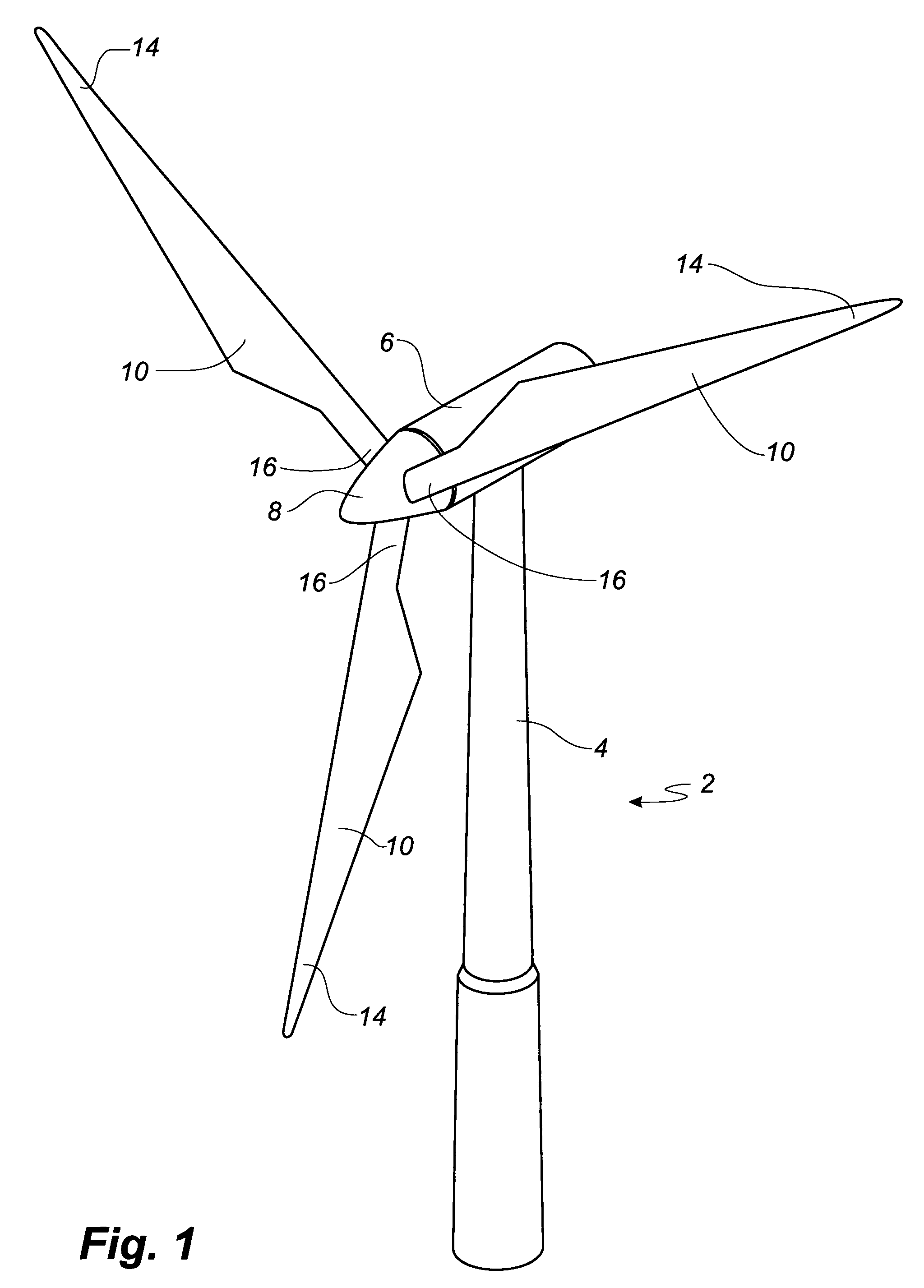

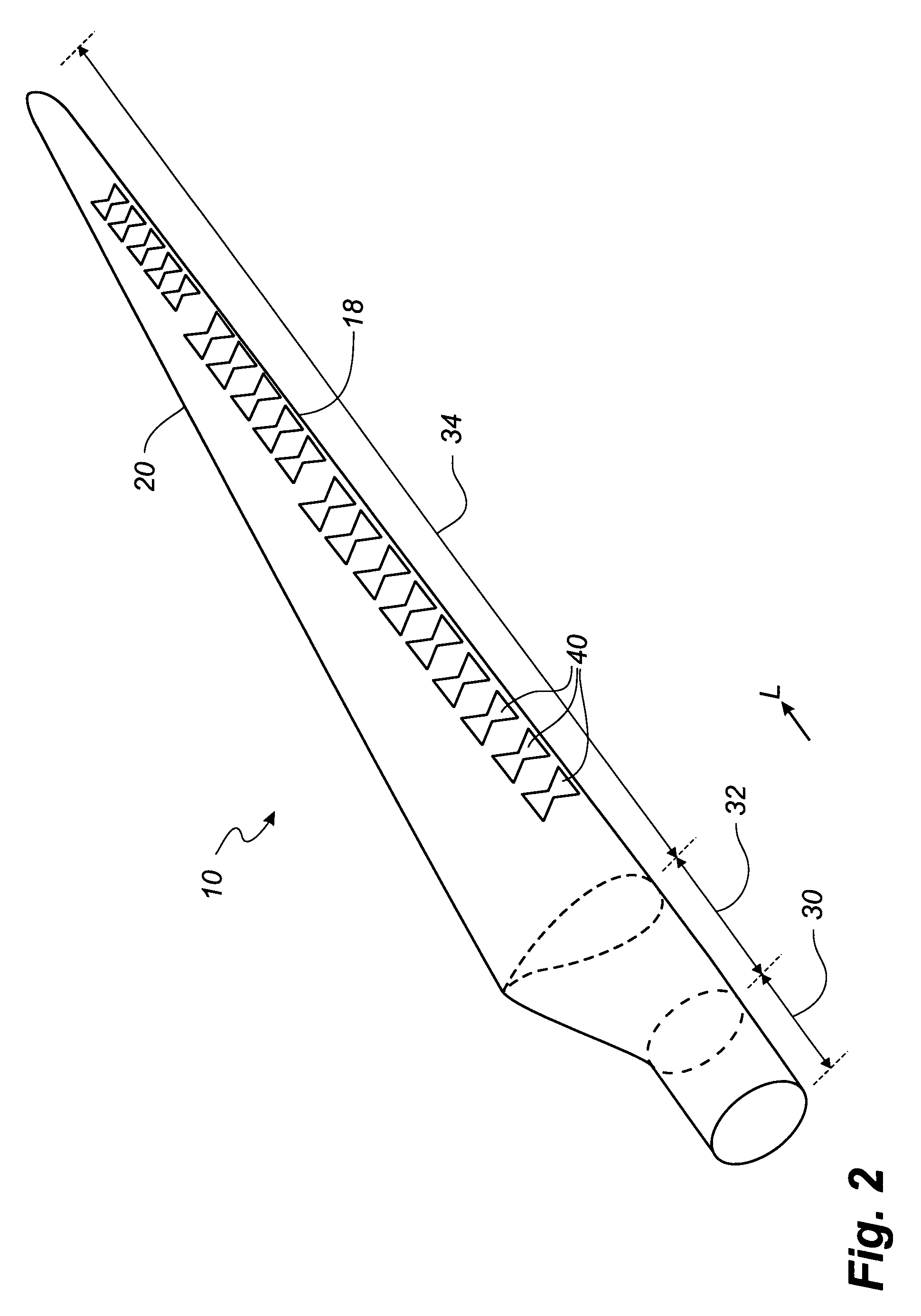

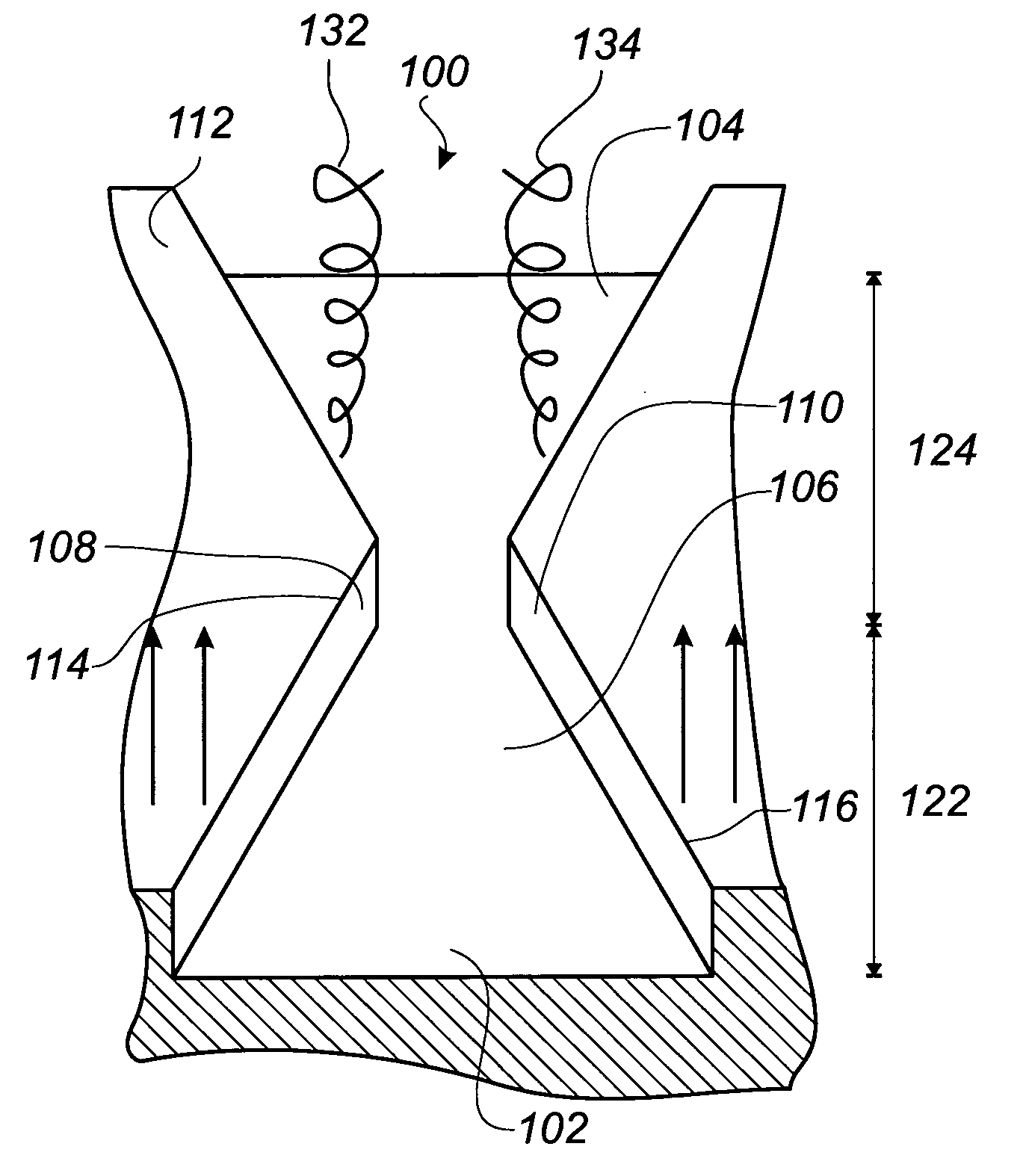

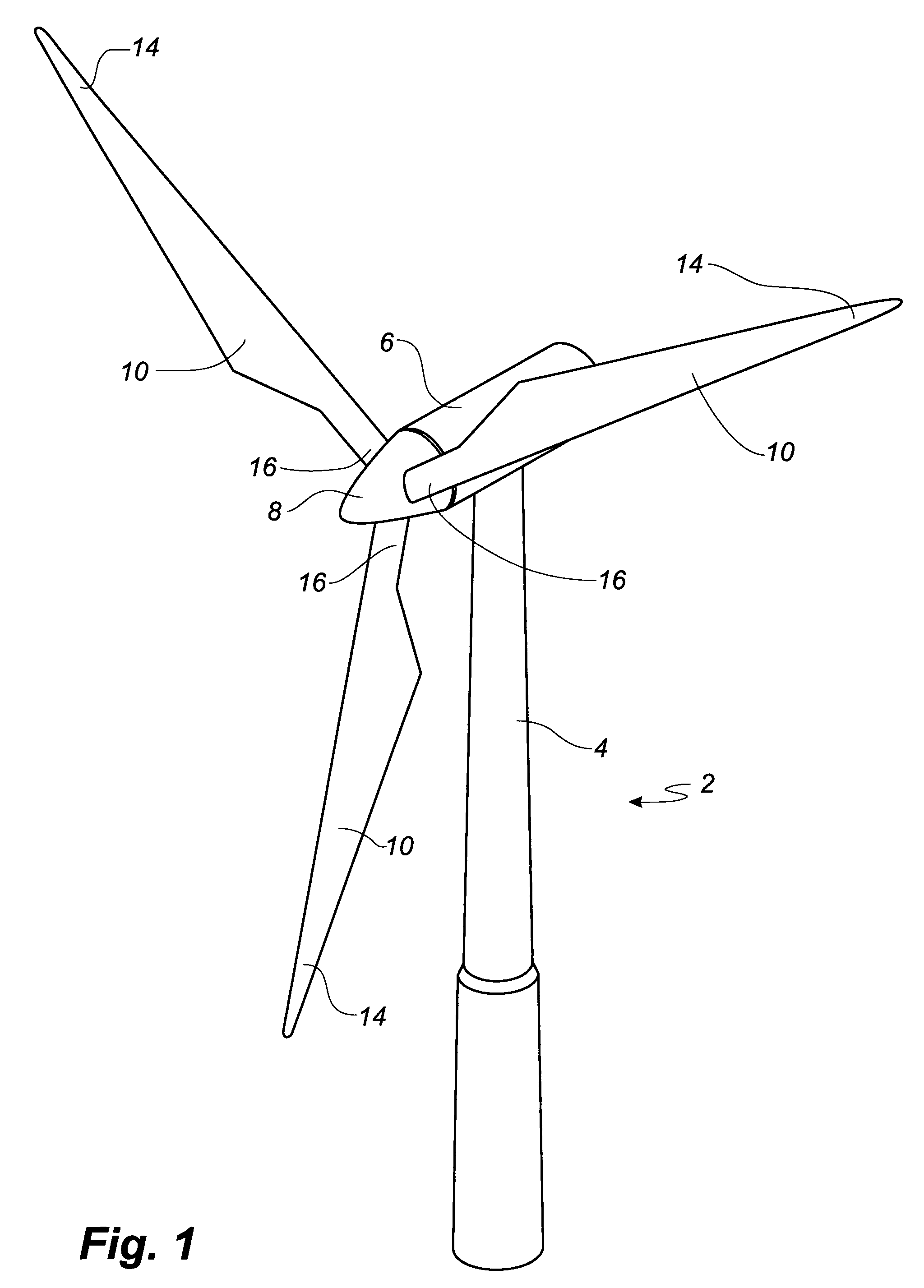

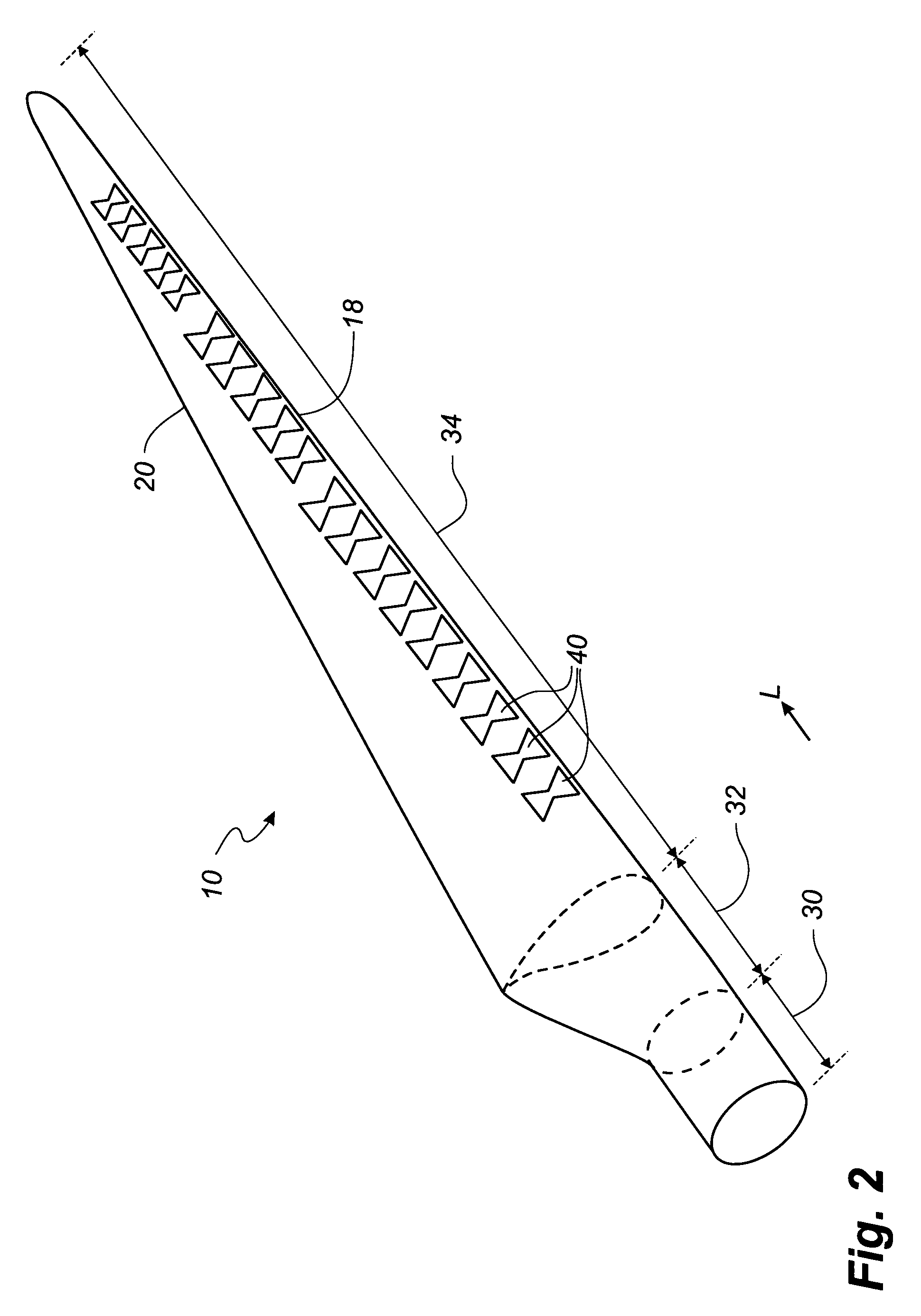

Wind turbine blade with submerged boundary layer control means comprising crossing sub-channels

ActiveUS20100260614A1Strong vortexSimple solutionPropellersRotary propellersTrailing edgeTurbine blade

A wind turbine blade having a longitudinal direction with a root end and a tip end as well as a chord extending in a transverse direction between a leading edge and a trailing edge is described. The blade comprises a flow control surface with a suction side and a pressure side. A number of boundary layer control means is formed in the flow control surface. The boundary layer control means include a channel submerged in the flow control surface with a first end facing towards the leading edge and a second end facing towards the trailing edge of the blade. The channel further comprises a bottom surface extending from the first end to the second end. The channel at the first end comprises a first channel zone comprising a first sub-channel having a first cross-sectional area and a second sub-channel having a second cross-sectional area, the first sub-channel and the second sub-channel crossing each other at a point of crossing.

Owner:LM GLASSFIBER

Lighting and/or signalling device with a moveable daytime element

InactiveUS20120051070A1Drawback can be obviatedEasy outLighting support devicesOptical signallingEffect lightEngineering

Owner:VALEO VISION SA

Wind turbine blade with submerged boundary layer control means

InactiveUS8579594B2Strong vorticityImprove efficiencyPropellersPump componentsLeading edgeTurbine blade

A wind turbine blade having a longitudinal direction with a root end and a tip end as well as a chord extending in a transverse direction between a leading edge and a trailing edge is described. The blade comprises a flow control surface with a suction side and a pressure side. A number of boundary layer control means is formed in the flow control surface. The boundary layer control means include a channel submerged in the flow control surface with a first end facing towards the leading edge and a second end facing towards the trailing edge of the blade. The channel comprises: a bottom surface extending from the first end to the second end, a first sidewall extending between the flow control surface and the bottom surface and extending between the first end and the second end, the first sidewall forming a first sidewall edge between the first side wall and the flow control surface, and a second sidewall extending between the flow control surface and the bottom surface and extending between the first end and the second end, the second sidewall forming a second sidewall edge between the second side wall and the flow control surface. The channel at the first end comprises a first flow accelerating channel zone adapted for accelerating a flow, and at the second end comprises a second channel zone, where the first sidewall and the second sidewall are diverging towards the trailing edge of the blade.

Owner:LM GLASSFIBER

Golf tee setting device and method

Owner:SUWITO WANTJINARJO

Device and method for locking apparatuses

InactiveUS20080178641A1Strong lockReduce effortMechanical controlsFriction grip releasable fasteningsMechanical engineeringEngineering

The present invention relates to a system for locking apparatuses having a profile frame for receiving at least one apparatus. Furthermore, the present invention relates to a device for receiving one or more apparatuses, which has a profile frame, as well as a modified apparatus foot and a method for locking. The system according to the present invention is characterized in that the apparatus has apparatus feet modified for the engagement of a locking hook and the profile frame has at least one receptacle and at least one locking hook and one unlocking slider for each apparatus foot to be received, no screw connection parts used for locking the apparatus being provided.

Owner:LINDE AG

Infinitely-variable, hydro-mechanical transmission using fixed displacement pumps and motors

ActiveUS20110056195A1Low costSignificant variabilityFluid couplingsGearing controlGear wheelHydraulic pump

This invention consists of two or more fixed displacement hydraulic pump / motors mounted on a common input shaft hydraulically connected to two or more fixed hydraulic pump / motors mounted on a common output shaft. The relative displacements of the pump / motors are chosen such that by selectively activating the individual pump / motors, the transmission ratio can be changed in the case when the input devices and acting as pumps driving the output devices as motors (conversely when driving the vehicle in reverse). Further, a hydraulic accumulator and reservoir are attached in a manner that allows the pressurized fluid to augment the flow produce by the input pumps in order to increase the transmission ratio. Similarly, the transmission ratio can also be reduced by causing the input pumps to pump fluid into the accumulator at the same time they are pumping fluid through the output motors. The transmission also contains a single speed all mechanical by-pass for use when cruising and an input reduction gear to increase the torque and power capacity of the transmission.A further feature of the transmission is a valve arrangement that allows the transmission to generate a continuously variable braking torque when the transmission is used to supply braking force to the vehicle.In addition, the transmission includes a selectable, one-way clutch that connects the input directly to the output. When engaged, this clutch provides an all mechanical by-pass to the hydraulic transmission for use when cruising in order to improve the efficiency.

Owner:LLOYDCO

Assembly structure of a cabinet and thin display device

InactiveUS20080297013A1Easy to separateHigh degree of forming efficiencyTelevision system detailsColor television detailsDisplay deviceEngineering

A projection is formed on the upper edge of the side wall of a front cabinet, a depression is formed on the upper edge of the side wall of a front cover, and a protrusion is formed on the upper edge of the side wall of a rear cabinet. The front cabinet is supported between the front cover and the rear cabinet, such that the projection of the front cabinet is pressed against the depression of the front cover by the protrusion of the rear cabinet and the upper edge of the side wall thereof, and the projection of the front cabinet is locked by the depression of the front cover.

Owner:FUNAI ELECTRIC CO LTD

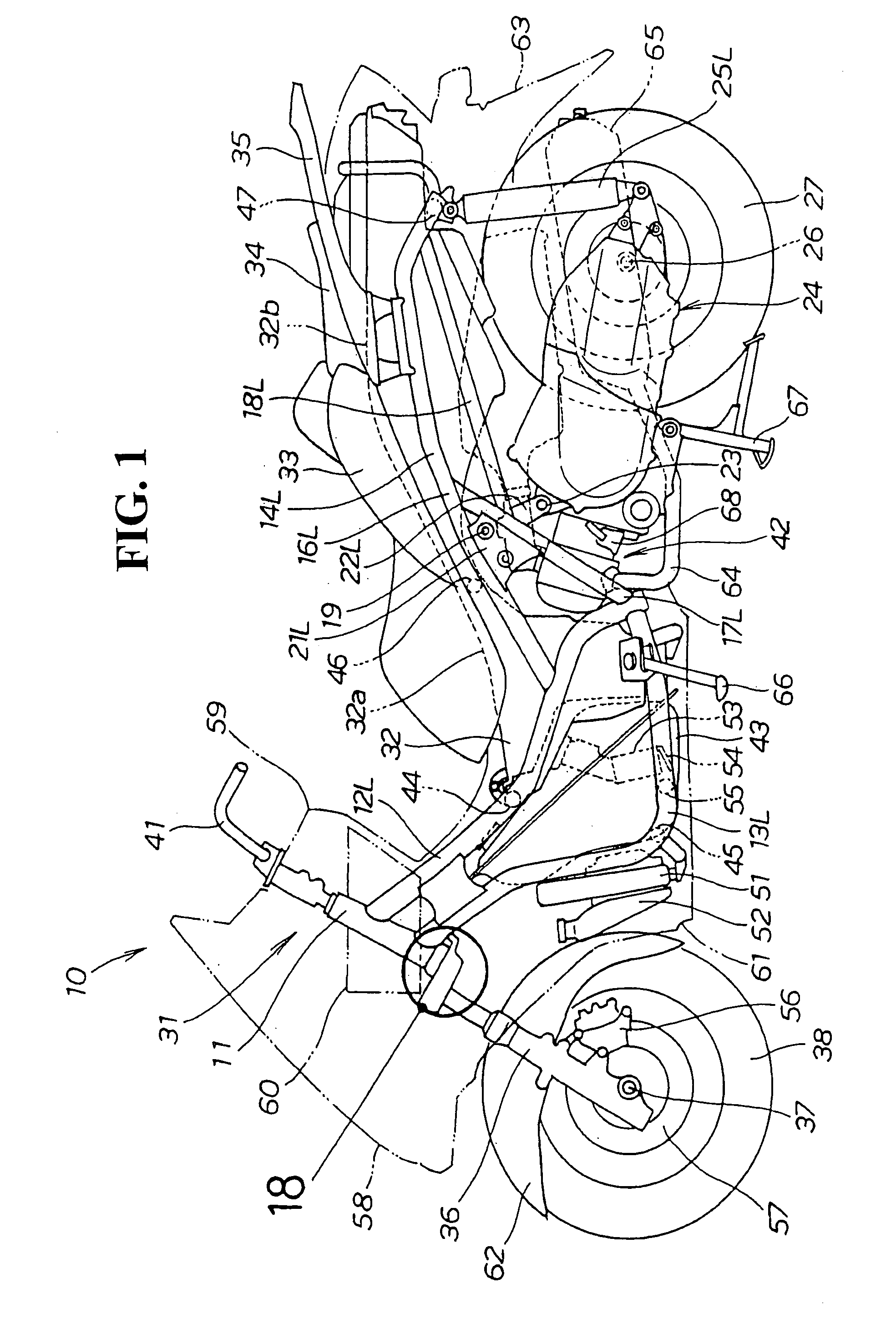

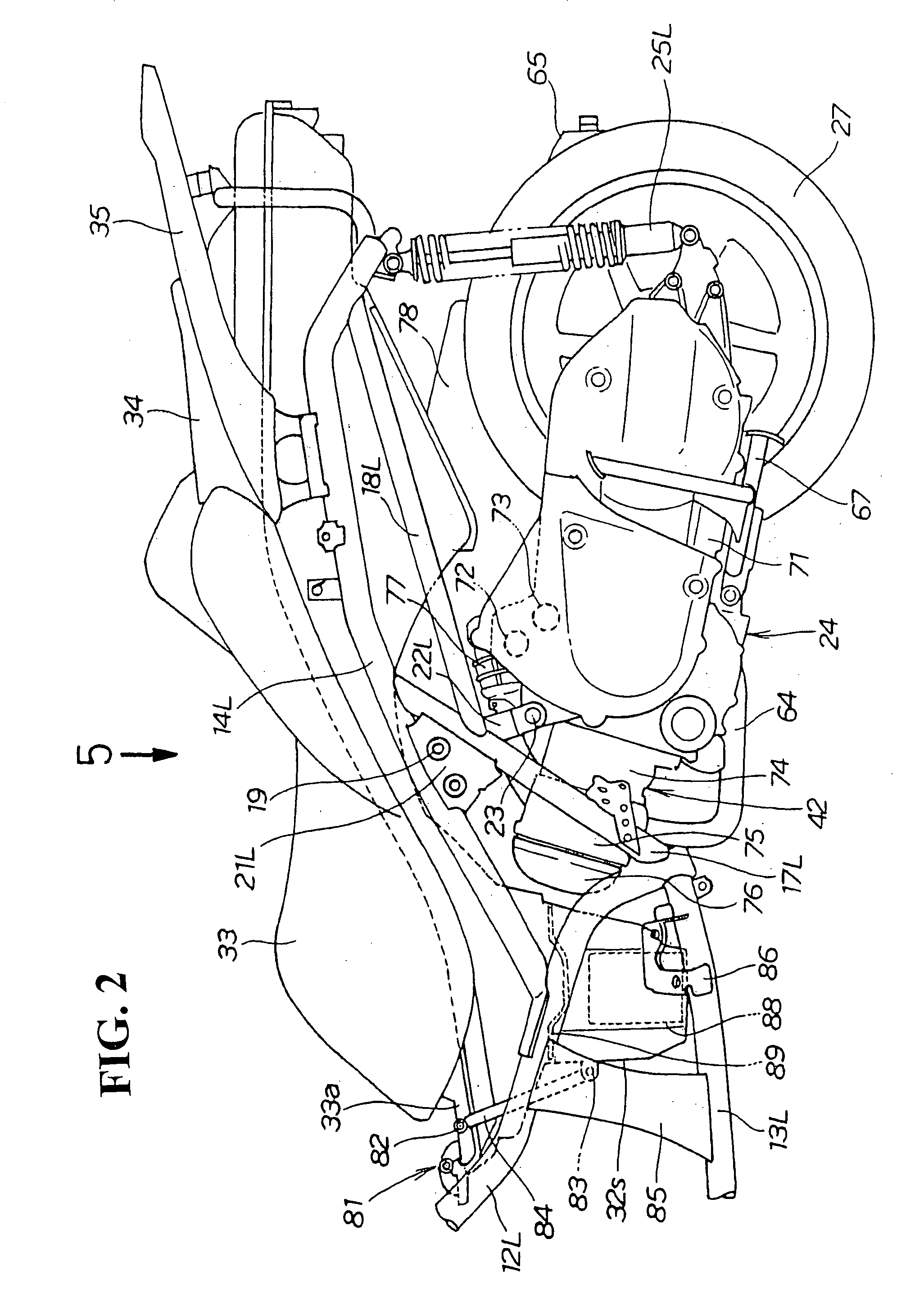

Motorcycle

InactiveUS20080156561A1Easy to takeEasy outMotorised scootersSuperstructure subunitsEngineeringBody frame

A motorcycle that can facilitate identification of and taking in and out of an article stored below a rear seat includes a storage box that is mounted to a body frame. The front portion of the storage box is covered by a front seat. The rear portion of the storage box is covered by the rear seat and the rear seat is surrounded by the rear spoiler. The rear spoiler has an opening portion that is almost-rectangular as viewed from above. When the rear seat is removed, an article can be put in and taken out from the storage box through the opening portion. A first seal member is attached to the bottom plate of the rear seat, and is pressed against the circumferential edge portion of the opening portion to thereby seal between the rear seat and the rear spoiler.

Owner:HONDA MOTOR CO LTD

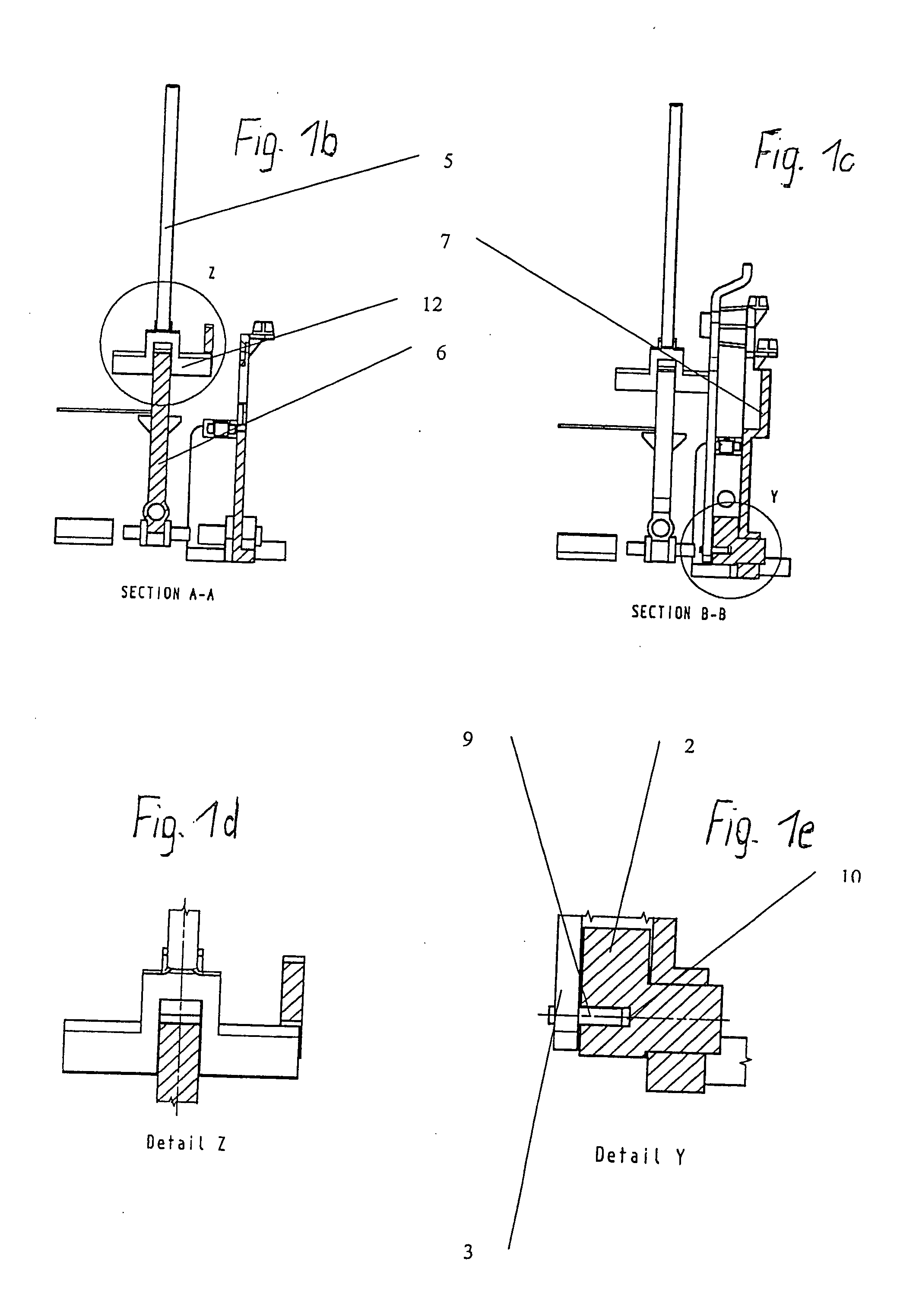

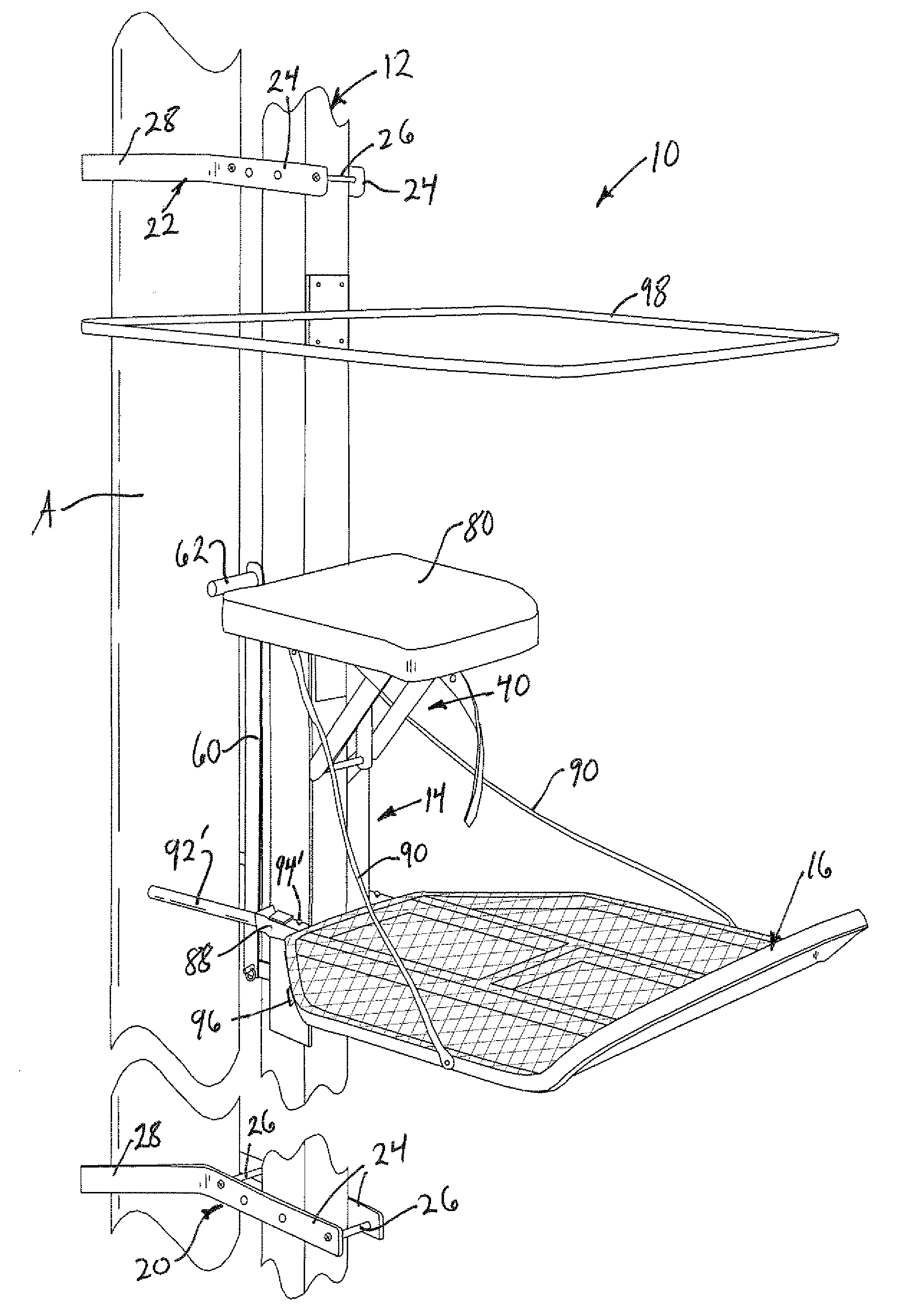

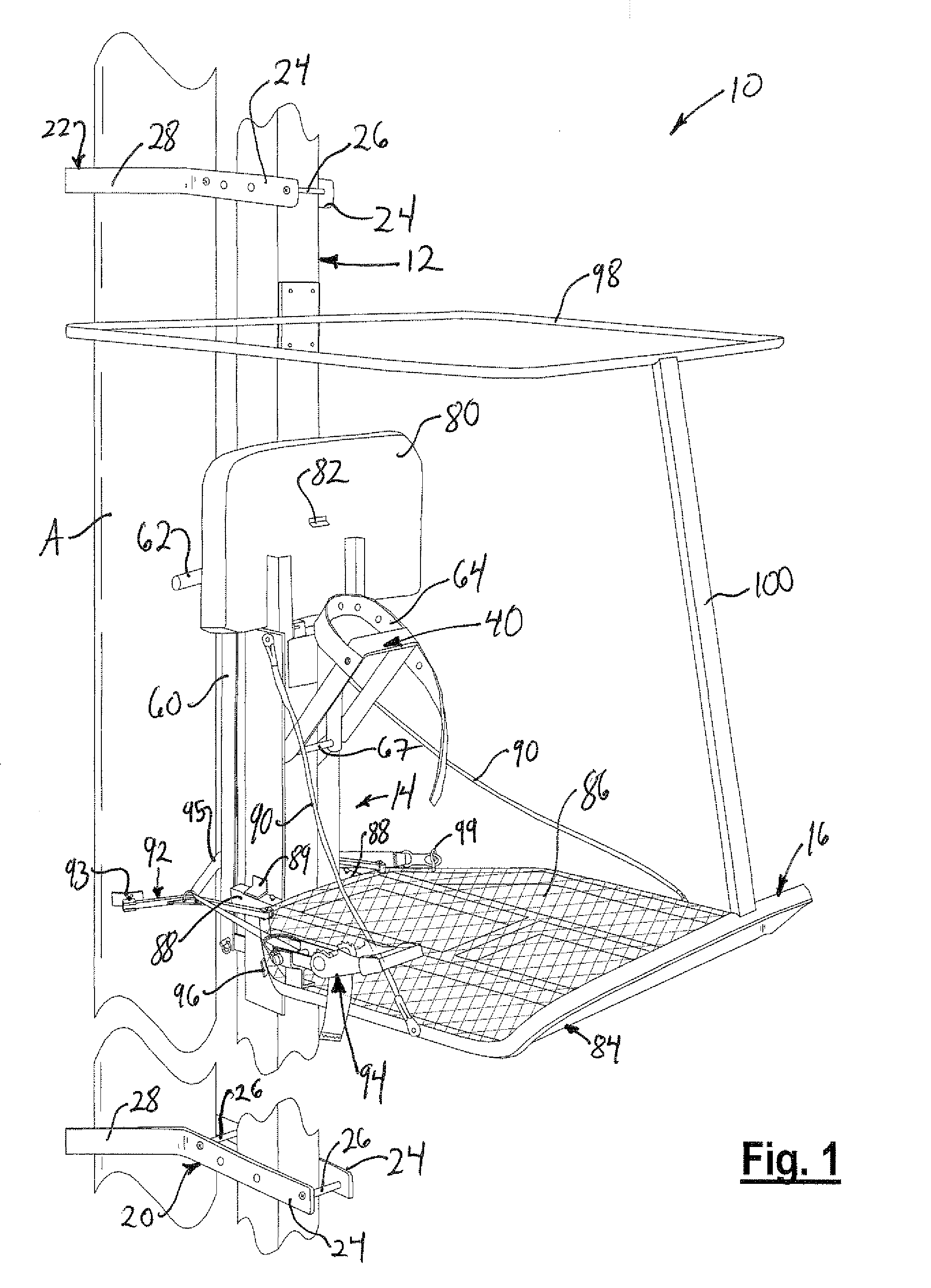

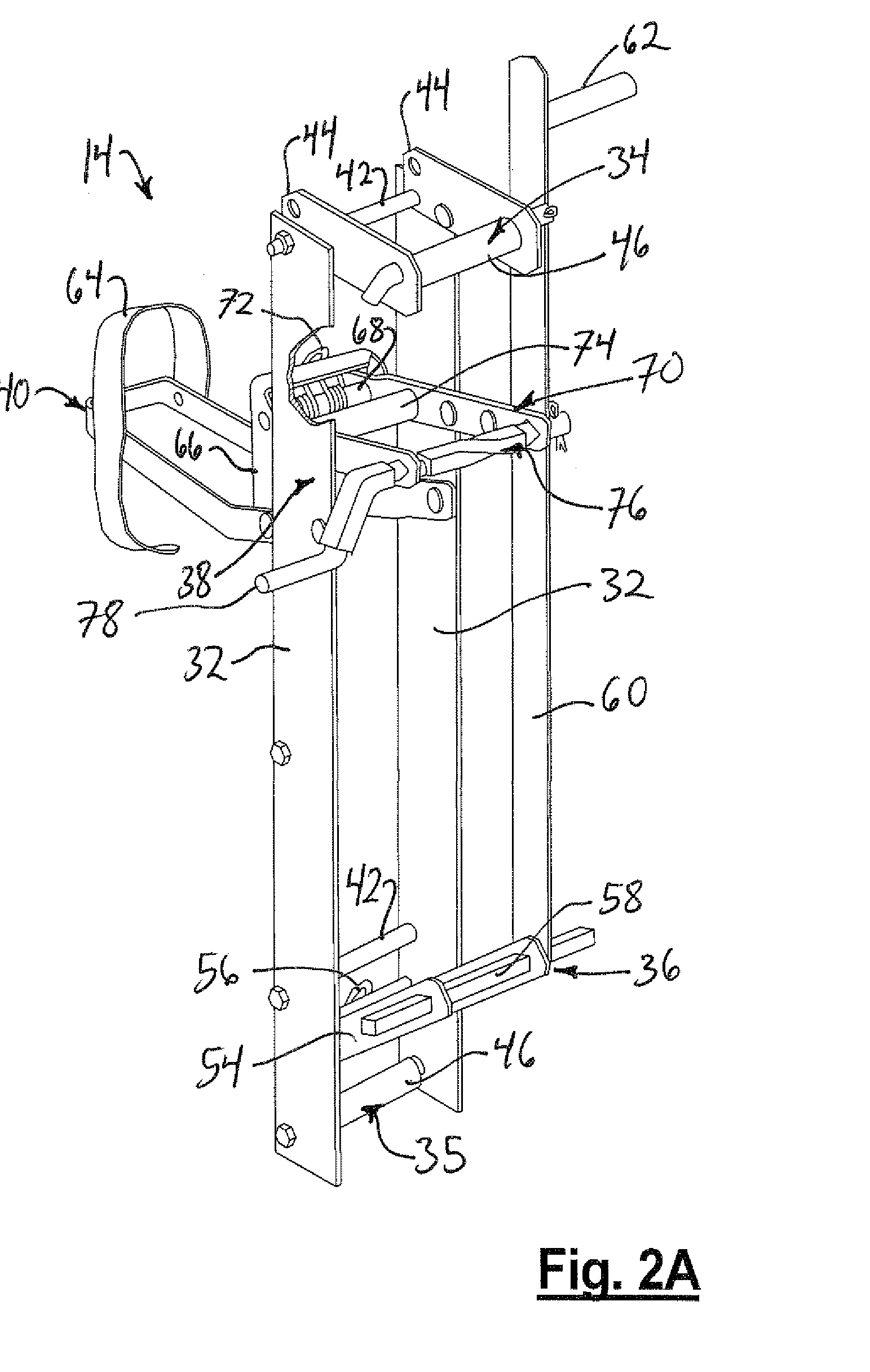

Pump jack tree stand

InactiveUS20070175702A1Probability of malfunctionEasy to get intoAnimal huntingClimbingTree standJackscrew

The invention comprises, in one form thereof, a pump jack tree stand including a platform and a seat engaging a pump jack. The pump jack cooperates with a pole that is supported by an adjacent tree. The user actuates a foot lever on the pump jack to climb the pole. The pump jack's release is hand actuated as opposed to the commonly used foot-actuated release.

Owner:SIMONE ANTHONY +1

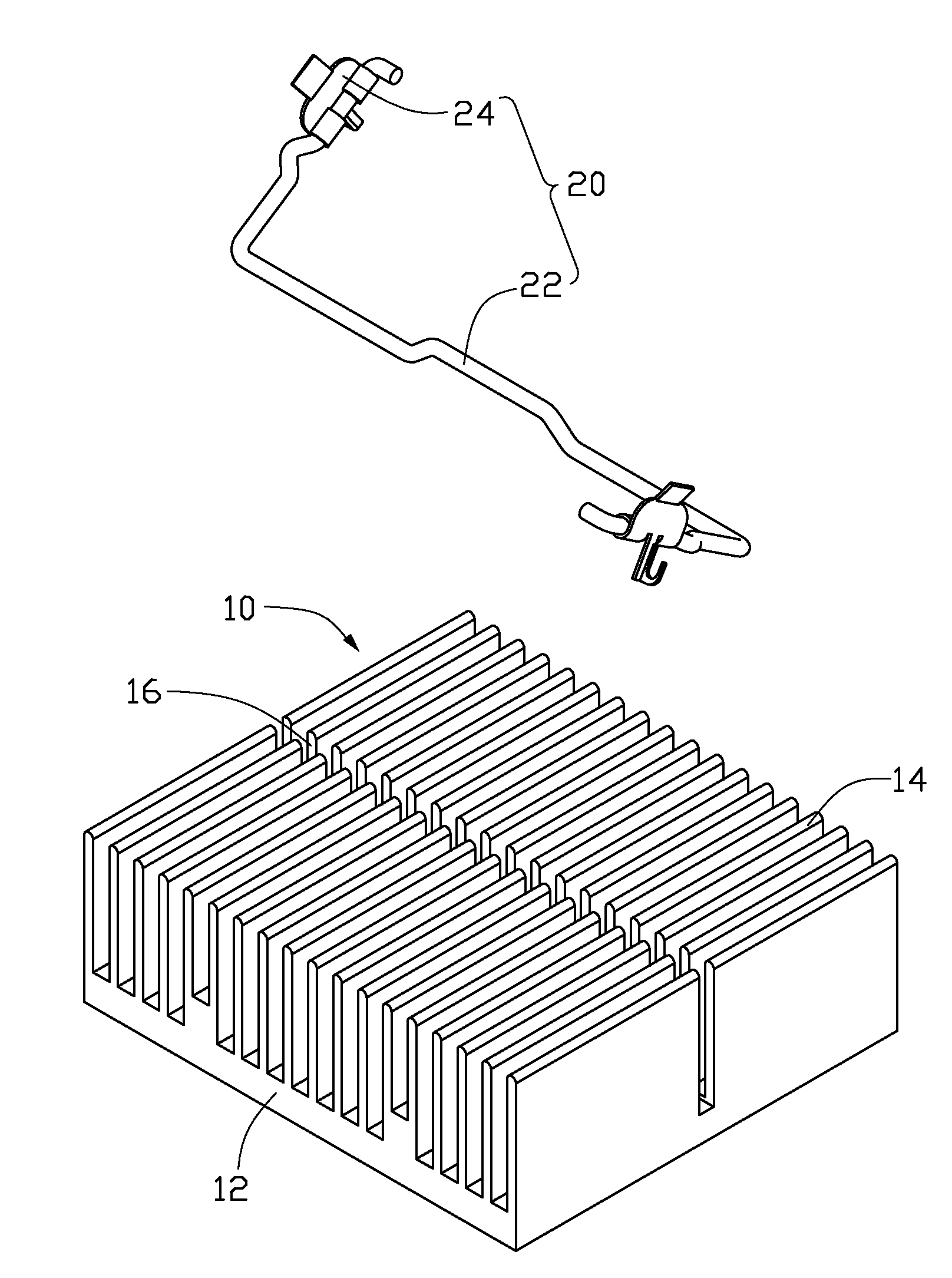

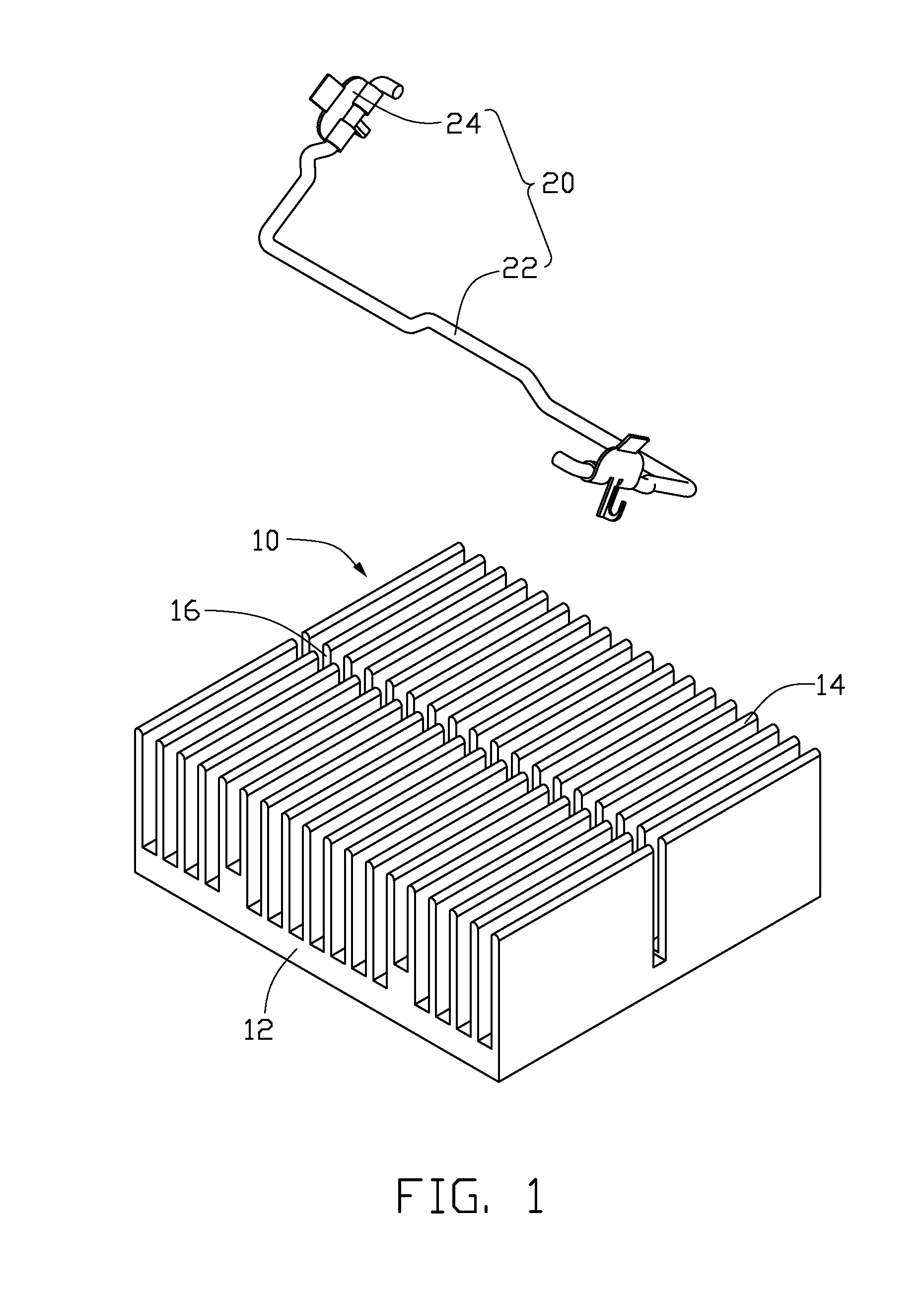

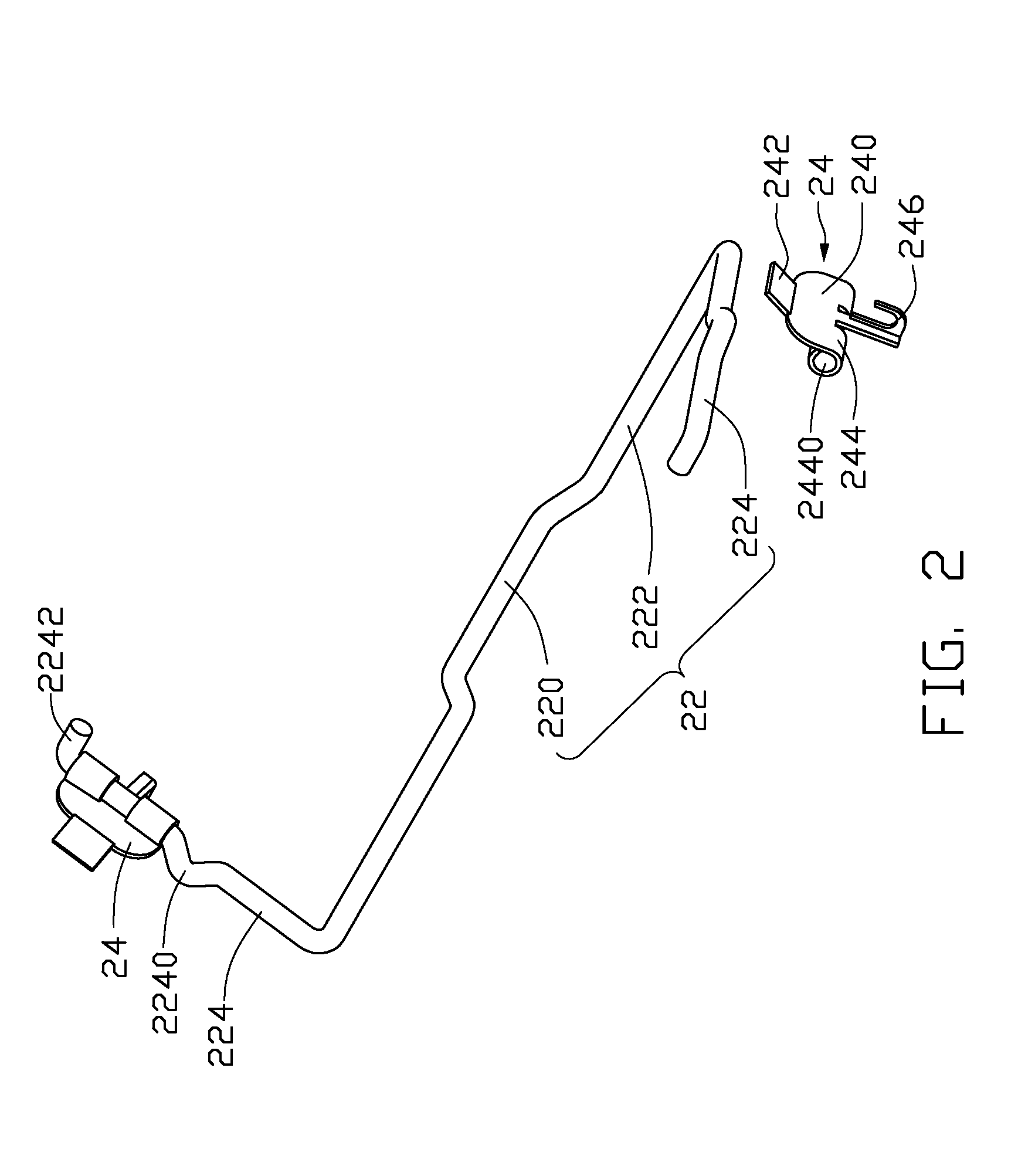

Heat sink assembly having a clip

InactiveUS20100002396A1Accurately and easily engageEasy to assembleSnap fastenersDigital data processing detailsPrinted circuit boardHeat spreader

A heat sink assembly includes a heat sink and a clip assembly. The clip assembly includes a clip and a pair of movable fasteners pivotally connected to the clip. The clip includes a main body, two pressing portions extending from two opposite ends of the main body and two locking arms extending oppositely from the two pressing portions, respectively. The movable fasteners each include a main body, a pair of receiving portions curved upwardly from the main body and receiving a corresponding locking arm therein and a hook extending downwardly from the main body and engaging with a clasp on a printed circuit board. A distance from each of the hooks of the movable fasteners to a corresponding clasp can be adjustable via rotation of the movable fasteners around the locking arms of the clip.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

Adapter with a base housing for a bus bar system having a number of bus bars

InactiveUS6113439AEasy outSolve the lack of spaceBus-bar/wiring layoutsClamped/spring connectionsMechanical engineeringEngineering

An adapter for a base housing to which suspension hooks are attached, is accessible for the insertion of connecting contacts to connect contact rails with bus bars. A pre-assembled unit including the contact support, a spring element and a connecting contact is snapped into a snap-in receiver void of the base housing in the area of the base housing suspension hook and makes definite connections between the bus bar, the connecting contact and the contact rail.

Owner:RITTALWERK RUDOLF LOH GMBH & CO KG

Wind turbine blade with submerged boundary layer control means

InactiveUS20100209257A1Improve efficiencyStrong vorticityPropellersWind motor controlTrailing edgeWind force

A wind turbine blade having a longitudinal direction with a root end and a tip end as well as a chord extending in a transverse direction between a leading edge and a trailing edge is described. The blade comprises a flow control surface with a suction side and a pressure side. A number of boundary layer control means is formed in the flow control surface. The boundary layer control means include a channel submerged in the flow control surface with a first end facing towards the leading edge and a second end facing towards the trailing edge of the blade. The channel comprises: a bottom surface extending from the first end to the second end, a first sidewall extending between the flow control surface and the bottom surface and extending between the first end and the second end, the first sidewall forming a first sidewall edge between the first side wall and the flow control surface, and a second sidewall extending between the flow control surface and the bottom surface and extending between the first end and the second end, the second sidewall forming a second sidewall edge between the second side wall and the flow control surface. The channel at the first end comprises a first flow accelerating channel zone adapted for accelerating a flow, and at the second end comprises a second channel zone, where the first sidewall and the second sidewall are diverging towards the trailing edge of the blade.

Owner:LM GLASSFIBER

Method for removing sodium in high-sodium coal

The invention provides a method for removing sodium in high-sodium coal. The method is characterized by comprising the following steps: step 1, crushing high-sodium coal into crushed raw coal of a certain size, putting the crushed raw coal into a container tank, and adding a washing solution into the container tank; step 2, putting the container tank into microwave equipment, performing microwave treatment on the crushed raw coal and the washing solution, heating the crushed raw coal and the washing solution to the temperature of 160-260 DEG C to obtain a high-temperature mixed solution, and preserving the temperature of the high-temperature mixed solution for 5-30 minutes to wash the crushed raw coal by using the washing solution, wherein the microwave equipment comprises a pressure control system, and the air pressure in the container tank is maintained to be 1-2 times that of saturated vapor pressure which corresponds to the temperature of the washing solution; and step 3, taking the container tank out of the microwave equipment, filtering the high-temperature mixed solution, and washing the filtered product with water, thereby obtaining low-sodium coal. According to the method for removing sodium in high-sodium coal disclosed by the invention, the content of sodium in the high-sodium coal can be effectively reduced, and the quality of the raw coal is improved.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

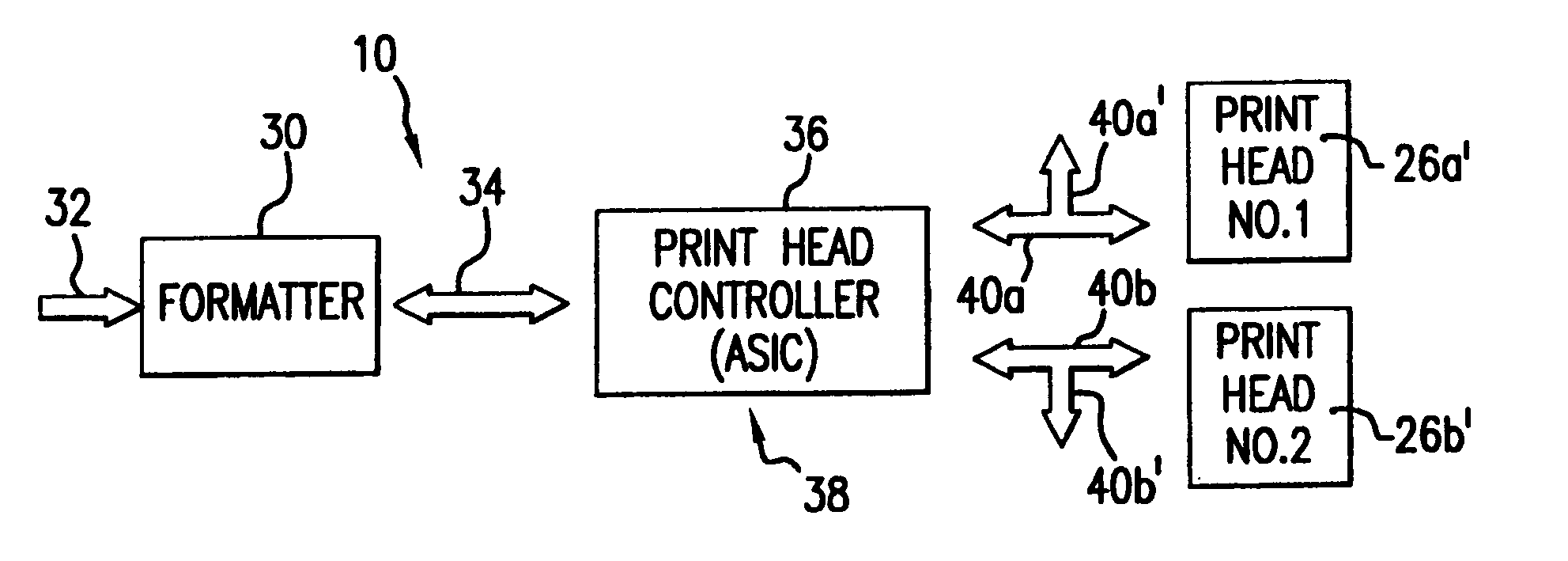

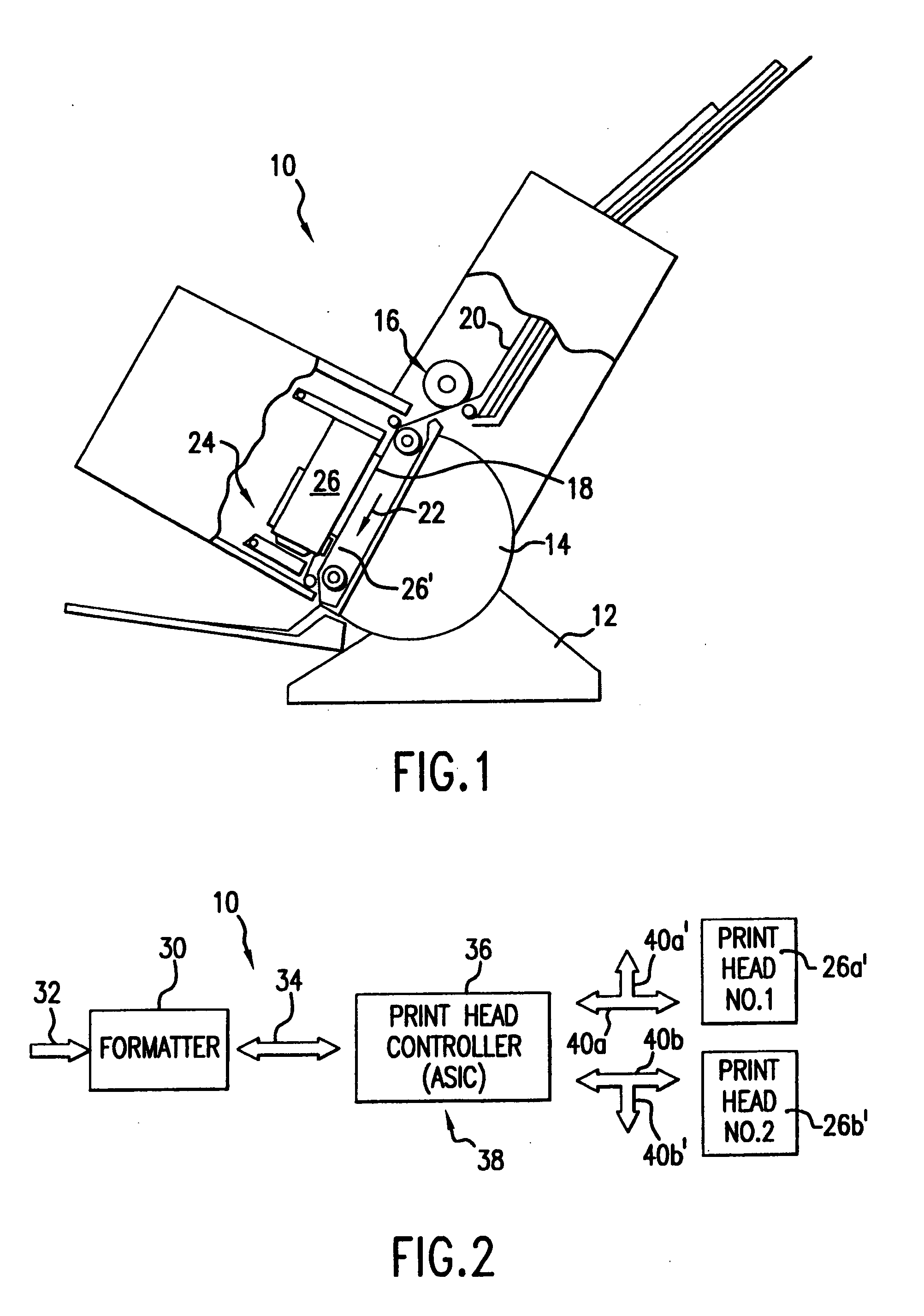

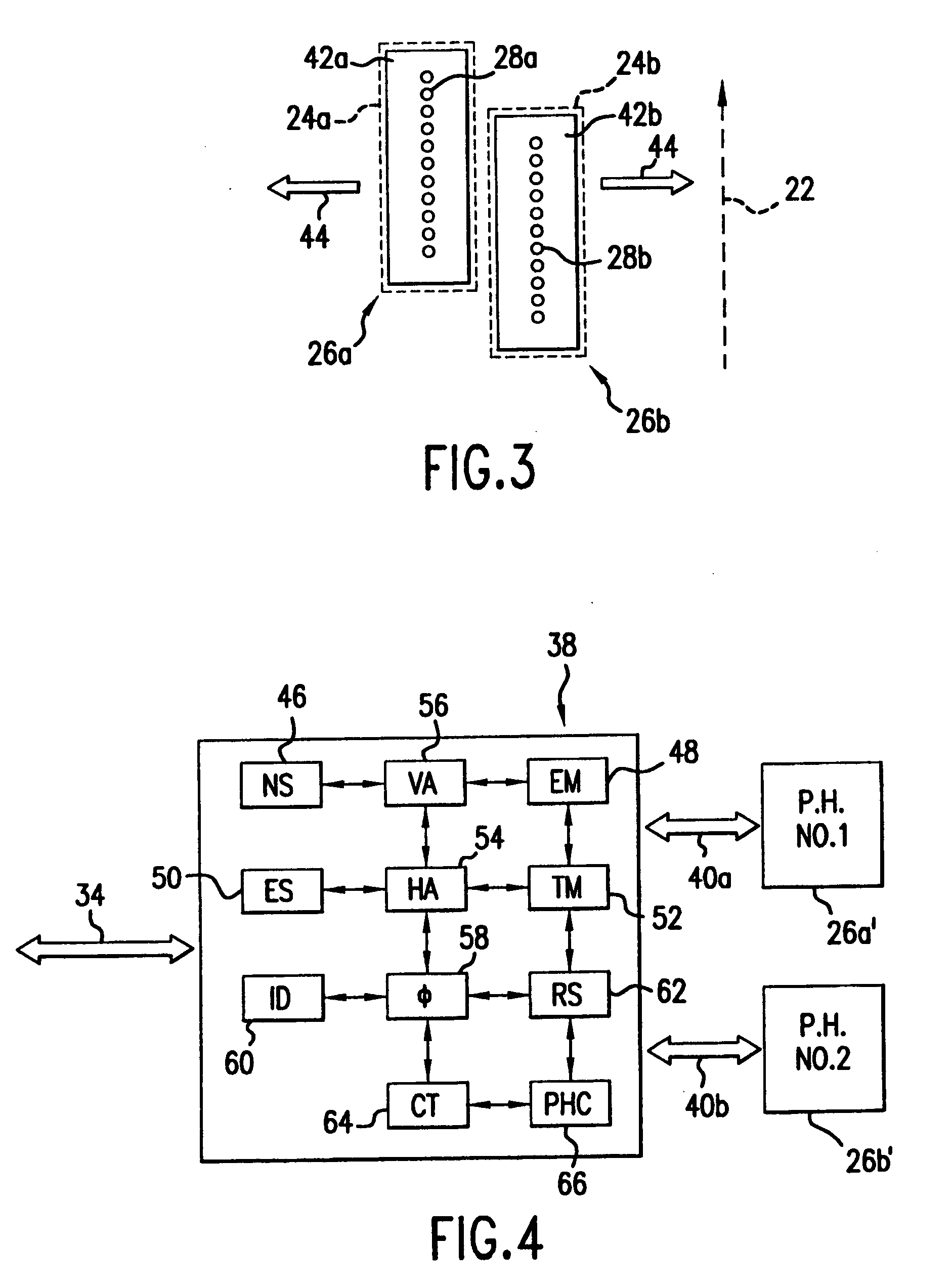

Inkjet printing and method

InactiveUS20040061878A1Reduce eliminateEasy to changeDigitally marking record carriersVisual representation by matrix printersEngineeringIntermediate level

An inkjet printer includes a print formatter circuit which receives high-level printing signals from a host computer, such as a PC or mainframe computer. The print formatter circuit translates the high level printing signals into signals of an intermediate-level interface language, which is communicated to a printhead controller circuit. The printhead controller circuit in turn translates the intermediate-level interface language signals into discreet-event commands, and other finite action-element or condition-element signals or requirements, that are communicated to the inkjet printer and to a printhead in the printer. The discreet-event commands, finite action-element, and finite condition-element signals effect control of the movements of a carriage of the printer, or print medium movable past the carriage, and the actions of an inkjet printing cartridge carried in the carriage such that ink or other printing fluid is controllably ejected from the printing cartridge onto the print medium to form images or characters.

Owner:HEWLETT PACKARD DEV CO LP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com